Bulk storage offers efficient space utilization and easier mechanized handling for cereals, reducing labor costs and minimizing contamination risks. Bag storage provides flexibility in inventory management and protection against pests when properly maintained but demands more manual labor and storage area. Choosing the appropriate method depends on the scale of operations and resource availability to ensure cereal quality and minimize post-harvest losses.

Table of Comparison

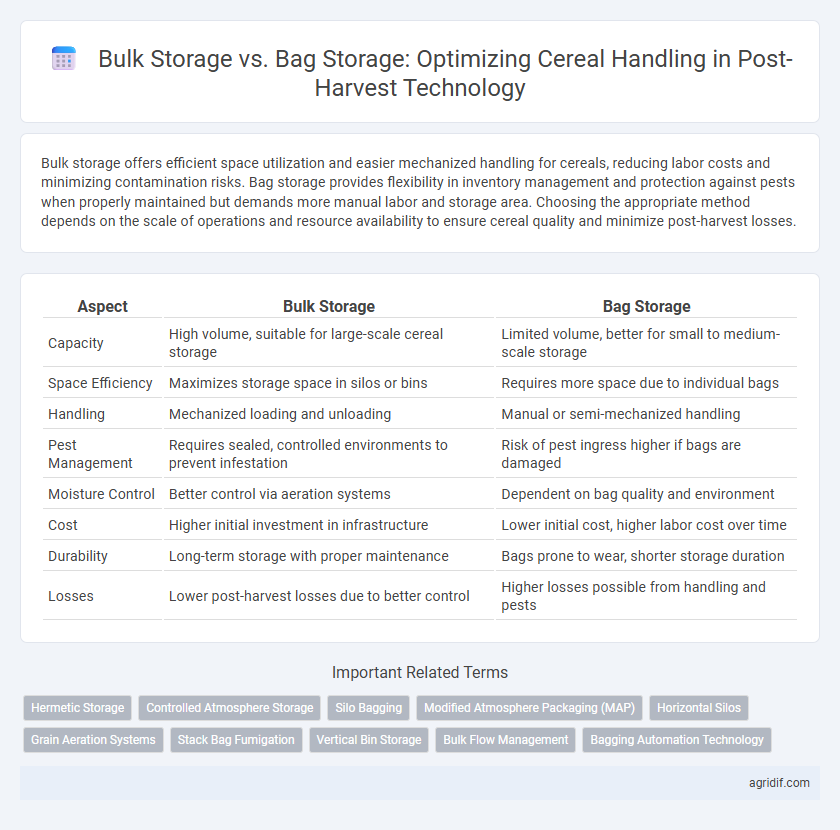

| Aspect | Bulk Storage | Bag Storage |

|---|---|---|

| Capacity | High volume, suitable for large-scale cereal storage | Limited volume, better for small to medium-scale storage |

| Space Efficiency | Maximizes storage space in silos or bins | Requires more space due to individual bags |

| Handling | Mechanized loading and unloading | Manual or semi-mechanized handling |

| Pest Management | Requires sealed, controlled environments to prevent infestation | Risk of pest ingress higher if bags are damaged |

| Moisture Control | Better control via aeration systems | Dependent on bag quality and environment |

| Cost | Higher initial investment in infrastructure | Lower initial cost, higher labor cost over time |

| Durability | Long-term storage with proper maintenance | Bags prone to wear, shorter storage duration |

| Losses | Lower post-harvest losses due to better control | Higher losses possible from handling and pests |

Introduction to Cereal Storage Methods

Cereal storage methods primarily include bulk storage and bag storage, each with distinct advantages and challenges in post-harvest handling. Bulk storage facilitates large-scale, efficient management of cereals using silos and bins that help maintain grain quality by controlling temperature and moisture. Bag storage offers flexibility and ease of transport, allowing farmers to handle smaller quantities but requires careful monitoring to prevent pest infestation and moisture buildup.

Overview of Bulk Storage Systems

Bulk storage systems for cereals offer enhanced capacity and efficiency compared to bag storage, enabling the handling of large quantities with minimal labor. These systems utilize silos, bins, or warehouses designed to maintain optimal temperature and humidity, significantly reducing grain spoilage and pest infestation. Advanced aeration and monitoring technologies in bulk storage ensure better grain quality preservation and streamlined inventory management.

Understanding Bag Storage Techniques

Bag storage techniques for cereals involve stacking and sealing grains in polypropylene or jute bags, providing flexibility and ease of access while minimizing contamination risks. Proper aeration, regular inspection for pests, and maintaining optimal moisture levels around 12-14% are critical to reduce spoilage and fungal growth during storage. Compared to bulk storage, bag storage facilitates efficient handling in small-scale operations but may require more intensive monitoring to prevent insect infestations and grain quality deterioration.

Comparative Analysis: Bulk vs Bag Storage

Bulk storage offers higher capacity and reduced handling costs for cereals compared to bag storage, which requires more labor and is prone to physical damage and pest infestation. Bulk storage systems provide better aeration and moisture control, enhancing grain preservation and minimizing post-harvest losses. On the other hand, bag storage allows easier segregation and mobility but lacks the efficiency and protection offered by modern bulk storage facilities.

Cost Implications of Storage Choices

Bulk storage systems for cereals typically offer lower long-term costs due to reduced labor, minimized packaging expenses, and better space efficiency compared to bag storage. Bag storage incurs higher operational costs from repeated handling, increased risk of grain damage, and the need for continuous purchase of storage bags. Investing in bulk storage infrastructure can significantly enhance cost-effectiveness and grain quality preservation over extended post-harvest periods.

