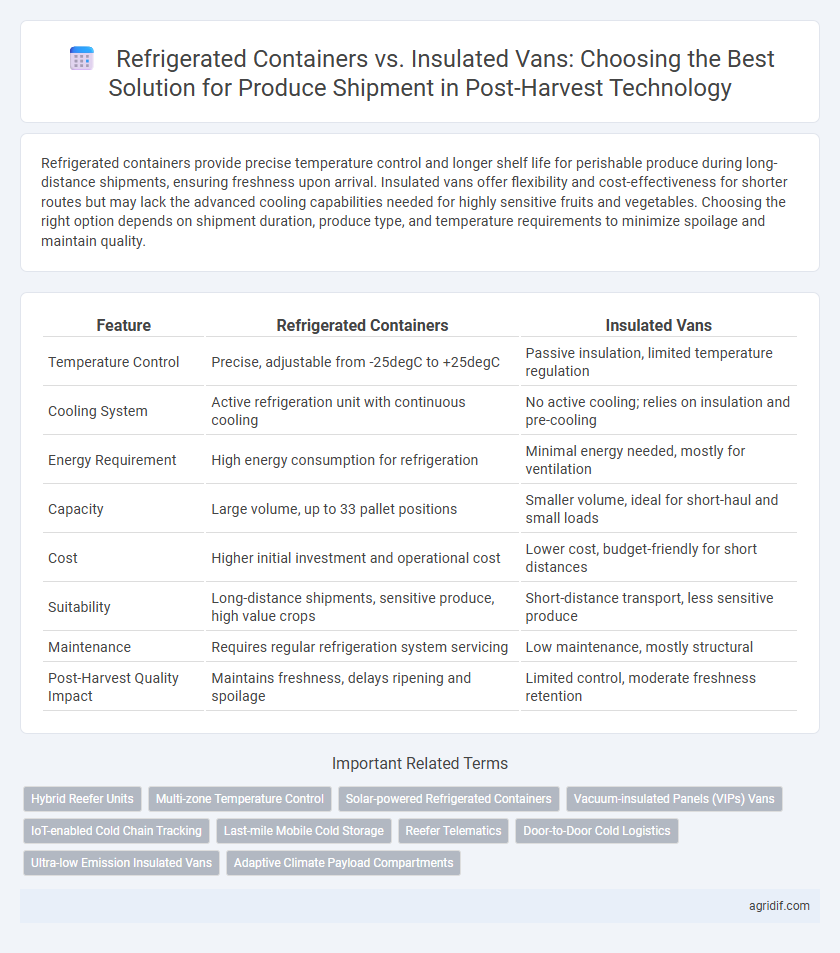

Refrigerated containers provide precise temperature control and longer shelf life for perishable produce during long-distance shipments, ensuring freshness upon arrival. Insulated vans offer flexibility and cost-effectiveness for shorter routes but may lack the advanced cooling capabilities needed for highly sensitive fruits and vegetables. Choosing the right option depends on shipment duration, produce type, and temperature requirements to minimize spoilage and maintain quality.

Table of Comparison

| Feature | Refrigerated Containers | Insulated Vans |

|---|---|---|

| Temperature Control | Precise, adjustable from -25degC to +25degC | Passive insulation, limited temperature regulation |

| Cooling System | Active refrigeration unit with continuous cooling | No active cooling; relies on insulation and pre-cooling |

| Energy Requirement | High energy consumption for refrigeration | Minimal energy needed, mostly for ventilation |

| Capacity | Large volume, up to 33 pallet positions | Smaller volume, ideal for short-haul and small loads |

| Cost | Higher initial investment and operational cost | Lower cost, budget-friendly for short distances |

| Suitability | Long-distance shipments, sensitive produce, high value crops | Short-distance transport, less sensitive produce |

| Maintenance | Requires regular refrigeration system servicing | Low maintenance, mostly structural |

| Post-Harvest Quality Impact | Maintains freshness, delays ripening and spoilage | Limited control, moderate freshness retention |

Introduction to Cold Chain Logistics in Agriculture

Refrigerated containers maintain precise temperature control using mechanical cooling systems, making them ideal for long-distance shipment of perishable produce under strict cold chain requirements. Insulated vans rely primarily on thermal insulation to preserve temperature and are more suitable for short-distance or last-mile distribution where active cooling may not be necessary. Effective cold chain logistics in agriculture optimize these transport options to minimize post-harvest losses and maintain the quality and shelf life of fresh fruits and vegetables.

