Extrusion cooking in snack manufacturing offers rapid processing, consistent texture, and enhanced nutrient retention compared to traditional baking methods. The high-temperature, short-time extrusion process efficiently produces diverse snack shapes with improved shelf life and reduced energy consumption. Traditional baking, while providing classic flavors and textures, involves longer cooking times and often results in higher moisture content and less uniformity in the final product.

Table of Comparison

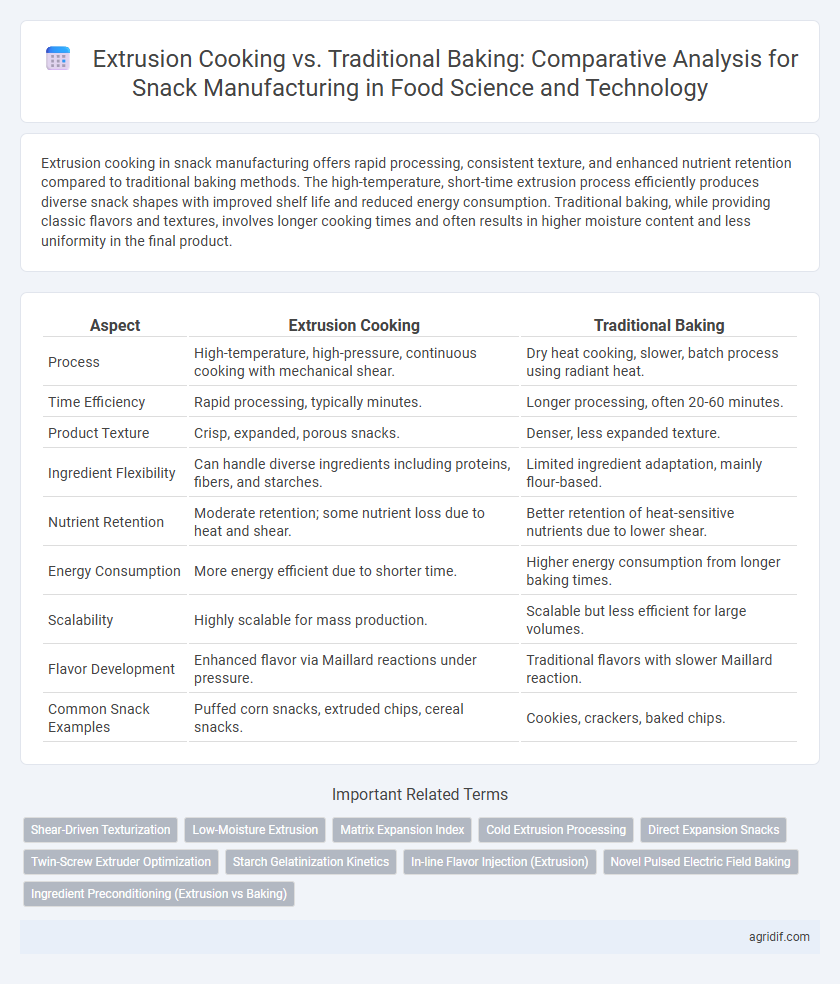

| Aspect | Extrusion Cooking | Traditional Baking |

|---|---|---|

| Process | High-temperature, high-pressure, continuous cooking with mechanical shear. | Dry heat cooking, slower, batch process using radiant heat. |

| Time Efficiency | Rapid processing, typically minutes. | Longer processing, often 20-60 minutes. |

| Product Texture | Crisp, expanded, porous snacks. | Denser, less expanded texture. |

| Ingredient Flexibility | Can handle diverse ingredients including proteins, fibers, and starches. | Limited ingredient adaptation, mainly flour-based. |

| Nutrient Retention | Moderate retention; some nutrient loss due to heat and shear. | Better retention of heat-sensitive nutrients due to lower shear. |

| Energy Consumption | More energy efficient due to shorter time. | Higher energy consumption from longer baking times. |

| Scalability | Highly scalable for mass production. | Scalable but less efficient for large volumes. |

| Flavor Development | Enhanced flavor via Maillard reactions under pressure. | Traditional flavors with slower Maillard reaction. |

| Common Snack Examples | Puffed corn snacks, extruded chips, cereal snacks. | Cookies, crackers, baked chips. |

Introduction to Snack Manufacturing Technologies

Extrusion cooking and traditional baking represent key technologies in snack manufacturing, each offering distinct processing mechanisms and product attributes. Extrusion cooking uses high temperature and pressure to transform raw ingredients into expanded, crispy snacks with controlled texture and moisture content, enabling rapid production and ingredient versatility. Traditional baking relies on dry heat to develop flavor and texture through Maillard reactions, often resulting in denser snacks with varied shapes but longer processing times and higher energy consumption.

