Roller conveying offers superior durability and minimal maintenance for packhouse handling, making it ideal for transporting heavy or bulky produce with consistent spacing and alignment. Belt conveying provides gentle handling with smooth, continuous motion, reducing damage to delicate fruits and vegetables during post-harvest processing. Selecting between roller and belt conveying depends on product type, desired speed, and handling sensitivity in the post-harvest technology environment.

Table of Comparison

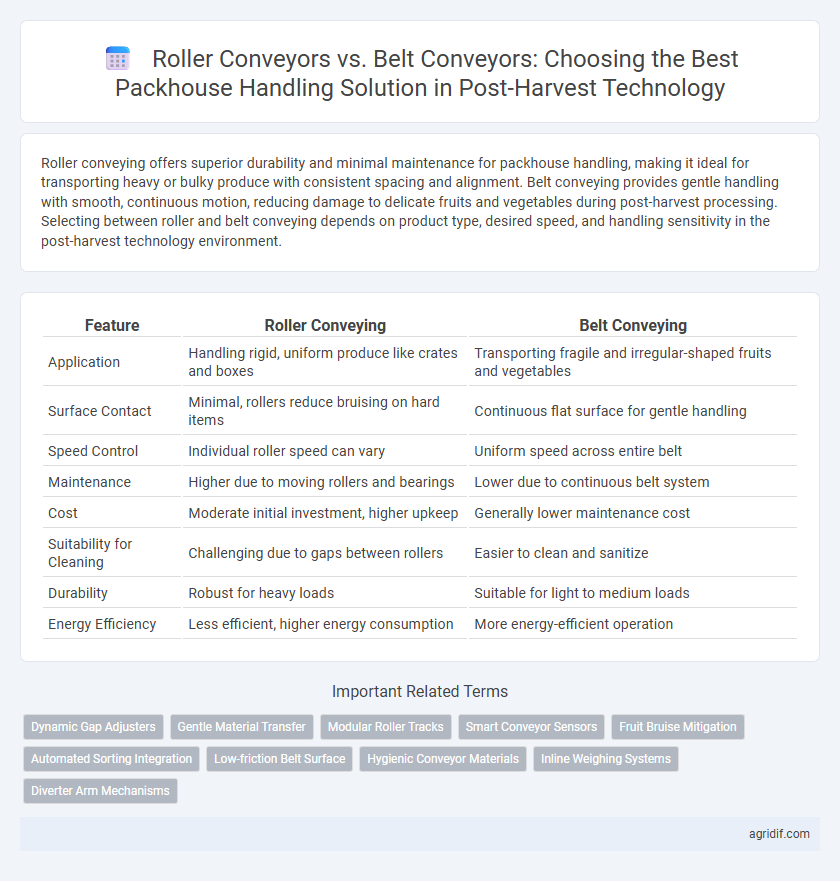

| Feature | Roller Conveying | Belt Conveying |

|---|---|---|

| Application | Handling rigid, uniform produce like crates and boxes | Transporting fragile and irregular-shaped fruits and vegetables |

| Surface Contact | Minimal, rollers reduce bruising on hard items | Continuous flat surface for gentle handling |

| Speed Control | Individual roller speed can vary | Uniform speed across entire belt |

| Maintenance | Higher due to moving rollers and bearings | Lower due to continuous belt system |

| Cost | Moderate initial investment, higher upkeep | Generally lower maintenance cost |

| Suitability for Cleaning | Challenging due to gaps between rollers | Easier to clean and sanitize |

| Durability | Robust for heavy loads | Suitable for light to medium loads |

| Energy Efficiency | Less efficient, higher energy consumption | More energy-efficient operation |

Introduction to Packhouse Conveying Systems

Roller conveying systems in packhouses offer efficient handling of produce with low friction and minimal damage, making them ideal for heavier or irregularly shaped items. Belt conveying systems provide continuous, smooth transport suitable for delicate fruits and vegetables, ensuring gentle handling and reduced spoilage. Selecting the appropriate system depends on product type, throughput requirements, and the packhouse's operational design.

