Rapid freezing preserves seafood quality by forming smaller ice crystals that reduce cell damage, maintaining texture and flavor more effectively than traditional methods. Cryogenic freezing utilizes liquid nitrogen or carbon dioxide to achieve ultra-low temperatures instantaneously, further minimizing ice crystal formation and microbial growth. These techniques enhance shelf life and safety, with cryogenic freezing offering superior preservation for high-value seafood products requiring extended storage.

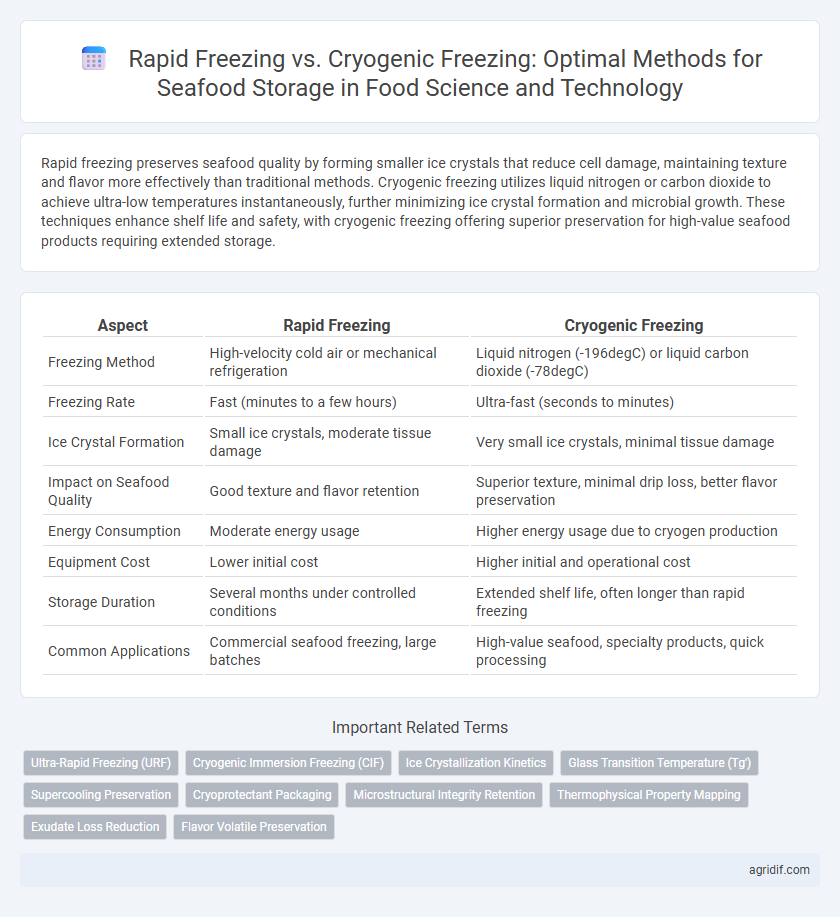

Table of Comparison

| Aspect | Rapid Freezing | Cryogenic Freezing |

|---|---|---|

| Freezing Method | High-velocity cold air or mechanical refrigeration | Liquid nitrogen (-196degC) or liquid carbon dioxide (-78degC) |

| Freezing Rate | Fast (minutes to a few hours) | Ultra-fast (seconds to minutes) |

| Ice Crystal Formation | Small ice crystals, moderate tissue damage | Very small ice crystals, minimal tissue damage |

| Impact on Seafood Quality | Good texture and flavor retention | Superior texture, minimal drip loss, better flavor preservation |

| Energy Consumption | Moderate energy usage | Higher energy usage due to cryogen production |

| Equipment Cost | Lower initial cost | Higher initial and operational cost |

| Storage Duration | Several months under controlled conditions | Extended shelf life, often longer than rapid freezing |

| Common Applications | Commercial seafood freezing, large batches | High-value seafood, specialty products, quick processing |

Introduction to Seafood Freezing Methods

Rapid freezing employs temperatures around -30degC to -40degC using traditional mechanical freezers to quickly reduce the temperature of seafood, minimizing ice crystal formation and preserving texture. Cryogenic freezing utilizes ultra-low temperatures, typically below -70degC, often achieved with liquid nitrogen or carbon dioxide, resulting in faster freezing rates and superior quality retention. Both methods aim to prevent cellular damage and maintain the nutritional value of seafood, but cryogenic freezing offers enhanced preservation ideal for high-value products.

