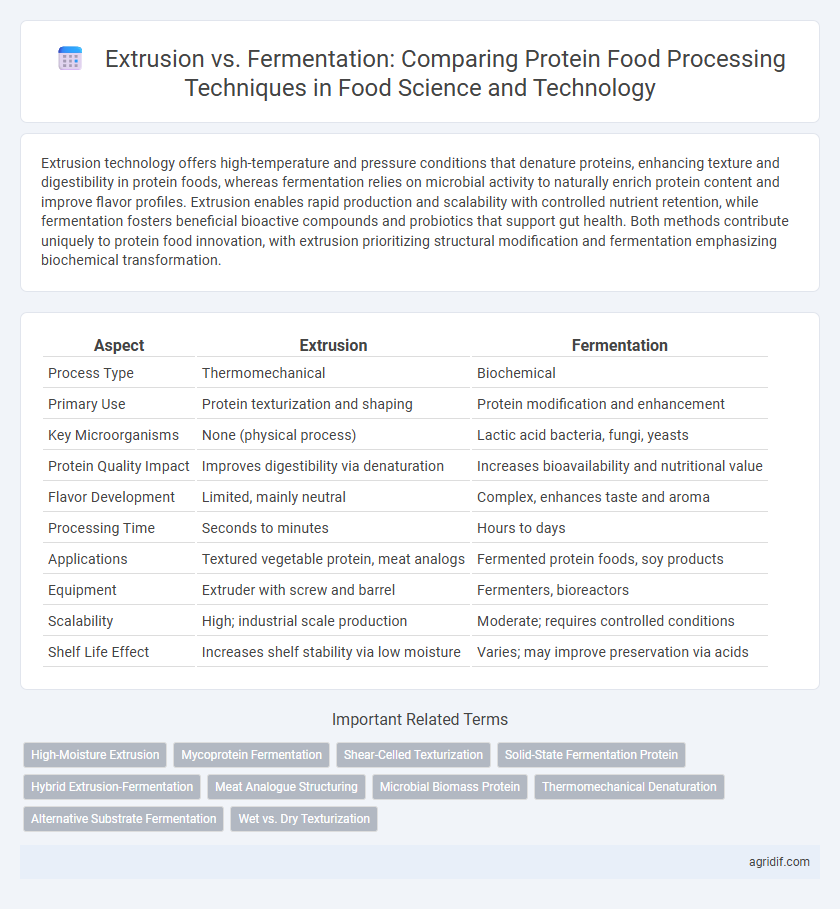

Extrusion technology offers high-temperature and pressure conditions that denature proteins, enhancing texture and digestibility in protein foods, whereas fermentation relies on microbial activity to naturally enrich protein content and improve flavor profiles. Extrusion enables rapid production and scalability with controlled nutrient retention, while fermentation fosters beneficial bioactive compounds and probiotics that support gut health. Both methods contribute uniquely to protein food innovation, with extrusion prioritizing structural modification and fermentation emphasizing biochemical transformation.

Table of Comparison

| Aspect | Extrusion | Fermentation |

|---|---|---|

| Process Type | Thermomechanical | Biochemical |

| Primary Use | Protein texturization and shaping | Protein modification and enhancement |

| Key Microorganisms | None (physical process) | Lactic acid bacteria, fungi, yeasts |

| Protein Quality Impact | Improves digestibility via denaturation | Increases bioavailability and nutritional value |

| Flavor Development | Limited, mainly neutral | Complex, enhances taste and aroma |

| Processing Time | Seconds to minutes | Hours to days |

| Applications | Textured vegetable protein, meat analogs | Fermented protein foods, soy products |

| Equipment | Extruder with screw and barrel | Fermenters, bioreactors |

| Scalability | High; industrial scale production | Moderate; requires controlled conditions |

| Shelf Life Effect | Increases shelf stability via low moisture | Varies; may improve preservation via acids |

Introduction to Protein Food Processing Technologies

Extrusion and fermentation represent pivotal protein food processing technologies that enhance nutritional value and functional properties. Extrusion utilizes high temperature, pressure, and shear to texturize plant proteins, creating meat analogs with improved digestibility and shelf-life. Fermentation employs microbial activity to enrich protein content, reduce anti-nutritional factors, and develop unique flavors, supporting sustainable and health-promoting protein food innovations.

