Hot water treatment effectively eliminates pests on fruits and vegetables by submerging produce in precisely controlled temperatures, ensuring thorough disinfection without chemical residues. Vapour heat treatment uses heated steam to penetrate harder-to-reach areas on produce, offering a non-chemical alternative that maintains product quality and shelf life. Both methods serve as eco-friendly, residue-free solutions for pest control in post-harvest technology, with selection depending on crop sensitivity and pest type.

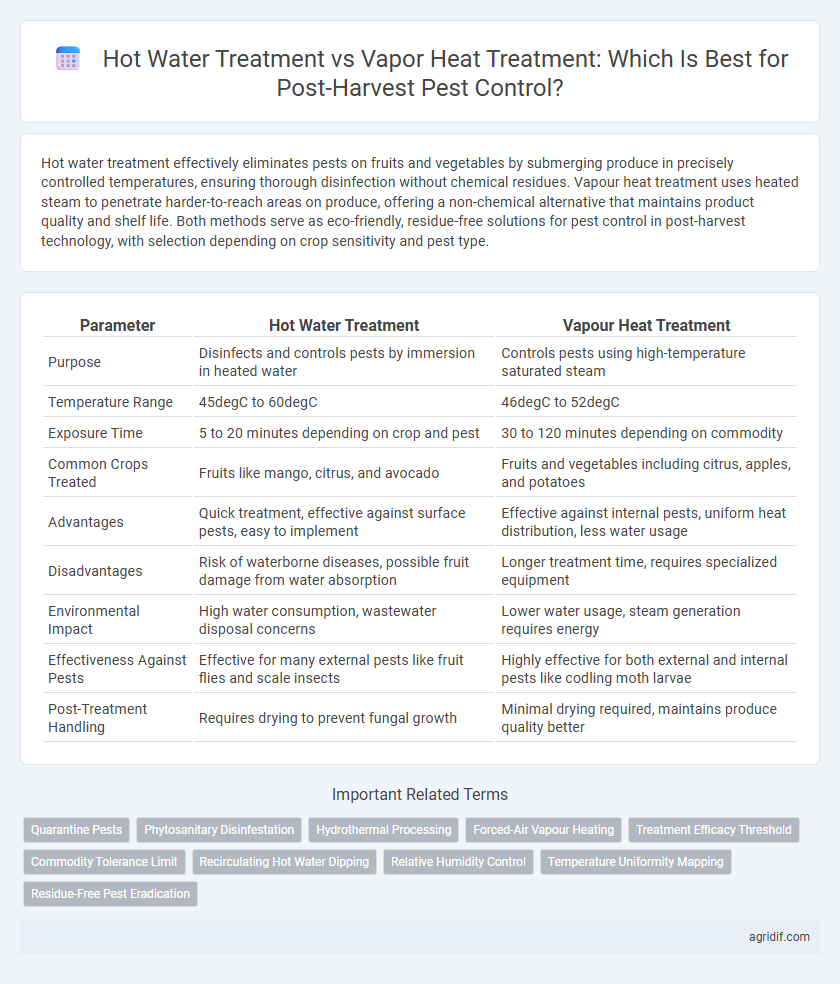

Table of Comparison

| Parameter | Hot Water Treatment | Vapour Heat Treatment |

|---|---|---|

| Purpose | Disinfects and controls pests by immersion in heated water | Controls pests using high-temperature saturated steam |

| Temperature Range | 45degC to 60degC | 46degC to 52degC |

| Exposure Time | 5 to 20 minutes depending on crop and pest | 30 to 120 minutes depending on commodity |

| Common Crops Treated | Fruits like mango, citrus, and avocado | Fruits and vegetables including citrus, apples, and potatoes |

| Advantages | Quick treatment, effective against surface pests, easy to implement | Effective against internal pests, uniform heat distribution, less water usage |

| Disadvantages | Risk of waterborne diseases, possible fruit damage from water absorption | Longer treatment time, requires specialized equipment |

| Environmental Impact | High water consumption, wastewater disposal concerns | Lower water usage, steam generation requires energy |

| Effectiveness Against Pests | Effective for many external pests like fruit flies and scale insects | Highly effective for both external and internal pests like codling moth larvae |

| Post-Treatment Handling | Requires drying to prevent fungal growth | Minimal drying required, maintains produce quality better |

Understanding Post-Harvest Pest Control Challenges

Hot water treatment effectively targets pests on fruit surfaces by exposing produce to precise temperature thresholds that eliminate insects without damaging the commodity, ensuring compliance with international quarantine standards. Vapour heat treatment offers a controlled environment using saturated steam to penetrate fruit crevices, eradicating internal pests while minimizing quality degradation. Understanding post-harvest pest control challenges requires balancing efficacy in pest elimination, maintaining fruit quality, and adhering to phytosanitary regulations to reduce export rejections and losses.

