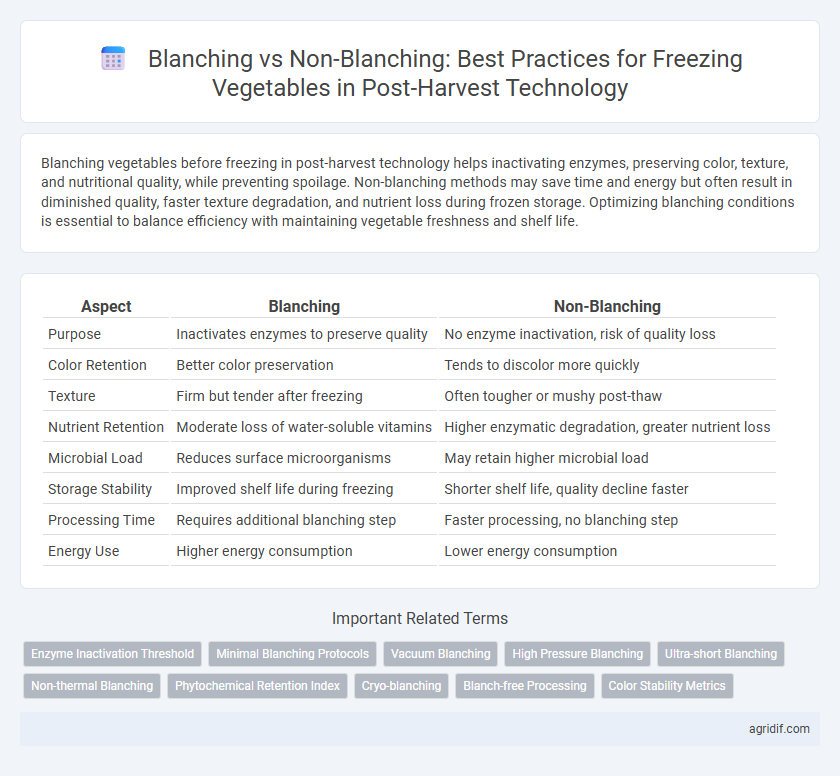

Blanching vegetables before freezing in post-harvest technology helps inactivating enzymes, preserving color, texture, and nutritional quality, while preventing spoilage. Non-blanching methods may save time and energy but often result in diminished quality, faster texture degradation, and nutrient loss during frozen storage. Optimizing blanching conditions is essential to balance efficiency with maintaining vegetable freshness and shelf life.

Table of Comparison

| Aspect | Blanching | Non-Blanching |

|---|---|---|

| Purpose | Inactivates enzymes to preserve quality | No enzyme inactivation, risk of quality loss |

| Color Retention | Better color preservation | Tends to discolor more quickly |

| Texture | Firm but tender after freezing | Often tougher or mushy post-thaw |

| Nutrient Retention | Moderate loss of water-soluble vitamins | Higher enzymatic degradation, greater nutrient loss |

| Microbial Load | Reduces surface microorganisms | May retain higher microbial load |

| Storage Stability | Improved shelf life during freezing | Shorter shelf life, quality decline faster |

| Processing Time | Requires additional blanching step | Faster processing, no blanching step |

| Energy Use | Higher energy consumption | Lower energy consumption |

Introduction to Vegetable Freezing Methods

Vegetable freezing methods include blanching and non-blanching techniques, each impacting quality and shelf life differently. Blanching involves brief exposure to hot water or steam, inactivating enzymes that cause spoilage and preserving color, texture, and nutrients during freezing. Non-blanching freezing skips this step, leading to faster processing but potentially compromising vegetable quality due to enzyme activity and textural changes.

What is Blanching? Key Principles Explained

Blanching is a heat treatment process involving brief exposure of vegetables to boiling water or steam, which inactivates enzymes responsible for quality deterioration during freezing. This step preserves color, texture, and nutritional value by halting enzymatic activity and reducing microbial load. Non-blanching freezing risks enzymatic browning, texture degradation, and nutrient loss, making blanching essential for maintaining frozen vegetable quality.

Non-Blanching: A Simplified Freezing Approach

Non-blanching in vegetable freezing eliminates the thermal pretreatment step, preserving more nutrients and natural flavors compared to blanching. This simplified freezing approach reduces processing time and energy consumption while maintaining acceptable quality in certain vegetables with low enzymatic activity. Studies indicate that non-blanching is viable for spinach, kale, and green beans, where minimal enzymatic browning and texture degradation occur during frozen storage.

Impact of Blanching on Vegetable Color and Texture

Blanching significantly preserves vegetable color by inactivating enzymes responsible for browning and color degradation during freezing. This process helps maintain a vibrant appearance and prevents texture softening that often occurs in non-blanched vegetables. As a result, blanching is crucial for retaining the sensory quality and market value of frozen vegetables.

Nutrient Retention: Blanching vs Non-Blanching

Blanching vegetables before freezing inactivates enzymes that cause nutrient degradation, significantly preserving vitamin C and chlorophyll content compared to non-blanched vegetables. Non-blanching often results in greater nutrient loss, especially of water-soluble vitamins, due to continued enzymatic activity during storage. Studies show that blanching optimizes nutrient retention, extending shelf-life and maintaining quality in frozen vegetables.

Microbial Safety and Shelf Life Considerations

Blanching vegetables before freezing effectively reduces microbial load by inactivating enzymes and killing surface bacteria, thereby enhancing microbial safety and extending shelf life. Non-blanching methods may retain more nutrients but increase the risk of microbial growth and enzymatic activity, leading to shorter shelf life and potential food safety concerns. Proper blanching parameters such as temperature and time are critical to optimize microbial control while preserving vegetable quality.

