Wet milling in cereal processing involves soaking grains in water to separate their components, enhancing starch extraction and improving product quality. Dry milling grinds grains without moisture, preserving nutritional content but often resulting in coarser textures and lower starch yields. Choosing between wet and dry milling depends on the desired end-product characteristics and processing efficiency.

Table of Comparison

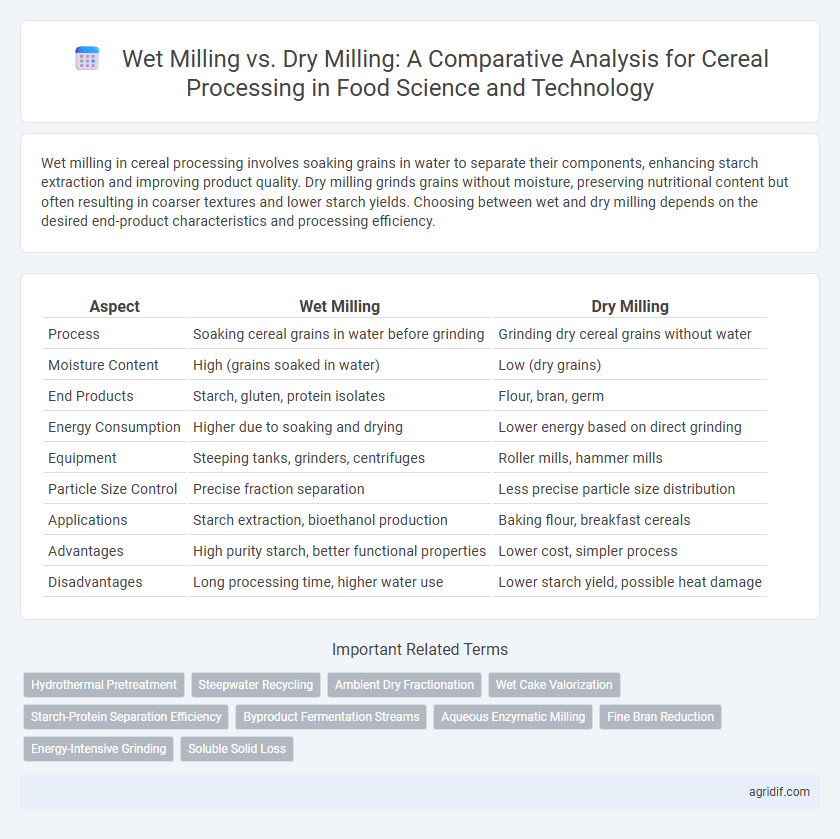

| Aspect | Wet Milling | Dry Milling |

|---|---|---|

| Process | Soaking cereal grains in water before grinding | Grinding dry cereal grains without water |

| Moisture Content | High (grains soaked in water) | Low (dry grains) |

| End Products | Starch, gluten, protein isolates | Flour, bran, germ |

| Energy Consumption | Higher due to soaking and drying | Lower energy based on direct grinding |

| Equipment | Steeping tanks, grinders, centrifuges | Roller mills, hammer mills |

| Particle Size Control | Precise fraction separation | Less precise particle size distribution |

| Applications | Starch extraction, bioethanol production | Baking flour, breakfast cereals |

| Advantages | High purity starch, better functional properties | Lower cost, simpler process |

| Disadvantages | Long processing time, higher water use | Lower starch yield, possible heat damage |

Introduction to Cereal Milling: Wet vs Dry Techniques

Wet milling involves soaking cereals in water to soften kernels for easier separation of starch, protein, and fiber, resulting in higher purity and yield of components like starch and gluten. Dry milling uses mechanical grinding without moisture, maintaining native cereal properties but producing coarser fractions and potentially more heat-sensitive nutrient loss. Selection between wet and dry milling depends on desired product quality, processing efficiency, and end-use applications in food science and cereal technology.

Fundamental Principles of Wet Milling

Wet milling in cereal processing involves soaking grains in water to soften the kernels, allowing for easier separation of starch, protein, fiber, and oil components. This method utilizes enzymatic activity and controlled temperature to enhance the breakdown of cellulose and starch granules, leading to higher purity and yield of extracted ingredients. Wet milling is essential for producing fine-textured flours and specialized derivatives used in food formulations and industrial applications.

Key Processes in Dry Milling

Dry milling in cereal processing involves grinding grains into flour without soaking, preserving the bran, germ, and endosperm as separate fractions. Key processes include cleaning to remove impurities, tempering to adjust moisture content for easier bran separation, and grinding using roller mills that produce refined flour with controlled particle size. Techniques such as sifting and air classification follow grinding to separate bran and germ from finely milled endosperm, optimizing flour quality for baking or other food applications.

Comparison of Yield and Product Quality

Wet milling of cereals typically results in higher yield and superior product quality due to the separation of components such as starch, protein, and fiber under controlled moisture conditions. Dry milling often leads to lower extraction rates and increased damaged starch content, negatively impacting flour functionality and baking performance. The controlled hydration in wet milling also enhances the purity and functional properties of the end products, making it preferable for applications demanding high-quality starch and gluten fractions.

Impact on Nutritional Value of Cereals

Wet milling preserves higher levels of essential nutrients such as vitamins, amino acids, and minerals by minimizing heat exposure during cereal processing, which helps maintain the integrity of sensitive compounds like thiamine and lysine. Dry milling often leads to nutrient loss due to abrasive forces and higher processing temperatures that degrade heat-sensitive vitamins and reduce protein quality. Selecting wet milling over dry milling can significantly enhance the nutritional profile of cereal products, improving consumer health benefits.

