Direct acidification in yogurt production involves adding food-grade acids like lactic or citric acid to milk, resulting in a faster fermentation process and consistent sourness. Natural acidification relies on bacterial cultures to ferment lactose into lactic acid, enhancing the yogurt's texture, flavor complexity, and probiotic benefits. Choosing between these methods affects product shelf life, nutritional profile, and consumer sensory experience in food science and technology.

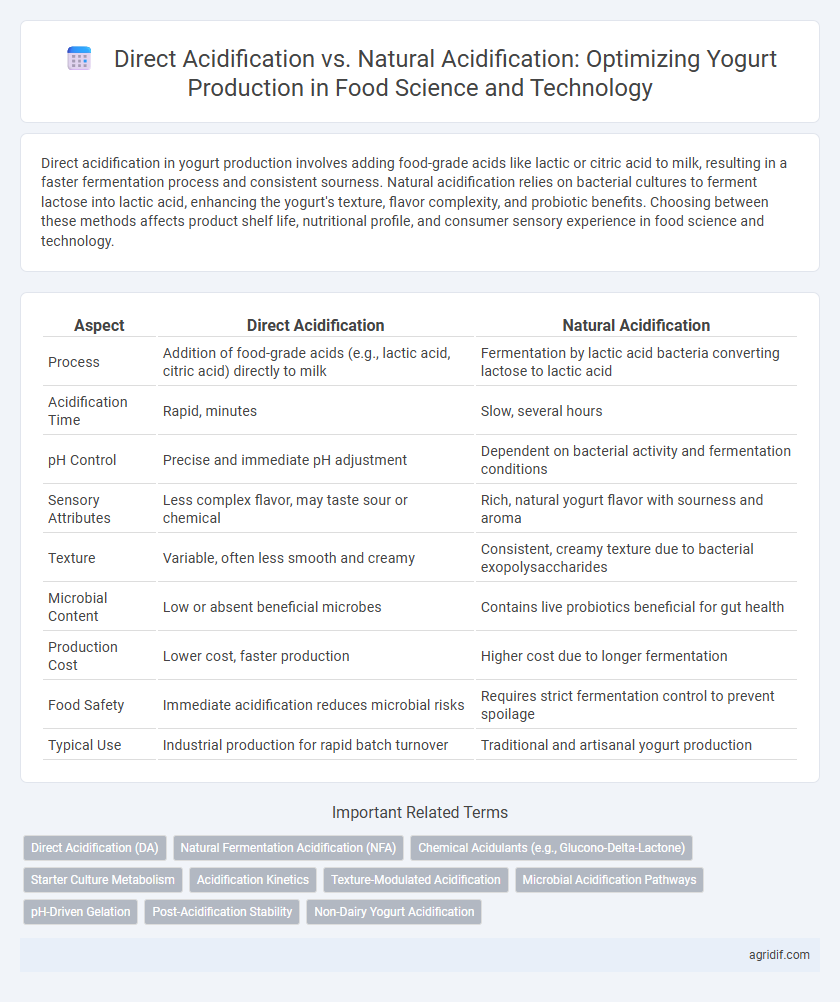

Table of Comparison

| Aspect | Direct Acidification | Natural Acidification |

|---|---|---|

| Process | Addition of food-grade acids (e.g., lactic acid, citric acid) directly to milk | Fermentation by lactic acid bacteria converting lactose to lactic acid |

| Acidification Time | Rapid, minutes | Slow, several hours |

| pH Control | Precise and immediate pH adjustment | Dependent on bacterial activity and fermentation conditions |

| Sensory Attributes | Less complex flavor, may taste sour or chemical | Rich, natural yogurt flavor with sourness and aroma |

| Texture | Variable, often less smooth and creamy | Consistent, creamy texture due to bacterial exopolysaccharides |

| Microbial Content | Low or absent beneficial microbes | Contains live probiotics beneficial for gut health |

| Production Cost | Lower cost, faster production | Higher cost due to longer fermentation |

| Food Safety | Immediate acidification reduces microbial risks | Requires strict fermentation control to prevent spoilage |

| Typical Use | Industrial production for rapid batch turnover | Traditional and artisanal yogurt production |

Introduction to Yogurt Acidification Methods

Direct acidification in yogurt production involves adding acids like lactic or citric acid to milk, rapidly lowering pH and controlling fermentation speed, resulting in consistent texture and flavor. Natural acidification relies on live bacterial cultures such as Lactobacillus bulgaricus and Streptococcus thermophilus, promoting a gradual pH decrease that enhances probiotic properties and complex flavor development. Both methods impact yogurt's microbial activity, texture, and shelf life, with natural fermentation offering improved probiotic benefits and direct acidification providing faster production cycles.

