Vacuum packing removes air from the package to inhibit microbial growth and oxidation, extending the shelf life of fresh produce while maintaining texture and flavor. Modified Atmosphere Packaging (MAP) adjusts the gas composition inside the package, optimizing oxygen, carbon dioxide, and nitrogen levels to slow respiration and spoilage. Both methods improve post-harvest quality, but MAP is often preferred for sensitive produce due to its ability to tailor the atmosphere to specific crop needs.

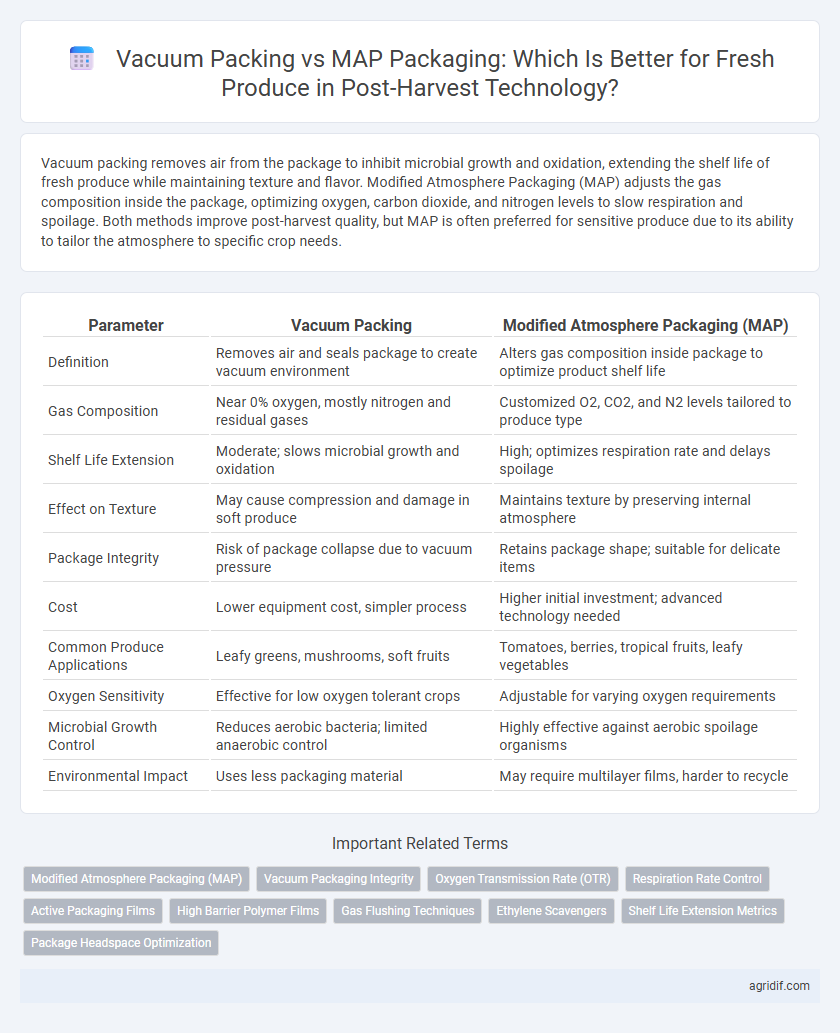

Table of Comparison

| Parameter | Vacuum Packing | Modified Atmosphere Packaging (MAP) |

|---|---|---|

| Definition | Removes air and seals package to create vacuum environment | Alters gas composition inside package to optimize product shelf life |

| Gas Composition | Near 0% oxygen, mostly nitrogen and residual gases | Customized O2, CO2, and N2 levels tailored to produce type |

| Shelf Life Extension | Moderate; slows microbial growth and oxidation | High; optimizes respiration rate and delays spoilage |

| Effect on Texture | May cause compression and damage in soft produce | Maintains texture by preserving internal atmosphere |

| Package Integrity | Risk of package collapse due to vacuum pressure | Retains package shape; suitable for delicate items |

| Cost | Lower equipment cost, simpler process | Higher initial investment; advanced technology needed |

| Common Produce Applications | Leafy greens, mushrooms, soft fruits | Tomatoes, berries, tropical fruits, leafy vegetables |

| Oxygen Sensitivity | Effective for low oxygen tolerant crops | Adjustable for varying oxygen requirements |

| Microbial Growth Control | Reduces aerobic bacteria; limited anaerobic control | Highly effective against aerobic spoilage organisms |

| Environmental Impact | Uses less packaging material | May require multilayer films, harder to recycle |

Introduction to Post-Harvest Packaging Technologies

Post-harvest packaging technologies such as vacuum packing and Modified Atmosphere Packaging (MAP) play vital roles in extending the shelf life of fresh produce by controlling gas composition and moisture levels. Vacuum packing removes air to inhibit aerobic microbial growth and oxidation, while MAP replaces the ambient air with a tailored gas mixture optimized for specific fruits or vegetables. Both methods significantly reduce spoilage rates and maintain nutritional quality, making them essential for modern supply chains.

