Homogenization improves the texture and stability of liquid dairy products by breaking down fat globules into smaller sizes, preventing cream separation. Pasteurization ensures safety by applying heat to eliminate harmful microorganisms without significantly altering nutritional value. Combining both processes enhances product quality, shelf life, and consumer acceptance in dairy processing.

Table of Comparison

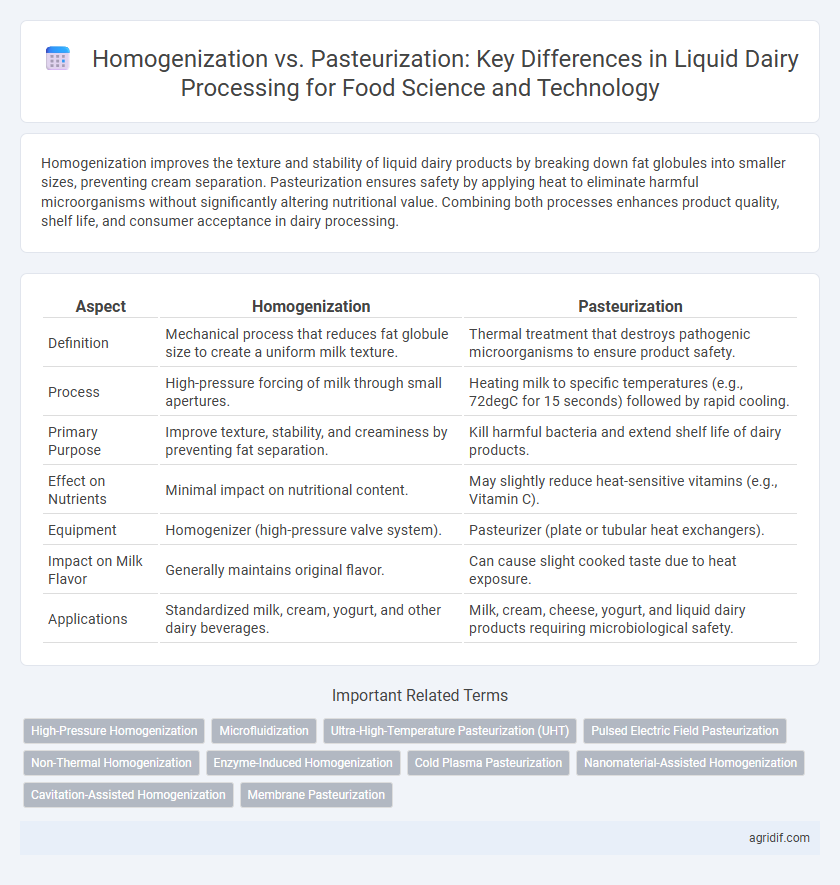

| Aspect | Homogenization | Pasteurization |

|---|---|---|

| Definition | Mechanical process that reduces fat globule size to create a uniform milk texture. | Thermal treatment that destroys pathogenic microorganisms to ensure product safety. |

| Process | High-pressure forcing of milk through small apertures. | Heating milk to specific temperatures (e.g., 72degC for 15 seconds) followed by rapid cooling. |

| Primary Purpose | Improve texture, stability, and creaminess by preventing fat separation. | Kill harmful bacteria and extend shelf life of dairy products. |

| Effect on Nutrients | Minimal impact on nutritional content. | May slightly reduce heat-sensitive vitamins (e.g., Vitamin C). |

| Equipment | Homogenizer (high-pressure valve system). | Pasteurizer (plate or tubular heat exchangers). |

| Impact on Milk Flavor | Generally maintains original flavor. | Can cause slight cooked taste due to heat exposure. |

| Applications | Standardized milk, cream, yogurt, and other dairy beverages. | Milk, cream, cheese, yogurt, and liquid dairy products requiring microbiological safety. |

Introduction to Liquid Dairy Processing

Homogenization breaks down fat globules in milk to create a uniform texture and prevent cream separation, enhancing consistency and mouthfeel. Pasteurization involves heating milk to specific temperatures to eliminate pathogenic microorganisms and extend shelf life without significantly altering nutritional content. Both processes are critical steps in liquid dairy processing, ensuring product safety, quality, and consumer acceptance.

