Vacuum packing removes air to create an oxygen-free environment that significantly slows down oxidation and microbial growth, thereby extending the shelf life of pulses. Nitrogen flushing replaces oxygen with nitrogen gas, reducing oxidation and insect infestation while maintaining the natural appearance and texture of pulses. Both techniques enhance pulse preservation, but vacuum packing offers superior protection against aerobic spoilage organisms, whereas nitrogen flushing is effective in maintaining product quality during storage.

Table of Comparison

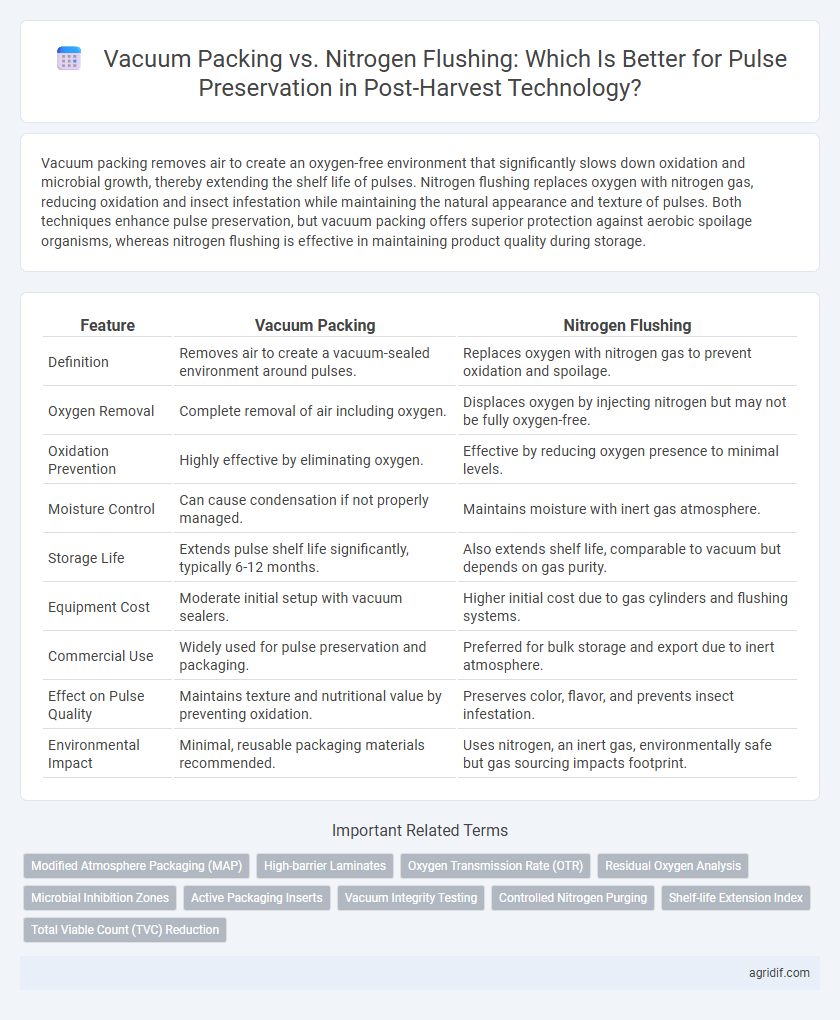

| Feature | Vacuum Packing | Nitrogen Flushing |

|---|---|---|

| Definition | Removes air to create a vacuum-sealed environment around pulses. | Replaces oxygen with nitrogen gas to prevent oxidation and spoilage. |

| Oxygen Removal | Complete removal of air including oxygen. | Displaces oxygen by injecting nitrogen but may not be fully oxygen-free. |

| Oxidation Prevention | Highly effective by eliminating oxygen. | Effective by reducing oxygen presence to minimal levels. |

| Moisture Control | Can cause condensation if not properly managed. | Maintains moisture with inert gas atmosphere. |

| Storage Life | Extends pulse shelf life significantly, typically 6-12 months. | Also extends shelf life, comparable to vacuum but depends on gas purity. |

| Equipment Cost | Moderate initial setup with vacuum sealers. | Higher initial cost due to gas cylinders and flushing systems. |

| Commercial Use | Widely used for pulse preservation and packaging. | Preferred for bulk storage and export due to inert atmosphere. |

| Effect on Pulse Quality | Maintains texture and nutritional value by preventing oxidation. | Preserves color, flavor, and prevents insect infestation. |

| Environmental Impact | Minimal, reusable packaging materials recommended. | Uses nitrogen, an inert gas, environmentally safe but gas sourcing impacts footprint. |

Introduction to Post-Harvest Preservation in Pulses

Post-harvest preservation of pulses is critical for maintaining quality, nutritional value, and shelf life. Vacuum packing removes air to reduce oxidation and microbial growth, while nitrogen flushing replaces oxygen with inert nitrogen gas to inhibit spoilage. Both technologies effectively minimize moisture loss and prevent insect infestation, enhancing pulse storage and marketability.

