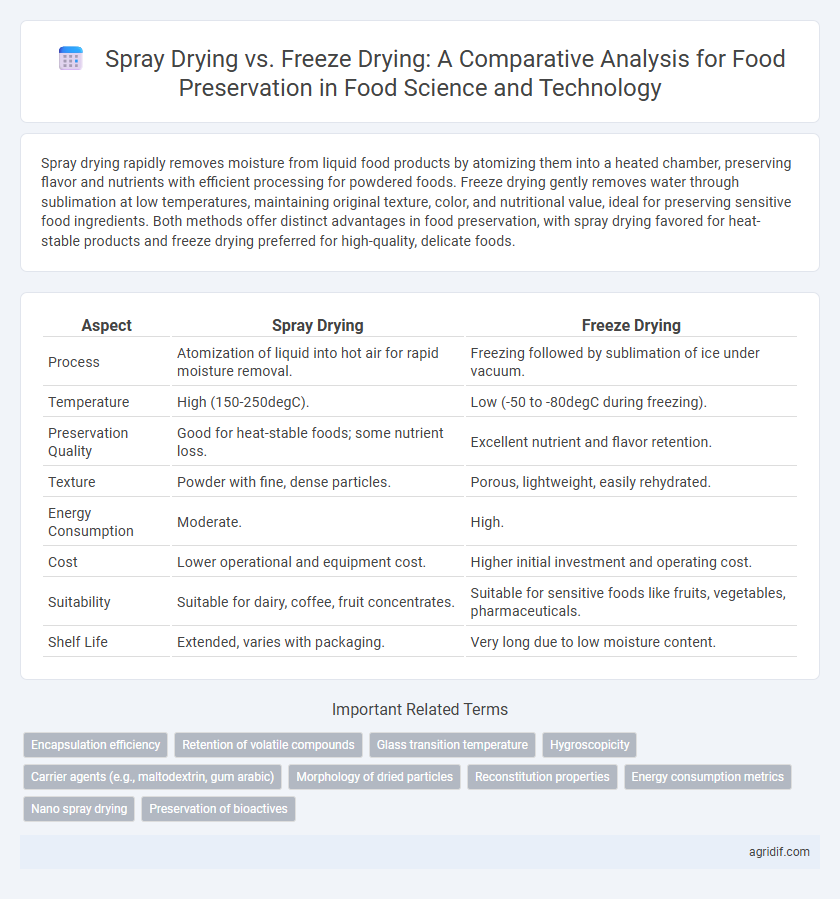

Spray drying rapidly removes moisture from liquid food products by atomizing them into a heated chamber, preserving flavor and nutrients with efficient processing for powdered foods. Freeze drying gently removes water through sublimation at low temperatures, maintaining original texture, color, and nutritional value, ideal for preserving sensitive food ingredients. Both methods offer distinct advantages in food preservation, with spray drying favored for heat-stable products and freeze drying preferred for high-quality, delicate foods.

Table of Comparison

| Aspect | Spray Drying | Freeze Drying |

|---|---|---|

| Process | Atomization of liquid into hot air for rapid moisture removal. | Freezing followed by sublimation of ice under vacuum. |

| Temperature | High (150-250degC). | Low (-50 to -80degC during freezing). |

| Preservation Quality | Good for heat-stable foods; some nutrient loss. | Excellent nutrient and flavor retention. |

| Texture | Powder with fine, dense particles. | Porous, lightweight, easily rehydrated. |

| Energy Consumption | Moderate. | High. |

| Cost | Lower operational and equipment cost. | Higher initial investment and operating cost. |

| Suitability | Suitable for dairy, coffee, fruit concentrates. | Suitable for sensitive foods like fruits, vegetables, pharmaceuticals. |

| Shelf Life | Extended, varies with packaging. | Very long due to low moisture content. |

Introduction to Food Preservation Techniques

Spray drying and freeze drying are two advanced food preservation techniques that extend shelf life by removing moisture from food products. Spray drying rapidly converts liquid food into powder form using hot air, ideal for heat-sensitive substances requiring quick drying. Freeze drying preserves food by sublimating ice under low temperature and pressure, maintaining nutritional quality and flavor more effectively than thermal methods.