Understanding Homogenization: Principles and Purpose

Homogenization in liquid dairy processing involves mechanically breaking down fat globules to achieve a uniform milk consistency and prevent cream separation. This process enhances milk stability, texture, and mouthfeel by reducing globule size and ensuring even fat distribution. Unlike pasteurization, which focuses on microbial safety through heat treatment, homogenization primarily aims to improve physical quality and consumer acceptance of dairy products.

Pasteurization: Definition and Key Methods

Pasteurization in liquid dairy processing involves heating milk to a specific temperature--typically 72degC for 15 seconds in the high-temperature short-time (HTST) method--to eliminate pathogenic microorganisms and extend shelf life. Key pasteurization techniques include batch pasteurization, where milk is held at 63degC for 30 minutes, and ultra-pasteurization, which heats milk above 135degC for a few seconds to achieve longer preservation. This thermal treatment ensures microbiological safety while maintaining essential nutrients and flavor profiles in dairy products.

Homogenization vs Pasteurization: Core Differences

Homogenization involves mechanically breaking down fat globules in liquid dairy to create a uniform texture, preventing cream separation, while pasteurization uses heat treatment to eliminate harmful microorganisms and extend shelf life. Homogenization primarily affects the physical properties of milk, enhancing texture and consistency, whereas pasteurization ensures microbiological safety and complies with food safety regulations. Both processes are integral in liquid dairy processing but serve distinct purposes--textural improvement versus microbial control.

Impacts on Nutritional Quality of Dairy

Homogenization reduces fat globule size, improving texture and consistency but causing slight increases in lipid oxidation that may marginally affect vitamin A stability in dairy products. Pasteurization eliminates pathogenic bacteria through heat treatment, preserving macronutrients like proteins and carbohydrates while potentially causing minor losses in heat-sensitive vitamins such as vitamin C and certain B-complex vitamins. Both processes contribute differently to nutritional quality, with homogenization primarily affecting physical properties and pasteurization impacting microbial safety and nutrient retention.

Effects on Shelf Life and Microbial Safety

Homogenization reduces fat globule size in liquid dairy, improving texture and stability but has limited impact on microbial load and shelf life. Pasteurization effectively eliminates pathogenic microorganisms through controlled heating, significantly enhancing microbial safety and extending shelf life. Combining homogenization with pasteurization optimizes product quality while ensuring safety and prolonged freshness.

Influence on Flavor, Texture, and Appearance

Homogenization in liquid dairy processing breaks down fat globules, creating a smoother texture and uniform appearance, while pasteurization primarily targets microbial safety without significantly altering flavor or texture. Pasteurization preserves the milk's natural flavor but can sometimes impart a cooked taste due to heat treatment. Homogenized products exhibit creamier mouthfeel and improved stability, enhancing sensory appeal compared to non-homogenized liquids.

Technological Challenges in Dairy Processing

Homogenization in liquid dairy processing involves breaking down fat globules to create a uniform fat distribution, which prevents cream separation but requires high-pressure equipment and precise control to avoid heat generation that can affect milk quality. Pasteurization focuses on microbial safety by heating milk to specific temperatures, yet maintaining nutritional and sensory properties presents challenges such as enzyme inactivation and protein denaturation. The integration of both technologies demands optimization of process parameters to balance microbial safety, product stability, and sensory characteristics while minimizing energy consumption and equipment wear.

Regulatory Standards for Homogenization and Pasteurization

Regulatory standards for homogenization in liquid dairy processing primarily focus on equipment specifications and operational parameters to ensure uniform fat dispersion and product stability without compromising microbial safety. Pasteurization regulations are more stringent, mandating specific temperature-time combinations, such as 72degC for 15 seconds (HTST) or 63degC for 30 minutes (LTLT), to effectively reduce pathogenic microorganisms and extend shelf life. Both processes must comply with local and international food safety standards, such as those set by the FDA, USDA, and Codex Alimentarius, to guarantee product safety and consumer protection.