Overview of Vacuum Packing in Fresh Produce

Vacuum packing for fresh produce involves removing air to reduce oxygen levels, which slows respiration rates and microbial growth, thereby extending shelf life. This technology is particularly effective for leafy greens, berries, and mushrooms, maintaining freshness while minimizing oxidation and spoilage. By creating a low-oxygen environment, vacuum packing helps preserve color, texture, and nutrients in post-harvest handling.

Fundamentals of Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) involves altering the gas composition surrounding fresh produce, typically by reducing oxygen and increasing carbon dioxide levels, to slow respiration and microbial growth, thereby extending shelf life. Vacuum packing removes air entirely, creating an anaerobic environment that effectively inhibits aerobic spoilage organisms but may not be suitable for all types of produce due to potential texture and flavor changes. Understanding the gas permeability of packaging materials and the respiration rate of the specific produce is fundamental to designing MAP systems that maintain optimal freshness and quality during storage and distribution.

Comparing Shelf Life: Vacuum vs MAP Packaging

Vacuum packaging extends the shelf life of fresh produce by removing air and reducing oxidation, effectively slowing microbial growth and enzymatic reactions. Modified Atmosphere Packaging (MAP) adjusts oxygen, carbon dioxide, and nitrogen levels to create an optimized atmosphere that preserves color, texture, and nutritional quality while further inhibiting spoilage organisms. Studies show MAP can maintain freshness longer than vacuum packaging for certain fruits and vegetables, but vacuum packing provides a stronger barrier against aerobic pathogens, making the choice dependent on the specific produce type and storage conditions.

Impact on Nutritional Quality and Freshness

Vacuum packing reduces oxygen exposure, slowing enzymatic reactions and microbial growth, thus preserving the nutritional quality and extending the freshness of fresh produce. Modified Atmosphere Packaging (MAP) alters the gaseous environment by controlling oxygen, carbon dioxide, and humidity levels, effectively maintaining freshness and nutrient retention by minimizing respiration rates. Both technologies significantly impact shelf life and quality, but MAP allows for tailored gas compositions optimized for specific fruits and vegetables, enhancing nutritional preservation more precisely than vacuum packing.

Effects on Flavor, Texture, and Appearance

Vacuum packing removes air to slow oxidation, preserving the fresh produce's natural flavor and maintaining firm texture while reducing microbial growth. Modified Atmosphere Packaging (MAP) adjusts gas composition inside the package, which can extend shelf life by slowing respiration but may sometimes alter taste or soften texture due to elevated CO2 levels. Both methods enhance appearance by minimizing browning and spoilage, but MAP allows better control over humidity and gas exchange, optimizing freshness retention for various produce types.

Packaging Materials and Equipment Requirements

Vacuum packing requires flexible, high-barrier films capable of withstanding air extraction without compromising seal integrity, often necessitating vacuum chamber machines that remove oxygen and prolong shelf life of fresh produce. Modified Atmosphere Packaging (MAP) utilizes specialized films with selective gas permeability combined with equipment that modifies internal gas composition, such as oxygen absorbers or gas flushers, to maintain optimal respiration rates and freshness. While vacuum packing demands robust sealing equipment for airtight packaging, MAP systems require precise gas control machinery and materials engineered for controlled atmosphere retention.

Cost and Scalability Considerations

Vacuum packing offers lower initial investment and simpler machinery, making it cost-effective for small to medium-scale fresh produce operations, while Modified Atmosphere Packaging (MAP) requires higher upfront costs due to advanced packaging systems and gas mixtures but excels in scalability for large volume processing. MAP packaging enhances shelf life by controlling oxygen and carbon dioxide levels, benefiting retailers with extended distribution but necessitates substantial capital and technical expertise. Vacuum packing is more flexible and suitable for diverse produce types, whereas MAP's scalability supports automated, high-throughput production lines, impacting long-term operational expenses.

Environmental Footprint and Sustainability

Vacuum packing significantly reduces oxygen exposure, extending the shelf life of fresh produce with minimal material use, thereby lowering environmental impact through decreased food waste. Modified Atmosphere Packaging (MAP) uses specialized gas mixtures and multilayer films to preserve freshness longer but often involves more complex materials that challenge recycling processes. Prioritizing sustainability involves balancing MAP's enhanced preservation capabilities against vacuum packing's simpler, lower-footprint packaging, emphasizing innovations in biodegradable and recyclable materials for both methods.

