Gamma irradiation effectively reduces microbial load on post-harvest products by penetrating deep into tissues, ensuring thorough sterilization without compromising quality. UV-C treatment targets surface microorganisms on fruits and vegetables by damaging their DNA, offering a non-chemical and residue-free disinfection method. Both techniques enhance shelf life and safety, with gamma irradiation providing deeper microbial control, while UV-C serves as an eco-friendly and energy-efficient alternative for surface decontamination.

Table of Comparison

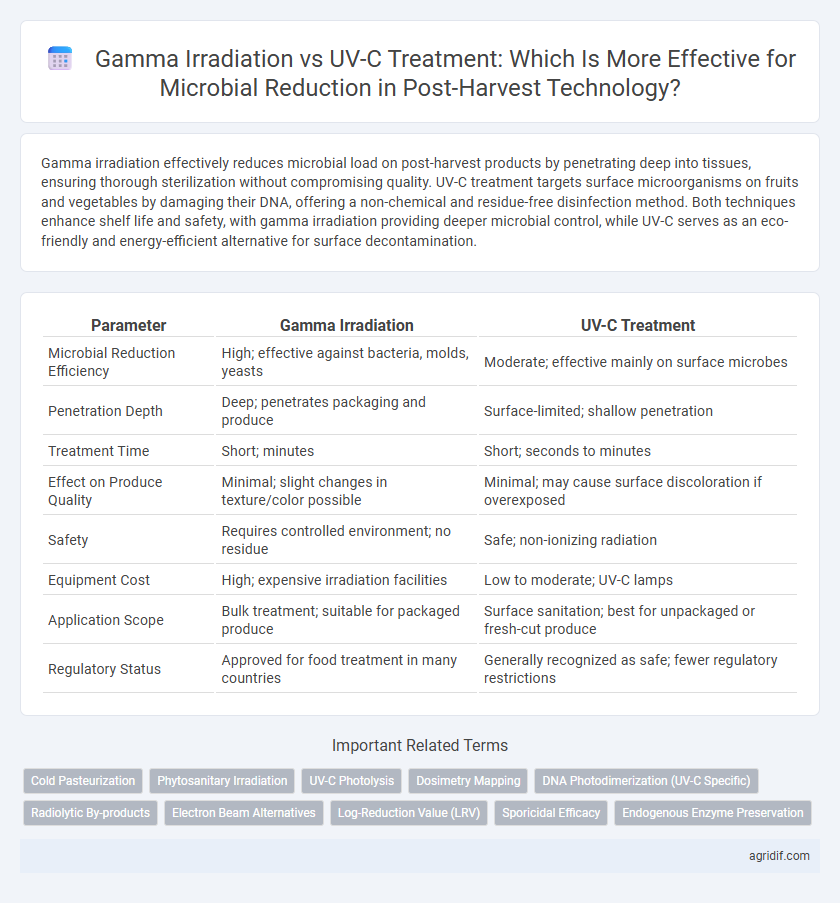

| Parameter | Gamma Irradiation | UV-C Treatment |

|---|---|---|

| Microbial Reduction Efficiency | High; effective against bacteria, molds, yeasts | Moderate; effective mainly on surface microbes |

| Penetration Depth | Deep; penetrates packaging and produce | Surface-limited; shallow penetration |

| Treatment Time | Short; minutes | Short; seconds to minutes |

| Effect on Produce Quality | Minimal; slight changes in texture/color possible | Minimal; may cause surface discoloration if overexposed |

| Safety | Requires controlled environment; no residue | Safe; non-ionizing radiation |

| Equipment Cost | High; expensive irradiation facilities | Low to moderate; UV-C lamps |

| Application Scope | Bulk treatment; suitable for packaged produce | Surface sanitation; best for unpackaged or fresh-cut produce |

| Regulatory Status | Approved for food treatment in many countries | Generally recognized as safe; fewer regulatory restrictions |

Introduction to Post-Harvest Microbial Risks

Post-harvest microbial risks primarily involve the contamination of fruits and vegetables by bacteria, fungi, and molds, leading to spoilage and reduced shelf life. Gamma irradiation and UV-C treatment serve as effective non-chemical interventions to reduce microbial load on produce surfaces, targeting pathogens such as Escherichia coli, Salmonella spp., and Penicillium spp. These technologies enhance food safety and extend post-harvest storage by disrupting microbial DNA and inhibiting cellular functions.