Overview of Extrusion Cooking in Food Production

Extrusion cooking in food production utilizes high temperature, pressure, and mechanical shear to transform raw ingredients into expanded, textured snacks with consistent quality and extended shelf life. This method enables precise control over product characteristics, such as density, shape, and moisture content, surpassing traditional baking techniques in efficiency and versatility. Extrusion's continuous processing capacity reduces production time and energy consumption, making it a preferred technology for large-scale snack manufacturing.

Traditional Baking: Methods and Applications

Traditional baking in snack manufacturing involves heating dough or batter through conduction and convection, creating distinct textures and flavors through Maillard reactions and caramelization. Common methods include oven baking, rotary ovens, and deck ovens, suited for products like cookies, crackers, and breadsticks, emphasizing controlled moisture reduction and uniform heat distribution. Applications leverage baking to produce snacks with crispy exteriors, tender interiors, and rich aromas, often preferred for artisanal and specialty snack items.

Ingredient Functionality in Extrusion vs Baking

Extrusion cooking transforms ingredients through high temperature, pressure, and shear, resulting in starch gelatinization, protein denaturation, and enhanced ingredient binding that improves texture and expansion in snacks. Traditional baking relies on slower heat transfer which allows for gradual moisture evaporation and Maillard reactions, preserving distinct ingredient functionalities but often requiring added leavening agents for volume. The intense mechanical and thermal effects in extrusion modify ingredient matrices more extensively, optimizing snack crispness and shelf stability compared to the more delicate ingredient interactions maintained during baking.

Nutritional Impact: Extrusion Cooking vs Baking

Extrusion cooking enhances protein digestibility and reduces anti-nutritional factors more effectively than traditional baking, resulting in snacks with improved nutrient bioavailability. The high temperature and pressure conditions of extrusion lead to starch gelatinization and decreased fat content, which can lower calorie density compared to baked snacks. However, extrusion may cause some loss of heat-sensitive vitamins, whereas baking preserves these nutrients better but often results in higher fat absorption due to longer cooking times.

Product Texture and Flavor Development

Extrusion cooking in snack manufacturing produces a unique crispy and porous texture due to rapid moisture evaporation and high shear forces, contrasting with the denser and more uniform crumb structure achieved through traditional baking. Flavor development in extrusion is enhanced by Maillard reactions at high temperatures and short residence times, creating intense toasted and caramelized notes, whereas traditional baking allows gradual flavor development with more subtle, evenly distributed tastes. The choice between these methods significantly impacts the sensory profile and consumer acceptance of snack products.

Energy Efficiency and Process Sustainability

Extrusion cooking offers higher energy efficiency compared to traditional baking by utilizing continuous high-temperature, short-time processes that reduce overall cooking time and fuel consumption. The process also promotes sustainability through lower water usage and the ability to incorporate diverse, nutrient-rich ingredients with minimal waste. Traditional baking, while effective for certain textures, generally demands longer heating periods and greater energy inputs, resulting in a larger carbon footprint and less efficient resource utilization.

Food Safety and Shelf Life Considerations

Extrusion cooking enhances food safety in snack manufacturing by subjecting ingredients to high temperature and pressure, effectively reducing microbial contamination compared to traditional baking methods. The dense, uniform structure produced by extrusion limits moisture migration, significantly extending shelf life through improved resistance to spoilage and staling. In contrast, traditional baking often results in variable moisture content and texture, increasing susceptibility to microbial growth and reducing overall product stability over time.

Innovations and Advances in Snack Manufacturing

Extrusion cooking in snack manufacturing offers rapid processing times and precise control over texture and shape, enabling the production of novel, nutritious snacks with enhanced functional properties. Innovations such as twin-screw extruders and real-time monitoring systems improve ingredient blending and reduce energy consumption compared to traditional baking methods. Advances in extrusion technology also facilitate the incorporation of alternative proteins and fibers, meeting consumer demands for healthier, sustainable snack options.