Principles of Spray Drying in Food Science

Spray drying in food science involves atomizing a liquid food into a hot drying chamber, rapidly evaporating moisture to produce a fine, stable powder. The process relies on precise control of inlet temperature, feed rate, and airflow to preserve nutritional quality and flavor while ensuring microbial safety. Compared to freeze drying, spray drying offers faster processing times and cost efficiency, making it ideal for heat-sensitive liquids like milk powders and fruit extracts.

Fundamentals of Freeze Drying in Food Technology

Freeze drying, or lyophilization, preserves food by freezing it and then reducing surrounding pressure to allow frozen water to sublimate directly from ice to vapor. This method maintains the food's nutritional content, texture, and flavor more effectively than spray drying by preventing thermal degradation. Freeze drying is particularly suitable for sensitive food products such as fruits, coffee, and pharmaceuticals, where preserving bioactive compounds and structural integrity is critical.

Comparative Analysis: Efficiency and Cost

Spray drying offers higher efficiency with faster processing times and lower energy consumption compared to freeze drying, making it suitable for large-scale production of powdered foods. Freeze drying preserves nutritional and sensory qualities better but incurs significantly higher operational costs due to prolonged drying cycles and expensive equipment. Cost analysis reveals spray drying as more economical for mass production, while freeze drying remains preferable for high-value, heat-sensitive products requiring superior quality retention.

Impact on Nutrient Retention and Product Quality

Spray drying efficiently preserves heat-sensitive nutrients like vitamins A and C by minimizing exposure time to high temperatures, resulting in powders with good solubility and flow properties ideal for instant foods. Freeze drying better retains thermolabile compounds and antioxidants due to low-temperature dehydration, maintaining the original food structure and flavor while producing lightweight, porous products. Nutrient retention in spray drying varies with processing conditions, whereas freeze drying consistently yields higher vitamin and enzyme preservation, impacting product shelf life and quality.

Suitability for Different Food Types

Spray drying is highly suitable for heat-resistant products like fruit juices, milk powders, and instant coffee due to its rapid moisture removal and cost-effectiveness. Freeze drying excels in preserving heat-sensitive foods such as fruits, vegetables, and premium dairy products by maintaining nutritional quality, flavor, and texture through sublimation. The choice between spray drying and freeze drying depends on the food matrix, thermal sensitivity, and desired shelf life of the final product.

Energy Consumption and Environmental Considerations

Spray drying consumes significantly less energy compared to freeze drying, as it operates at higher temperatures and shorter processing times, reducing overall energy demand. Freeze drying, while preserving food quality and nutrients better, requires intense energy input for freezing and vacuum sublimation, leading to higher electricity usage and operational costs. Environmental considerations favor spray drying due to its lower carbon footprint and reduced water consumption, whereas freeze drying's high energy consumption contributes to greater greenhouse gas emissions.

Shelf Life and Microbial Stability

Spray drying significantly reduces moisture content, resulting in powders with extended shelf life and enhanced microbial stability due to low water activity inhibiting microbial growth. Freeze drying preserves food by sublimating ice under low pressure, maintaining structural integrity and nutrient content while providing excellent microbial stability through moisture removal. Compared to freeze drying, spray drying is faster and more cost-effective, but freeze drying offers superior preservation of sensitive bioactive compounds and longer shelf life under optimal storage conditions.

Product Texture, Flavor, and Rehydration Properties

Spray drying produces powders with a fine, uniform texture but can cause some loss of volatile flavor compounds due to heat exposure, affecting taste quality. Freeze drying preserves the original texture and flavor more effectively by sublimating moisture at low temperatures, maintaining cellular structure and volatile components. Rehydration properties are superior in freeze-dried products, as their porous matrix allows for quicker and more complete water absorption compared to the denser particles from spray drying.