Understanding Vacuum Packing Technology

Vacuum packing technology preserves pulses by removing oxygen from the packaging environment, significantly reducing oxidative degradation and microbial growth. This method extends shelf life by maintaining product freshness, texture, and nutritional quality without the use of chemical preservatives. Compared to nitrogen flushing, vacuum packing creates a tight seal that minimizes oxygen exposure more effectively, enhancing pulse preservation during storage and transportation.

Exploring Nitrogen Flushing Methods

Nitrogen flushing extends pulse shelf life by replacing oxygen with inert nitrogen gas, significantly reducing oxidation and microbial growth compared to vacuum packing, which primarily removes air but may cause seed deformation. Advanced nitrogen flushing methods utilize controlled atmosphere packaging that maintains optimal oxygen and nitrogen levels, preserving the nutritional quality and texture of pulses. Studies show nitrogen flushing outperforms vacuum packing in retaining protein content and preventing rancidity during storage.

Mechanisms of Pulse Deterioration Post-Harvest

Vacuum packing preserves pulses by removing oxygen, thus inhibiting aerobic microbial growth and oxidative enzymatic reactions responsible for seed deterioration. Nitrogen flushing replaces oxygen with inert nitrogen gas, reducing oxidative stress and slowing enzymatic activity that degrades pulse quality. Both techniques effectively delay rancidity, moisture loss, and nutrient degradation by minimizing oxygen-induced damage in post-harvest pulse storage.

Comparative Analysis: Vacuum Packing vs. Nitrogen Flushing

Vacuum packing reduces oxygen levels by removing air, limiting microbial growth and oxidation in pulses, thereby extending shelf life and preserving nutritional quality. Nitrogen flushing replaces oxygen with inert nitrogen gas, preventing oxidative spoilage and maintaining color and aroma without compressing the product. Comparative analysis indicates vacuum packing offers better protection against aerobic microbes, while nitrogen flushing is more effective in preserving seed structure and preventing physical damage during storage.

Impact on Shelf Life and Quality of Pulses

Vacuum packing significantly extends the shelf life of pulses by removing oxygen, which slows down oxidation and microbial growth, thus maintaining quality. Nitrogen flushing replaces oxygen with inert nitrogen gas, effectively reducing oxidation and preserving the color, texture, and nutritional value of pulses. Both methods enhance storage stability, but nitrogen flushing is particularly effective in preventing oxidative rancidity and maintaining sensory attributes in long-term storage.

Cost-Effectiveness and Resource Requirements

Vacuum packing reduces oxygen exposure by removing air, which extends pulse shelf life but requires durable packaging materials and energy-intensive equipment, impacting initial investment costs. Nitrogen flushing replaces oxygen with inert gas, offering faster processing and lower packaging costs but demands a steady nitrogen supply and may incur higher operational expenses. Evaluating cost-effectiveness depends on scale, with vacuum packing favored for high-value pulses due to better preservation, while nitrogen flushing suits large-scale operations prioritizing throughput.

Environmental Considerations and Sustainability

Vacuum packing reduces oxygen exposure, minimizing oxidation and microbial growth in pulses, while nitrogen flushing replaces oxygen with inert gas to extend shelf life without chemical preservatives. Both methods lower food waste by enhancing preservation, but nitrogen flushing requires energy-intensive gas production, impacting environmental sustainability. Vacuum packaging often uses less energy and fewer synthetic gases, presenting a more eco-friendly option for sustainable pulse preservation.

Practical Applications in Commercial Pulse Storage

Vacuum packing and nitrogen flushing are widely employed in commercial pulse storage to extend shelf life by reducing oxidative degradation and moisture uptake. Vacuum packing effectively removes air to inhibit microbial growth, while nitrogen flushing replaces oxygen with inert gas, preventing oxidation and preserving seed viability. Implementing these techniques enhances pulse quality, reduces spoilage, and maintains nutritional value during long-term storage.

