Modified Atmosphere Packaging (MAP) extends the shelf life of fresh produce by altering the gas composition around the product, typically increasing CO2 and reducing O2 levels to slow respiration and microbial growth. Vacuum packaging removes air entirely, minimizing oxidation and moisture loss but may cause anaerobic conditions that can affect the texture and flavor of sensitive produce. Selecting between MAP and vacuum packaging depends on the specific respiratory rate and sensitivity of the fresh produce to ensure optimal quality and freshness.

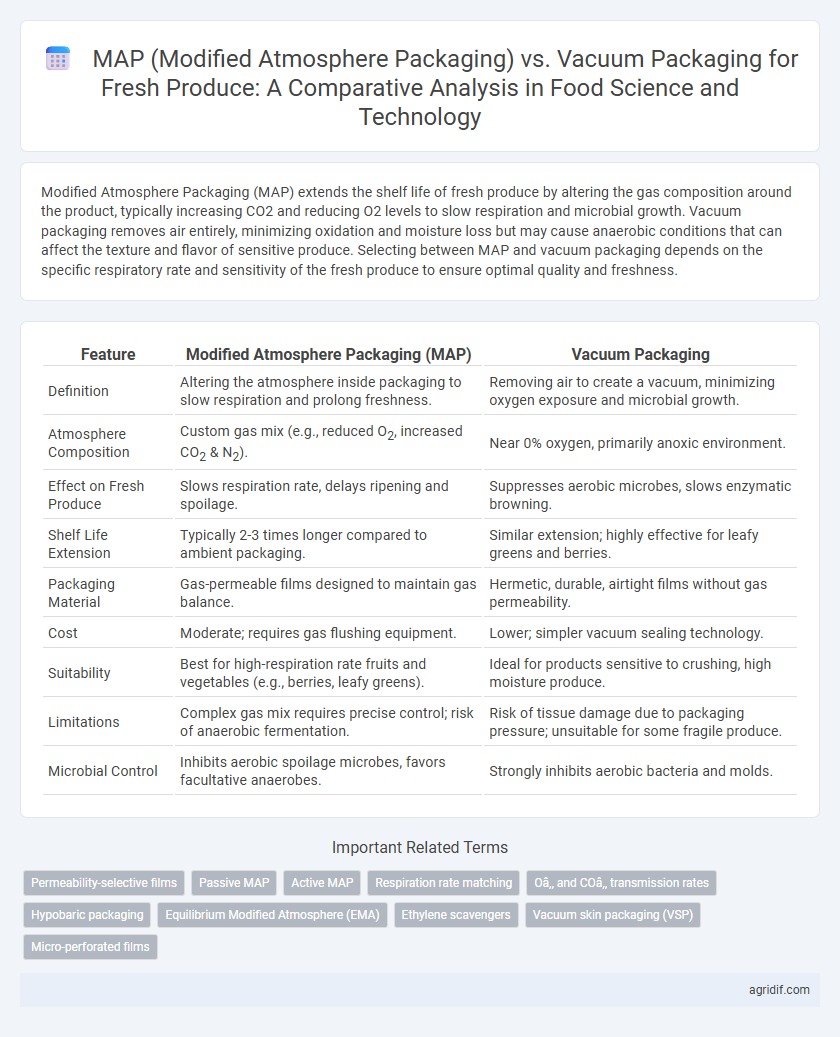

Table of Comparison

| Feature | Modified Atmosphere Packaging (MAP) | Vacuum Packaging |

|---|---|---|

| Definition | Altering the atmosphere inside packaging to slow respiration and prolong freshness. | Removing air to create a vacuum, minimizing oxygen exposure and microbial growth. |

| Atmosphere Composition | Custom gas mix (e.g., reduced O2, increased CO2 & N2). | Near 0% oxygen, primarily anoxic environment. |

| Effect on Fresh Produce | Slows respiration rate, delays ripening and spoilage. | Suppresses aerobic microbes, slows enzymatic browning. |

| Shelf Life Extension | Typically 2-3 times longer compared to ambient packaging. | Similar extension; highly effective for leafy greens and berries. |

| Packaging Material | Gas-permeable films designed to maintain gas balance. | Hermetic, durable, airtight films without gas permeability. |

| Cost | Moderate; requires gas flushing equipment. | Lower; simpler vacuum sealing technology. |

| Suitability | Best for high-respiration rate fruits and vegetables (e.g., berries, leafy greens). | Ideal for products sensitive to crushing, high moisture produce. |

| Limitations | Complex gas mix requires precise control; risk of anaerobic fermentation. | Risk of tissue damage due to packaging pressure; unsuitable for some fragile produce. |

| Microbial Control | Inhibits aerobic spoilage microbes, favors facultative anaerobes. | Strongly inhibits aerobic bacteria and molds. |

Introduction to Packaging Technologies in Fresh Produce

Modified Atmosphere Packaging (MAP) and vacuum packaging are advanced technologies designed to extend shelf life and maintain quality in fresh produce by altering the atmospheric composition surrounding the product. MAP typically replaces oxygen with controlled levels of carbon dioxide and nitrogen to slow respiration rates and microbial growth, whereas vacuum packaging removes air entirely, creating an anaerobic environment that inhibits aerobic spoilage organisms. Both methods are critical in the food science and technology sector for reducing post-harvest losses and preserving sensory attributes in fruits and vegetables during storage and distribution.

