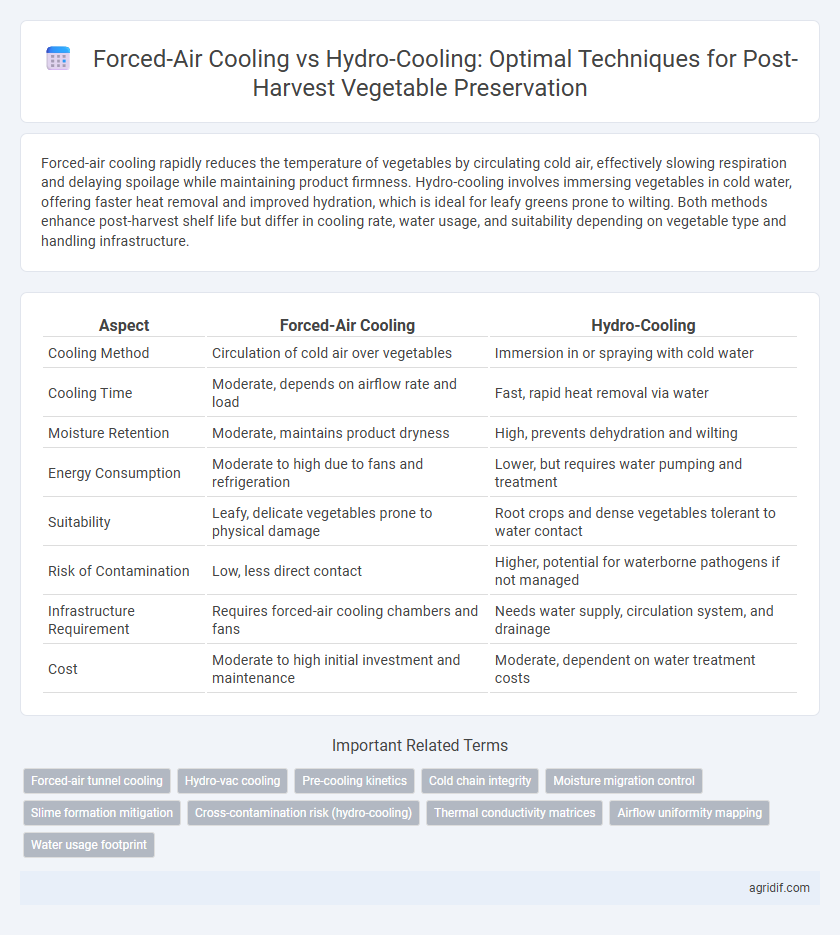

Forced-air cooling rapidly reduces the temperature of vegetables by circulating cold air, effectively slowing respiration and delaying spoilage while maintaining product firmness. Hydro-cooling involves immersing vegetables in cold water, offering faster heat removal and improved hydration, which is ideal for leafy greens prone to wilting. Both methods enhance post-harvest shelf life but differ in cooling rate, water usage, and suitability depending on vegetable type and handling infrastructure.

Table of Comparison

| Aspect | Forced-Air Cooling | Hydro-Cooling |

|---|---|---|

| Cooling Method | Circulation of cold air over vegetables | Immersion in or spraying with cold water |

| Cooling Time | Moderate, depends on airflow rate and load | Fast, rapid heat removal via water |

| Moisture Retention | Moderate, maintains product dryness | High, prevents dehydration and wilting |

| Energy Consumption | Moderate to high due to fans and refrigeration | Lower, but requires water pumping and treatment |

| Suitability | Leafy, delicate vegetables prone to physical damage | Root crops and dense vegetables tolerant to water contact |

| Risk of Contamination | Low, less direct contact | Higher, potential for waterborne pathogens if not managed |

| Infrastructure Requirement | Requires forced-air cooling chambers and fans | Needs water supply, circulation system, and drainage |

| Cost | Moderate to high initial investment and maintenance | Moderate, dependent on water treatment costs |

Introduction to Post-Harvest Vegetable Cooling Methods

Forced-air cooling rapidly removes field heat from vegetables by circulating chilled air through the produce, enhancing shelf life and maintaining freshness. Hydro-cooling uses cold water immersion to quickly lower the temperature of vegetables, improving moisture retention and reducing spoilage. Both methods are critical in post-harvest technology to optimize vegetable preservation by minimizing respiration rates and microbial growth.

