Sensory evaluation in food science relies on human senses to assess flavor, texture, aroma, and appearance, providing critical insights into consumer preferences and product acceptability. Instrumental analysis offers objective, precise measurements of food properties such as chemical composition, texture, and color, ensuring consistency and detecting contaminants or spoilage. Combining sensory evaluation with instrumental analysis enhances food quality control by balancing subjective sensory perceptions with reliable, quantitative data.

Table of Comparison

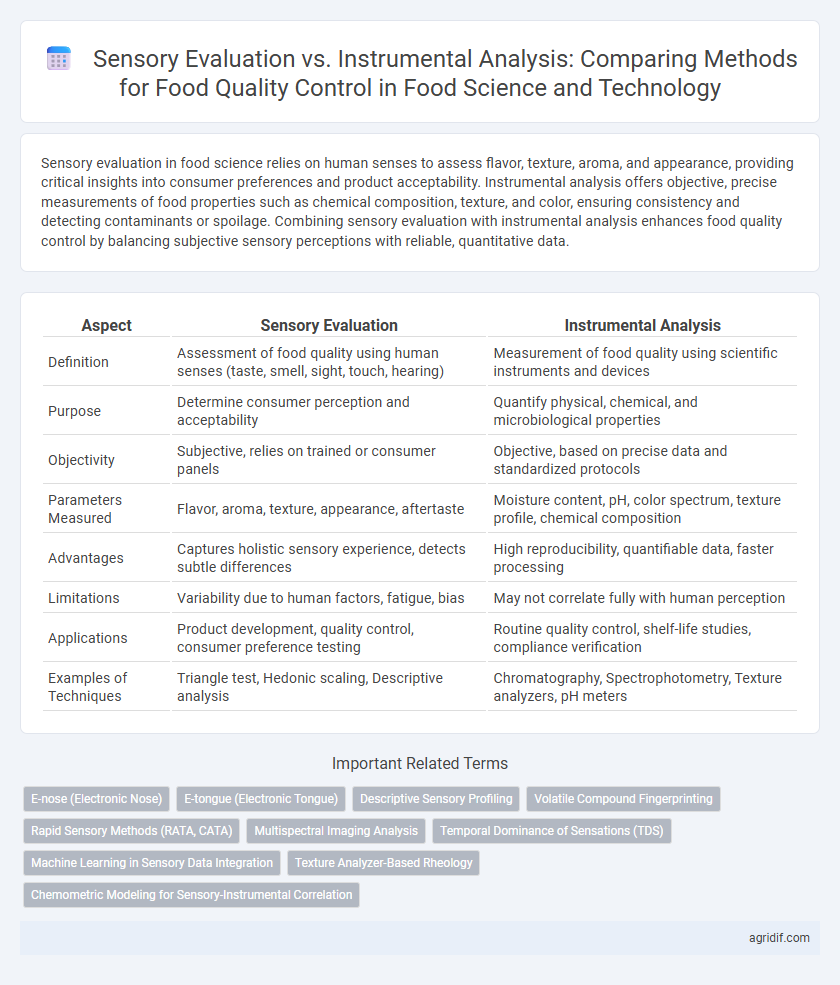

| Aspect | Sensory Evaluation | Instrumental Analysis |

|---|---|---|

| Definition | Assessment of food quality using human senses (taste, smell, sight, touch, hearing) | Measurement of food quality using scientific instruments and devices |

| Purpose | Determine consumer perception and acceptability | Quantify physical, chemical, and microbiological properties |

| Objectivity | Subjective, relies on trained or consumer panels | Objective, based on precise data and standardized protocols |

| Parameters Measured | Flavor, aroma, texture, appearance, aftertaste | Moisture content, pH, color spectrum, texture profile, chemical composition |

| Advantages | Captures holistic sensory experience, detects subtle differences | High reproducibility, quantifiable data, faster processing |

| Limitations | Variability due to human factors, fatigue, bias | May not correlate fully with human perception |

| Applications | Product development, quality control, consumer preference testing | Routine quality control, shelf-life studies, compliance verification |

| Examples of Techniques | Triangle test, Hedonic scaling, Descriptive analysis | Chromatography, Spectrophotometry, Texture analyzers, pH meters |

Introduction to Food Quality Control Methods

Sensory evaluation involves human panels assessing food attributes such as taste, aroma, texture, and appearance to capture consumer perception and acceptability, playing a critical role in food quality control. Instrumental analysis uses advanced technologies like chromatographs, spectrometers, and texture analyzers to quantify physical and chemical properties, providing objective and reproducible data. Combining sensory evaluation with instrumental methods enhances accuracy and reliability in monitoring food quality, ensuring product consistency and safety in the food industry.