Overview of Roller Conveying Technology

Roller conveying technology in packhouse handling uses cylindrical rollers to transport harvested crops efficiently, minimizing damage and allowing easy sorting and inspection. This system excels in handling heavy loads with low friction, reducing energy consumption compared to belt conveying. Its modular design enables flexible configurations suited for various packhouse layouts and post-harvest processing requirements.

Understanding Belt Conveying Solutions

Belt conveying solutions in post-harvest packhouse handling offer smooth, continuous transport of fruits and vegetables, minimizing product damage through gentle movement and consistent speed control. These systems provide superior flexibility for handling different produce sizes and shapes compared to roller conveying, reducing bruising and increasing packing efficiency. Optimized belt materials with food-grade properties ensure hygiene compliance and ease of cleaning, enhancing overall post-harvest quality preservation.

Key Performance Metrics: Roller vs Belt Conveyors

Roller conveyors provide higher load capacity and durability, making them ideal for handling heavy or irregularly shaped agricultural produce in packhouse operations. Belt conveyors offer smoother, continuous transport with minimal product damage, enhancing efficiency for delicate items like fruits and vegetables. Key performance metrics indicate roller conveyors excel in throughput speed and maintenance costs, while belt conveyors outperform in product safety and noise reduction.

Material Compatibility with Roller and Belt Conveyors

Roller conveyors excel in handling rigid, uniform packages and crates commonly used in packhouses, ensuring stable transport with minimal slippage due to their spaced rollers and solid support. Belt conveyors provide versatility for a wide range of product shapes and sizes, including loose or irregular agricultural produce, by offering a continuous, smooth surface that prevents small or soft items from falling through. Material compatibility with roller conveyors is optimized for sturdy, flat-bottomed loads, whereas belt conveyors accommodate delicate or inconsistent materials better, reducing damage during post-harvest handling.

Space and Layout Considerations in Packhouses

Roller conveying systems offer a compact footprint ideal for tight packhouse layouts, maximizing floor space utilization and enabling flexible product handling paths. In contrast, belt conveyors typically require more linear space due to their continuous surface and support structures, potentially limiting design options in constrained environments. Selecting roller conveyors can enhance spatial efficiency by facilitating modular installation and easier integration with existing packhouse equipment.

Maintenance and Operational Costs Analysis

Roller conveying systems in packhouse operations typically demand higher maintenance due to frequent roller replacements and lubrication requirements, leading to increased operational costs over time. In contrast, belt conveyors offer lower maintenance needs with fewer moving parts but may incur higher initial investment and occasional belt replacements. Cost analysis reveals that belt conveyors often prove more economical in long-term post-harvest handling scenarios, balancing durable performance with reduced downtime.

Impact on Product Quality and Damage Reduction

Roller conveying in packhouse handling offers precise control and reduced contact points, minimizing bruising and surface damage to delicate fruits and vegetables. Belt conveying provides continuous, smooth movement but can increase the risk of product slippage and crushing if not properly tensioned or cushioned. Choosing roller conveying systems can significantly enhance product quality by lowering mechanical impact and preserving the integrity of perishable commodities during post-harvest operations.

Energy Efficiency: Roller Conveyors vs Belt Conveyors

Roller conveyors typically consume less energy than belt conveyors due to their reduced friction and lower resistance during operation, making them more energy-efficient for packhouse handling in post-harvest technology. Belt conveyors require continuous motor power to drive the belt surface, often resulting in higher electricity consumption compared to the mechanical movement facilitated by rollers. Selecting roller conveyors can significantly decrease energy costs and improve sustainability in post-harvest handling processes.