Overview of Gamma Irradiation in Agriculture

Gamma irradiation in agriculture serves as an effective post-harvest technology to reduce microbial contamination on fresh produce by disrupting the DNA of bacteria, molds, and fungi, thereby extending shelf life and enhancing food safety. This method employs high-energy photons emitted from cobalt-60 or cesium-137 sources to penetrate deeply into agricultural products, ensuring comprehensive microbial inactivation without compromising nutritional quality. Its adoption is supported by international regulatory agencies for controlling spoilage and pathogenic microorganisms while maintaining the sensory and physicochemical properties of fruits and vegetables.

Fundamentals of UV-C Treatment for Crop Safety

UV-C treatment utilizes wavelengths between 200-280 nm to disrupt microbial DNA, effectively reducing pathogens on harvested crops without chemical residues. This non-thermal technology enhances crop safety by damaging the nucleic acids of bacteria, fungi, and viruses, thereby preventing their replication and spoilage. Compared to gamma irradiation, UV-C offers a targeted surface sterilization approach that maintains produce quality while extending shelf life.

Mechanisms of Microbial Inactivation: Gamma vs UV-C

Gamma irradiation in post-harvest technology employs high-energy photons to penetrate microbial cells, causing ionization that damages DNA and cellular structures, leading to microbial inactivation. UV-C treatment uses ultraviolet light at 254 nm to induce the formation of thymine dimers in microbial DNA, disrupting replication and transcription processes. While gamma irradiation offers deeper penetration and broad-spectrum antimicrobial effects, UV-C primarily affects surface microorganisms due to limited penetration depth.

Comparative Efficacy on Pathogen Reduction

Gamma irradiation demonstrates superior microbial reduction in post-harvest treatments by penetrating deeply and effectively eliminating pathogens such as E. coli and Salmonella on produce surfaces and internal tissues. UV-C treatment primarily targets surface pathogens with limited penetration, resulting in less comprehensive microbial control but reduced risk of quality degradation. Comparative studies reveal gamma irradiation achieves higher log reductions in microbial populations, making it more efficacious for pathogen mitigation in post-harvest technology applications.

Effects on Nutritional and Sensory Quality

Gamma irradiation effectively reduces microbial load in post-harvest produce while preserving essential nutrients such as vitamins C and E with minimal degradation. UV-C treatment also achieves microbial reduction but may cause slight changes in surface texture and color, potentially affecting sensory quality. Both treatments maintain overall nutritional integrity, though UV-C is often preferred for its lower impact on sensory attributes in fresh fruits and vegetables.

Safety Regulations and Consumer Acceptance

Gamma irradiation effectively reduces microbial load on post-harvest produce while complying with strict safety regulations set by agencies like the FDA and WHO, ensuring minimal residue and no significant nutritional loss. UV-C treatment offers a chemical-free alternative, gaining consumer acceptance due to its non-ionizing nature and visible safety profile, although regulatory guidelines remain less standardized compared to gamma irradiation. Both technologies require continuous validation to meet global food safety standards and address consumer concerns regarding health impacts and environmental sustainability.

Practical Considerations: Cost, Scalability, and Accessibility

Gamma irradiation offers deep penetration and effective microbial reduction but involves high operational costs and requires specialized facilities, limiting its scalability and accessibility for small-scale producers. UV-C treatment is more cost-effective and easier to implement on-site, making it scalable for various production sizes, though it provides limited penetration and may be less effective on irregular surfaces. Practical implementation decisions should weigh equipment investment, treatment throughput, and regulatory compliance to optimize post-harvest microbial control.

Environmental Impact of Both Technologies

Gamma irradiation offers deep penetration for effective microbial reduction but generates radioactive waste requiring strict disposal protocols, posing significant environmental challenges. UV-C treatment, while less penetrating, minimizes chemical residues and avoids radioactive byproducts, resulting in a lower environmental footprint. However, UV-C's limited efficacy on shaded surfaces may necessitate repeated applications, potentially increasing energy consumption.