Equipment and Technology Requirements

Wet milling of cereals requires specialized equipment such as soaking tanks, grinders, and separators designed to handle high moisture content and facilitate starch extraction, whereas dry milling relies on hammer mills, roller mills, and sifters optimized for particle size reduction without moisture addition. Wet milling technology involves complex processes including soaking, grinding, and centrifugation, demanding robust materials resistant to corrosion and moisture, while dry milling equipment emphasizes high-speed milling and precision screening to maintain grain integrity. Investment in wet milling systems is higher due to energy consumption and maintenance, but it yields higher purity starch, whereas dry milling is more cost-effective, faster, and suited for producing flakes, flours, and grits with consistent texture.

Energy Consumption and Efficiency

Wet milling in cereal processing consumes significantly more energy due to the additional drying stages required post-milling, whereas dry milling offers higher energy efficiency by eliminating these steps. The moisture content in wet milling necessitates extensive water handling and drying, impacting overall process energy use. Dry milling, despite lower starch extraction yields compared to wet milling, provides a more cost-effective and energy-saving alternative for large-scale cereal processing operations.

Environmental Implications of Milling Methods

Wet milling consumes significantly more water and generates large volumes of wastewater, raising concerns about water resource depletion and pollution from organic matter. Dry milling offers lower water usage and minimal wastewater production, reducing environmental impact but may increase energy consumption due to higher processing temperatures. Life cycle assessments highlight that dry milling's reduced water footprint often outweighs its energy demands, making it a more sustainable option in cereal processing.

Applications in Food Product Development

Wet milling enables efficient extraction of starch, proteins, and oils from cereals, making it ideal for producing refined ingredients like glucose syrups and ethanol. Dry milling is preferred for whole grain processing to retain fiber and nutrients, commonly used in breakfast cereals and snack foods. Food product development leverages wet milling for ingredient purity and dry milling for texture and nutritional integrity, depending on the desired end-product characteristics.

Future Trends in Cereal Milling Technologies

Future trends in cereal milling technologies emphasize increased automation and integration of sensor-based monitoring systems to optimize both wet milling and dry milling processes. Advances in precision milling equipment aim to enhance extraction efficiency, reduce energy consumption, and minimize nutrient loss while maintaining product quality. Emerging innovations also include enzyme-assisted milling and novel moisture control techniques to improve yield and functional properties of cereal-based ingredients.

Related Important Terms

Hydrothermal Pretreatment

Hydrothermal pretreatment in wet milling enhances the gelatinization of starch and softens cereal kernels, improving the efficiency of starch extraction and enzymatic hydrolysis compared to dry milling, which lacks moisture and heat interaction. This pretreatment optimizes particle size reduction and increases fermentable sugar yields, crucial for bioethanol production and food ingredient applications.

Steepwater Recycling

Wet milling in cereal processing produces steepwater rich in nutrients like amino acids, peptides, and minerals, enabling efficient steepwater recycling to reduce water usage and environmental impact. Dry milling lacks a steepwater phase, making water conservation challenging and limiting opportunities for nutrient recovery compared to wet milling processes.

Ambient Dry Fractionation

Ambient dry fractionation in cereal processing offers energy-efficient particle separation without the moisture addition required in wet milling, preserving heat-sensitive nutrients and reducing drying costs. Dry milling enables targeted separation of bran, germ, and endosperm fractions, enhancing product functionality and nutritional value while minimizing environmental impact.

Wet Cake Valorization

Wet milling enhances cereal processing by producing wet cake rich in starch, gluten, and fiber, which serves as a valuable raw material for bioethanol, animal feed, and biodegradable film production. This valorization approach maximizes resource efficiency and supports sustainable food technology innovations.

Starch-Protein Separation Efficiency

Wet milling achieves higher starch-protein separation efficiency in cereal processing by leveraging water-based techniques that swell and separate starch granules from protein matrices more effectively than dry milling methods. Dry milling often results in lower purity fractions due to mechanical grinding that causes starch and protein to remain closely associated, reducing separation precision.

Byproduct Fermentation Streams

Wet milling in cereal processing generates carbohydrate-rich byproduct streams ideal for fermentation into biofuels and biochemicals, enhancing resource utilization and economic value. Dry milling produces less fermentable byproducts with higher fiber content, limiting its efficiency for microbial fermentation applications in food science and technology.

Aqueous Enzymatic Milling

Aqueous enzymatic milling in cereal processing enhances starch and protein extraction by utilizing specific enzymes to break down cell walls in a wet milling environment, improving yield and functionality compared to traditional dry milling methods. This technique reduces energy consumption and preserves nutritional quality, making it a preferred approach for producing high-value cereal-based products.

Fine Bran Reduction

Wet milling in cereal processing significantly enhances fine bran reduction by utilizing water to soften bran layers, enabling more efficient separation and finer particle size compared to dry milling. The wet milling process also improves starch quality and yield, making it the preferred method for producing refined cereal products with lower bran content.

Energy-Intensive Grinding

Wet milling in cereal processing uses water to soften grains, significantly reducing the energy required for grinding compared to dry milling, which demands higher energy consumption due to the hardness and brittleness of dry grains. Energy-intensive grinding in dry milling leads to higher operational costs and increased wear on equipment, making wet milling more efficient for producing finer and more uniform cereal flour.

Soluble Solid Loss

Wet milling of cereals typically results in lower soluble solid loss compared to dry milling due to its aqueous environment which minimizes nutrient leaching and preserves starch granules. Dry milling often causes higher soluble solid loss as mechanical forces generate heat and friction, leading to increased solubilization and degradation of valuable components like proteins and sugars.

Wet Milling vs Dry Milling for Cereal Processing Infographic

agridif.com

agridif.com