Defining Sensory Evaluation in Food Science

Sensory evaluation in food science involves systematic methods to measure, analyze, and interpret human perceptions of food products using the five senses: taste, smell, sight, touch, and hearing. It provides crucial insights into consumer acceptability and product consistency by capturing subjective data on flavor, texture, aroma, and appearance. This method complements instrumental analysis by assessing sensory attributes that instruments cannot quantify, ensuring comprehensive food quality control.

Overview of Instrumental Analysis Techniques

Instrumental analysis techniques in food quality control include spectroscopy, chromatography, and texture analyzers, which provide objective and precise measurements of food composition and physical properties. These methods allow for the quantification of moisture content, color, flavor compounds, and texture parameters, enabling consistent product standards. Unlike sensory evaluation, instrumental analysis reduces variability caused by human perception and increases repeatability in quality assessment.

Key Differences Between Sensory and Instrumental Approaches

Sensory evaluation relies on human senses to assess food attributes such as taste, aroma, texture, and appearance, providing direct insights into consumer perception. Instrumental analysis employs analytical devices like spectrometers, chromatographs, and texture analyzers to generate objective, quantifiable data on chemical composition and physical properties. Key differences include subjectivity versus objectivity, human variability versus machine precision, and qualitative sensory descriptors versus quantitative instrumental measurements.

Advantages of Sensory Evaluation for Food Quality

Sensory evaluation offers direct insights into consumer perception by assessing taste, aroma, texture, and appearance, which are critical for product acceptance and market success. It captures complex flavor profiles and subtle sensory attributes that instruments may miss, providing a holistic understanding of food quality. This method enables real-time feedback on food products, facilitating rapid adjustments during development and quality control processes.

Benefits of Instrumental Analysis in Quality Assurance

Instrumental analysis provides objective, reproducible, and quantifiable data essential for consistent food quality control and assurance. Unlike sensory evaluation, it reduces human bias and variability, enabling precise measurement of parameters such as texture, color, and chemical composition. This technology enhances product standardization, accelerates quality assessment, and supports regulatory compliance in the food industry.

Limitations of Sensory Evaluation Methods

Sensory evaluation methods in food quality control often face limitations such as subjectivity, variability among panelists, and susceptibility to external factors like environment and mood. These factors can lead to inconsistent results, making it challenging to standardize sensory data across different batches and production lines. Moreover, sensory tests are time-consuming and require trained evaluators, which increases operational costs compared to rapid instrumental analysis techniques.

Challenges of Instrumental Analysis in Food Testing

Instrumental analysis in food quality control faces challenges such as limited ability to replicate human sensory perceptions, including taste, aroma, and texture. Instruments may struggle with complex food matrices where multiple components interact, causing difficulties in accurate quantification and detection. Furthermore, high costs and the need for specialized technical expertise can hinder widespread adoption and routine use in food testing laboratories.

When to Use Sensory Evaluation vs Instrumental Analysis

Sensory evaluation is essential when assessing consumer preferences, detecting subtle flavor or texture differences, and evaluating overall acceptability of food products, making it ideal during product development and market testing phases. Instrumental analysis excels in providing objective, precise, and reproducible measurements of physical and chemical properties such as moisture content, color, and texture, which are critical for quality control and regulatory compliance. Combining sensory evaluation with instrumental analysis ensures comprehensive food quality assessment, balancing human perception with analytical accuracy in various stages of production.