Future Trends and Innovations in Dairy Processing

Advancements in dairy processing emphasize integrating homogenization and pasteurization through ultrasonic and membrane technologies to enhance texture and microbial safety while preserving nutritional quality. Emerging trends include the use of high-pressure homogenization combined with non-thermal pasteurization methods like pulsed electric fields to minimize heat damage and extend shelf life. Innovations in real-time monitoring sensors and AI-driven process control optimize these methods for energy efficiency and product consistency in liquid dairy production.

Related Important Terms

High-Pressure Homogenization

High-Pressure Homogenization (HPH) in liquid dairy processing improves microbial safety and extends shelf life by disrupting microbial cells and enhancing protein dispersion, distinct from pasteurization that relies on heat to eliminate pathogens. Unlike conventional pasteurization, HPH preserves nutritional and sensory qualities by avoiding thermal degradation while achieving microbial inactivation through mechanical forces.

Microfluidization

Microfluidization enhances homogenization by using high-pressure streams to reduce fat globule size and improve emulsion stability in liquid dairy products, creating a finer, more uniform texture compared to conventional methods. Unlike pasteurization, which primarily focuses on microbial safety through heat treatment, microfluidization optimizes particle size and consistency without significantly altering nutritional quality.

Ultra-High-Temperature Pasteurization (UHT)

Ultra-High-Temperature (UHT) pasteurization heats liquid dairy products to at least 135degC for 2-5 seconds, effectively sterilizing while preserving shelf life up to several months without refrigeration. Homogenization mechanically reduces fat globule size to improve texture and stability but does not eliminate microbial load, making UHT essential for microbial safety in long-life dairy processing.

Pulsed Electric Field Pasteurization

Pulsed Electric Field (PEF) pasteurization in liquid dairy processing preserves nutritional quality and flavor by using short bursts of high voltage to inactivate microorganisms without heat, contrasting with traditional thermal pasteurization that relies on heat and can affect taste and nutrient content. Unlike homogenization, which mechanically reduces fat globule size to improve texture and stability, PEF focuses on microbial safety while maintaining the natural properties of milk products.

Non-Thermal Homogenization

Non-thermal homogenization techniques, such as ultrasonic and high-pressure homogenization, enhance the stability and shelf life of liquid dairy without applying heat, preserving sensory and nutritional qualities better than traditional pasteurization. These methods disrupt fat globules more uniformly, improving texture and emulsification while minimizing microbial load through physical cell damage rather than thermal denaturation.

Enzyme-Induced Homogenization

Enzyme-induced homogenization enhances fat globule size reduction in liquid dairy processing, improving texture and stability more effectively than traditional mechanical homogenization. Unlike pasteurization, which primarily focuses on microbial safety by heating, enzyme-induced homogenization optimizes product consistency and shelf-life through biocatalytic modification of milk fat structures.

Cold Plasma Pasteurization

Cold plasma pasteurization in liquid dairy processing offers a non-thermal alternative that effectively reduces microbial load while preserving nutritional and sensory qualities compared to traditional thermal pasteurization. Unlike homogenization, which primarily targets fat globule size for improved texture and stability, cold plasma pasteurization inactivates pathogens through reactive species without altering the physicochemical properties of milk.

Nanomaterial-Assisted Homogenization

Nanomaterial-assisted homogenization enhances liquid dairy processing by achieving finer fat globule dispersion and improved stability compared to traditional pasteurization, which primarily targets microbial reduction through heat treatment. Integrating nanomaterials like cellulose nanocrystals facilitates energy-efficient homogenization, promoting superior texture, extended shelf life, and enhanced nutrient bioavailability in dairy products.

Cavitation-Assisted Homogenization

Cavitation-assisted homogenization enhances liquid dairy processing by generating microbubbles that rupture fat globules, improving emulsion stability and texture beyond conventional homogenization. This technique also reduces energy consumption and preserves nutritional and sensory qualities compared to traditional pasteurization methods.

Membrane Pasteurization

Membrane pasteurization utilizes selective membranes to remove microorganisms and enzymes from liquid dairy products, providing precise microbial control without heat-induced quality degradation common in traditional homogenization and pasteurization processes. This technique maintains nutritional and sensory properties while extending shelf life, offering an advanced alternative for dairy preservation in food science and technology.

Homogenization vs pasteurization for liquid dairy processing Infographic

agridif.com

agridif.com