Cold chain logistics ensure perishable foods maintain optimal freshness by controlling temperature from production to consumption, significantly reducing spoilage and microbial growth. Ambient storage, while cost-effective, poses higher risks of quality degradation due to fluctuating temperatures and extended exposure to harmful environmental factors. Advanced Cold chain technologies enhance food safety and shelf life, making them essential for supply chains handling temperature-sensitive products.

Table of Comparison

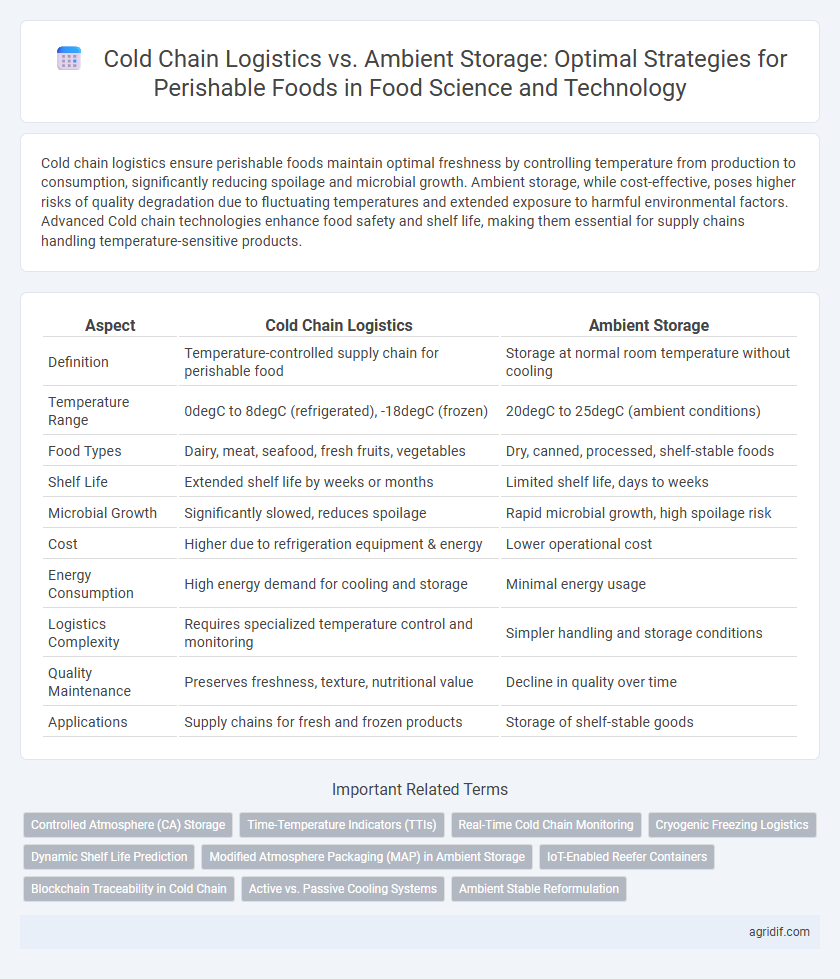

| Aspect | Cold Chain Logistics | Ambient Storage |

|---|---|---|

| Definition | Temperature-controlled supply chain for perishable food | Storage at normal room temperature without cooling |

| Temperature Range | 0degC to 8degC (refrigerated), -18degC (frozen) | 20degC to 25degC (ambient conditions) |

| Food Types | Dairy, meat, seafood, fresh fruits, vegetables | Dry, canned, processed, shelf-stable foods |

| Shelf Life | Extended shelf life by weeks or months | Limited shelf life, days to weeks |

| Microbial Growth | Significantly slowed, reduces spoilage | Rapid microbial growth, high spoilage risk |

| Cost | Higher due to refrigeration equipment & energy | Lower operational cost |

| Energy Consumption | High energy demand for cooling and storage | Minimal energy usage |

| Logistics Complexity | Requires specialized temperature control and monitoring | Simpler handling and storage conditions |

| Quality Maintenance | Preserves freshness, texture, nutritional value | Decline in quality over time |

| Applications | Supply chains for fresh and frozen products | Storage of shelf-stable goods |

Introduction to Cold Chain Logistics in Perishable Food Handling

Cold chain logistics involves the temperature-controlled supply chain process crucial for maintaining the freshness and safety of perishable foods from production to consumption. It employs refrigeration technologies at every stage, including transport, storage, and distribution, to slow microbial growth and enzymatic activity. Effective cold chain management minimizes spoilage and extends shelf life, ensuring compliance with food safety standards.

