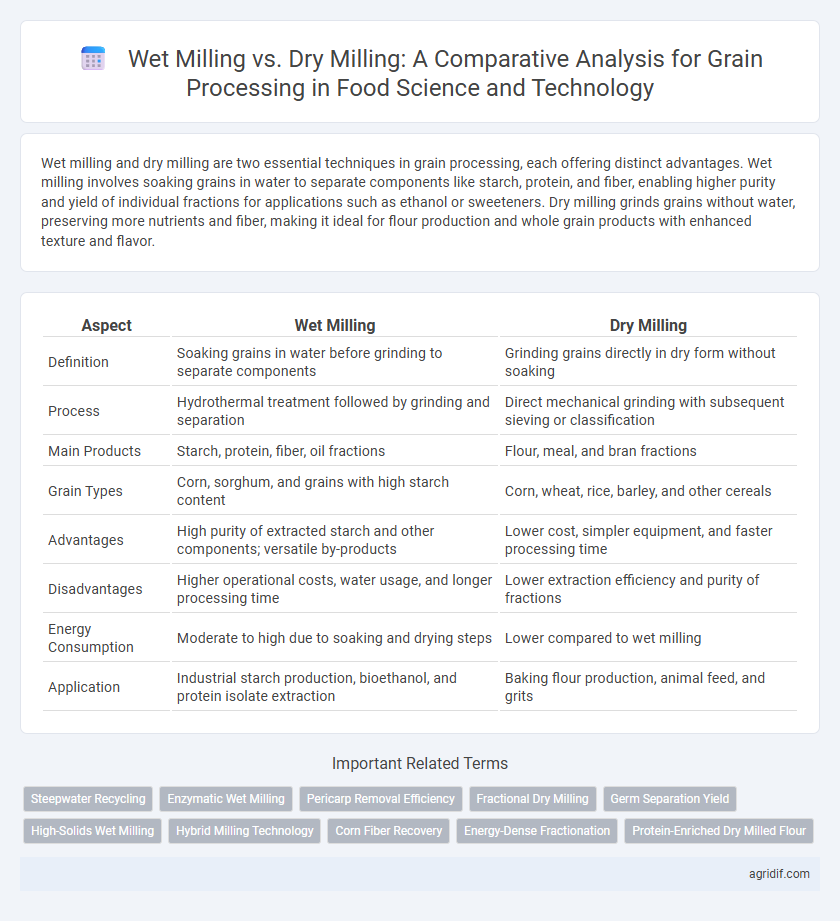

Wet milling and dry milling are two essential techniques in grain processing, each offering distinct advantages. Wet milling involves soaking grains in water to separate components like starch, protein, and fiber, enabling higher purity and yield of individual fractions for applications such as ethanol or sweeteners. Dry milling grinds grains without water, preserving more nutrients and fiber, making it ideal for flour production and whole grain products with enhanced texture and flavor.

Table of Comparison

| Aspect | Wet Milling | Dry Milling |

|---|---|---|

| Definition | Soaking grains in water before grinding to separate components | Grinding grains directly in dry form without soaking |

| Process | Hydrothermal treatment followed by grinding and separation | Direct mechanical grinding with subsequent sieving or classification |

| Main Products | Starch, protein, fiber, oil fractions | Flour, meal, and bran fractions |

| Grain Types | Corn, sorghum, and grains with high starch content | Corn, wheat, rice, barley, and other cereals |

| Advantages | High purity of extracted starch and other components; versatile by-products | Lower cost, simpler equipment, and faster processing time |

| Disadvantages | Higher operational costs, water usage, and longer processing time | Lower extraction efficiency and purity of fractions |

| Energy Consumption | Moderate to high due to soaking and drying steps | Lower compared to wet milling |

| Application | Industrial starch production, bioethanol, and protein isolate extraction | Baking flour production, animal feed, and grits |

Introduction to Grain Processing: Wet vs Dry Milling

Wet milling and dry milling are two primary techniques in grain processing, each impacting product quality and application differently. Wet milling involves soaking grains in water to separate components like starch, protein, and fiber, enhancing yield and purity for products such as corn syrup and ethanol. Dry milling grinds whole grains without soaking, preserving more natural fiber content, commonly used for flour and feed production.

Overview of Wet Milling Processes in Agriculture

Wet milling in grain processing involves soaking grains in water or a chemical solution to soften them before mechanical grinding, enhancing starch extraction efficiency. This technique allows separation of components such as starch, protein, fiber, and oil, leading to higher product purity and value. Widely used in corn and sorghum processing, wet milling supports the production of sweeteners, ethanol, and industrial starch derivatives.

Key Steps in Dry Milling Technology

Dry milling technology in grain processing involves critical steps such as cleaning, conditioning, grinding, and sifting to separate bran, germ, and endosperm efficiently. Conditioning adjusts the moisture content of grains to enhance grinding performance and product quality, while sifting separates flour fractions based on particle size. The emphasis on precise control during each phase ensures optimal yield and functional properties of milled grains for food applications.

Comparative Analysis: Efficiency of Wet and Dry Milling

Wet milling of grains enhances starch extraction efficiency by utilizing water to separate components, resulting in higher yields of starch, protein, and fiber compared to dry milling. Dry milling is more energy-efficient and less complex, but it produces coarser fractions with lower purity, impacting the quality of end products. The choice between wet and dry milling depends on desired product specifications, energy consumption, and processing costs.

Impact on Nutritional Quality of Grains

Wet milling enhances the retention of vitamins and minerals in grains by minimizing heat generation and preserving natural antioxidants, unlike dry milling which often leads to nutrient loss due to high temperatures and abrasion. The enzymatic activity during wet milling helps maintain protein integrity and improves the bioavailability of essential nutrients. Dry milling typically results in a coarser product with reduced nutritional quality, as it removes bran and germ components rich in dietary fiber and micronutrients.

