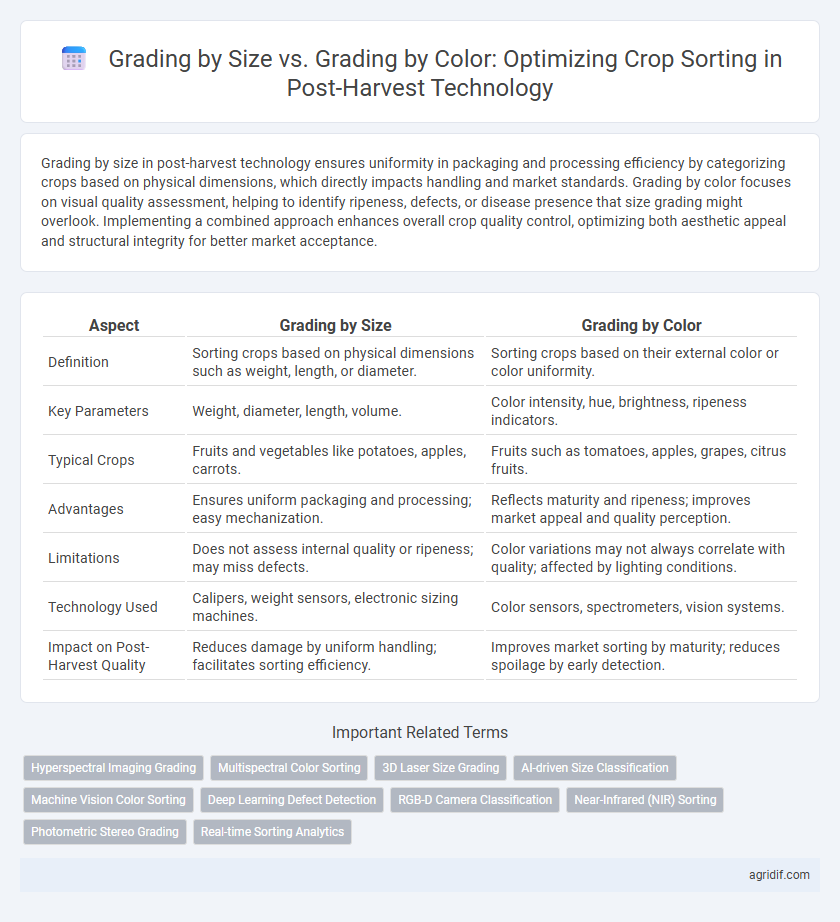

Grading by size in post-harvest technology ensures uniformity in packaging and processing efficiency by categorizing crops based on physical dimensions, which directly impacts handling and market standards. Grading by color focuses on visual quality assessment, helping to identify ripeness, defects, or disease presence that size grading might overlook. Implementing a combined approach enhances overall crop quality control, optimizing both aesthetic appeal and structural integrity for better market acceptance.

Table of Comparison

| Aspect | Grading by Size | Grading by Color |

|---|---|---|

| Definition | Sorting crops based on physical dimensions such as weight, length, or diameter. | Sorting crops based on their external color or color uniformity. |

| Key Parameters | Weight, diameter, length, volume. | Color intensity, hue, brightness, ripeness indicators. |

| Typical Crops | Fruits and vegetables like potatoes, apples, carrots. | Fruits such as tomatoes, apples, grapes, citrus fruits. |

| Advantages | Ensures uniform packaging and processing; easy mechanization. | Reflects maturity and ripeness; improves market appeal and quality perception. |

| Limitations | Does not assess internal quality or ripeness; may miss defects. | Color variations may not always correlate with quality; affected by lighting conditions. |

| Technology Used | Calipers, weight sensors, electronic sizing machines. | Color sensors, spectrometers, vision systems. |

| Impact on Post-Harvest Quality | Reduces damage by uniform handling; facilitates sorting efficiency. | Improves market sorting by maturity; reduces spoilage by early detection. |

Introduction to Post-Harvest Grading Methods

Grading by size in post-harvest crop sorting utilizes dimensions such as weight and diameter to categorize produce, ensuring uniformity for packaging and market standards. Grading by color assesses external appearance to determine ripeness, quality, and visual appeal, which directly influences consumer preference. Both methods enhance supply chain efficiency by reducing losses and optimizing product quality for distribution.