Understanding Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) extends the shelf life of fresh produce by altering the internal gas composition, typically reducing oxygen and increasing carbon dioxide levels to slow respiration and microbial growth. MAP contrasts with vacuum packaging by maintaining a protective gas mixture rather than removing all air, which helps preserve texture and freshness of perishable fruits and vegetables. Optimizing gas ratios tailored to specific produce types enhances quality retention and reduces spoilage during transportation and storage.

Principles and Process of Vacuum Packaging

Vacuum packaging involves removing air from the package before sealing to reduce oxygen levels, thereby slowing the respiration rate and microbial growth in fresh produce. This process preserves freshness by minimizing oxidative reactions and moisture loss, maintaining the quality and extending shelf life. The principle relies on creating an anaerobic environment, which contrasts with the gas modification in MAP that selectively alters oxygen, carbon dioxide, and nitrogen concentrations.

Key Differences Between MAP and Vacuum Packaging

Modified Atmosphere Packaging (MAP) adjusts the gas composition surrounding fresh produce, typically increasing carbon dioxide and reducing oxygen to slow respiration and microbial growth, whereas vacuum packaging removes air entirely to inhibit aerobic bacteria and oxidation. MAP maintains a controlled atmosphere that can extend shelf life while preserving texture and color, while vacuum packaging often results in compressed produce, which may affect appearance and texture. Shelf life extension in MAP varies by produce type and gas mixture, while vacuum packaging offers uniform oxygen reduction but may not be suitable for delicate items due to potential physical damage.

Impact on Shelf Life and Quality of Fresh Produce

Modified Atmosphere Packaging (MAP) extends fresh produce shelf life by regulating oxygen and carbon dioxide levels, slowing respiration and microbial growth, which preserves texture, color, and nutritional quality. Vacuum packaging removes air entirely, reducing oxidative reactions and microbial spoilage, but may cause tissue compression and alter sensory attributes in delicate produce. Studies reveal MAP better maintains freshness and firmness in leafy greens and berries, while vacuum packaging suits firmer fruits, highlighting the importance of produce-specific packaging strategies.

Effects on Nutritional Value and Sensory Attributes

Modified Atmosphere Packaging (MAP) preserves fresh produce by regulating oxygen, carbon dioxide, and nitrogen levels, effectively slowing respiration and enzymatic degradation, which helps maintain higher vitamin C content and enhances sensory attributes like color and texture compared to vacuum packaging. Vacuum packaging removes oxygen entirely, reducing oxidative spoilage but can cause tissue compression and off-flavors, potentially diminishing the sensory quality and some heat-sensitive nutrients. Studies indicate MAP better retains aromas and firmness, making it preferable for fresh produce requiring extended shelf life with minimal nutrient loss.

Microbial Safety in MAP vs Vacuum Packaging

Modified Atmosphere Packaging (MAP) enhances microbial safety in fresh produce by altering gas compositions, primarily reducing oxygen levels and increasing carbon dioxide, which inhibits the growth of aerobic spoilage microorganisms more effectively than vacuum packaging. Vacuum packaging removes air but may not control gas composition precisely, sometimes allowing facultative anaerobes or anaerobic pathogens to proliferate under low-oxygen conditions. Studies show MAP extends shelf life and reduces microbial load better than vacuum packaging, offering superior protection against foodborne pathogens and spoilage microbes in fresh fruits and vegetables.

Cost-Efficiency and Commercial Applications

Modified Atmosphere Packaging (MAP) offers enhanced shelf life and quality retention for fresh produce by controlling gas composition, resulting in reduced spoilage and lower overall costs in commercial applications. Vacuum packaging effectively minimizes oxygen exposure, significantly extending freshness but often involves higher initial equipment investments and limited scalability for diverse produce types. Cost-efficiency in large-scale operations favors MAP due to its adaptability and compatibility with automated packaging systems, making it a preferred choice for maximizing profitability in fresh produce distribution.

Environmental Considerations and Sustainability

Modified Atmosphere Packaging (MAP) reduces oxygen levels to extend shelf life of fresh produce while using less plastic compared to traditional packaging, supporting waste reduction and resource efficiency. Vacuum packaging effectively prevents microbial growth by removing air but often requires thicker, less recyclable materials, increasing environmental impact. Sustainable packaging strategies favor MAP due to its balance between product preservation, reduced food waste, and lower plastic consumption in the fresh produce supply chain.