Future Trends in Pulse Preservation Technologies

Vacuum packing and nitrogen flushing both enhance pulse preservation by reducing oxygen exposure and moisture content, thereby extending shelf life and maintaining nutritional quality. Emerging trends emphasize combining these techniques with smart sensors and biodegradable packaging materials to improve pulse freshness monitoring and sustainability. Advances in modified atmosphere packaging and nanotechnology integration promise more effective control of microbial growth and oxidation in pulse storage.

Related Important Terms

Modified Atmosphere Packaging (MAP)

Vacuum packing and nitrogen flushing are key Modified Atmosphere Packaging (MAP) techniques for pulse preservation, where vacuum packing removes air to reduce oxygen and inhibit microbial growth, while nitrogen flushing replaces oxygen with inert nitrogen gas to maintain quality and extend shelf life. Studies show nitrogen flushing better preserves nutritional content and texture in pulses by minimizing oxidative damage compared to vacuum packing, making it optimal for long-term storage.

High-barrier Laminates

Vacuum packing and nitrogen flushing both extend the shelf life of pulses by reducing oxygen exposure, but high-barrier laminates significantly enhance the effectiveness of these methods by providing superior oxygen and moisture permeability resistance. When combined with high-barrier laminates, nitrogen flushing often outperforms vacuum packing by maintaining the product's natural shape and color while further minimizing oxidative rancidity and microbial growth.

Oxygen Transmission Rate (OTR)

Vacuum packing significantly reduces the Oxygen Transmission Rate (OTR) by removing air from the package, thus minimizing oxidative spoilage in pulses. Nitrogen flushing displaces oxygen with inert nitrogen gas, effectively lowering OTR and extending shelf life by preventing lipid oxidation and microbial growth.

Residual Oxygen Analysis

Vacuum packing significantly reduces residual oxygen levels in pulses, effectively minimizing oxidative degradation and extending shelf life compared to nitrogen flushing, which may leave trace oxygen pockets. Residual oxygen analysis reveals vacuum-packed pulses consistently maintain oxygen concentrations below 0.5%, ensuring superior preservation quality.

Microbial Inhibition Zones

Vacuum packing and nitrogen flushing techniques significantly impact microbial inhibition zones in pulse preservation, with nitrogen flushing creating larger inhibition zones due to its ability to replace oxygen and limit aerobic microbial growth. Studies indicate that nitrogen flushing maintains better microbial stability by suppressing oxidation and extending shelf life more effectively than vacuum packing, which primarily reduces oxygen levels but may allow limited anaerobic microorganism activity.

Active Packaging Inserts

Active packaging inserts enhance pulse preservation by controlling the internal atmosphere; vacuum packing removes oxygen entirely, while nitrogen flushing replaces oxygen with inert nitrogen gas to inhibit oxidation and microbial growth. Incorporating active packaging inserts such as oxygen scavengers or moisture absorbers within vacuum-packed or nitrogen-flushed pulses extends shelf life and maintains quality by continuously managing residual gases and humidity.

Vacuum Integrity Testing

Vacuum packing preserves pulses by removing air to inhibit microbial growth, with vacuum integrity testing ensuring airtight seals that prevent oxygen ingress and moisture penetration. Nitrogen flushing replaces oxygen with inert nitrogen but requires continuous verification of gas levels, whereas vacuum integrity testing provides a reliable measure of packaging effectiveness critical for maintaining pulse quality and shelf life.

Controlled Nitrogen Purging

Controlled nitrogen purging in pulse preservation effectively reduces oxygen levels, minimizing oxidative degradation and microbial growth, thereby extending shelf life compared to vacuum packing alone. This method maintains pulse quality by preserving color, texture, and nutritional content through an inert atmosphere that slows enzymatic reactions and lipid oxidation.

Shelf-life Extension Index

Vacuum packing and nitrogen flushing both significantly extend the shelf-life of pulses by reducing oxygen exposure; however, nitrogen flushing often achieves a higher Shelf-life Extension Index by creating an inert atmosphere that slows oxidative degradation more effectively than vacuum packing alone. Studies indicate nitrogen flushing can increase shelf life by up to 50% compared to vacuum packing, making it a preferred method for long-term pulse preservation.

Total Viable Count (TVC) Reduction

Vacuum packing significantly reduces Total Viable Count (TVC) in pulses by limiting oxygen availability, inhibiting microbial growth more effectively than nitrogen flushing. While nitrogen flushing replaces oxygen with inert gas, vacuum packing creates a superior low-oxygen environment, enhancing pulse preservation and extending shelf life through better TVC reduction.

Vacuum packing vs nitrogen flushing for pulse preservation Infographic

agridif.com

agridif.com