Choosing the Right Conveyor System for Your Packhouse

Roller conveying systems offer precise control and durability for handling heavy or rigid produce, optimizing efficiency in packhouse operations with minimal maintenance requirements. Belt conveying provides a gentle, continuous surface ideal for delicate fruits and vegetables, reducing damage and ensuring smooth transportation through sorting and packing stages. Selecting the right conveyor system depends on the type of produce, operational throughput, and maintenance capacity, balancing cost-effectiveness with product integrity in post-harvest handling.

Related Important Terms

Dynamic Gap Adjusters

Dynamic gap adjusters in roller conveying systems optimize the spacing between rollers to accommodate varying pack sizes and reduce product damage during post-harvest handling. Belt conveying, while effective for continuous transport, lacks this adaptive feature, making roller conveyors with dynamic gap adjusters more suitable for delicate or irregularly shaped produce in packhouse operations.

Gentle Material Transfer

Roller conveying provides gentle material transfer by minimizing friction and impact during packhouse handling, reducing damage to delicate produce compared to belt conveying. The controlled movement and precise spacing of rollers enable smooth handling while maintaining the quality and integrity of agricultural products.

Modular Roller Tracks

Modular roller tracks in packhouse handling offer enhanced flexibility and durability compared to belt conveying systems, facilitating efficient post-harvest product movement with reduced maintenance and energy consumption. These roller conveyors excel in handling varying load sizes and improve operational throughput by enabling easy customization and quick track modifications.

Smart Conveyor Sensors

Smart conveyor sensors integrated into roller conveying systems enable precise monitoring of package alignment, speed, and weight, enhancing operational efficiency and reducing product damage during packhouse handling. Belt conveying systems equipped with advanced sensor technology offer continuous tracking and real-time data analytics, optimizing flow control and minimizing downtime in post-harvest processing lines.

Fruit Bruise Mitigation

Roller conveying systems reduce fruit bruising during packhouse handling by minimizing pressure points through gentle, spaced support, whereas belt conveyors risk higher impact damage due to continuous, friction-based movement. Optimizing roller spacing and speed effectively mitigates mechanical stress, preserving fruit integrity and quality post-harvest.

Automated Sorting Integration

Roller conveying systems offer precise control and easy integration with automated sorting technologies, enhancing efficiency in packhouse handling by enabling rapid and accurate item orientation and segregation. In contrast, belt conveying provides continuous flow but may require additional sensors and actuators for sorting, making roller conveyors preferable for seamless, high-speed automated sorting integration.

Low-friction Belt Surface

Roller conveying systems offer efficient bulk handling but often cause higher friction and potential damage to delicate produce compared to low-friction belt surfaces that minimize abrasion and maintain product quality in packhouse operations. Low-friction belt conveying enhances gentle handling by reducing mechanical stress and energy consumption, optimizing post-harvest technology workflows.

Hygienic Conveyor Materials

Roller conveying systems in packhouse handling often utilize stainless steel rollers that resist corrosion and facilitate easy cleaning, enhancing hygiene standards compared to traditional belt conveyors. Belt conveying systems typically employ food-grade polyurethane or PVC belts designed for antimicrobial properties and easy sanitation, reducing contamination risks in post-harvest processing environments.

Inline Weighing Systems

Roller conveying systems in packhouse handling offer precise control and smooth movement ideal for integrating inline weighing systems, minimizing product slippage and ensuring consistent weight measurements. Belt conveying, while versatile and suitable for uneven surfaces, can introduce vibrations and speed variations that may affect the accuracy of inline weighing in post-harvest technology operations.

Diverter Arm Mechanisms

Roller conveying systems in packhouse handling offer precise control with diverter arm mechanisms that enable smooth and accurate redirection of produce, reducing damage during sorting. Belt conveying systems rely on diverter arms that gently guide items without abrupt stops, enhancing throughput efficiency while maintaining product integrity in post-harvest operations.

Roller Conveying vs Belt Conveying for packhouse handling Infographic

agridif.com

agridif.com