Market Trends and Consumer Preferences

Extrusion cooking dominates the snack manufacturing market due to its efficiency in producing diverse shapes and textures, aligning with consumer demand for innovative and convenient snacks. Traditional baking retains appeal among health-conscious consumers seeking clean-label and less-processed options, driving niche market growth. Recent trends show rising preference for gluten-free and protein-enriched extruded snacks, highlighting the industry's shift towards functional and specialty ingredients.

Related Important Terms

Shear-Driven Texturization

Extrusion cooking utilizes high shear forces and rapid temperature changes to create unique textural properties in snacks, resulting in expanded, porous structures distinct from the denser, uniform crumb produced by traditional baking methods. Shear-driven texturization in extrusion enhances fiber alignment and starch gelatinization, enabling the development of innovative snack textures with superior crispiness and reduced moisture content compared to conventional baked products.

Low-Moisture Extrusion

Low-moisture extrusion cooking in snack manufacturing offers precise control over texture and expansion, producing consistently crisp snacks with reduced moisture content compared to traditional baking. This method enhances shelf life and nutrient retention while allowing rapid processing and versatile ingredient incorporation, making it ideal for developing innovative snack products.

Matrix Expansion Index

Extrusion cooking significantly enhances the Matrix Expansion Index (MEI) compared to traditional baking, resulting in snacks with greater porosity and improved textural properties. The high shear and rapid pressure drop in extrusion promote superior starch gelatinization and expansion, optimizing snack volume and crispiness.

Cold Extrusion Processing

Cold extrusion processing in snack manufacturing offers precise control over moisture content and texture compared to traditional baking, resulting in uniform, high-quality products with enhanced nutritional retention. This method reduces energy consumption and processing time, making it a sustainable and efficient alternative for producing diverse snack formulations.

Direct Expansion Snacks

Extrusion cooking produces direct expansion snacks by rapidly heating and pressurizing ingredients to create expanded, porous textures with uniform shape and enhanced shelf life, outperforming traditional baking in efficiency and product consistency. Traditional baking relies on gradual heat transfer and moisture evaporation, resulting in denser textures and longer production times, making extrusion cooking the preferred technology for high-volume, scalable snack manufacturing.

Twin-Screw Extruder Optimization

Twin-screw extruder optimization enhances snack manufacturing by improving product texture, uniformity, and nutritional retention compared to traditional baking methods, which often result in uneven heat distribution and longer processing times. Controlling screw speed, temperature profiles, and feed moisture in twin-screw extrusion ensures precise expansion and ingredient incorporation, leading to consistently high-quality, shelf-stable snacks with increased production efficiency.

Starch Gelatinization Kinetics

Extrusion cooking accelerates starch gelatinization kinetics by applying high temperature, pressure, and shear forces, resulting in uniform starch gelatinization and enhanced texture in snack manufacturing. Traditional baking relies on slower heat transfer, causing uneven gelatinization and longer processing times, which can affect the final product's quality and consistency.

In-line Flavor Injection (Extrusion)

In-line flavor injection during extrusion cooking allows precise and uniform flavor distribution within snacks, enhancing taste intensity and reducing flavor degradation compared to traditional baking methods. This technique optimizes manufacturing efficiency by integrating flavor infusion directly into the process, resulting in consistent product quality and reduced processing times.

Novel Pulsed Electric Field Baking

Extrusion cooking offers high-throughput production and enhanced textural control in snack manufacturing, while traditional baking provides uniform heat distribution and flavor development; novel Pulsed Electric Field (PEF) baking integrates electric pulses to modify dough microstructures, improving product crispness, reducing baking time, and enhancing nutrient retention. PEF technology optimizes thermal efficiency and preserves bioactive compounds, making it a promising innovation for healthier, sustainable snack production compared to conventional methods.

Ingredient Preconditioning (Extrusion vs Baking)

Extrusion cooking involves ingredient preconditioning through high moisture and temperature under shear forces, which gelatinizes starches and denatures proteins rapidly, enhancing texture and nutrient bioavailability in snacks. Traditional baking preconditions ingredients by mixing and resting dough with lower moisture and heat, resulting in slower starch gelatinization and protein denaturation, yielding denser texture and longer production times.

Extrusion cooking vs traditional baking for snack manufacturing Infographic

agridif.com

agridif.com