Wax coating provides an effective moisture barrier by creating a hydrophobic layer that slows down water loss in post-harvest fruits and vegetables. Edible film coatings offer moisture retention benefits while also being biodegradable and safe for consumption, often incorporating natural polymers like chitosan or alginate. Compared to wax coatings, edible films can enhance shelf life by combining moisture control with antimicrobial properties, making them a sustainable choice for post-harvest technology.

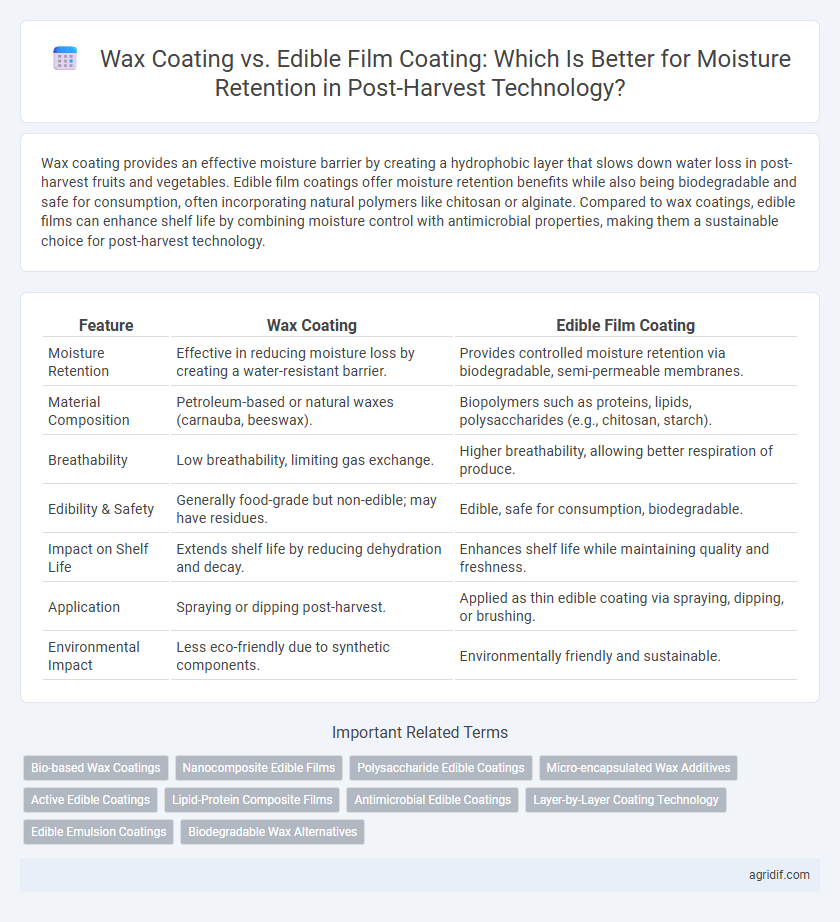

Table of Comparison

| Feature | Wax Coating | Edible Film Coating |

|---|---|---|

| Moisture Retention | Effective in reducing moisture loss by creating a water-resistant barrier. | Provides controlled moisture retention via biodegradable, semi-permeable membranes. |

| Material Composition | Petroleum-based or natural waxes (carnauba, beeswax). | Biopolymers such as proteins, lipids, polysaccharides (e.g., chitosan, starch). |

| Breathability | Low breathability, limiting gas exchange. | Higher breathability, allowing better respiration of produce. |

| Edibility & Safety | Generally food-grade but non-edible; may have residues. | Edible, safe for consumption, biodegradable. |

| Impact on Shelf Life | Extends shelf life by reducing dehydration and decay. | Enhances shelf life while maintaining quality and freshness. |

| Application | Spraying or dipping post-harvest. | Applied as thin edible coating via spraying, dipping, or brushing. |

| Environmental Impact | Less eco-friendly due to synthetic components. | Environmentally friendly and sustainable. |

Introduction to Post-Harvest Moisture Loss

Post-harvest moisture loss significantly impacts the quality and shelf life of fruits and vegetables, with wax coating and edible film coating serving as primary methods to mitigate this issue. Wax coatings act as a moisture barrier by creating a hydrophobic layer on the produce surface, reducing transpiration rates, whereas edible films, often composed of biopolymers like chitosan or cellulose, provide a semi-permeable membrane that controls gas exchange and moisture retention. Comparative studies highlight that edible films offer enhanced biodegradability and consumer safety, while wax coatings tend to provide more robust moisture retention but may involve synthetic components.