What is Forced-air Cooling?

Forced-air cooling is a post-harvest technology that rapidly removes heat from vegetables by circulating chilled air through packed produce, ensuring uniform temperature reduction. This method enhances shelf life by slowing respiration rates and reducing microbial growth without introducing excess moisture. Forced-air cooling is widely preferred for its efficiency and compatibility with various types of vegetables compared to hydro-cooling, which uses water immersion.

What is Hydro-cooling?

Hydro-cooling is a post-harvest technique that rapidly reduces the temperature of vegetables by immersing them in or spraying them with cold water, effectively slowing down respiration and delaying spoilage. This method enhances moisture retention and reduces thermal gradients within the produce, leading to improved freshness and extended shelf life compared to other cooling methods. Hydro-cooling is particularly effective for vegetables with high surface area and porous textures, such as leafy greens and asparagus.

Efficiency of Temperature Reduction: Forced-air vs Hydro-cooling

Forced-air cooling rapidly decreases the temperature of vegetables by circulating cold air uniformly around the produce, achieving optimal cooling rates for items with low moisture content. Hydro-cooling employs cold water immersion or sprays, providing more efficient heat removal for high-moisture vegetables due to direct thermal conductivity, but may increase water usage and risk contamination. Overall, hydro-cooling offers faster temperature reduction for water-rich vegetables, while forced-air cooling is more suitable for delicate or leafy greens requiring gentle handling and reduced moisture exposure.

Impact on Vegetable Quality and Shelf-life

Forced-air cooling rapidly removes field heat from vegetables by circulating cold air, preserving texture and firmness while extending shelf-life by reducing respiration rates and microbial growth. Hydro-cooling, immersing vegetables in chilled water, effectively lowers temperature but may increase moisture uptake and risk surface microbial contamination, potentially compromising quality. Both methods extend shelf-life, but forced-air cooling generally better maintains vegetable quality by minimizing moisture-related deterioration and preserving natural texture.

Energy Consumption and Cost Analysis

Forced-air cooling consumes less energy compared to hydro-cooling due to its efficient air circulation system, resulting in lower operational costs for vegetable preservation. Hydro-cooling requires a significant amount of water and energy to maintain low temperatures, leading to higher utility expenses and increased maintenance costs. Energy efficiency metrics and cost-benefit analyses consistently favor forced-air cooling for large-scale post-harvest vegetable storage.

Suitability for Different Vegetable Types

Forced-air cooling is highly effective for leafy greens, broccoli, and other vegetables with high surface area due to rapid, uniform temperature reduction achieved by circulating cold air. Hydro-cooling suits root vegetables, such as carrots and potatoes, as well as fruits like tomatoes, where direct contact with cold water removes field heat efficiently without causing dehydration. Selecting the appropriate cooling method depends on the vegetable's surface texture, moisture sensitivity, and susceptibility to decay, optimizing shelf life and quality retention.

Microbial Safety and Sanitation Concerns

Forced-air cooling rapidly reduces vegetable temperature by circulating cold air, minimizing microbial growth without water contact, reducing cross-contamination risks. Hydro-cooling immerses vegetables in cold water, which can harbor pathogens if water quality and sanitation protocols are not strictly maintained. Effective microbial safety in hydro-cooling depends on continuous water treatment, while forced-air systems require regular air filter maintenance to sustain sanitation standards.

Environmental Considerations of Cooling Methods

Forced-air cooling uses less water and has a lower environmental impact compared to hydro-cooling, making it a more sustainable option for vegetable preservation. Hydro-cooling consumes substantial water resources and requires proper water treatment to prevent contamination and waste. Implementing energy-efficient fans and recycling water in forced-air and hydro-cooling systems further reduces environmental footprints.