Principles of Rapid Freezing in Seafood Storage

Rapid freezing in seafood storage involves quickly lowering the temperature to just below the seafood's freezing point, typically around -20degC to -30degC, to minimize ice crystal formation and preserve cellular structure. This process reduces the time seafood spends in the critical zone where ice crystals grow large, thereby maintaining texture, flavor, and nutritional quality. Rapid freezing techniques often use blast freezers or plate freezers to achieve uniform cooling rates that prevent spoilage and extend shelf life.

Overview of Cryogenic Freezing Technology

Cryogenic freezing technology utilizes ultra-low temperatures, typically below -150degC, achieved through liquid nitrogen or liquid carbon dioxide to rapidly freeze seafood. This method minimizes ice crystal formation, preserving the cellular structure, texture, and nutritional quality better than conventional freezing techniques. Cryogenic freezing enables extended shelf life and superior product quality, making it ideal for high-value seafood storage and long-distance transportation.

Impact on Seafood Quality: Texture, Flavor, and Moisture

Rapid freezing preserves seafood texture by minimizing ice crystal formation, reducing cellular damage and maintaining firmness. Cryogenic freezing, using liquid nitrogen, enhances flavor retention through ultra-fast freezing rates that inhibit enzymatic and microbial activity. Moisture content remains higher in cryogenically frozen seafood due to less thaw drip and reduced dehydration, ensuring superior quality upon thawing.

Freezing Rates and Ice Crystal Formation

Rapid freezing achieves freezing rates of approximately 1 to 10 cm per hour, producing relatively small ice crystals that help preserve the texture of seafood. Cryogenic freezing employs liquid nitrogen or carbon dioxide, reaching freezing rates up to 100 cm per hour, which leads to the formation of ultra-small ice crystals that minimize cellular damage. The faster freezing in cryogenic methods results in superior retention of seafood quality by reducing drip loss and structural degradation.

Nutrient Retention in Rapid vs Cryogenic Freezing

Rapid freezing preserves seafood nutrients by minimizing ice crystal formation, reducing cellular damage and nutrient loss. Cryogenic freezing, using liquid nitrogen, achieves faster freezing rates, resulting in even smaller ice crystals and better retention of vitamins, minerals, and omega-3 fatty acids. Studies indicate cryogenic freezing maintains higher levels of heat-sensitive nutrients compared to conventional rapid freezing methods.

Microbial Safety and Shelf Life Extension

Rapid freezing achieves microbial safety and shelf life extension of seafood by quickly passing through the temperature zone where ice crystals grow, thus minimizing cellular damage and microbial proliferation. Cryogenic freezing, using liquid nitrogen or carbon dioxide, offers faster freezing rates than conventional rapid freezing, leading to smaller ice crystals, reduced microbial activity, and significantly prolonged shelf life. Both methods enhance preservation, but cryogenic freezing provides superior microbial safety and longer storage stability in high-value seafood products.

Energy Efficiency and Operational Costs

Rapid freezing of seafood typically consumes less energy due to shorter processing times and relies on conventional refrigeration systems, resulting in lower operational costs compared to cryogenic freezing. Cryogenic freezing, utilizing liquid nitrogen or carbon dioxide, offers ultra-fast freezing rates that preserve seafood quality but incurs higher energy consumption and increased expenses from cryogen supply and specialized equipment maintenance. Energy efficiency in rapid freezing supports cost-effective large-scale seafood storage, whereas cryogenic methods prioritize product quality at a premium operational cost.

Environmental Considerations and Sustainability

Rapid freezing in seafood storage consumes less energy compared to cryogenic freezing, reducing overall carbon emissions and environmental impact. Cryogenic freezing, while offering superior ice crystal control and preserving quality, relies on liquid nitrogen or carbon dioxide, which involve higher production and transportation energy costs. Sustainable seafood storage practices should balance energy efficiency with product quality, favoring rapid freezing methods in facilities prioritizing reduced ecological footprints.

Future Trends in Seafood Freezing Technology

Emerging trends in seafood freezing technology emphasize advances in rapid freezing to minimize ice crystal formation and preserve texture, flavor, and nutritional quality more effectively. Cryogenic freezing, utilizing liquid nitrogen or carbon dioxide, offers ultra-fast freezing rates that reduce cellular damage and enhance shelf life, making it increasingly favored for premium seafood products. Innovations in hybrid freezing systems and energy-efficient cryogenic equipment are expected to drive the future of sustainable and high-quality seafood preservation.