Wax Coating: Traditional Approach for Moisture Retention

Wax coating remains a traditional approach in post-harvest technology for moisture retention, forming a hydrophobic barrier that significantly reduces water loss in fruits such as apples, citrus, and mangoes. This method helps maintain firmness and extend shelf life by minimizing respiration and transpiration rates. Compared to edible film coatings, wax coatings provide a more durable, long-lasting protection, though they may lack the nutrient-enriching properties offered by some modern edible films.

Edible Film Coating: Innovative Solutions in Post-Harvest Preservation

Edible film coatings offer advanced moisture retention by forming a semi-permeable barrier that regulates gas exchange and reduces water loss in fresh produce. Unlike traditional wax coatings, edible films utilize biopolymers such as cellulose, chitosan, and alginate, enhancing freshness while being safe for consumption. These innovative coatings extend shelf life, maintain nutritional quality, and provide eco-friendly alternatives in post-harvest preservation.

Comparative Analysis: Moisture Barrier Properties

Wax coating provides a robust moisture barrier by forming a hydrophobic layer that significantly reduces water loss from fresh produce, thereby extending shelf life. In contrast, edible film coatings, typically composed of polysaccharides, proteins, or lipids, offer moderate moisture retention with the added benefit of being biodegradable and safe for consumption. Comparative studies reveal wax coatings excel in moisture barrier efficacy, while edible films optimize breathability and maintain sensory qualities, making the choice context-dependent based on preservation goals and consumer preferences.

Impact on Shelf Life and Quality of Produce

Wax coating and edible film coating both enhance moisture retention in post-harvest produce, but edible films generally provide superior gas exchange control, reducing respiration rates and delaying senescence. Wax coatings primarily create a hydrophobic barrier, limiting water loss but potentially restricting oxygen diffusion, which can lead to anaerobic conditions and quality degradation. Edible films composed of polysaccharides, proteins, or lipids offer customizable permeability, better maintaining firmness, color, and nutritional value, thereby significantly extending shelf life.

Food Safety and Regulatory Considerations

Wax coating provides a durable barrier against moisture loss in post-harvest produce, but it often raises concerns due to potential residue and limited biodegradability. Edible film coatings, derived from natural biopolymers such as chitosan and alginate, enhance moisture retention while ensuring food safety through biodegradability and non-toxicity. Regulatory frameworks by agencies like the FDA and EFSA emphasize stringent approval processes for edible coatings, prioritizing ingredient safety and labeling transparency to protect consumer health.

Consumer Acceptance and Market Trends

Wax coating enhances moisture retention by creating a durable barrier on fruits and vegetables, leading to widespread consumer acceptance due to its established use and familiarity. Edible film coatings, made from natural polymers like chitosan and alginate, are gaining market traction as innovative, eco-friendly alternatives valued for their biodegradability and minimal impact on taste. Current trends show increasing consumer preference for edible coatings driven by demand for clean-label, sustainable produce preservation methods.

Environmental Sustainability: Wax vs Edible Films

Edible film coatings outperform traditional wax coatings in environmental sustainability by being biodegradable and reducing plastic waste in post-harvest technology. Wax coatings, often petroleum-based, pose disposal challenges and contribute to environmental pollution due to their non-biodegradable nature. The use of edible films derived from natural polymers like chitosan, cellulose, and starch supports eco-friendly moisture retention, enhancing shelf life while minimizing ecological impact.

Cost-Effectiveness in Commercial Applications

Wax coating offers a cost-effective solution for moisture retention in post-harvest fruit preservation due to its low material cost and ease of application in large volumes. Edible film coatings, although often more expensive, provide enhanced barrier properties and can incorporate functional additives, potentially reducing spoilage-related losses in high-value commercial markets. Choosing wax coatings typically benefits large-scale operations prioritizing budget efficiency, while edible films serve premium segments focused on product quality and extended shelf life.