Integrating Both Methods for Comprehensive Food Quality Control

Integrating sensory evaluation with instrumental analysis enhances food quality control by combining human perception with precise, objective measurements, ensuring a holistic assessment of flavor, texture, and appearance. Sensory panels identify complex attributes and consumer preferences while instrumental techniques quantify chemical composition, texture profile, and colorimetry with high reproducibility. This complementary approach improves product consistency, accelerates defect detection, and supports regulatory compliance in food science and technology.

Related Important Terms

E-nose (Electronic Nose)

Sensory evaluation relies on human perception to assess food quality, while instrumental analysis, such as the E-nose (Electronic Nose), utilizes sensor arrays to detect volatile compounds for objective and rapid aroma profiling. The E-nose enhances consistency and sensitivity in food quality control by providing reproducible data that correlates closely with sensory panel results.

E-tongue (Electronic Tongue)

The E-tongue offers precise, reproducible detection of taste profiles and chemical compounds, enhancing food quality control by objectively assessing sensory attributes that human panels may overlook. Integration of electronic tongue data with traditional sensory evaluation accelerates product development while ensuring consistent flavor quality and consumer satisfaction.

Descriptive Sensory Profiling

Descriptive sensory profiling provides detailed qualitative and quantitative data on food attributes such as aroma, texture, and flavor, enabling precise consumer-centered product development. Instrumental analysis offers objective, reproducible measurements of physical and chemical properties but cannot fully capture the complex sensory experiences that influence consumer perception.

Volatile Compound Fingerprinting

Volatile compound fingerprinting in food quality control reveals intricate aroma profiles that sensory evaluation may subjectively interpret, while instrumental analysis provides precise, reproducible quantification of these compounds using techniques such as gas chromatography-mass spectrometry (GC-MS). Integrating sensory evaluation with instrumental data enhances the correlation between chemical composition and perceived flavor, optimizing product consistency and consumer acceptance.

Rapid Sensory Methods (RATA, CATA)

Rapid sensory methods such as Rate-All-That-Apply (RATA) and Check-All-That-Apply (CATA) provide efficient and consumer-relevant assessments by capturing nuanced flavor, texture, and aroma profiles directly from sensory panels in food quality control. These techniques complement instrumental analysis by highlighting perceptual differences and consumer preferences that instruments like gas chromatography or texture analyzers may overlook, enabling more holistic and precise product optimization.

Multispectral Imaging Analysis

Multispectral imaging analysis in food quality control offers precise quantification of color, texture, and compositional attributes, surpassing traditional sensory evaluation by reducing subjectivity and enabling rapid, non-destructive testing. This technology captures detailed spectral data across multiple wavelengths, facilitating objective assessment of freshness, ripeness, and contamination that enhances consistency and efficiency in food safety monitoring.

Temporal Dominance of Sensations (TDS)

Temporal Dominance of Sensations (TDS) provides dynamic insights into the sensory profiles of food products by capturing dominant sensations over time, enhancing the consumer perception understanding beyond static assessments. Integrating TDS with instrumental analysis allows precise correlation between sensory experiences and physicochemical properties, optimizing food quality control and product development processes.

Machine Learning in Sensory Data Integration

Machine learning enhances sensory evaluation by integrating complex sensory data with instrumental analysis to improve accuracy and objectivity in food quality control. Advanced algorithms process multi-dimensional sensory inputs alongside chemical and physical measurements, enabling predictive modeling and real-time quality assessment in food production.

Texture Analyzer-Based Rheology

Texture analyzer-based rheology provides precise quantitative measurements of food texture attributes such as firmness, cohesiveness, and elasticity, offering objective data critical for consistent food quality control. Sensory evaluation complements this by capturing human perception and preference, linking instrumental measurements to consumer experience and ensuring comprehensive assessment of food texture.

Chemometric Modeling for Sensory-Instrumental Correlation

Chemometric modeling enhances the correlation between sensory evaluation and instrumental analysis by integrating multivariate data to predict sensory attributes from instrumental measurements accurately. This approach improves food quality control by enabling objective, reproducible assessments that complement human sensory panels with precise analytical data.

Sensory Evaluation vs Instrumental Analysis for Food Quality Control Infographic

agridif.com

agridif.com