Emerging Trends and Innovations in Drying Technologies

Emerging trends in food drying technologies highlight advancements in spray drying and freeze drying that enhance nutrient retention and energy efficiency. Innovations such as low-temperature spray drying and hybrid freeze drying methods improve powder quality while reducing processing time and operational costs. Integration of AI and sensor-driven controls further optimizes drying parameters, ensuring consistent product stability and extended shelf life in diverse food matrices.

Related Important Terms

Encapsulation efficiency

Spray drying offers high encapsulation efficiency for heat-stable bioactive compounds by rapidly converting liquid feed into powders through hot air, ensuring protective matrix formation around sensitive nutrients. Freeze drying excels in preserving encapsulation efficiency for heat-sensitive ingredients due to its low-temperature sublimation process that maintains structural integrity and bioactivity without thermal degradation.

Retention of volatile compounds

Spray drying often causes significant loss of volatile compounds due to high temperatures and rapid evaporation, leading to reduced flavor retention in food products. Freeze drying preserves volatile compounds more effectively by removing moisture under low temperature and vacuum conditions, maintaining aroma and taste profiles critical for food quality.

Glass transition temperature

Spray drying typically operates above the glass transition temperature (Tg) of food solids, enabling rapid moisture removal by converting the material into a rubbery state that facilitates particle formation. Freeze drying maintains the food matrix below the Tg, preserving structural integrity and nutrient stability by sublimating ice directly to vapor without crossing into the rubbery phase.

Hygroscopicity

Spray drying typically produces powders with higher hygroscopicity due to their porous structure and larger surface area, leading to faster moisture absorption and potential caking. Freeze drying yields low-hygroscopicity products with a porous and amorphous matrix that better resists moisture uptake, enhancing shelf life and stability in food preservation.

Carrier agents (e.g., maltodextrin, gum arabic)

Carrier agents like maltodextrin and gum arabic play a crucial role in spray drying by enhancing powder flowability and preventing stickiness, whereas freeze drying often requires minimal or no carrier due to its low-temperature dehydration process that preserves structural integrity and flavor. Maltodextrin is preferred in spray drying for its high solubility and low viscosity, while gum arabic provides emulsifying properties that stabilize sensitive bioactive compounds during drying.

Morphology of dried particles

Spray drying typically produces spherical particles with a smooth surface and a relatively uniform size distribution, ideal for powders requiring rapid rehydration and flowability. Freeze drying results in porous, irregularly shaped particles with a highly porous structure that retains more moisture and nutrients, enhancing solubility and preservation of sensitive bioactive compounds.

Reconstitution properties

Spray drying produces powders with smaller particle size and lower porosity, resulting in faster reconstitution times but may compromise the retention of volatile compounds. Freeze drying maintains the cellular structure and porosity, leading to superior retention of nutritional and sensory qualities, although it typically requires longer reconstitution periods due to larger, more porous particles.

Energy consumption metrics

Spray drying typically consumes 2 to 5 times less energy than freeze drying due to its continuous process and higher drying temperatures, often requiring around 3000 to 15000 kJ/kg of water evaporated. Freeze drying, while preserving nutritional quality better, demands significantly higher energy input, approximately 40000 to 60000 kJ/kg of water removed, due to the sublimation phase under vacuum conditions.

Nano spray drying

Nano spray drying offers precise control over particle size and morphology, enhancing the stability and bioavailability of food powders compared to traditional spray drying. Freeze drying preserves nutritional and sensory qualities by sublimating moisture at low temperatures, but nano spray drying provides faster processing and improved encapsulation of sensitive bioactives in food preservation.

Preservation of bioactives

Spray drying rapidly removes moisture from heat-sensitive bioactives by atomizing the liquid into a hot drying medium, minimizing degradation while maintaining antioxidant properties and enzyme activities. Freeze drying preserves bioactives more effectively by sublimating ice under low temperature and vacuum, retaining the structural integrity and nutritional value of vitamins, polyphenols, and probiotics.

Spray drying vs Freeze drying for food preservation Infographic

agridif.com

agridif.com