Energy Consumption in Wet and Dry Milling Methods

Wet milling consumes significantly more energy compared to dry milling due to the intensive water usage and the need for subsequent drying processes. Dry milling requires less energy as it involves grinding grains without added moisture, reducing the need for drying and minimizing processing stages. Energy efficiency in grain processing is critical for sustainability, making dry milling a preferable choice in applications where energy consumption is a dominant concern.

Byproducts and Co-Product Utilization

Wet milling of grains produces valuable byproducts such as corn gluten meal, corn steep liquor, and bran, which serve as high-protein animal feed and fermentation substrates in biofuel production. Dry milling primarily yields bran and germ as co-products, commonly used in fiber supplements and oil extraction, but offers fewer commoditized byproducts compared to wet milling. Efficient utilization of these co-products enhances overall process sustainability and economic viability in grain processing industries.

Environmental Implications of Grain Milling Techniques

Wet milling consumes significantly more water and energy compared to dry milling, leading to increased environmental burdens such as higher wastewater generation and energy-related emissions. Dry milling, while less water-intensive, may produce more dust and particulate matter, affecting air quality if not properly controlled. Choosing between wet and dry milling techniques requires balancing resource consumption with pollution management to minimize the overall environmental footprint of grain processing.

Industrial Applications: Choosing the Right Milling Method

Wet milling in grain processing offers superior extraction of starch, proteins, and oils, making it ideal for industries requiring high-purity components like biofuel production and food additives. Dry milling is favored in industrial applications emphasizing whole grain utilization and energy efficiency, commonly used in flour and feed production. Selecting the right milling method depends on the desired product specifications, processing costs, and end-use applications.

Future Trends in Grain Processing Technologies

Emerging trends in grain processing technologies highlight advancements in wet milling techniques, emphasizing enzymatic treatments and microbial fermentation to enhance nutritional value and functional properties of grains. Innovations in dry milling focus on energy-efficient equipment and precision particle size control to improve product consistency and reduce waste. Integration of sensor-based quality monitoring and AI-driven process optimization is accelerating the shift toward more sustainable and high-throughput grain processing systems.

Related Important Terms

Steepwater Recycling

Wet milling enhances grain processing efficiency by allowing steepwater recycling, which recovers nutrients and reduces water consumption, improving sustainability and cost-effectiveness. In contrast, dry milling lacks a steepwater phase, resulting in limited nutrient recovery and higher water usage, making it less environmentally favorable.

Enzymatic Wet Milling

Enzymatic wet milling utilizes specific enzymes to break down starch-protein matrices in grains, enhancing yield and purity of starch, gluten, and fiber fractions compared to traditional dry milling methods. This biotechnological approach reduces energy consumption and environmental impact while improving product functionality in food applications.

Pericarp Removal Efficiency

Wet milling exhibits higher pericarp removal efficiency in grain processing due to its ability to soften the grain kernel through water immersion, facilitating easier separation of the pericarp from the endosperm and germ. Dry milling, while faster and less water-intensive, often results in incomplete pericarp removal, impacting the purity and quality of the final product.

Fractional Dry Milling

Fractional dry milling in grain processing enhances the separation of endosperm, bran, and germ by mechanically grinding grains without moisture, preserving nutrient integrity and improving downstream product quality. This technique offers higher energy efficiency and better control over particle size distribution compared to wet milling, making it ideal for producing fine flour fractions with minimal product loss.

Germ Separation Yield

Wet milling in grain processing significantly enhances germ separation yield by utilizing water to soften the grain, which facilitates more efficient separation of germ from other components; this method can achieve germ yields exceeding 95%. Dry milling offers lower germ separation efficiency, typically below 80%, due to reliance on mechanical abrasion without moisture, resulting in greater germ loss and lower oil recovery.

High-Solids Wet Milling

High-solids wet milling in grain processing enhances starch extraction efficiency by utilizing elevated moisture content and enzymatic treatment to break down cell walls, resulting in higher yield and purity compared to dry milling. This method improves particle size reduction and energy consumption while producing superior functional properties in starch-based products for food science applications.

Hybrid Milling Technology

Hybrid milling technology integrates wet milling and dry milling processes to enhance grain processing efficiency, producing higher yields of starch, protein, and fiber fractions with improved purity and functionality. This approach optimizes resource utilization and energy consumption while enabling versatile end-product applications in food science and technology.

Corn Fiber Recovery

Wet milling of corn enhances fiber recovery by physically separating fiber components through steeping and grinding, resulting in higher purity and yield of corn fiber compared to dry milling. Dry milling, relying on mechanical grinding alone, produces coarser fiber fractions with lower extraction efficiency and limited separation of fiber constituents.

Energy-Dense Fractionation

Wet milling of grains enhances energy-dense fractionation by allowing efficient separation of starch, protein, and fiber components through hydration and grinding, leading to higher purity and yield of valuable fractions such as corn starch and gluten. Dry milling, while simpler and less energy-intensive, produces coarser fractions with lower separation efficiency, limiting its capacity to isolate energy-dense components for high-value food and industrial applications.

Protein-Enriched Dry Milled Flour

Protein-enriched dry milled flour achieves higher protein concentration by mechanically separating bran and germ from endosperm, preserving protein content while minimizing moisture absorption compared to wet milling. This method enhances flour functionality for bakery applications, offering improved shelf life and nutritional quality through precise particle size control and reduced enzymatic activity.

Wet Milling vs Dry Milling for Grain Processing Infographic

agridif.com

agridif.com