Controlled atmosphere storage for apples maintains a constant mixture of oxygen, carbon dioxide, and humidity to slow down respiration and prolong freshness. Dynamic controlled atmosphere adjusts these gas levels in response to real-time fruit physiology, enhancing storage efficiency and reducing storage disorders. This advanced method optimizes fruit quality during long-term storage compared to traditional controlled atmosphere techniques.

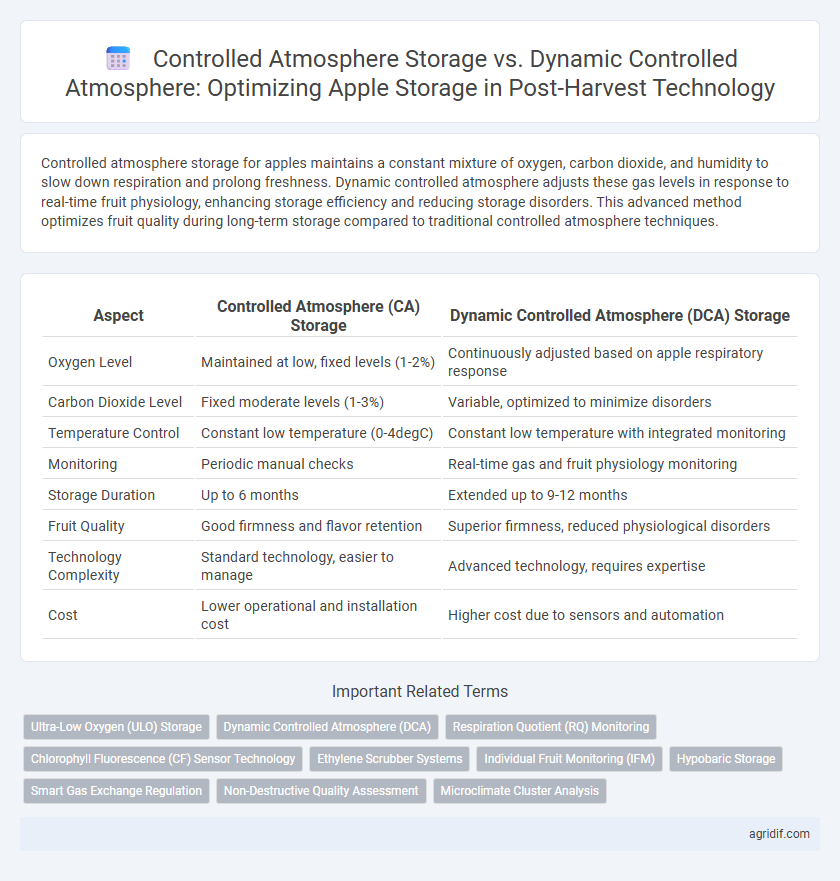

Table of Comparison

| Aspect | Controlled Atmosphere (CA) Storage | Dynamic Controlled Atmosphere (DCA) Storage |

|---|---|---|

| Oxygen Level | Maintained at low, fixed levels (1-2%) | Continuously adjusted based on apple respiratory response |

| Carbon Dioxide Level | Fixed moderate levels (1-3%) | Variable, optimized to minimize disorders |

| Temperature Control | Constant low temperature (0-4degC) | Constant low temperature with integrated monitoring |

| Monitoring | Periodic manual checks | Real-time gas and fruit physiology monitoring |

| Storage Duration | Up to 6 months | Extended up to 9-12 months |

| Fruit Quality | Good firmness and flavor retention | Superior firmness, reduced physiological disorders |

| Technology Complexity | Standard technology, easier to manage | Advanced technology, requires expertise |

| Cost | Lower operational and installation cost | Higher cost due to sensors and automation |

Introduction to Post-Harvest Apple Storage Technologies

Controlled atmosphere storage for apples involves maintaining fixed levels of oxygen, carbon dioxide, and temperature to slow respiration and delay ripening, extending shelf life significantly. Dynamic controlled atmosphere storage continuously monitors and adjusts gas concentrations based on fruit respiration rates, enhancing precision and reducing storage disorders such as superficial scald and internal browning. Both technologies are critical in post-harvest apple storage to preserve quality, firmness, flavor, and nutritional value during long-term storage and transportation.

Understanding Controlled Atmosphere (CA) Storage

Controlled Atmosphere (CA) storage involves regulating oxygen, carbon dioxide, and humidity levels to slow apple respiration and delay ripening, thereby extending shelf life and preserving fruit quality. Dynamic Controlled Atmosphere (DCA) enhances this process by continuously monitoring and adjusting gas concentrations based on real-time fruit physiological responses, reducing oxygen levels to near anaerobic thresholds without inducing stress. This advanced approach optimizes apple storage conditions, minimizing disorders like internal browning and maintaining firmness more effectively than static CA methods.

Exploring Dynamic Controlled Atmosphere (DCA) Storage

Dynamic Controlled Atmosphere (DCA) storage optimizes oxygen levels in real-time by continuously monitoring apple respiration rates and adjusting gas compositions to reduce oxidative stress and delay ripening. Unlike traditional controlled atmosphere storage with fixed gas mixtures, DCA enhances apple firmness retention, decreases decay incidence, and extends shelf life more effectively. This technology leverages advanced sensor systems and automated control to create a tailored storage environment, maximizing post-harvest quality and marketability of apples.

Key Differences Between CA and DCA Storage

Controlled Atmosphere (CA) storage maintains fixed oxygen and carbon dioxide levels to slow apple respiration and delay ripening, extending shelf life. Dynamic Controlled Atmosphere (DCA) storage continuously monitors apple respiration and adjusts gas concentrations in real-time to optimize storage conditions and further reduce fruit stress. The key difference lies in DCA's responsiveness to fruit physiology, providing enhanced quality preservation and reduced storage disorders compared to static CA environments.