Choosing the Right Cooling Method for Your Operation

Selecting the appropriate cooling method for vegetable preservation depends on factors like crop type, facility size, and available resources. Forced-air cooling excels in efficiency and uniform temperature reduction for large-scale operations with well-ventilated storage, while hydro-cooling offers rapid surface cooling ideal for highly perishable vegetables with high moisture content. Evaluating cooling rate requirements, water availability, and energy costs ensures optimal post-harvest quality and shelf life extension.

Related Important Terms

Forced-air tunnel cooling

Forced-air tunnel cooling rapidly reduces the temperature of vegetables by circulating cold air through a tunnel, ensuring uniform cooling and minimizing moisture loss, which extends shelf life and maintains quality. Compared to hydro-cooling, forced-air cooling uses less water and reduces the risk of microbial contamination, making it a more sustainable and hygienic option for post-harvest vegetable preservation.

Hydro-vac cooling

Hydro-vac cooling offers rapid and uniform temperature reduction for vegetables, effectively minimizing respiration rates and moisture loss compared to forced-air cooling. This method utilizes vacuum pressure to accelerate water evaporation directly from the produce surface, enhancing shelf life and maintaining post-harvest quality in perishable crops.

Pre-cooling kinetics

Forced-air cooling rapidly removes field heat from vegetables by circulating cold air evenly, achieving faster temperature reduction and minimizing moisture loss compared to hydro-cooling. Hydro-cooling relies on direct water immersion, which slows pre-cooling kinetics due to water's lower heat transfer rate but provides uniform cooling and surface cleaning benefits.

Cold chain integrity

Forced-air cooling rapidly reduces the temperature of vegetables by circulating cold air uniformly, minimizing moisture loss and maintaining cold chain integrity during post-harvest handling. Hydro-cooling submerges produce in cold water to quickly remove field heat but risks microbial contamination and waterlogging, potentially compromising the cold chain's effectiveness and vegetable quality.

Moisture migration control

Forced-air cooling effectively controls moisture migration by rapidly removing field heat through high-velocity air circulation, reducing condensation and surface moisture on vegetables. Hydro-cooling, while efficient in cooling, can increase surface moisture and risk of microbial growth due to water immersion, potentially accelerating moisture loss and spoilage.

Slime formation mitigation

Forced-air cooling rapidly lowers vegetable temperature by circulating chilled air to minimize microbial growth and enzyme activity, effectively reducing slime formation on sensitive produce. Hydro-cooling, which involves immersing vegetables in cold water, can increase moisture on surfaces and potentially promote slime development if not properly managed.

Cross-contamination risk (hydro-cooling)

Forced-air cooling reduces cross-contamination risk by using cold air to rapidly lower vegetable temperature without direct water contact, while hydro-cooling involves immersion in chilled water, increasing the potential for pathogen transfer and spread among produce. Proper sanitation and water management practices are critical in hydro-cooling systems to mitigate microbial contamination and ensure vegetable safety during post-harvest handling.

Thermal conductivity matrices

Forced-air cooling accelerates heat removal by circulating cold air through the vegetable mass, relying on air's low thermal conductivity, which can limit cooling uniformity in dense produce. Hydro-cooling improves thermal conductivity by immersing vegetables in cold water, facilitating rapid and uniform heat transfer essential for maintaining freshness and extending shelf life.

Airflow uniformity mapping

Forced-air cooling demonstrates superior airflow uniformity mapping compared to hydro-cooling, ensuring consistent temperature reduction across all vegetable surfaces and minimizing hot spots that accelerate spoilage. Hydro-cooling often results in uneven cooling rates due to variable water contact, leading to less effective preservation and higher risks of microbial growth.

Water usage footprint

Forced-air cooling uses significantly less water compared to hydro-cooling, making it a more sustainable option for vegetable preservation by reducing water consumption and runoff risks. Hydro-cooling, while effective in rapidly lowering produce temperature, has a higher water usage footprint due to continuous water immersion or spraying, which can lead to increased water wastage and management challenges.

Forced-air cooling vs Hydro-cooling for vegetable preservation Infographic

agridif.com

agridif.com