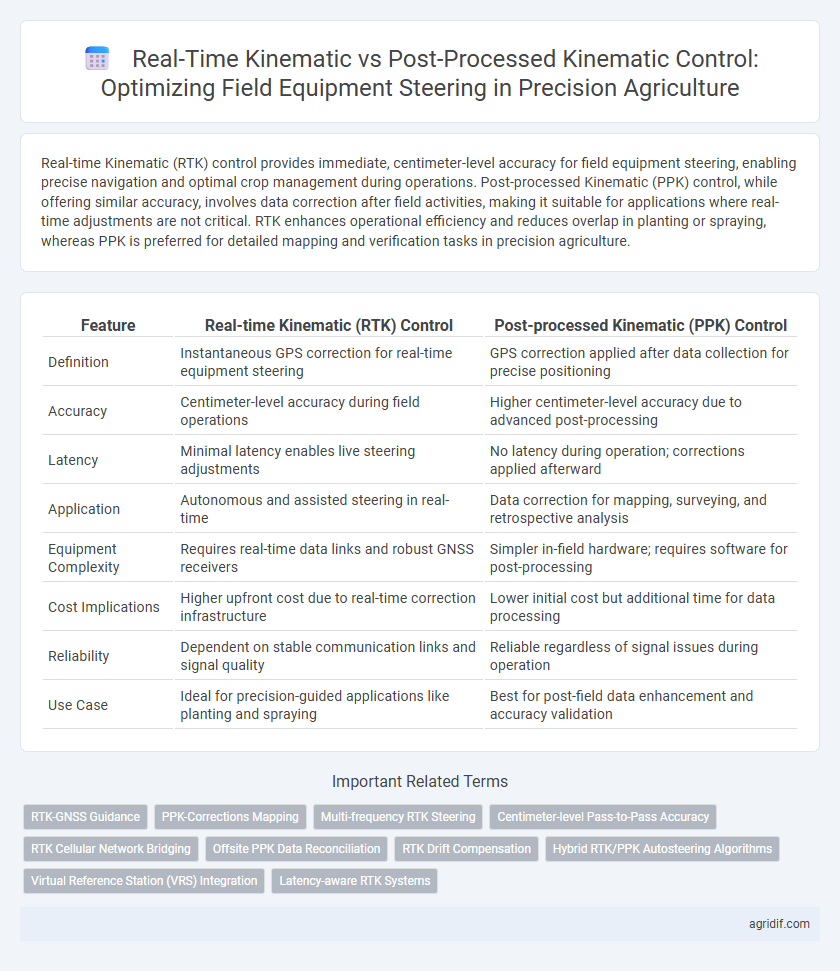

Real-time Kinematic (RTK) control provides immediate, centimeter-level accuracy for field equipment steering, enabling precise navigation and optimal crop management during operations. Post-processed Kinematic (PPK) control, while offering similar accuracy, involves data correction after field activities, making it suitable for applications where real-time adjustments are not critical. RTK enhances operational efficiency and reduces overlap in planting or spraying, whereas PPK is preferred for detailed mapping and verification tasks in precision agriculture.

Table of Comparison

| Feature | Real-time Kinematic (RTK) Control | Post-processed Kinematic (PPK) Control |

|---|---|---|

| Definition | Instantaneous GPS correction for real-time equipment steering | GPS correction applied after data collection for precise positioning |

| Accuracy | Centimeter-level accuracy during field operations | Higher centimeter-level accuracy due to advanced post-processing |

| Latency | Minimal latency enables live steering adjustments | No latency during operation; corrections applied afterward |

| Application | Autonomous and assisted steering in real-time | Data correction for mapping, surveying, and retrospective analysis |

| Equipment Complexity | Requires real-time data links and robust GNSS receivers | Simpler in-field hardware; requires software for post-processing |

| Cost Implications | Higher upfront cost due to real-time correction infrastructure | Lower initial cost but additional time for data processing |

| Reliability | Dependent on stable communication links and signal quality | Reliable regardless of signal issues during operation |

| Use Case | Ideal for precision-guided applications like planting and spraying | Best for post-field data enhancement and accuracy validation |

Introduction to Kinematic Positioning in Precision Agriculture

Kinematic positioning in precision agriculture utilizes satellite signals to provide centimeter-level accuracy for field equipment steering, essential for tasks like planting and fertilizing. Real-time kinematic (RTK) control delivers immediate correction data, enabling precise machine guidance during operations, while post-processed kinematic (PPK) control applies corrections after data collection, enhancing accuracy for mapping and analysis. The choice between RTK and PPK depends on operational needs, as RTK supports live adjustments whereas PPK improves positional data quality for subsequent decision-making.