Importance of Crop Grading in Quality Control

Crop grading by size ensures uniformity in packaging and market standards, facilitating efficient handling and consumer preference alignment. Grading by color directly impacts visual appeal and indicates ripeness or disease presence, crucial for maintaining crop quality and reducing post-harvest losses. Implementing precise grading methods enhances quality control by standardizing produce, improving shelf life, and increasing market value in post-harvest technology.

Grading by Size: Techniques and Technologies

Grading by size in post-harvest technology utilizes techniques such as mechanical sieves, drum graders, and optical sensors to sort crops efficiently based on diameter, weight, or volume. Technologies like laser scanning and machine vision systems enhance accuracy by precisely measuring size dimensions, improving consistency in product quality. This method reduces manual labor, increases throughput, and ensures uniformity critical for market standards and packaging requirements.

Advantages of Size-Based Grading for Crop Sorting

Size-based grading in crop sorting enhances uniformity, leading to consistent packaging and improved market value. This method allows for precise sorting using automated machinery, increasing efficiency and reducing labor costs. Additionally, size grading minimizes damage during handling, preserving crop quality and extending shelf life.

Grading by Color: Methods and Optical Systems

Grading by color in post-harvest crop sorting utilizes advanced optical systems such as multispectral imaging and hyperspectral cameras to accurately detect and categorize produce based on surface color variations, which correlate with ripeness, quality, and defect presence. These color-based grading methods enhance sorting precision by differentiating subtle chromatic differences unperceivable by the human eye, improving overall product uniformity and market value. Integration of AI-driven image analysis further optimizes sorting efficiency and consistency, reducing waste and ensuring better compliance with quality standards.

Benefits of Color-Based Grading in Agriculture

Color-based grading in agriculture enhances crop sorting accuracy by effectively distinguishing produce maturity, ripeness, and quality levels, leading to improved market value. This method reduces post-harvest losses by identifying defects such as bruises, diseases, or contamination often undetectable through size grading. Implementing color-based grading systems increases consumer satisfaction and ensures consistency in product standards across supply chains.

Comparing Efficiency: Size vs. Color Grading

Grading by size offers consistent efficiency in sorting crops, as it relies on measurable physical dimensions that allow rapid, automated processing with minimal error. Color grading enhances quality assessment by identifying ripeness and defects, but it requires complex imaging technology and can be influenced by lighting conditions, reducing throughput speed. Size grading generally delivers higher operational efficiency in large-scale post-harvest sorting, while color grading adds value through improved quality control, making a combined approach optimal for maximizing overall post-harvest technology performance.

Impact on Market Value and Consumer Preferences

Grading by size enhances market value by ensuring uniformity in packaging and pricing, which aligns with consumer expectations for consistent product quality. Grading by color appeals directly to consumer preferences by emphasizing visual quality and ripeness, often commanding higher prices for premium appearance. Combining size and color grading optimizes product sorting, maximizing market value through meeting diverse consumer demands efficiently.

Technology Trends in Automated Crop Grading

Automated crop grading integrates advanced imaging systems and machine learning algorithms to enhance grading accuracy by size and color, crucial parameters for quality assessment. Grading by size utilizes laser or optical sensors to measure dimensions precisely, enabling efficient sorting of uniform produce, while color grading leverages hyperspectral imaging and AI models to detect ripeness and defects with higher sensitivity. Emerging trends focus on multispectral cameras and deep learning frameworks to combine size and color data, optimizing sorting speed and reducing human error in post-harvest technology.