Principles of Direct Acidification

Direct acidification in yogurt production involves adding food-grade acids like lactic or citric acid to milk, rapidly lowering the pH to initiate coagulation without microbial fermentation. This process allows precise control over acidity, shortening production time and reducing the risk of contamination compared to natural acidification by lactic acid bacteria. By bypassing microbial metabolism, direct acidification ensures consistent texture and taste but may lack the complex flavor profile developed through bacterial fermentation.

Process of Natural Acidification in Yogurt Production

Natural acidification in yogurt production relies on the fermentation activity of lactic acid bacteria such as Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus, which convert lactose into lactic acid, lowering the pH and causing milk proteins to coagulate. The process involves incubating milk with specific starter cultures at controlled temperatures, typically around 42-45degC, to optimize bacterial growth and acid production over several hours. This method enhances the yogurt's texture, flavor complexity, and probiotic qualities by promoting the development of bioactive peptides and organic acids naturally.

Microbial Roles in Natural Acidification

Natural acidification in yogurt production relies predominantly on the metabolic activity of lactic acid bacteria such as Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus, which convert lactose into lactic acid, lowering pH and contributing to yogurt's texture and flavor. These microorganisms play a crucial role in developing bioactive peptides and exopolysaccharides that enhance yogurt's nutritional and rheological properties. Microbial viability during fermentation impacts acidification rate, proteolysis, and development of organoleptic characteristics, distinguishing natural acidification from direct acidification methods that use chemical acids without microbial activity.

Acidulants Used in Direct Acidification: Types and Effects

Direct acidification in yogurt production involves the addition of acidulants such as lactic acid, citric acid, and phosphoric acid to rapidly lower pH and control texture and flavor. Lactic acid contributes to a mild tang and smooth consistency, while citric acid enhances tartness but may lead to a watery texture if overused. The choice and concentration of acidulants directly affect microbial stability, sensory properties, and shelf life of the yogurt product.

Flavor and Texture Outcomes: Direct vs Natural Acidification

Direct acidification in yogurt production yields a tart, consistent flavor and a firmer texture due to rapid pH reduction using food-grade acids like lactic or citric acid. Natural acidification, driven by lactic acid bacteria fermentation, enhances complex flavor profiles through organic acid and metabolite development, producing a creamier, smoother texture. Flavor complexity and mouthfeel richness in naturally acidified yogurt often surpass the simpler, more acidic characteristics found in direct acidified products.

Nutritional Implications of Acidification Methods

Direct acidification in yogurt production involves adding food-grade acids like lactic or citric acid, resulting in a rapid pH decrease that preserves specific nutrients such as calcium but may reduce bioavailability of some vitamins. Natural acidification relies on fermentation by lactic acid bacteria, enhancing probiotic content and promoting beneficial microbial metabolism that increases bioactive peptides and B vitamins. The choice between these methods significantly impacts yogurt's nutritional profile, with fermented yogurts generally offering superior probiotic benefits and improved digestibility.

Impact on Yogurt Shelf Life and Safety

Direct acidification in yogurt production uses food-grade acids to rapidly lower pH, leading to shorter fermentation times but often resulting in a less complex flavor profile and potentially reduced probiotic viability. Natural acidification relies on live bacterial cultures producing lactic acid, enhancing microbial stability and contributing to longer shelf life through the production of antimicrobial compounds like bacteriocins. Studies indicate that naturally acidified yogurts generally exhibit improved safety profiles due to the sustained activity of beneficial microbes that inhibit pathogen growth during storage.

Industry Applications and Production Efficiency

Direct acidification in yogurt production accelerates fermentation by adding food-grade acids, enhancing production efficiency and ensuring consistent pH levels, which is vital for large-scale industrial applications. Natural acidification relies on bacterial fermentation, producing complex flavor profiles and probiotic benefits, but requires longer incubation times and precise microbial management, impacting throughput. Balancing these methods in industry depends on desired product characteristics, with direct acidification favored for rapid turnover and natural acidification preferred for premium, health-oriented yogurt products.

Consumer Preferences and Market Trends

Consumer preferences in yogurt production reveal a growing demand for natural acidification methods due to perceived health benefits and authentic taste profiles. Market trends indicate a significant rise in organic and probiotic yogurts produced through natural fermentation, aligning with increasing awareness of gut health and clean label products. Direct acidification remains favored in large-scale industrial production for cost efficiency and consistent quality, yet it faces challenges in markets prioritizing artisanal and minimally processed dairy.