Overview of Extrusion in Protein Food Production

Extrusion in protein food production involves high-temperature, high-pressure processing that transforms protein ingredients into structured, meat-like textures suitable for plant-based products. This technique enhances protein functionality by denaturing proteins and aligning fibers, improving texture, flavor binding, and digestibility. It offers efficient scalability and consistent product quality compared to traditional methods like fermentation.

Fundamentals of Fermentation for Protein Enrichment

Fermentation enhances protein foods by utilizing microorganisms to break down complex substrates into bioavailable amino acids, peptides, and enzymes, improving nutritional quality and digestibility. Key factors include selecting specific strains like Lactobacillus, optimizing pH, temperature, and substrate composition for maximal proteolytic activity. This biochemical transformation not only enriches protein content but also generates functional compounds that can improve flavor, texture, and shelf-life of protein-based foods.

Comparison of Extrusion and Fermentation Techniques

Extrusion and fermentation are distinct processing techniques widely used in protein food production, each influencing texture, flavor, and nutritional profiles differently. Extrusion applies high heat and shear forces to transform plant proteins into meat-like structures, enhancing digestibility and protein availability. Fermentation relies on microbial activity to enrich protein content, develop unique flavors, and improve bioavailability of essential amino acids, offering functional and sensory benefits unique to fermented protein foods.

Nutritional Impacts: Extrusion vs Fermentation

Extrusion processing denatures proteins and reduces anti-nutritional factors, enhancing digestibility and protein quality in food products. Fermentation improves protein bioavailability by synthesizing essential amino acids and increasing vitamin content while reducing allergenic compounds. Both methods alter protein structure differently, with extrusion emphasizing physical transformation and fermentation promoting biochemical enhancement for improved nutritional profiles.

Functional Properties of Extruded vs Fermented Proteins

Extruded proteins exhibit enhanced functional properties such as improved texture, water-holding capacity, and heat stability due to the high shear and temperature involved in the process, which induces protein denaturation and alignment. Fermented proteins, on the other hand, display superior digestibility, flavor development, and bioactive peptide formation through microbial enzymatic activity, enhancing nutritional value and sensory attributes. Both techniques influence protein solubility and emulsification differently, making extrusion ideal for structured meat analogs while fermentation excels in flavor complexity and health benefits.

Sensory Quality and Consumer Acceptance

Extrusion processing enhances protein food texture by creating a meat-like fibrous structure, improving sensory quality and consumer acceptance through its ability to mimic traditional meat products. Fermentation develops unique flavors and digestibility by introducing beneficial microbes that produce savory compounds, appealing to consumers seeking natural and probiotic-enriched foods. Sensory evaluations reveal extrusion products are favored for texture, while fermentation products excel in flavor complexity, influencing diverse consumer preferences.

Sustainability and Environmental Considerations

Extrusion technology and fermentation both offer sustainable approaches to producing protein-rich foods, with extrusion utilizing less water and energy compared to traditional cooking processes, while fermentation relies on microbial activity that can enhance nutrient profiles with minimal environmental impact. Fermentation produces lower greenhouse gas emissions by naturally breaking down substrates, whereas extrusion enables efficient use of plant-based raw materials, reducing reliance on animal proteins and deforestation. Life cycle assessments indicate that combining extrusion with fermentation can optimize resource use, minimize waste, and lower the overall carbon footprint of protein food production.

Industrial Applications and Market Trends

Extrusion technology enables high-throughput production of textured protein foods with consistent quality, widely utilized in meat analogs and snack industries due to its efficiency and scalability. Fermentation leverages microbial activity to enhance protein bioavailability and flavor complexity, gaining traction in niche markets focused on clean-label and functional foods. Market trends indicate a growing demand for hybrid approaches combining extrusion's texturizing capabilities with fermentation's nutritional benefits to meet consumer preferences for sustainable and plant-based protein options.