Future Trends in Fresh Produce Packaging Technologies

Emerging trends in fresh produce packaging emphasize advanced MAP systems integrated with smart sensors to monitor respiration rates and optimize gas compositions in real time, extending shelf life more effectively than traditional vacuum packaging. Innovations in biodegradable, nanocomposite films enhance gas permeability control and antimicrobial properties, addressing sustainability and food safety challenges. Future research focuses on combining MAP with active packaging technologies to dynamically respond to produce physiology for improved freshness and reduced waste.

Related Important Terms

Permeability-selective films

Permeability-selective films in Modified Atmosphere Packaging (MAP) enhance the shelf life of fresh produce by finely controlling gas exchange, optimizing oxygen and carbon dioxide levels to maintain freshness and reduce spoilage. Compared to vacuum packaging, which removes oxygen entirely, MAP with selective permeability better preserves texture and flavor by allowing respiration while limiting anaerobic conditions that can lead to off-flavors.

Passive MAP

Passive Modified Atmosphere Packaging (MAP) for fresh produce relies on the natural respiration of fruits and vegetables to alter the gas composition inside the package, typically reducing oxygen levels and increasing carbon dioxide to slow down metabolic rates and extend shelf life. In contrast to vacuum packaging, which removes air completely and can cause tissue damage and anaerobic conditions, passive MAP maintains a protective environment that preserves texture, color, and freshness by allowing controlled gas exchange through film permeability.

Active MAP

Active Modified Atmosphere Packaging (Active MAP) enhances the shelf life and quality of fresh produce by dynamically regulating oxygen and carbon dioxide levels through integrated sensors or gas emitters, optimizing respiration rates and reducing microbial growth compared to static vacuum packaging. Unlike vacuum packaging that solely removes air, Active MAP actively adjusts internal gas composition to maintain freshness, texture, and nutritional value during storage and transportation.

Respiration rate matching

Modified Atmosphere Packaging (MAP) optimizes the gas composition around fresh produce to closely match the respiration rate, thereby slowing metabolic processes and extending shelf life. In contrast, vacuum packaging removes oxygen entirely, which can inhibit respiration but may also cause anaerobic conditions that negatively affect produce quality.

O₂ and CO₂ transmission rates

Modified Atmosphere Packaging (MAP) controls O2 and CO2 transmission rates to slow respiration and extend the shelf life of fresh produce by maintaining an optimal atmospheric balance, while vacuum packaging removes air entirely, drastically reducing O2 levels but potentially causing anaerobic conditions that may affect product quality. MAP films are engineered with specific gas permeability to allow selective O2 and CO2 exchange, optimizing freshness, whereas vacuum packaging's minimal gas exchange can lead to rapid quality degradation in highly respiring produce.

Hypobaric packaging

Hypobaric packaging, a subset of Modified Atmosphere Packaging (MAP), reduces oxygen levels and pressure around fresh produce, slowing respiration and delaying spoilage more effectively than traditional vacuum packaging. This technique preserves texture and extends shelf life by maintaining optimal gas mixtures, minimizing anaerobic damage common in vacuum sealed products.

Equilibrium Modified Atmosphere (EMA)

Equilibrium Modified Atmosphere (EMA) in MAP technology stabilizes gas composition around fresh produce by balancing respiration rates with package permeability, extending shelf life and preserving quality better than conventional vacuum packaging. Vacuum packaging removes air but can cause tissue damage and anaerobic conditions, whereas EMA maintains optimal O2 and CO2 levels to reduce spoilage and maintain freshness.

Ethylene scavengers

Modified Atmosphere Packaging (MAP) enhances fresh produce shelf life by regulating gas compositions and integrating ethylene scavengers that actively reduce ethylene concentration, thereby delaying ripening and spoilage. Vacuum packaging, while effective at limiting oxygen exposure, does not specifically target ethylene removal, making MAP with ethylene scavengers a superior solution for maintaining postharvest quality.

Vacuum skin packaging (VSP)

Vacuum skin packaging (VSP) extends the shelf life of fresh produce by tightly conforming a flexible film onto the product, reducing oxygen exposure and minimizing oxidation and microbial growth compared to traditional MAP methods. VSP enhances sensory quality and preserves texture and color, making it a superior choice for high-value fruits and vegetables requiring extended freshness during distribution.

Micro-perforated films

Micro-perforated films in Modified Atmosphere Packaging (MAP) enhance gas exchange, maintaining optimal O2 and CO2 levels to extend the shelf life of fresh produce while preserving texture and nutritional quality. Compared to vacuum packaging, which can cause anaerobic conditions and potential quality degradation, MAP with micro-perforated films better controls respiration rates and reduces moisture condensation, ensuring fresher, longer-lasting produce.

MAP (Modified Atmosphere Packaging) vs vacuum packaging for fresh produce Infographic

agridif.com

agridif.com