Understanding Real-time Kinematic (RTK) Control

Real-time Kinematic (RTK) control enhances field equipment steering by providing centimeter-level positioning accuracy through satellite signals combined with correction data transmitted in real-time. This method enables immediate adjustments for precise navigation, reducing overlap and input waste during agricultural operations. RTK systems rely on a base station or network of reference stations, offering continuous correction that significantly improves the efficiency and productivity of precision agriculture.

Overview of Post-processed Kinematic (PPK) Control

Post-processed Kinematic (PPK) control enhances field equipment steering accuracy by applying GNSS correction data after data collection, improving positional precision compared to real-time methods. This technique reduces reliance on continuous communication with correction sources, making it ideal for challenging signal environments. PPK offers higher data integrity and cost efficiency by storing raw GNSS data onboard and processing it later with base station information, enabling precise agricultural operations such as planting and spraying.

Accuracy Requirements for Field Equipment Steering

Real-time kinematic (RTK) control offers centimeter-level accuracy immediately, essential for precise guidance of field equipment in variable rate applications and planting. Post-processed kinematic (PPK) control achieves similar accuracy by applying corrections after data collection, suitable for operations where immediate guidance is less critical but high precision is required. Accuracy requirements for field equipment steering demand consistent positional precision within 2-5 centimeters to optimize input application, minimize overlap, and enhance crop yields.

Latency and Response Time: RTK vs PPK

Real-time kinematic (RTK) control offers minimal latency with immediate correction signals, enabling field equipment to perform precise steering adjustments instantly for improved operational efficiency. Post-processed kinematic (PPK) control, while highly accurate, involves delayed signal correction analyzed after data collection, resulting in slower response times unsuitable for dynamic steering tasks. RTK's low-latency performance is critical for real-time navigation, whereas PPK excels in accuracy for post-mission data analysis but cannot match RTK in response speed during active fieldwork.

Data Correction Methods in RTK and PPK Systems

Real-time kinematic (RTK) control relies on immediate satellite data corrections transmitted via radio or cellular networks, enabling precise equipment steering with minimal latency. Post-processed kinematic (PPK) control uses data logged during field operations, applying corrections after completion through reference station data to enhance positional accuracy. RTK's instantaneous corrections optimize real-time navigation, while PPK's retrospective adjustments improve reliability in environments with compromised signal quality.

Connectivity and Infrastructure Demands

Real-time kinematic (RTK) control in precision agriculture requires continuous, reliable connectivity through GNSS correction signals, demanding robust infrastructure such as base stations and communication networks to minimize latency and ensure accurate field equipment steering. Post-processed kinematic (PPK) control operates independently of real-time data streams, allowing correction data to be applied after field operations, reducing dependency on constant network availability and enabling flexibility in areas with limited connectivity. RTK's infrastructure demands increase operational costs and complexity, while PPK offers cost-effective solutions for remote or underserved regions without compromising steering accuracy.

Cost Comparison: RTK vs PPK for Agricultural Operations

Real-time Kinematic (RTK) control offers immediate centimeter-level accuracy for field equipment steering but typically requires higher upfront investment and ongoing subscription fees for correction signals. Post-processed Kinematic (PPK) control reduces costs by eliminating real-time communication needs, relying instead on data processing after fieldwork, making it a cost-effective option for operators with limited connectivity. Despite lower operational costs, PPK may result in delayed data availability, influencing timely decision-making in precision agriculture tasks.

Practical Applications and Field Scenarios

Real-time Kinematic (RTK) control enables precise field equipment steering through immediate satellite correction signals, enhancing efficiency in planting, fertilizing, and harvesting operations by reducing overlap and gaps. Post-processed Kinematic (PPK) control offers higher accuracy by correcting positional data after fieldwork, proving valuable in scenarios where real-time signal interruptions occur or for detailed mapping tasks. Choosing between RTK and PPK depends on factors like real-time guidance needs, environmental conditions, and the specific precision levels required for field operations.

