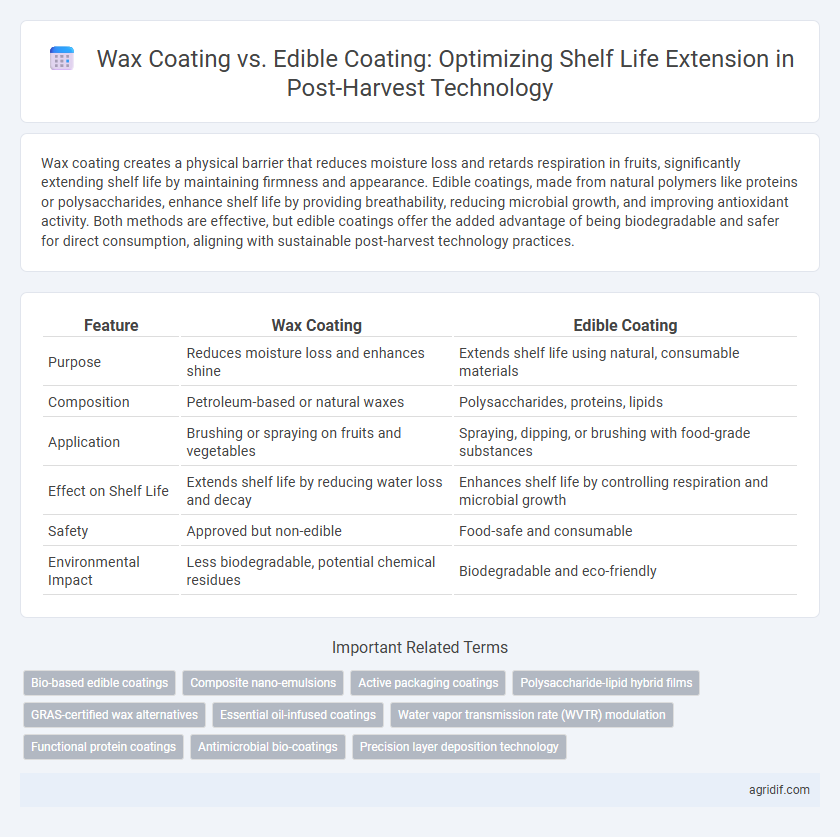

Wax coating creates a physical barrier that reduces moisture loss and retards respiration in fruits, significantly extending shelf life by maintaining firmness and appearance. Edible coatings, made from natural polymers like proteins or polysaccharides, enhance shelf life by providing breathability, reducing microbial growth, and improving antioxidant activity. Both methods are effective, but edible coatings offer the added advantage of being biodegradable and safer for direct consumption, aligning with sustainable post-harvest technology practices.

Table of Comparison

| Feature | Wax Coating | Edible Coating |

|---|---|---|

| Purpose | Reduces moisture loss and enhances shine | Extends shelf life using natural, consumable materials |

| Composition | Petroleum-based or natural waxes | Polysaccharides, proteins, lipids |

| Application | Brushing or spraying on fruits and vegetables | Spraying, dipping, or brushing with food-grade substances |

| Effect on Shelf Life | Extends shelf life by reducing water loss and decay | Enhances shelf life by controlling respiration and microbial growth |

| Safety | Approved but non-edible | Food-safe and consumable |

| Environmental Impact | Less biodegradable, potential chemical residues | Biodegradable and eco-friendly |

Introduction to Post-Harvest Shelf Life Challenges

Post-harvest shelf life challenges include moisture loss, microbial decay, and enzymatic spoilage, which lead to significant quality degradation in fresh produce. Wax coating and edible coating technologies serve as protective barriers, reducing respiration rates and water loss while enhancing resistance to microbial infection. Advances in edible coatings, often derived from natural polymers like chitosan or alginate, offer improved biodegradability and consumer acceptance compared to traditional petroleum-based wax coatings.