Future Perspectives in Protein Food Technology

Extrusion technology offers scalable production and texture customization for plant-based proteins, making it a leading method for creating meat analogs with high consumer appeal. Fermentation enhances protein digestibility and introduces novel flavors through microbial activity, enabling the development of functional and clean-label protein foods. Future advancements are likely to integrate fermentation-derived enzymes and precision extrusion processes to optimize nutritional profiles and sustainability in protein food production.

Related Important Terms

High-Moisture Extrusion

High-moisture extrusion technology enables the production of fibrous, meat-like protein structures by applying heat, pressure, and shear to plant-based ingredients, enhancing texture and functionality compared to fermentation methods that rely on microbial activity for protein modification. While fermentation improves nutritional profiles and flavor development through enzymatic processes, high-moisture extrusion offers scalable, rapid production with precise control over product consistency and moisture content in protein foods.

Mycoprotein Fermentation

Mycoprotein fermentation utilizes fungal biomass growth through controlled fermentation processes, producing high-protein, fiber-rich foods with a sustainable environmental footprint. Unlike extrusion, fermentation preserves protein structure and enhances bioavailability, resulting in superior texture, flavor development, and nutritional value in meat alternatives.

Shear-Celled Texturization

Shear-celled texturization in protein foods leverages extrusion to apply intense mechanical shear and heat, creating fibrous, meat-like structures by aligning proteins into layered matrices. In contrast, fermentation enhances protein functionality and flavor development through microbial activity but lacks the direct mechanical restructuring capabilities essential for producing textured, cell-like protein networks.

Solid-State Fermentation Protein

Solid-state fermentation (SSF) enhances protein foods by using microorganisms to convert substrates into high-quality protein with improved digestibility and bioavailability, surpassing traditional extrusion methods that rely on high heat and pressure to texturize proteins. SSF preserves nutritional content and bioactive compounds, offering a sustainable and energy-efficient alternative for developing functional protein-rich foods.

Hybrid Extrusion-Fermentation

Hybrid extrusion-fermentation combines the high-temperature, mechanical shear benefits of extrusion with the metabolic enhancements of fermentation, producing protein foods with improved texture, flavor, and nutritional profiles. This integrated approach optimizes protein digestibility, enhances bioactive compound synthesis, and reduces antinutritional factors more effectively than standalone extrusion or fermentation methods.

Meat Analogue Structuring

Extrusion technology enables the creation of fibrous meat analogue structures by applying high temperature, pressure, and shear, resulting in protein denaturation and alignment that mimics muscle texture. Fermentation enhances protein functionality and flavor development through microbial activity but lacks the mechanical structuring capabilities necessary for replicating the complex texture of meat analogues.

Microbial Biomass Protein

Extrusion produces high-protein foods by applying heat and shear to microbial biomass, enhancing texture and digestibility, while fermentation uses microbial growth under controlled conditions to increase protein content and bioavailability naturally. Microbial biomass protein from extrusion often results in a more uniform product with faster processing times, whereas fermentation offers improved flavor profiles and potential probiotic benefits.

Thermomechanical Denaturation

Thermomechanical denaturation during extrusion transforms protein structures through high-temperature, high-shear processes enhancing digestibility and texture in protein foods. Fermentation induces enzymatic protein modifications via microbial activity at moderate temperatures, preserving functional properties but producing less pronounced structural changes.

Alternative Substrate Fermentation

Alternative substrate fermentation in protein foods enhances nutritional profiles by leveraging diverse agricultural by-products such as quinoa, chickpea, and okara, enabling sustainable protein production with reduced environmental impact. This method promotes bioactive peptide formation and improved digestibility, contrasting extrusion's thermal degradation risks while supporting functional and sensory attributes through microbial metabolism.

Wet vs. Dry Texturization

Wet texturization via extrusion utilizes high moisture levels (40-80%) and shear forces to create fibrous, meat-like protein structures, enhancing texture and mouthfeel in plant-based foods. Dry texturization, often involving lower moisture content (<30%) and fermentation, relies on microbial enzymatic activity to modify protein structure and flavor, producing distinct textures and nutritional profiles in protein foods.

Extrusion vs Fermentation for Protein Foods Infographic

agridif.com

agridif.com