Pasteurization and sterilization are critical methods used in milk processing to ensure safety and extend shelf life. Pasteurization involves heating milk to a specific temperature below boiling to eliminate pathogenic bacteria while preserving taste and nutritional value, whereas sterilization applies higher temperatures to destroy all microorganisms, resulting in a longer shelf life but potential changes in flavor and nutrient content. Choosing between these techniques depends on the desired product quality, storage conditions, and consumer preferences in the dairy industry.

Table of Comparison

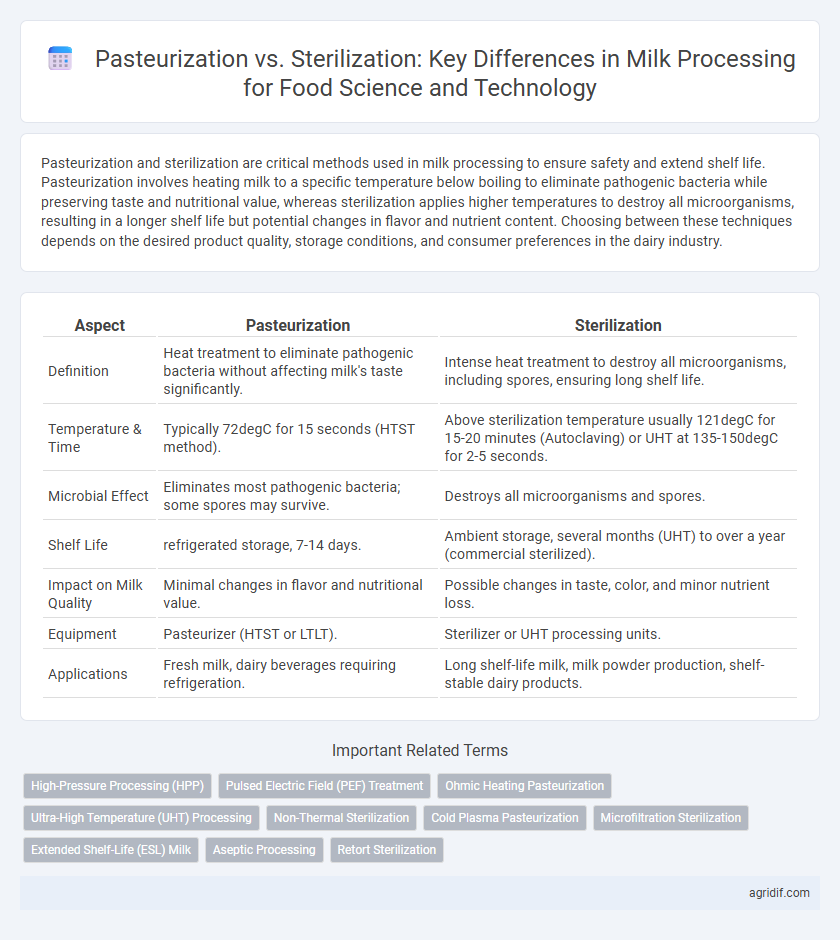

| Aspect | Pasteurization | Sterilization |

|---|---|---|

| Definition | Heat treatment to eliminate pathogenic bacteria without affecting milk's taste significantly. | Intense heat treatment to destroy all microorganisms, including spores, ensuring long shelf life. |

| Temperature & Time | Typically 72degC for 15 seconds (HTST method). | Above sterilization temperature usually 121degC for 15-20 minutes (Autoclaving) or UHT at 135-150degC for 2-5 seconds. |

| Microbial Effect | Eliminates most pathogenic bacteria; some spores may survive. | Destroys all microorganisms and spores. |

| Shelf Life | refrigerated storage, 7-14 days. | Ambient storage, several months (UHT) to over a year (commercial sterilized). |

| Impact on Milk Quality | Minimal changes in flavor and nutritional value. | Possible changes in taste, color, and minor nutrient loss. |

| Equipment | Pasteurizer (HTST or LTLT). | Sterilizer or UHT processing units. |

| Applications | Fresh milk, dairy beverages requiring refrigeration. | Long shelf-life milk, milk powder production, shelf-stable dairy products. |

Introduction to Milk Processing Methods

Milk processing methods such as pasteurization and sterilization are essential for ensuring safety and extending shelf life by eliminating harmful microorganisms. Pasteurization typically heats milk to 72degC for 15 seconds to reduce pathogens while preserving nutritional quality and flavor. Sterilization involves higher temperatures, usually above 121degC for 15-20 minutes, resulting in a longer shelf life but with potential changes in taste and nutrient content.