Impact on Grain Quality and Safety

Bulk storage preserves grain quality better by minimizing mechanical damage and reducing pest infestation through controlled aeration and temperature management. Bag storage often leads to higher moisture variability and increased risk of fungal contamination due to inadequate ventilation and physical damage during handling. Implementing bulk storage systems can significantly enhance grain safety and extend shelf life by maintaining optimal storage conditions and reducing post-harvest losses.

Storage Efficiency and Space Utilization

Bulk storage offers superior storage efficiency by minimizing grain handling and reducing post-harvest losses through controlled aeration and moisture monitoring systems, optimizing cereal quality over extended periods. Bag storage enables modular space utilization, allowing flexible stacking and easier inspection, but requires more physical space and labor-intensive management, which can increase overall storage costs. Efficient space utilization in bulk storage leads to higher volume capacity per square meter compared to bag storage, making it ideal for large-scale cereal handling operations.

Pest and Moisture Management in Storage

Bulk storage systems for cereals enable better control of temperature and aeration, reducing moisture accumulation and limiting pest infestations effectively. Bag storage, while flexible and low-cost, often poses higher risks of pest penetration and uneven moisture retention due to limited ventilation. Implementing integrated pest management and moisture monitoring technologies is critical in both methods to preserve grain quality during storage.

Environmental and Labor Considerations

Bulk storage offers superior environmental control by reducing exposure to pests, moisture, and temperature fluctuations, leading to lower grain spoilage rates compared to bag storage. Labor requirements are significantly decreased with bulk storage as automated systems streamline handling processes, whereas bag storage demands intensive manual labor for bag filling, stacking, and transportation. Effective environmental management combined with reduced labor costs makes bulk storage a more sustainable and cost-efficient option for large-scale cereal handling.

Future Trends in Cereal Storage Technologies

Emerging trends in cereal storage technologies emphasize bulk storage systems equipped with advanced aeration, temperature control, and real-time monitoring sensors to reduce post-harvest losses and maintain grain quality. Innovations in intelligent bag storage solutions incorporate antimicrobial coatings and moisture-resistant materials to enhance durability and protect against pest infestations. Integration of IoT-enabled platforms facilitates precise environmental management and predictive analytics, optimizing both bulk and bag storage efficacy for future cereal handling.

Related Important Terms

Hermetic Storage

Hermetic storage in bulk systems offers superior protection against pests and moisture compared to bag storage, significantly reducing grain losses during post-harvest handling. This airtight environment maintains grain quality by limiting oxygen and inhibiting fungal growth, making it a preferred method for long-term cereal preservation.

Controlled Atmosphere Storage

Controlled Atmosphere Storage (CAS) in bulk storage significantly reduces pest infestations and preserves cereal quality by maintaining optimal oxygen, carbon dioxide, and humidity levels, unlike traditional bag storage methods that allow higher exposure to environmental fluctuations and insect contamination. CAS technology enhances shelf life and maintains nutritional content by creating a stable microenvironment, making bulk storage a superior choice for large-scale, long-term cereal preservation.

Silo Bagging

Silo bagging offers a scalable and cost-effective bulk storage solution for cereals, reducing post-harvest losses through controlled aeration and moisture management. Unlike traditional bag storage, silo bags enable large-volume handling with minimized pest infestation and extended grain quality preservation.

Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) enhances cereal preservation by controlling oxygen and moisture levels, reducing spoilage and pest infestation more effectively than traditional bulk or bag storage. This technology significantly extends shelf life and maintains grain quality by creating an optimal controlled environment, surpassing the limitations of conventional storage methods.

Horizontal Silos

Horizontal silos in bulk storage offer superior efficiency for cereal handling by providing uniform ventilation and reducing grain spoilage compared to bag storage, which limits aeration and increases contamination risk. Their design supports large capacity storage with enhanced temperature and moisture control, crucial for maintaining cereal quality post-harvest.

Grain Aeration Systems

Grain aeration systems in bulk storage provide uniform temperature and moisture control, significantly reducing spoilage and insect infestation compared to bag storage, where limited airflow often leads to hot spots and quality deterioration. Efficient aeration in bulk bins enhances grain preservation by promoting consistent air circulation, whereas bag storage lacks this controlled environment, making it less effective for long-term cereal handling.

Stack Bag Fumigation

Stack bag fumigation effectively controls insect infestation during bag storage of cereals by sealing stacked bags in a controlled atmosphere, reducing post-harvest losses and maintaining grain quality. Bulk storage offers higher capacity and automated pest management, but stack bag fumigation provides a cost-efficient, flexible solution for small- to medium-scale farmers emphasizing localized pest control.

Vertical Bin Storage

Vertical bin storage offers superior protection against pest infestation and moisture accumulation compared to traditional bag storage, enhancing grain quality during bulk storage. Its controlled environment minimizes post-harvest losses and reduces labor costs associated with bag handling and transportation in cereal management.

Bulk Flow Management

Bulk storage improves cereal handling efficiency by enabling controlled bulk flow management, which minimizes grain breakage and aeration costs compared to bag storage. This method optimizes air circulation and moisture control, reducing spoilage and maintaining cereal quality throughout extended storage periods.

Bagging Automation Technology

Bagging automation technology in cereal handling enhances efficiency by reducing manual labor, minimizing grain contamination, and improving precision in packaging, leading to better preservation of grain quality. Compared to bulk storage, automated bagging systems enable faster processing and ease of transport while maintaining optimal moisture control and reducing post-harvest losses.

Bulk Storage vs Bag Storage for cereal handling Infographic

agridif.com

agridif.com