Future Prospects in Coating Technologies for Agriculture

Wax coating and edible film coating each offer distinct advantages for moisture retention in post-harvest technology, with wax coatings providing a hydrophobic barrier that reduces water loss, while edible films offer biocompatible, breathable layers that maintain produce freshness. Future advancements focus on nano-engineered materials and biodegradable composites to enhance retention efficiency and environmental sustainability. Integration of smart coatings with sensors for real-time monitoring is anticipated to revolutionize moisture management and extend shelf life in agricultural supply chains.

Related Important Terms

Bio-based Wax Coatings

Bio-based wax coatings, derived from natural materials like carnauba and beeswax, offer superior moisture retention compared to traditional edible film coatings by creating a hydrophobic barrier that minimizes water loss. These coatings enhance shelf life and maintain fruit firmness while being environmentally friendly and biodegradable, making them a preferred option in sustainable post-harvest technology.

Nanocomposite Edible Films

Nanocomposite edible films enhance moisture retention by incorporating nanoparticles that improve barrier properties compared to traditional wax coatings, resulting in extended shelf life and reduced water loss in post-harvest fruits and vegetables. These films form a semi-permeable layer that regulates gas exchange and maintains optimal humidity, outperforming conventional wax coatings in preserving freshness and quality.

Polysaccharide Edible Coatings

Polysaccharide edible coatings, derived from starch, cellulose, and alginate, enhance moisture retention by forming semi-permeable barriers that regulate water vapor exchange in post-harvest fruits and vegetables. Compared to traditional wax coatings, these biodegradable films improve gas permeability, reduce weight loss, and maintain produce freshness while offering a sustainable alternative in post-harvest technology.

Micro-encapsulated Wax Additives

Micro-encapsulated wax additives in wax coatings enhance moisture retention by creating a controlled barrier that minimizes transpiration and water loss from harvested produce. Compared to edible film coatings, these micro-encapsulated waxes offer prolonged protection and improved durability, optimizing shelf life and maintaining post-harvest quality.

Active Edible Coatings

Active edible coatings enhance moisture retention in post-harvest technology by forming a semi-permeable barrier that regulates gas exchange and reduces water loss, outperforming traditional wax coatings in maintaining fruit and vegetable freshness. These bio-based films can be infused with antimicrobial and antioxidant agents, extending shelf life while preserving quality without compromising edibility.

Lipid-Protein Composite Films

Lipid-protein composite films outperform traditional wax coatings in moisture retention by creating a semi-permeable barrier that reduces water vapor transmission while maintaining product breathability and texture. These edible films enhance post-harvest shelf life by integrating hydrophobic lipids and hydrophilic proteins, optimizing moisture regulation without compromising fruit quality.

Antimicrobial Edible Coatings

Antimicrobial edible coatings enhance moisture retention by forming a semi-permeable barrier that reduces water loss while inhibiting microbial growth on fresh produce, unlike traditional wax coatings that primarily focus on moisture barrier properties without antimicrobial benefits. These bio-based films incorporate natural antimicrobial agents such as chitosan, essential oils, or plant extracts, improving shelf life and maintaining fruit quality through targeted inhibition of spoilage organisms.

Layer-by-Layer Coating Technology

Layer-by-layer coating technology enhances moisture retention in post-harvest products by sequentially applying wax and edible film coatings, combining the hydrophobic barrier of wax with the breathable, biodegradable properties of edible films. This synergistic approach optimizes moisture control, reduces transpiration rates, and extends shelf life more effectively than single-layer coatings.

Edible Emulsion Coatings

Edible emulsion coatings outperform wax coatings in moisture retention by forming a semi-permeable barrier that reduces water loss while maintaining gas exchange, crucial for extending the shelf life of fresh produce. These coatings, composed of natural polymers like proteins and lipids, provide superior biodegradability and consumer safety compared to conventional wax coatings.

Biodegradable Wax Alternatives

Biodegradable wax alternatives, such as carnauba and beeswax-based coatings, offer superior moisture retention compared to traditional edible film coatings by forming a hydrophobic barrier that reduces water loss in post-harvest fruits and vegetables. These environmentally friendly waxes enhance shelf life while minimizing plastic waste, aligning with sustainable agriculture and food packaging practices.

Wax Coating vs Edible Film Coating for moisture retention Infographic

agridif.com

agridif.com