Future Trends in Post-Harvest Microbial Control

Gamma irradiation and UV-C treatment are emerging as pivotal technologies in post-harvest microbial control, offering significant reductions in pathogenic and spoilage microorganisms on fresh produce. Advances in dosage optimization and combined treatment approaches are driving enhanced efficacy, with ongoing research aiming to minimize quality degradation while maximizing microbial safety. Future trends emphasize integration with smart packaging and sensor technologies to enable real-time monitoring and precise application, ultimately improving shelf life and reducing post-harvest losses.

Related Important Terms

Cold Pasteurization

Gamma irradiation offers deep penetration and effective microbial inactivation in cold pasteurization of fresh produce, significantly reducing spoilage without compromising nutritional quality. UV-C treatment provides surface-level microbial reduction, ideal for delicate fruits and vegetables, but its limited penetration may require combination with other methods for comprehensive cold pasteurization.

Phytosanitary Irradiation

Gamma irradiation offers deep microbial reduction through ionizing radiation, effectively penetrating dense produce for comprehensive phytosanitary treatment, while UV-C treatment provides surface-level microbial inactivation via ultraviolet light but has limited penetration abilities. Phytosanitary irradiation using gamma rays is widely recognized for its efficacy in controlling quarantine pests and pathogens in exported fruits and vegetables, ensuring compliance with international trade standards.

UV-C Photolysis

UV-C photolysis effectively disrupts microbial DNA, achieving significant microbial reduction on post-harvest produce surfaces without chemical residues. Compared to gamma irradiation, UV-C treatment offers a rapid, energy-efficient alternative with minimal impact on fruit quality and a lower risk of generating harmful byproducts.

Dosimetry Mapping

Dosimetry mapping in Gamma Irradiation ensures precise dose distribution for effective microbial reduction, crucial for optimizing product safety in post-harvest technology. UV-C treatment requires detailed mapping of light intensity and exposure time to achieve uniform microbial inactivation on produce surfaces.

DNA Photodimerization (UV-C Specific)

Gamma irradiation effectively reduces microbial load by causing DNA strand breaks and oxidative damage, leading to cell death, while UV-C treatment specifically induces DNA photodimerization, forming cyclobutane pyrimidine dimers and pyrimidine-pyrimidone (6-4) photoproducts that inhibit microbial replication. The targeted DNA damage through UV-C photodimerization disrupts microbial genome integrity, offering a precise mode of action compared to the broader ionizing effects of gamma irradiation.

Radiolytic By-products

Gamma irradiation effectively reduces microbial load on post-harvest products but often generates radiolytic by-products that may affect food safety and quality. UV-C treatment offers microbial reduction with minimal formation of harmful by-products, making it a safer alternative for maintaining post-harvest produce integrity.

Electron Beam Alternatives

Gamma irradiation and UV-C treatment are effective post-harvest technologies for microbial reduction, with electron beam (e-beam) irradiation emerging as a powerful alternative offering rapid, chemical-free decontamination and minimal impact on product quality. Electron beam technology utilizes high-energy electrons to disrupt microbial DNA, providing precise dose control and shorter processing times compared to conventional gamma irradiation, while avoiding UV-C's limited penetration and surface-only treatment capabilities.

Log-Reduction Value (LRV)

Gamma irradiation achieves higher microbial log-reduction values (LRV), often exceeding 5 logs, compared to UV-C treatment, which typically produces LRVs between 1 to 3 logs. The superior penetration ability of gamma rays ensures more effective inactivation of pathogens on various post-harvest products, enhancing shelf life and safety.

Sporicidal Efficacy

Gamma irradiation demonstrates superior sporicidal efficacy compared to UV-C treatment by penetrating deeper into produce tissues and effectively inactivating resilient spore-forming microorganisms. UV-C treatment, while effective on surface microbes, shows limited penetration and lower sporicidal performance, making gamma irradiation more reliable for comprehensive microbial reduction in post-harvest technology.

Endogenous Enzyme Preservation

Gamma irradiation effectively reduces microbial load while causing minimal damage to endogenous enzymes due to its deep penetration and low heat generation, preserving the nutritional and sensory quality of post-harvest produce. In contrast, UV-C treatment primarily targets surface microorganisms but may induce higher oxidative stress, potentially compromising enzyme activity and accelerating post-harvest senescence.

Gamma Irradiation vs UV-C Treatment for microbial reduction Infographic

agridif.com

agridif.com