Overview of Ambient Storage Systems in Agriculture

Ambient storage systems in agriculture maintain perishable foods at natural temperature and humidity conditions without mechanical refrigeration, relying on controlled ventilation, airflow, and moisture regulation to extend shelf life. These systems utilize techniques such as evaporative cooling, root cellars, and modified atmospheres to reduce respiration rates and delay spoilage. Ambient storage offers energy-efficient and cost-effective solutions for preserving fruits, vegetables, and other perishables when cold chain logistics are unavailable or impractical.

Key Differences Between Cold Chain and Ambient Storage

Cold chain logistics maintains perishable foods at controlled temperatures typically between 0degC and 8degC, crucial for preserving freshness, nutrient quality, and shelf life by slowing microbial growth and enzymatic reactions. Ambient storage holds products at room temperature, generally ranging from 15degC to 25degC, suitable for less perishable items but increasing the risk of spoilage and reduced product safety for temperature-sensitive foods. Key differences include temperature control, impact on shelf life where cold chain significantly extends usability, and infrastructure requirements such as refrigeration equipment versus standard warehousing.

Impact on Food Safety and Quality

Cold chain logistics maintains perishable foods at controlled low temperatures from production to consumption, significantly reducing microbial growth and enzymatic activity, which directly enhances food safety and preserves nutritional quality. In contrast, ambient storage exposes perishable foods to fluctuating temperatures and humidity, accelerating spoilage, microbial contamination, and quality degradation. Optimizing cold chain management minimizes foodborne illnesses and extends shelf life, making it essential for maintaining the safety and sensory attributes of temperature-sensitive produce, dairy, and meat products.

Energy and Cost Considerations for Storage Methods

Cold chain logistics require continuous refrigeration, resulting in higher energy consumption and increased operational costs compared to ambient storage methods. Ambient storage reduces energy usage but limits the shelf life and quality of perishable foods, leading to potential economic losses due to spoilage. Optimizing energy-efficient refrigeration technologies within cold chain logistics can balance cost with food safety and product longevity.

Technological Innovations in Cold Chain Logistics

Technological innovations in cold chain logistics for perishable foods include advanced temperature monitoring systems, such as IoT-enabled sensors that provide real-time data to ensure consistent cold storage conditions. Automated cold storage facilities use AI-driven algorithms to optimize inventory management and reduce spoilage rates. These advancements significantly enhance food safety and extend shelf life compared to traditional ambient storage methods.

Environmental Implications of Cold vs Ambient Storage

Cold chain logistics for perishable foods results in significantly higher energy consumption and greenhouse gas emissions compared to ambient storage due to continuous refrigeration requirements. Ambient storage reduces carbon footprint but increases the risk of food spoilage, leading to potential food waste that also contributes to environmental degradation. Optimizing cold chain efficiency and integrating renewable energy sources can mitigate environmental impacts while preserving food quality.

Case Studies: Success Stories and Failures

Case studies consistently demonstrate that cold chain logistics significantly extend the shelf life and maintain the quality of perishable foods such as dairy, seafood, and fresh produce, reducing microbial growth and enzymatic activity. Successful cold chain implementations in multinational retail chains show decreased spoilage rates and higher consumer satisfaction, whereas failures often result from inadequate temperature monitoring and interrupted cooling cycles, leading to food safety hazards and economic losses. In contrast, ambient storage is viable only for specific low-moisture or shelf-stable perishable items, with case studies indicating a higher risk of quality degradation and shortened usability for most highly perishable commodities.

Regulatory Standards and Compliance in Food Storage

Cold chain logistics for perishable foods is stringently regulated by agencies such as the FDA and USDA, requiring precise temperature control and real-time monitoring to prevent microbial growth and ensure food safety. Ambient storage, governed by less stringent standards, mandates strict limits on humidity and packaging to extend shelf life without refrigeration, often regulated by Codex Alimentarius and local food safety authorities. Compliance with these regulatory standards is critical to minimize food spoilage, reduce economic losses, and protect public health across the food supply chain.