Choosing the Right Kinematic Control System for Your Farm

Real-time Kinematic (RTK) control provides immediate, centimeter-level accuracy for field equipment steering, essential for time-sensitive tasks like planting and spraying, whereas Post-processed Kinematic (PPK) control delivers high precision through data correction after operations, suitable for applications where timing is less critical. Selecting between RTK and PPK depends on farm size, workflow urgency, and budget constraints, with RTK favored for large-scale, continuous operations requiring instant guidance and PPK preferred for smaller farms prioritizing cost-efficiency and data refinement. Integrating GNSS receivers with robust correction services enhances both systems' performance, optimizing crop yield and resource management through precise steering control.

Related Important Terms

RTK-GNSS Guidance

RTK-GNSS guidance offers centimeter-level accuracy in real-time, enabling precise field equipment steering essential for optimizing crop inputs and reducing overlap in precision agriculture. Compared to post-processed kinematic control, RTK enhances operational efficiency by providing immediate positional corrections, minimizing downtime and improving overall productivity.

PPK-Corrections Mapping

Real-time kinematic (RTK) control enables immediate, centimeter-level accuracy in field equipment steering through continuous satellite signal corrections, enhancing planting and harvesting precision. Post-processed kinematic (PPK) control, while not providing instant corrections, allows for detailed correction mapping by applying error adjustments after data collection, improving long-term accuracy and field data reliability.

Multi-frequency RTK Steering

Multi-frequency Real-time Kinematic (RTK) steering enhances precision agriculture by providing centimeter-level accuracy instantly, enabling dynamic adjustment of field equipment paths and reducing overlap and input waste. Compared to Post-processed Kinematic (PPK) control, multi-frequency RTK integrates multiple GNSS signals to minimize signal loss and multipath errors, ensuring continuous guidance and increased operational efficiency during planting and fertilizing tasks.

Centimeter-level Pass-to-Pass Accuracy

Real-time kinematic (RTK) control enables centimeter-level pass-to-pass accuracy by providing instantaneous satellite correction data to field equipment steering systems, ensuring precise navigation during active operations. Post-processed kinematic (PPK) control achieves similar accuracy through after-the-fact data correction, making RTK preferable for real-time decision-making and efficiency in precision agriculture workflows.

RTK Cellular Network Bridging

Real-time kinematic (RTK) control leveraging cellular network bridging provides immediate centimeter-level positioning accuracy for precision agriculture equipment, enabling seamless field operations with minimal latency. Post-processed kinematic (PPK) control, while offering similar accuracy, requires data processing after fieldwork, which delays feedback and limits real-time adjustments critical for efficient steering and crop management.

Offsite PPK Data Reconciliation

Offsite Post-Processed Kinematic (PPK) data reconciliation enhances field equipment steering accuracy by correcting GPS positioning errors after data collection, enabling precise geospatial alignment without real-time connectivity. This method offers higher positional accuracy compared to Real-time Kinematic (RTK) control, especially in areas with poor signal reception or limited cellular coverage, optimizing precision agriculture operations through reliable, corrected guidance data integration.

RTK Drift Compensation

Real-time kinematic (RTK) control provides immediate satellite signal corrections, enabling precise field equipment steering with minimal drift in precision agriculture operations. Post-processed kinematic (PPK) control corrects positional data after fieldwork but lacks the immediate drift compensation, making RTK preferable for applications requiring continuous, real-time accuracy.

Hybrid RTK/PPK Autosteering Algorithms

Hybrid RTK/PPK autosteering algorithms combine Real-time Kinematic (RTK) Control's continuous satellite correction updates with Post-Processed Kinematic (PPK) Control's enhanced positional accuracy to optimize field equipment steering precision. This integration improves navigation performance by minimizing signal interruptions and refining trajectory corrections, resulting in higher accuracy for precision agriculture operations.

Virtual Reference Station (VRS) Integration

Real-time Kinematic (RTK) control with Virtual Reference Station (VRS) integration offers centimeter-level accuracy and instant correction data to field equipment steering, enhancing operational efficiency and minimizing overlap in precision agriculture. Post-processed Kinematic (PPK) control, while providing high accuracy through data correction after collection, lacks the immediate feedback of VRS-based RTK, potentially reducing real-time decision-making capabilities in dynamic field conditions.

Latency-aware RTK Systems

Latency-aware RTK systems enhance real-time kinematic control by reducing positional delays, enabling precise and immediate field equipment steering compared to post-processed kinematic control, which relies on delayed data corrections after field operations. Integrating low-latency GNSS corrections improves navigation accuracy and operational efficiency in precision agriculture, optimizing autonomous machinery performance and minimizing crop damage.

Real-time Kinematic Control vs Post-processed Kinematic Control for Field Equipment Steering Infographic

agridif.com

agridif.com