What is Wax Coating? Definition and Applications

Wax coating is a post-harvest treatment involving the application of natural or synthetic waxes on fruits and vegetables to form a protective barrier that reduces moisture loss and gas exchange, thereby extending shelf life. Commonly used in apples, cucumbers, and citrus fruits, wax coatings help maintain firmness, retard decay, and enhance visual appeal during storage and transportation. This method is favored in commercial supply chains due to its cost-effectiveness and ability to improve produce marketability without altering taste.

Edible Coatings: Composition and Functionality

Edible coatings are composed of natural biopolymers such as polysaccharides, proteins, and lipids, which form a semi-permeable barrier on the surface of fresh produce. These coatings regulate gas exchange and moisture loss, thus maintaining fruit firmness and delaying ripening processes to extend shelf life. The incorporation of antioxidants, antimicrobials, and plasticizers enhances the functional properties of edible coatings, improving protection against microbial spoilage and maintaining quality during storage.

Mechanisms of Shelf Life Extension: Wax vs Edible Coatings

Wax coatings create a moisture barrier by sealing fruit surfaces, reducing water loss and delaying dehydration, which slows down respiration and senescence. Edible coatings, composed of biopolymers like chitosan or alginate, enhance shelf life by providing selective permeability that maintains gas exchange while controlling moisture, thus reducing oxidation and microbial growth. The controlled gas exchange in edible coatings modulates ethylene production and respiration rates more effectively than wax, resulting in prolonged freshness and firmness.

Impact on Fruit and Vegetable Quality

Wax coating enhances fruit and vegetable shelf life by reducing moisture loss and slowing respiration, preserving firmness and appearance. Edible coatings, made from natural materials like proteins, lipids, or polysaccharides, form a breathable barrier that allows gas exchange, maintaining freshness without compromising texture or flavor. Both methods improve post-harvest quality, but edible coatings offer added benefits of being biodegradable and potentially nutritive, aligning with consumer demand for clean-label produce.

Food Safety and Regulatory Considerations

Wax coatings provide a physical barrier that reduces moisture loss and slows respiration rates, effectively extending shelf life but often involve synthetic or petroleum-based substances that may raise food safety concerns. Edible coatings, derived from natural biopolymers such as chitosan, proteins, and polysaccharides, offer biodegradable, non-toxic protection and comply more readily with stringent food safety regulations imposed by authorities like the FDA and EFSA. Regulatory frameworks prioritize coatings that do not compromise food safety, making edible coatings preferable for enhancing shelf life while meeting compliance standards.

Environmental Implications: Biodegradability and Sustainability

Wax coatings provide effective moisture barrier properties but often involve petroleum-based materials, raising concerns about their environmental impact and limited biodegradability. Edible coatings, derived from natural polymers like chitosan, starch, or proteins, offer sustainable alternatives with enhanced biodegradability and reduced ecological footprint. Choosing edible coatings supports circular economy principles and reduces post-consumer waste accumulation in agricultural supply chains.

Consumer Preferences and Market Trends

Wax coating remains popular for extending shelf life due to its cost-effectiveness and ability to reduce moisture loss, though its non-edible nature limits consumer acceptance. Edible coatings, derived from natural biopolymers like chitosan and alginate, align with increasing consumer demand for clean-label, sustainable solutions, thus gaining traction in premium markets. Market trends indicate a shift towards edible coatings as consumers prioritize health, safety, and environmental impact in post-harvest technology products.

Cost-effectiveness in Commercial Operations

Wax coating offers a cost-effective solution for commercial post-harvest operations due to its low material cost and straightforward application process, enabling large-scale shelf life extension with minimal investment. Edible coatings, while providing added nutritional benefits and consumer appeal, typically involve higher costs related to raw materials and specialized equipment, impacting overall profitability. Commercial producers favor wax coatings when prioritizing affordability and efficiency in extending fruit and vegetable shelf life.

Future Prospects and Innovations in Coating Technologies

Emerging innovations in post-harvest technology focus on developing biodegradable and nutrient-enriched edible coatings that enhance fruit and vegetable shelf life more sustainably than traditional wax coatings. Nanotechnology integration enables precision delivery of antimicrobial agents, improving freshness retention and reducing spoilage. Future prospects highlight smart coatings with embedded sensors for real-time quality monitoring, revolutionizing supply chain management and reducing food waste.