Future Trends in Perishable Food Storage Solutions

Emerging trends in perishable food storage emphasize advancements in cold chain logistics incorporating IoT sensors and AI-driven temperature monitoring to enhance real-time tracking and reduce spoilage rates. Innovations in phase change materials and vacuum insulation panels are developing ambient storage solutions that extend shelf life without continuous refrigeration. Integration of blockchain technology ensures transparency and traceability across the supply chain, optimizing freshness preservation and compliance with food safety standards.

Related Important Terms

Controlled Atmosphere (CA) Storage

Controlled Atmosphere (CA) Storage effectively slows down metabolic processes in perishable foods by regulating oxygen, carbon dioxide, and humidity levels, significantly extending shelf life compared to ambient storage methods. This advanced cold chain logistics technique reduces spoilage and maintains quality, ensuring optimal freshness and safety during transportation and long-term storage.

Time-Temperature Indicators (TTIs)

Time-Temperature Indicators (TTIs) provide critical real-time data on the cumulative thermal exposure of perishable foods, enabling precise monitoring of cold chain logistics to maintain product quality and safety. In contrast, ambient storage lacks such dynamic tracking, increasing the risk of spoilage and reducing shelf life due to uncontrolled temperature fluctuations.

Real-Time Cold Chain Monitoring

Real-time cold chain monitoring leverages IoT sensors and RFID technology to ensure optimal temperature control during the transportation of perishable foods, significantly reducing spoilage and extending shelf life compared to ambient storage methods. Continuous data tracking enables proactive intervention against temperature deviations, preserving food quality and safety throughout the supply chain.

Cryogenic Freezing Logistics

Cryogenic freezing logistics employs ultra-low temperatures using liquid nitrogen or carbon dioxide to rapidly freeze perishable foods, preserving cellular structure and extending shelf life significantly compared to ambient storage. This method ensures superior quality retention and reduces microbial growth during transportation and storage within the cold chain, crucial for maintaining food safety and freshness.

Dynamic Shelf Life Prediction

Dynamic shelf life prediction integrates real-time temperature data from cold chain logistics to accurately estimate the remaining usability of perishable foods, enhancing inventory management and reducing waste. In contrast, ambient storage lacks precise monitoring, leading to conservative shelf life estimates that do not adapt to fluctuating environmental conditions.

Modified Atmosphere Packaging (MAP) in Ambient Storage

Modified Atmosphere Packaging (MAP) in ambient storage extends the shelf life of perishable foods by altering the gas composition surrounding the product, reducing oxygen levels and increasing carbon dioxide or nitrogen to inhibit microbial growth and enzymatic spoilage. This technology offers a cost-effective alternative to cold chain logistics by maintaining food quality and safety at room temperature, crucial for distribution in regions with limited refrigeration infrastructure.

IoT-Enabled Reefer Containers

IoT-enabled reefer containers enhance cold chain logistics by providing real-time temperature monitoring, humidity control, and predictive maintenance, significantly reducing spoilage rates in perishable foods compared to ambient storage. These smart containers integrate sensors and wireless communication to ensure optimal storage conditions, improving food safety, traceability, and shelf-life during transportation and storage.

Blockchain Traceability in Cold Chain

Blockchain traceability enhances cold chain logistics for perishable foods by providing real-time monitoring and immutable records of temperature, humidity, and handling conditions, ensuring product freshness and safety. This technology minimizes risks of spoilage and contamination compared to ambient storage by enabling transparent, tamper-proof data sharing among stakeholders throughout the supply chain.

Active vs. Passive Cooling Systems

Active cooling systems in cold chain logistics utilize mechanical refrigeration to precisely control temperature and humidity, ensuring optimal preservation of perishable foods by slowing microbial growth and enzymatic activity. Passive cooling systems rely on insulation and phase change materials to maintain low temperatures without continuous energy use, offering cost-effective solutions but with less precise temperature control compared to active systems.

Ambient Stable Reformulation

Ambient stable reformulation extends the shelf life of perishable foods by modifying ingredients and processing techniques to maintain product quality without refrigeration. This approach reduces reliance on cold chain logistics, lowering transportation costs and energy consumption while ensuring food safety and sensory attributes.

Cold Chain Logistics vs Ambient Storage for Perishable Foods Infographic

agridif.com

agridif.com