Overview of Refrigerated Containers for Produce Shipment

Refrigerated containers for produce shipment maintain precise temperature control between -2degC and 8degC, ensuring freshness and extending shelf life during transit. These containers utilize advanced refrigeration systems with humidity regulation to prevent moisture loss and spoilage of fruits and vegetables. Equipped with robust insulation materials, refrigerated containers offer superior thermal performance compared to insulated vans, making them ideal for long-distance and high-volume fresh produce transport.

Insulated Vans: Features and Functionality

Insulated vans for produce shipment maintain moderate temperature control through high-quality thermal insulation materials that reduce heat exchange without active cooling systems. These vans are equipped with robust sealing mechanisms and moisture barriers that help preserve freshness during short to medium-distance transport. Their energy-efficient design lowers operational costs while ensuring produce retains firmness and nutritional value, making them ideal for regional distribution.

Temperature Control: Comparing Refrigeration and Insulation

Refrigerated containers maintain precise temperature control using advanced cooling systems essential for perishable produce requiring consistent low temperatures. Insulated vans rely primarily on thermal insulation to reduce temperature fluctuations but lack active cooling, making them suitable for short-distance transport or less temperature-sensitive goods. The choice between refrigeration and insulation directly impacts produce freshness, shelf life, and quality during transit.

Produce Quality Preservation: Which Option Delivers Better Results?

Refrigerated containers maintain a consistent low temperature and humidity, significantly reducing respiration rates and delaying spoilage, making them ideal for long-distance produce shipment. Insulated vans provide moderate temperature control but are less effective in maintaining optimal conditions throughout transit, often resulting in faster quality degradation. Therefore, refrigerated containers deliver superior produce quality preservation by ensuring stable environmental parameters critical for freshness.

Operational Costs: Refrigerated Containers vs Insulated Vans

Refrigerated containers typically incur higher initial investment and energy costs due to their robust cooling systems and insulation, making them costlier to operate over long durations compared to insulated vans. Insulated vans, while offering lower energy consumption and reduced operational expenses, may require additional cooling solutions to maintain optimal produce freshness during extended shipments. Evaluating factors such as shipment distance, duration, and temperature sensitivity of produce is crucial for optimizing operational costs between these two transportation options.

Suitability for Different Types of Produce

Refrigerated containers maintain precise temperature control, making them ideal for highly perishable produce like berries, leafy greens, and tropical fruits that require consistent low temperatures and humidity levels throughout long-distance transport. Insulated vans provide moderate temperature regulation suitable for less sensitive produce such as root vegetables, citrus fruits, and certain types of melons, benefiting from shorter transport times and cost-effective cooling. Selecting the appropriate cold chain option depends on the perishability, storage requirements, and transit duration of the specific produce to minimize spoilage and maintain quality.

Energy Efficiency and Environmental Impact

Refrigerated containers offer superior energy efficiency due to advanced temperature control systems that minimize energy consumption during produce shipment. Insulated vans rely primarily on passive cooling, resulting in higher energy use from auxiliary refrigeration units and increased carbon emissions. The advanced insulation and precise cooling in refrigerated containers contribute to a reduced environmental impact by lowering greenhouse gas emissions compared to traditional insulated vans.

Flexibility and Accessibility in Post-Harvest Transport

Refrigerated containers offer superior temperature control for perishable produce, ensuring extended shelf life during long-distance transport. Insulated vans provide greater accessibility and flexibility for urban deliveries, allowing faster loading and unloading in tight spaces. Choosing between these options depends on shipment scale, route complexity, and required temperature management in post-harvest logistics.