Principles of Hot Water Treatment (HWT)

Hot Water Treatment (HWT) for pest control involves immersing produce in carefully controlled hot water baths at temperatures typically between 46degC and 52degC for specific durations to eliminate insect pests without damaging the fruit. The principle relies on heat penetration that disrupts the metabolic processes and protein structures of pests while maintaining the produce's physiological integrity. Precise temperature management and exposure time are critical for achieving effective disinfestation and preserving post-harvest quality.

Principles of Vapour Heat Treatment (VHT)

Vapour Heat Treatment (VHT) operates by exposing produce to saturated steam at controlled temperatures typically between 46-50degC for precise durations to eliminate pests without compromising fruit quality. This method relies on the high thermal conductivity of steam to uniformly raise the internal temperature of the product, targeting insects in all developmental stages by interrupting their metabolic processes. VHT offers a safer alternative to chemical fumigation, reducing residues and environmental impact while ensuring compliance with international quarantine requirements.

Efficacy Against Key Agricultural Pests

Hot Water Treatment effectively eliminates common agricultural pests like fruit flies (Ceratitis capitata) and mango seed weevil (Sternochetus mangiferae) by exposing produce to precise temperature ranges (46-52degC) for specific durations, ensuring pest mortality without compromising fruit quality. Vapour Heat Treatment, utilizing controlled moist heat typically between 38-48degC, targets pests such as Mediterranean fruit fly and avocado seed moth by penetrating deeper into the produce, offering enhanced efficacy against infestations resistant to surface treatments. Both methods play crucial roles in integrated pest management, with efficacy dependent on pest species, exposure time, and temperature precision to prevent post-harvest losses.

Impact on Fruit and Vegetable Quality

Hot water treatment effectively reduces pests while maintaining firmness and color in fruits and vegetables, though it can sometimes cause slight surface damage or heat stress. Vapour heat treatment offers more uniform heat distribution, minimizing physical damage and preserving nutritional content, but may lead to higher moisture loss and potential texture softening. Selecting between these methods depends on the specific crop's sensitivity and desired post-harvest quality attributes.

Comparative Cost and Infrastructure Requirements

Hot water treatment for pest control typically involves lower initial infrastructure costs compared to vapor heat treatment, requiring basic heating tanks and water circulation systems. Vapor heat treatment demands more advanced and costly infrastructure, including sealed chambers and precise steam application technology to maintain uniform temperature and humidity. While operational expenses for hot water treatment are generally lower due to simpler equipment, vapor heat treatment may incur higher energy consumption and maintenance costs, affecting overall cost-efficiency.

Environmental and Safety Considerations

Hot Water Treatment for pest control in post-harvest technology uses precise temperature and timing to effectively eliminate pests without chemical residues, minimizing environmental impact and ensuring food safety. Vapour Heat Treatment also offers a chemical-free approach but requires careful monitoring of humidity and temperature to prevent produce damage and reduce energy consumption. Both methods emphasize sustainable pest control with minimal environmental hazards and improved worker safety compared to conventional chemical fumigants.

Suitability for Different Crop Types

Hot water treatment is highly effective for fruits with thick skins such as citrus and mangoes, as it penetrates pests without damaging the flesh, making it ideal for tropical and subtropical crops. Vapour heat treatment suits delicate crops like berries and stone fruits by offering uniform heat exposure that minimizes surface moisture, reducing the risk of spoilage. Crop-specific tolerance to temperature and humidity levels dictates the choice between these pest control methods for optimizing post-harvest quality and safety.

Regulatory Standards and Market Access

Hot Water Treatment meets stringent regulatory standards by effectively eliminating pests without chemical residues, ensuring compliance with international phytosanitary measures. Vapour Heat Treatment offers a chemical-free alternative, favored in markets with strict regulations on pesticide use, facilitating access to sensitive export destinations. Both methods align with global quarantine requirements, but selection depends on specific regulatory frameworks and target market preferences.