Future Perspectives: Integrating Size and Color Grading

Integrating size and color grading in post-harvest crop sorting enhances accuracy and efficiency by combining dimensional precision with visual quality assessment. Advanced optical sensors and machine learning algorithms enable real-time sorting that adapts to varietal differences and market standards. Future perspectives emphasize developing hybrid systems that improve throughput, reduce waste, and meet consumer demands for uniformity and quality.

Related Important Terms

Hyperspectral Imaging Grading

Grading by size evaluates crops based on physical dimensions, while grading by color assesses surface spectral properties; Hyperspectral Imaging (HSI) enables precise sorting by detecting subtle color variations and chemical compositions invisible to traditional vision systems. This technology enhances post-harvest quality control by accurately classifying crops according to biochemical maturity and defect presence, leading to optimized market value and reduced waste.

Multispectral Color Sorting

Grading by size primarily categorizes crops based on dimensional measurements, ensuring uniformity in packaging and market standards, while grading by color uses multispectral color sorting technology to detect subtle differences in crop ripeness, quality, and defects by analyzing reflectance across multiple wavelengths beyond visible light. Multispectral color sorting enhances post-harvest quality control by enabling precise discrimination of external and internal crop attributes, improving sorting accuracy and reducing waste compared to traditional size-based methods.

3D Laser Size Grading

Grading by size using 3D laser size grading technology offers precise dimensional measurements, enabling uniform sorting and reducing product variability compared to color grading, which relies on surface appearance and can be influenced by external factors such as lighting and crop maturity. This advanced 3D laser system enhances sorting accuracy, improves post-harvest handling efficiency, and increases market value by ensuring consistent size-based classification of produce.

AI-driven Size Classification

AI-driven size classification in post-harvest technology enables precise grading based on dimensional attributes, enhancing uniformity and market value of crops by sorting them into consistent size categories. Unlike color grading, which often varies due to environmental factors and crop maturity, size-based AI sorting provides objective, quantifiable data for efficient quality control and packaging automation.

Machine Vision Color Sorting

Machine vision color sorting excels in accurately separating crops based on color variations, enhancing quality control by detecting defects and ripeness levels that size grading might miss. While grading by size categorizes produce for uniformity and packaging efficiency, color sorting offers a more precise assessment of crop quality, leading to improved market value and reduced post-harvest losses.

Deep Learning Defect Detection

Grading by size focuses on sorting crops based on physical dimensions, optimizing uniformity for packaging and market standards, while grading by color leverages visual attributes to detect ripeness and potential defects. Deep learning defect detection excels in color-based grading by accurately identifying subtle imperfections and disease symptoms, enhancing post-harvest quality control beyond traditional size measurements.

RGB-D Camera Classification

Grading by size in post-harvest crop sorting uses RGB-D camera classification to precisely measure volume and dimensions, enabling uniform packaging and processing efficiency. In contrast, grading by color primarily relies on RGB data to assess ripeness and quality, with depth sensing playing a lesser role, making size grading more effective for structural analysis.

Near-Infrared (NIR) Sorting

Near-Infrared (NIR) sorting technology enhances post-harvest crop sorting accuracy by assessing internal quality attributes such as moisture, sugar content, and firmness, which grading by size or color cannot detect. Unlike size or color grading that relies on external features, NIR sorting offers precise, non-destructive evaluation of crop maturity and internal defects, improving overall quality control and reducing waste.

Photometric Stereo Grading

Grading by size utilizes dimensional measurements for crop sorting, while grading by color emphasizes surface appearance and ripeness; Photometric Stereo Grading enhances accuracy by capturing detailed surface normals to detect subtle color and texture variations. This advanced technique improves defect identification and uniformity assessment, optimizing post-harvest quality control.

Real-time Sorting Analytics

Grading by size enables precise categorization of crops using real-time sorting analytics that measure dimensions with optical sensors, enhancing uniformity and reducing processing time. In contrast, grading by color leverages spectral imaging technology to assess ripeness and quality simultaneously, offering dynamic quality control for market-ready produce.

Grading by size vs grading by color for crop sorting Infographic

agridif.com

agridif.com