Making the Right Choice: Key Considerations for Farmers

Farmers should evaluate factors such as shipment distance, produce sensitivity, and cost-effectiveness when choosing between refrigerated containers and insulated vans for post-harvest transport. Refrigerated containers provide precise temperature control ideal for long-distance shipments of highly perishable fruits and vegetables, while insulated vans offer adequate protection and flexibility for shorter routes with less temperature-sensitive produce. Considering energy consumption, maintenance costs, and load volume ensures optimal preservation of quality and minimizes post-harvest losses.

Related Important Terms

Hybrid Reefer Units

Hybrid reefer units combine advanced refrigeration and insulation technologies to optimize temperature control and energy efficiency during produce shipment, outperforming standard refrigerated containers and insulated vans. These units maintain precise humidity and airflow, reducing spoilage and extending shelf life for sensitive fresh produce across long-distance logistics.

Multi-zone Temperature Control

Refrigerated containers offer precise multi-zone temperature control, enabling different compartments to maintain optimal conditions for various produce types during shipment. Insulated vans, while effective for short-distance transport, typically lack advanced multi-zone systems, limiting their ability to preserve diverse temperature-sensitive fruits and vegetables simultaneously.

Solar-powered Refrigerated Containers

Solar-powered refrigerated containers offer a sustainable and efficient solution for transporting perishable produce, maintaining optimal temperature control while reducing carbon emissions compared to traditional insulated vans. These containers leverage renewable energy to extend cold chain integrity over long distances, enhancing produce freshness and minimizing spoilage in post-harvest logistics.

Vacuum-insulated Panels (VIPs) Vans

Vacuum-insulated panels (VIPs) in insulated vans offer superior thermal insulation compared to traditional refrigerated containers, enabling precise temperature control critical for extending the shelf life of perishable produce during shipment. The high thermal resistance of VIPs reduces energy consumption and temperature fluctuations, making them an efficient solution for maintaining produce quality in post-harvest logistics.

IoT-enabled Cold Chain Tracking

IoT-enabled cold chain tracking enhances the efficiency of refrigerated containers by providing real-time temperature and humidity monitoring, ensuring optimal produce freshness during long-distance shipment. Insulated vans, while cost-effective for shorter routes, lack advanced IoT integration, limiting precise environmental control and data-driven decision-making for perishable goods.

Last-mile Mobile Cold Storage

Refrigerated containers provide precise temperature control ideal for long-distance produce shipment, while insulated vans offer flexible, energy-efficient last-mile mobile cold storage essential for maintaining freshness during final delivery stages. Insulated vans reduce temperature fluctuations and extend shelf life by combining advanced insulation materials with portable cooling systems, optimizing perishable goods' quality in urban distribution.

Reefer Telematics

Reefer telematics enhances refrigerated containers by providing real-time monitoring and precise temperature control, crucial for maintaining produce freshness during extended shipments. Insulated vans, while offering passive thermal insulation, lack the advanced data-driven climate management and remote diagnostics capabilities that reefer telematics systems deliver for optimized post-harvest technology.

Door-to-Door Cold Logistics

Refrigerated containers offer precise temperature control and longer cold chain integrity for international produce shipment, minimizing spoilage during extended transit times. Insulated vans provide flexible, shorter-distance door-to-door cold logistics with rapid loading and unloading capabilities, optimizing freshness for regional deliveries.

Ultra-low Emission Insulated Vans

Ultra-low emission insulated vans offer superior temperature control and reduced environmental impact compared to traditional refrigerated containers, enhancing freshness and shelf life of perishable produce during shipment. These vans utilize advanced insulation materials and energy-efficient cooling systems, minimizing carbon footprint while maintaining optimal post-harvest conditions.

Adaptive Climate Payload Compartments

Refrigerated containers utilize advanced adaptive climate payload compartments to precisely control temperature and humidity, ensuring optimal preservation of fresh produce during long-distance shipping. Insulated vans, while effective for shorter routes, typically lack the sophisticated climate control systems required to maintain consistent conditions, making refrigerated containers superior for maintaining produce quality over extended transit times.

Refrigerated Containers vs Insulated Vans for produce shipment Infographic

agridif.com

agridif.com