Defining Pasteurization in Dairy Science

Pasteurization in dairy science is a heat treatment process designed to eliminate pathogenic microorganisms in milk without significantly affecting its nutritional value or flavor. Typically conducted at temperatures between 72degC and 75degC for 15 to 30 seconds, pasteurization ensures milk safety and extends shelf life while preserving essential proteins and vitamins. This process differs from sterilization, which uses higher temperatures to achieve complete microbial destruction, often resulting in altered taste and nutritional changes.

Sterilization: A Comprehensive Overview

Sterilization in milk processing employs ultra-high temperatures (UHT) above 135degC for a few seconds to eliminate all microorganisms and spores, ensuring extended shelf life without refrigeration. Unlike pasteurization, sterilization results in a more pronounced change in taste and nutritional content due to intense heat treatment. Industrial applications favor sterilization for producing shelf-stable milk products such as UHT milk, evaporated milk, and milk powders with minimal microbial risk.

Pasteurization Techniques and Parameters

Pasteurization techniques for milk processing primarily involve heating milk to specific temperatures for set durations to eliminate pathogenic microorganisms while preserving nutritional and sensory qualities. The most common parameters include High-Temperature Short Time (HTST) pasteurization at 72degC for 15 seconds and Low-Temperature Long Time (LTLT) pasteurization at 63degC for 30 minutes. Precise control of these thermal parameters ensures effective microbial inactivation and extends milk shelf life without compromising taste or nutrient content.

Sterilization Technologies Used in Milk

Sterilization technologies in milk processing include ultra-high temperature (UHT) treatment, which heats milk to 135-150degC for 2-5 seconds to achieve commercial sterility and extend shelf life without refrigeration. Another method, aseptic processing, combines sterilization of both milk and packaging in a sterile environment to prevent contamination. These sterilization techniques effectively eliminate pathogenic microorganisms and spores, ensuring milk safety and stability for long-term storage.

Microbial Reduction: Pasteurization vs Sterilization

Pasteurization reduces microbial load in milk by targeting pathogenic and spoilage microorganisms through mild heat treatment, typically at 72degC for 15 seconds, preserving nutritional and sensory qualities. Sterilization eliminates all forms of microbial life, including spores, via high-temperature processing above 121degC for several seconds, ensuring extended shelf life but potentially altering milk's flavor and nutrient profile. Microbial reduction achieved by sterilization is more comprehensive than pasteurization, making sterilized milk shelf-stable without refrigeration.

Impact on Milk Nutritional Quality

Pasteurization preserves most milk nutrients, maintaining vitamins B2, B12, and calcium bioavailability while effectively reducing pathogenic microorganisms. Sterilization, through ultra-high temperature processing, significantly diminishes heat-sensitive vitamins such as vitamin C and folate, resulting in a slight decrease in overall nutritional quality. Microbial safety is enhanced in sterilized milk, but nutrient retention is better optimized in pasteurized milk for balanced nutritional benefits.

Shelf Life Comparison of Pasteurized and Sterilized Milk

Pasteurization extends milk's shelf life to approximately 10-21 days under refrigeration by eliminating most pathogenic bacteria while preserving nutritional quality. Sterilization, particularly ultra-high temperature (UHT) processing, allows milk to remain shelf-stable for 6-9 months without refrigeration by destroying all microorganisms and spores. The trade-off between these methods involves balancing longer shelf life of sterilized milk against the fresher taste and higher nutrient retention in pasteurized milk.

Consumer Preferences and Market Trends

Consumer preferences in milk processing increasingly favor pasteurization due to its ability to retain more natural flavor and nutrients compared to sterilization, which often alters taste and reduces some vitamins. Market trends indicate a growing demand for minimally processed milk products with extended shelf life, driving innovation in high-temperature short-time (HTST) pasteurization techniques. Sterilized milk maintains longer shelf stability ideal for regions lacking consistent refrigeration, but consumer demand leans toward fresh-tasting pasteurized options in urban and health-conscious markets.