Related Important Terms

Ultra-Rapid Freezing (URF)

Ultra-Rapid Freezing (URF) uses extremely low temperatures and high freezing rates to preserve seafood quality by minimizing ice crystal formation, maintaining texture, flavor, and nutritional value more effectively than traditional rapid freezing methods. Cryogenic freezing, often employing liquid nitrogen, achieves even faster freezing rates but is cost-intensive, while URF balances efficiency and quality, making it ideal for large-scale seafood storage and processing.

Cryogenic Immersion Freezing (CIF)

Cryogenic Immersion Freezing (CIF) offers superior preservation of seafood quality by rapidly lowering temperatures through direct contact with liquid nitrogen or carbon dioxide, minimizing ice crystal formation and cellular damage. This method ensures extended shelf life and retention of texture, flavor, and nutritional value compared to conventional rapid freezing techniques.

Ice Crystallization Kinetics

Rapid freezing of seafood facilitates the formation of smaller ice crystals due to faster ice crystallization kinetics, which helps preserve cellular structure and texture more effectively than slower freezing methods. Cryogenic freezing, employing liquid nitrogen at extremely low temperatures, induces ultra-rapid ice nucleation, minimizing ice crystal growth and significantly reducing cellular damage, thus enhancing the quality and shelf life of frozen seafood.

Glass Transition Temperature (Tg')

Rapid freezing preserves seafood quality by quickly passing through the glass transition temperature (Tg'), minimizing ice crystal formation and cellular damage. Cryogenic freezing achieves even lower Tg' and faster cooling rates using liquid nitrogen, enhancing texture retention and extending shelf life in seafood storage.

Supercooling Preservation

Rapid freezing minimizes ice crystal formation in seafood by quickly lowering the temperature, preserving texture and flavor, while cryogenic freezing uses liquid nitrogen to achieve ultra-low temperatures even faster, enhancing supercooling preservation by maintaining cellular integrity and reducing drip loss. Supercooling preservation extends seafood shelf life by keeping products below freezing point without ice crystallization, optimizing freshness and sensory quality during storage.

Cryoprotectant Packaging

Cryogenic freezing employs ultra-low temperatures using liquid nitrogen, which significantly reduces ice crystal formation, preserving seafood texture and freshness more effectively than rapid freezing. Integrating cryoprotectant packaging with cryogenic freezing enhances protection by minimizing protein denaturation and moisture loss, thereby extending shelf life and maintaining optimal quality during seafood storage.

Microstructural Integrity Retention

Rapid freezing minimizes ice crystal size, preserving the muscle fibers and cellular structure of seafood, resulting in superior microstructural integrity retention compared to slower freezing methods. Cryogenic freezing achieves even faster temperature reduction with liquid nitrogen, further reducing ice crystal formation and maintaining seafood texture and quality at optimal levels during storage.

Thermophysical Property Mapping

Rapid freezing and cryogenic freezing differ significantly in thermophysical property mapping of seafood, with cryogenic freezing utilizing extremely low temperatures like liquid nitrogen (-196degC) to achieve faster freezing rates, resulting in smaller ice crystal formation and better preservation of cellular structure. Thermophysical properties such as thermal conductivity, specific heat, and latent heat of seafood influence the freezing kinetics, where cryogenic freezing ensures minimal quality degradation compared to conventional rapid freezing methods operating at higher temperatures around -30degC to -40degC.

Exudate Loss Reduction

Rapid freezing minimizes exudate loss in seafood by quickly forming small ice crystals that preserve muscle cell integrity, while cryogenic freezing, using liquid nitrogen or carbon dioxide, achieves even faster freezing rates that further reduce drip loss and maintain texture quality. Studies indicate cryogenic freezing reduces exudate loss by up to 40% compared to conventional rapid freezing methods, enhancing shelf life and sensory attributes in frozen seafood products.

Flavor Volatile Preservation

Rapid freezing preserves seafood flavor volatiles by minimizing ice crystal growth, thus reducing cellular damage and volatile compound loss. Cryogenic freezing, using liquid nitrogen at ultra-low temperatures, offers superior volatile preservation by halting enzymatic activity and oxidation more effectively than conventional rapid freezing methods.

Rapid freezing vs cryogenic freezing for seafood storage Infographic

agridif.com

agridif.com