Choosing the Right Packaging Solution for Fresh Produce

Vacuum packing extends shelf life by removing air and reducing oxygen exposure, effectively slowing microbial growth and enzymatic reactions in fresh produce. Modified Atmosphere Packaging (MAP) adjusts gas composition inside the package to optimize respiration rates, maintain freshness, and minimize spoilage tailored to specific fruits or vegetables. Selecting the right packaging depends on produce type, desired shelf life, and storage conditions to balance freshness preservation, visual appeal, and cost-effectiveness.

Related Important Terms

Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) enhances the shelf life of fresh produce by altering the gas composition inside the package to slow respiration rates and delay spoilage, optimizing oxygen, carbon dioxide, and nitrogen levels specific to each fruit or vegetable type. Unlike vacuum packing, which removes air completely and can cause compression damage, MAP maintains package structure while providing a controlled atmosphere that reduces microbial growth and preserves quality during storage and transport.

Vacuum Packaging Integrity

Vacuum packaging maintains superior product integrity by removing air and preventing oxidative spoilage, effectively extending the shelf life of fresh produce. Unlike Modified Atmosphere Packaging (MAP), vacuum packaging ensures a consistent, airtight seal that minimizes microbial growth and moisture loss, preserving quality during storage and transport.

Oxygen Transmission Rate (OTR)

Vacuum packing significantly reduces the Oxygen Transmission Rate (OTR) by creating an oxygen-depleted environment that slows respiration and microbial growth in fresh produce. Modified Atmosphere Packaging (MAP) adjusts the OTR by controlling gas composition through selective permeability materials, maintaining optimal oxygen levels to prolong freshness and shelf life.

Respiration Rate Control

Vacuum packing reduces oxygen levels around fresh produce, significantly slowing respiration rate and extending shelf life by minimizing oxidative processes. Modified Atmosphere Packaging (MAP) precisely adjusts oxygen, carbon dioxide, and humidity levels to optimize respiration rate control and maintain freshness while preventing anaerobic conditions.

Active Packaging Films

Vacuum packing removes air to inhibit microbial growth, extending shelf life of fresh produce, while Modified Atmosphere Packaging (MAP) uses active packaging films that regulate oxygen and carbon dioxide levels to maintain freshness and reduce spoilage. Active packaging films in MAP incorporate oxygen scavengers and moisture control layers to optimize the internal atmosphere, enhancing produce quality and shelf stability compared to traditional vacuum packaging.

High Barrier Polymer Films

High barrier polymer films in vacuum packing create an oxygen-free environment that significantly extends the shelf life of fresh produce by preventing oxidation and microbial growth. Modified Atmosphere Packaging (MAP) with such films selectively controls gas exchange, optimizing oxygen and carbon dioxide levels to maintain freshness and reduce spoilage.

Gas Flushing Techniques

Vacuum packing removes oxygen to inhibit microbial growth and enzymatic reactions, extending shelf life of fresh produce by maintaining freshness and texture. Modified Atmosphere Packaging (MAP) uses specific gas mixtures like nitrogen and carbon dioxide to optimize respiration rates and delay spoilage, with gas flushing techniques tailored to produce type for maximum quality retention.

Ethylene Scavengers

Vacuum packing removes oxygen to slow down respiration and ethylene production in fresh produce, preserving quality but may cause anaerobic conditions accelerating spoilage in some fruits. Modified Atmosphere Packaging (MAP) combined with ethylene scavengers selectively absorbs ethylene gas, effectively extending shelf life by delaying ripening and reducing decay in ethylene-sensitive fruits like tomatoes and avocados.

Shelf Life Extension Metrics

Vacuum packing reduces oxygen levels around fresh produce to slow microbial growth, often extending shelf life by 3 to 7 days depending on the product. Modified Atmosphere Packaging (MAP) adjusts oxygen, carbon dioxide, and humidity levels, with shelf life extensions ranging from 7 to 21 days by optimizing respiration rates and delaying spoilage.

Package Headspace Optimization

Vacuum packing minimizes package headspace by removing air, which helps reduce oxygen levels and slows down spoilage and oxidation in fresh produce, enhancing shelf life. Modified Atmosphere Packaging (MAP) optimizes headspace gas composition by balancing oxygen, carbon dioxide, and nitrogen levels to maintain freshness and delay ripening without compressing the product.

Vacuum Packing vs MAP Packaging for fresh produce Infographic

agridif.com

agridif.com