Flavor and Aroma Differences After Freezing

Blanching vegetables before freezing helps preserve flavor and aroma by inactivating enzymes that cause off-flavors and spoilage, maintaining a fresher taste profile. Non-blanched vegetables often experience diminished flavor intensity and development of undesirable aromas due to enzymatic activity during frozen storage. Research indicates that blanching minimizes volatile compound degradation, resulting in superior sensory quality after thawing.

Time, Energy, and Cost Implications of Each Method

Blanching vegetables before freezing inactivates enzymes, preserving color, texture, and nutritional quality, but requires additional time and energy for heating and cooling processes, increasing operational costs. Non-blanching methods save time and reduce energy consumption, lowering overall expenses, yet risk enzymatic degradation that can lead to quality loss and shorter shelf life during storage. Choosing between blanching and non-blanching depends on balancing upfront processing costs against long-term product quality and waste reduction in the frozen vegetable supply chain.

Suitability of Blanching for Different Vegetable Types

Blanching is especially suitable for vegetables with high enzyme activity such as green beans, broccoli, and carrots, as it effectively inactivates enzymes that cause spoilage and color degradation during freezing. Leafy greens and tender vegetables benefit significantly from blanching due to improved texture and retention of nutritional quality. However, root vegetables and mushrooms often require minimal or no blanching to preserve their firmness and natural flavor during frozen storage.

Best Practices for Home and Commercial Freezing

Blanching vegetables before freezing inactivates enzymes that cause loss of flavor, color, and texture, ensuring prolonged shelf life and nutrient retention, which is essential for both home and commercial freezing. Non-blanching methods may lead to inferior quality due to enzymatic activity, but can be suitable for quick freezing and immediate consumption where texture changes are minimal. For commercial freezing, standardized blanching times and temperatures are critical to maintain product consistency and safety, while home freezing benefits from simple blanching techniques like boiling water or steam to optimize vegetable preservation.

Related Important Terms

Enzyme Inactivation Threshold

Blanching vegetables before freezing significantly raises the enzyme inactivation threshold, effectively halting enzymatic activity that causes spoilage and quality degradation, whereas non-blanching preserves a lower inactivation threshold, leading to faster enzymatic reactions post-freezing. This difference critically impacts shelf life and texture, with blanching preventing discoloration and nutrient loss by stabilizing enzyme activity at temperatures typically above 70degC.

Minimal Blanching Protocols

Minimal blanching protocols for vegetable freezing enhance enzyme inactivation while preserving nutritional value and texture, reducing the negative impacts of over-processing. These optimized methods involve short-time heat treatments at precise temperatures to maintain color, flavor, and shelf life without compromising the vegetable's quality.

Vacuum Blanching

Vacuum blanching enhances vegetable freezing by reducing enzymatic activity and preserving color, flavor, and texture more effectively than non-blanching or traditional blanching methods. This technique employs low pressure to remove air from vegetable tissues, improving heat transfer and minimizing nutrient loss during the freezing process.

High Pressure Blanching

High Pressure Blanching (HPB) preserves the nutritional quality and sensory attributes of vegetables better than traditional blanching by inactivating enzymes at lower temperatures, reducing nutrient loss and texture degradation during freezing. Non-blanching methods often result in higher enzymatic activity and faster quality deterioration, making HPB a superior technology in post-harvest vegetable preservation.

Ultra-short Blanching

Ultra-short blanching significantly enhances the preservation of color, texture, and nutrient retention in frozen vegetables compared to non-blanching methods by rapidly inactivating enzymes responsible for spoilage. This technique, typically lasting 30 to 90 seconds at high temperatures, optimizes freezing quality and extends shelf life while minimizing nutrient losses often associated with conventional blanching.

Non-thermal Blanching

Non-thermal blanching methods, such as high-pressure processing (HPP) and pulsed electric fields (PEF), preserve the nutritional quality and texture of vegetables more effectively than traditional thermal blanching during freezing. These innovative techniques inhibit enzymatic activity without heat application, reducing nutrient loss and improving shelf life in frozen vegetables.

Phytochemical Retention Index

Blanching vegetables before freezing significantly influences the Phytochemical Retention Index by inactivating enzymes that cause nutrient degradation, thereby preserving higher levels of vitamins, antioxidants, and polyphenols compared to non-blanched samples. Non-blanching methods often result in lower phytochemical retention due to ongoing enzymatic activity during freezing and storage, leading to diminished nutritional quality and bioactive compound stability.

Cryo-blanching

Cryo-blanching, a cutting-edge technique in post-harvest technology, involves exposing vegetables to extremely low temperatures using liquid nitrogen or carbon dioxide, effectively inactivating enzymes that cause spoilage while preserving texture, color, and nutritional quality better than traditional hot water blanching. This method enhances freezing efficiency by minimizing enzymatic degradation, reducing surface moisture, and maintaining higher antioxidant levels, which ultimately extends shelf life and improves the sensory attributes of frozen vegetables.

Blanch-free Processing

Blanch-free processing for vegetable freezing preserves higher levels of nutrients, color, and texture by eliminating the heat treatment step that typically deactivates enzymes but can cause nutrient loss. Innovative technologies such as high-pressure processing and pulsed electric fields maintain enzyme inactivity without blanching, improving shelf life and sensory qualities in frozen vegetables.

Color Stability Metrics

Blanching vegetables before freezing enhances color stability by inactivating enzymes like polyphenol oxidase and peroxidase, which prevents enzymatic browning and pigment degradation. Non-blanching methods often result in increased chlorophyll degradation and higher metrics of color loss, including elevated L* (lightness) and a* (red-green) value shifts, indicating diminished visual quality during storage.

Blanching vs non-blanching for vegetable freezing Infographic

agridif.com

agridif.com