Regulatory Standards and Safety Considerations

Pasteurization of milk is regulated under standards such as the Pasteurized Milk Ordinance (PMO) in the United States, requiring a minimum temperature of 72degC for 15 seconds to ensure the inactivation of pathogenic microorganisms while preserving nutritional quality. Sterilization, often achieved through Ultra-High Temperature (UHT) processing at approximately 135degC for 2-5 seconds, meets stricter safety criteria by eliminating all microbial life, enabling extended shelf life without refrigeration. Both methods comply with Codex Alimentarius guidelines, but pasteurization mandates continuous refrigeration post-processing whereas sterilized milk prioritizes commercial sterility and global distribution safety.

Related Important Terms

High-Pressure Processing (HPP)

High-Pressure Processing (HPP) enhances milk safety by inactivating pathogens at low temperatures, preserving nutritional and sensory qualities better than traditional pasteurization or sterilization methods. Unlike thermal treatments, HPP maintains vitamin content and flavor profiles while extending shelf life through microbial reduction at pressures typically between 400 and 600 MPa.

Pulsed Electric Field (PEF) Treatment

Pulsed Electric Field (PEF) treatment offers a non-thermal alternative to traditional pasteurization and sterilization methods for milk processing, effectively inactivating microorganisms while preserving sensory and nutritional qualities. This technology applies short bursts of high voltage to disrupt microbial cell membranes, ensuring microbial safety with minimal impact on milk's flavor, vitamins, and proteins.

Ohmic Heating Pasteurization

Ohmic heating pasteurization in milk processing uses electrical current passed through milk to rapidly and uniformly raise temperature, preserving nutrients and flavor better than conventional pasteurization or sterilization methods. This technique offers enhanced microbial inactivation while minimizing thermal damage and energy consumption compared to traditional thermal sterilization.

Ultra-High Temperature (UHT) Processing

Ultra-High Temperature (UHT) processing heats milk to 135-150degC for 2-5 seconds, achieving commercial sterility and extending shelf life without refrigeration. This method contrasts with pasteurization, which uses lower temperatures (usually 72degC for 15 seconds) to reduce pathogenic bacteria but requires cold storage and results in shorter shelf life.

Non-Thermal Sterilization

Non-thermal sterilization techniques such as high-pressure processing (HPP) and pulsed electric fields (PEF) in milk processing inactivate pathogenic microorganisms while preserving nutritional and sensory qualities better than traditional thermal methods like pasteurization or sterilization. These advanced methods extend shelf life and ensure safety without the detrimental effects of heat, making them favorable for maintaining milk's functional properties and bioactive compounds.

Cold Plasma Pasteurization

Cold plasma pasteurization offers a non-thermal alternative to traditional milk processing techniques by inactivating pathogens through reactive species without compromising nutritional quality. Unlike conventional sterilization, this innovative method preserves milk's sensory properties while achieving microbial safety, making it a promising technology in food science and technology.

Microfiltration Sterilization

Microfiltration sterilization in milk processing utilizes membrane filters to remove microorganisms and spores, preserving the milk's natural flavor and nutritional content more effectively than traditional thermal sterilization methods. This technology extends shelf life by targeting pathogenic and spoilage microbes while minimizing heat-induced changes, offering a high-quality alternative to pasteurization and conventional sterilization.

Extended Shelf-Life (ESL) Milk

Pasteurization of milk involves heating to 72degC for 15 seconds, reducing pathogenic bacteria while preserving most nutrients and flavor, resulting in a short shelf-life of 7-10 days under refrigeration; sterilization uses higher temperatures above 135degC for a few seconds, eliminating all microorganisms and extending shelf-life up to several months at ambient temperature but may cause nutrient loss and flavor changes. Extended Shelf-Life (ESL) milk combines microfiltration and low-temperature pasteurization, enhancing bacterial removal and enzyme inactivation to achieve shelf stability of 21-30 days under refrigeration without the severe sensory degradation seen in sterilized milk.

Aseptic Processing

Aseptic processing combines high-temperature sterilization with sterile packaging to extend milk shelf life without refrigeration, preserving taste and nutritional quality better than traditional pasteurization or sterilization methods. This technique involves rapid heating to ultra-high temperatures (135-150degC) for a few seconds, effectively eliminating all microorganisms while maintaining milk's sensory and functional properties.

Retort Sterilization

Retort sterilization in milk processing involves heating milk in sealed containers at temperatures above 121degC to achieve commercial sterility, effectively eliminating all microbial life and spores. This method extends shelf life significantly compared to pasteurization, which uses lower temperatures (typically 72degC for 15 seconds) and mainly targets pathogenic microorganisms without sterilizing the product.

Pasteurization vs Sterilization for Milk Processing Infographic

agridif.com

agridif.com