Future Trends in Quarantine Heat Treatments

Future trends in quarantine heat treatments emphasize the integration of precise temperature monitoring and energy-efficient systems to enhance pest control efficacy while minimizing crop damage. Advances in sensor technology and data analytics enable real-time adjustment of hot water and vapour heat treatment processes, optimizing exposure times for diverse produce types. Research increasingly supports combining vapor heat's uniform heat penetration with hot water's targeted thermal impact to develop customizable, sustainable post-harvest pest management solutions.

Related Important Terms

Quarantine Pests

Hot Water Treatment effectively controls quarantine pests by immersing fruits at precise temperatures, ensuring deep heat penetration without damaging the produce, making it ideal for tropical fruits like mangoes and citrus. Vapour Heat Treatment uses saturated steam to eradicate pests on the surface and near-surface layers, providing a faster quarantine treatment option with minimal residue and maintaining fruit quality for commodities such as avocados and lychees.

Phytosanitary Disinfestation

Hot Water Treatment utilizes precise temperature control, typically between 46-52degC, to penetrate fruit surfaces and effectively eliminate pests such as fruit flies without compromising quality, making it ideal for sensitive produce like mangoes and citrus. Vapour Heat Treatment employs saturated steam at 46-48degC for specified durations, offering uniform heat application that targets internal and external pests including Codling Moth and Mediterranean Fruit Fly, ensuring phytosanitary compliance in commodities such as apples and stone fruits.

Hydrothermal Processing

Hydrothermal processing in post-harvest pest control utilizes precise temperature and moisture conditions to eliminate pests while preserving fruit quality, with hot water treatment penetrating the produce surface effectively. Vapour heat treatment offers uniform heat distribution through moist air, reducing thermal stress but often requiring longer exposure times compared to hot water immersion for microbial and pest eradication.

Forced-Air Vapour Heating

Forced-air vapour heating in post-harvest technology offers superior pest control by circulating high-temperature steam uniformly around produce, effectively eliminating insects and pathogens without causing thermal damage. Compared to hot water treatment, this method reduces moisture-related quality degradation, enhances shelf life, and ensures consistent pest eradication through precise temperature and exposure time control.

Treatment Efficacy Threshold

Hot Water Treatment achieves effective pest control at temperatures between 46degC and 52degC for 20 to 40 minutes, ensuring mortality of most quarantine pests without damaging produce. Vapour Heat Treatment requires precise temperature maintenance around 46.5degC to 48degC with exposure times of 40 to 90 minutes to meet efficacy thresholds for eliminating heat-sensitive insect pests while preserving fruit quality.

Commodity Tolerance Limit

Hot Water Treatment requires precise temperature and exposure time to avoid damaging heat-sensitive commodities like tropical fruits, whereas Vapour Heat Treatment offers a gentler alternative with lower risk of surface damage by using saturated steam at controlled humidity and temperature levels. Commodity tolerance limits for Hot Water Treatment typically lie between 45-55degC for 30-60 minutes, while Vapour Heat Treatment can often be conducted at slightly higher temperatures, around 50-60degC, due to uniform heat distribution minimizing stress on produce.

Recirculating Hot Water Dipping

Recirculating Hot Water Dipping in post-harvest technology effectively controls pests by maintaining consistent temperature and exposure time, ensuring thorough penetration and reducing thermal shock to produce. Compared to Vapour Heat Treatment, this method offers better energy efficiency, enhanced uniformity in heat distribution, and scalable adaptability for various fruit commodities.

Relative Humidity Control

Hot Water Treatment for pest control in post-harvest technology requires precise temperature regulation but often struggles with maintaining optimal relative humidity, risking dehydration and quality loss. Vapour Heat Treatment offers superior relative humidity control by saturating the environment, which minimizes moisture loss and preserves the commodity's freshness during the disinfestation process.

Temperature Uniformity Mapping

Temperature uniformity mapping in hot water treatment ensures consistent thermal exposure, reducing the risk of under- or over-treatment, which is critical for effective pest control and fruit quality preservation. Vapour heat treatment offers improved temperature uniformity due to better heat penetration and circulation, minimizing thermal gradients and enhancing overall disinfestation efficacy.

Residue-Free Pest Eradication

Hot water treatment eradicates pests by immersing produce in carefully controlled temperature baths, ensuring residue-free pest control without chemical additives, while vapor heat treatment uses humid hot air to achieve similar pest mortality with minimal moisture impact. Both methods effectively eliminate quarantine pests, enhancing shelf life and marketability through safe, residue-free post-harvest pest management.

Hot Water Treatment vs Vapour Heat Treatment for Pest Control Infographic

agridif.com

agridif.com