Related Important Terms

Bio-based edible coatings

Bio-based edible coatings, derived from natural polymers such as chitosan, starch, and alginate, enhance shelf life by providing a breathable barrier that reduces moisture loss and microbial growth while maintaining fruit quality. Unlike conventional wax coatings that create a non-breathable layer, bio-based edible coatings improve gas exchange and biodegradability, making them a sustainable choice for post-harvest preservation.

Composite nano-emulsions

Composite nano-emulsions used in edible coatings significantly enhance the shelf life of fruits and vegetables by providing a uniform barrier that reduces moisture loss and microbial growth, outperforming traditional wax coatings in maintaining freshness and nutritional quality. These nano-emulsions improve the mechanical properties and gas permeability of edible coatings, allowing better respiration control and extended post-harvest durability compared to conventional wax-based treatments.

Active packaging coatings

Active packaging coatings like edible coatings enhance shelf life by incorporating antimicrobial and antioxidant agents that interact with the fruit surface, reducing microbial growth and oxidation. Wax coatings primarily create a physical barrier to moisture loss and gas exchange but lack the functional bioactive properties found in advanced edible coatings for post-harvest preservation.

Polysaccharide-lipid hybrid films

Polysaccharide-lipid hybrid films in edible coatings offer improved barrier properties against moisture and gases, significantly extending the shelf life of fresh produce compared to traditional wax coatings. These hybrid coatings combine the biodegradability and film-forming ability of polysaccharides with the hydrophobic nature of lipids, enhancing fruit preservation without compromising food safety or quality.

GRAS-certified wax alternatives

GRAS-certified edible coatings, such as chitosan and alginate, offer biodegradable, non-toxic alternatives to traditional wax coatings for extending the shelf life of fresh produce by reducing moisture loss and microbial growth. These edible coatings enhance respiration control and maintain quality without the environmental concerns associated with synthetic waxes, aligning with sustainable post-harvest technology practices.

Essential oil-infused coatings

Essential oil-infused edible coatings enhance shelf life by providing antimicrobial and antioxidant properties that reduce microbial decay and oxidative damage, surpassing traditional wax coatings which primarily act as moisture barriers. These bioactive coatings improve post-harvest quality in fruits and vegetables by maintaining firmness, reducing respiration rates, and extending freshness with natural, biodegradable materials.

Water vapor transmission rate (WVTR) modulation

Wax coatings provide a robust barrier that significantly lowers the water vapor transmission rate (WVTR), effectively reducing moisture loss and extending the shelf life of fresh produce. Edible coatings, formulated with biopolymers like chitosan or starch, offer adjustable WVTR properties that balance moisture retention and gas exchange, enhancing post-harvest preservation while maintaining product edibility.

Functional protein coatings

Functional protein coatings in post-harvest technology provide a biodegradable and edible barrier that enhances moisture retention and reduces respiration rates, effectively extending the shelf life of fruits and vegetables. Compared to traditional wax coatings, these protein-based films offer improved gas permeability and nutrient preservation while maintaining food safety and environmental sustainability.

Antimicrobial bio-coatings

Antimicrobial bio-coatings, a subset of edible coatings, leverage natural compounds such as chitosan, essential oils, and bacteriocins to inhibit microbial growth, effectively extending the shelf life of fresh produce. Unlike traditional wax coatings that primarily reduce moisture loss, these bio-coatings provide active microbial protection while maintaining the fruit's natural appearance and safety for consumption.

Precision layer deposition technology

Precision layer deposition technology enhances the effectiveness of wax coating by applying uniform, controlled layers that improve moisture retention and reduce spoilage in fruits and vegetables. Edible coatings, developed using similar precise deposition methods, offer biodegradable alternatives that not only extend shelf life but also maintain food safety and consumer health standards.

Wax Coating vs Edible Coating for shelf life extension Infographic

agridif.com

agridif.com