Related Important Terms

Direct Acidification (DA)

Direct acidification in yogurt production involves adding food-grade acids such as lactic or citric acid to milk, rapidly lowering pH and eliminating the need for bacterial fermentation, which results in a shorter production time and consistent acidity levels. This method allows precise control over flavor and texture but often lacks the characteristic probiotic benefits and complex taste profile developed through natural acidification by live bacterial cultures.

Natural Fermentation Acidification (NFA)

Natural Fermentation Acidification (NFA) in yogurt production relies on symbiotic cultures of Lactobacillus bulgaricus and Streptococcus thermophilus to metabolize lactose, producing lactic acid that lowers the pH and develops characteristic texture and flavor profiles. This biological acidification enhances probiotic properties and bioavailability of nutrients compared to direct acidification, which uses chemical acids and lacks fermentation-associated benefits.

Chemical Acidulants (e.g., Glucono-Delta-Lactone)

Chemical acidulants like Glucono-Delta-Lactone (GDL) provide controlled and rapid acidification in yogurt production, resulting in consistent pH reduction and gel formation without relying on bacterial fermentation. This direct acidification method enables precise texture and shelf-life optimization, contrasting with natural acidification where lactic acid bacteria gradually lower pH during fermentation.

Starter Culture Metabolism

Direct acidification in yogurt production involves adding food-grade acids to lower pH rapidly, bypassing microbial metabolism, whereas natural acidification relies on starter culture metabolism, where lactic acid bacteria ferment lactose into lactic acid, gradually reducing pH and developing characteristic flavor and texture. Starter culture metabolism enhances probiotic benefits and bioactive peptide formation, crucial for yogurt's nutritional and sensory qualities.

Acidification Kinetics

Direct acidification in yogurt production involves adding food-grade acids, accelerating pH reduction and achieving rapid coagulation within minutes, while natural acidification relies on lactic acid bacteria fermentation, leading to slower, controlled pH decline over several hours that enhances flavor and texture development. Acidification kinetics in direct acidification show a steep pH drop curve, whereas natural acidification presents sigmoidal kinetics due to microbial growth phases and metabolic activities influencing acid production rates.

Texture-Modulated Acidification

Texture-modulated acidification in yogurt production leverages direct acidification to rapidly lower pH, resulting in a firmer, more homogeneous gel structure compared to natural acidification, which relies on microbial fermentation and offers a creamier, more complex texture due to gradual acid development. Selecting direct acidification optimizes consistency and shelf-life uniformity, while natural acidification promotes probiotic benefits and nuanced sensory profiles by modulating protein network formation during fermentation.

Microbial Acidification Pathways

Direct acidification in yogurt production involves adding food-grade acids such as lactic or citric acid to rapidly lower pH, bypassing microbial fermentation pathways, whereas natural acidification relies on live lactic acid bacteria like Lactobacillus delbrueckii subsp. bulgaricus and Streptococcus thermophilus metabolizing lactose into lactic acid through glycolysis and homofermentative pathways. Natural acidification enhances yogurt texture, flavor, and probiotic qualities by promoting microbial growth and metabolite synthesis, while direct acidification provides faster acidification but lacks microbial metabolic contributions.

pH-Driven Gelation

Direct acidification in yogurt production involves adding acids like lactic or citric acid to rapidly lower pH and induce gelation, resulting in a firmer texture but less complex flavor compared to natural acidification. Natural acidification relies on bacterial fermentation to gradually decrease pH through lactic acid production, promoting a delicate gel network with enhanced bioactive compounds and probiotic benefits.

Post-Acidification Stability

Direct acidification offers greater control over pH levels, minimizing post-acidification and ensuring consistent yogurt texture and flavor stability during storage. Natural acidification through lactic acid bacteria fermentation enhances probiotic benefits but leads to ongoing pH reduction, causing increased post-acidification and potential firmness and sourness changes over shelf life.

Non-Dairy Yogurt Acidification

Direct acidification in non-dairy yogurt production utilizes food-grade acids like lactic or citric acid to rapidly lower pH, ensuring consistent texture and extended shelf life without microbial fermentation variability. In contrast, natural acidification relies on fermentation by lactic acid bacteria, which develop complex flavors and bioactive compounds but require longer fermentation time and controlled environmental conditions.

Direct Acidification vs Natural Acidification for Yogurt Production Infographic

agridif.com

agridif.com