Impact on Apple Shelf Life and Quality

Controlled atmosphere (CA) storage extends apple shelf life by reducing oxygen and increasing carbon dioxide levels to slow respiration and delay ripening, preserving firmness and acidity. Dynamic controlled atmosphere (DCA) technology optimizes gas concentrations in real-time based on apple respiration rates, further enhancing quality retention by minimizing storage disorders such as superficial scald and internal browning. Studies demonstrate that DCA consistently outperforms traditional CA storage by maintaining apple sensory attributes and nutritional content, resulting in prolonged marketability and consumer satisfaction.

Managing Respiration and Ethylene Levels

Controlled atmosphere storage maintains low oxygen and elevated carbon dioxide levels to slow apple respiration and delay ripening, effectively reducing ethylene production. Dynamic controlled atmosphere adjusts gas concentrations in real-time based on the apples' physiological responses, optimizing respiration management and extending storage life. This technology minimizes the risk of anaerobic respiration and enhances fruit quality by precisely regulating ethylene levels and metabolic activity throughout storage.

Energy Efficiency and Cost Implications

Controlled atmosphere (CA) storage for apples maintains fixed levels of oxygen, carbon dioxide, and humidity, resulting in moderate energy consumption and stable operating costs. Dynamic controlled atmosphere (DCA) adjusts gas levels based on real-time oxygen consumption of apples, enhancing energy efficiency by reducing gas scrubber use and lowering refrigeration loads. While DCA typically requires higher initial investment, its precise atmosphere regulation can substantially reduce long-term energy expenses and storage losses, offering improved cost-effectiveness over traditional CA methods.

Disease Control and Spoilage Prevention

Controlled atmosphere (CA) storage for apples maintains low oxygen and elevated carbon dioxide levels to inhibit respiration and delay ripening, effectively reducing fungal growth and minimizing spoilage. Dynamic controlled atmosphere (DCA) technology continuously monitors and adjusts gas concentrations in real-time, optimizing conditions to further suppress decay pathogens like Penicillium expansum and Botrytis cinerea. Studies show DCA extends apple shelf life significantly longer than traditional CA storage by enhancing disease control and preventing spoilage through precise atmosphere regulation.

Commercial Adoption: Case Studies and Success Stories

Controlled atmosphere (CA) storage has been widely adopted in commercial apple storage, with numerous case studies highlighting its effectiveness in extending shelf life and maintaining fruit quality. Dynamic controlled atmosphere (DCA) technology, which adjusts oxygen and carbon dioxide levels in response to fruit respiration rates, shows promising results in minimizing storage disorders and maximizing flavor retention, particularly in high-value apple cultivars like Honeycrisp and Fuji. Success stories from leading apple producers in Washington and New Zealand demonstrate that DCA storage can significantly reduce losses during long-term storage while optimizing supply chain efficiency.

Future Trends in Apple Post-Harvest Storage Technologies

Dynamic controlled atmosphere (DCA) storage represents the future of apple post-harvest technology by continuously adjusting oxygen and carbon dioxide levels based on real-time fruit respiration rates, optimizing freshness and extending shelf life beyond traditional controlled atmosphere (CA) methods. Advances in sensor technology and automation enable precise management of storage environments, reducing storage disorders and preserving fruit quality with minimal energy consumption. Emerging trends focus on integrating machine learning algorithms with dynamic control systems to predict optimal storage conditions, enhancing scalability and sustainability in apple supply chains.

Related Important Terms

Ultra-Low Oxygen (ULO) Storage

Ultra-Low Oxygen (ULO) storage, a form of Controlled Atmosphere (CA) storage, maintains oxygen levels typically below 1% to extend apple shelf life by slowing respiration and delaying ripening. Dynamic Controlled Atmosphere (DCA) storage continuously adjusts oxygen and carbon dioxide concentrations based on real-time fruit responses, optimizing ULO conditions and reducing storage disorders more effectively than static CA methods.

Dynamic Controlled Atmosphere (DCA)

Dynamic Controlled Atmosphere (DCA) technology optimizes apple storage by continuously monitoring and adjusting oxygen and carbon dioxide levels to inhibit respiration and delay ripening, thereby extending shelf life and maintaining fruit quality. Compared to traditional Controlled Atmosphere (CA) storage, DCA offers more precise gas regulation that reduces risks of storage disorders like internal browning and improves firmness retention during long-term storage.

Respiration Quotient (RQ) Monitoring

Controlled atmosphere storage regulates oxygen and carbon dioxide levels to slow apple respiration, while dynamic controlled atmosphere adjusts gas composition based on real-time Respiration Quotient (RQ) monitoring, optimizing fruit quality and extending shelf life. Continuous RQ tracking enables precise detection of metabolic changes, allowing dynamic controlled atmosphere to better maintain apple freshness compared to static storage methods.

Chlorophyll Fluorescence (CF) Sensor Technology

Controlled atmosphere (CA) storage for apples maintains fixed gases like oxygen and carbon dioxide to slow ripening, while dynamic controlled atmosphere (DCA) adjusts these levels in real-time based on fruit physiology; Chlorophyll Fluorescence (CF) sensor technology provides precise monitoring of apple stress and respiration by measuring fluorescence changes, enabling optimized gas adjustments in DCA systems for improved fruit quality and extended shelf life. CF sensors enhance DCA's responsiveness compared to static CA, reducing anaerobic risks and preserving apple firmness, flavor, and nutritional value more effectively.

Ethylene Scrubber Systems

Controlled atmosphere storage uses fixed gas concentrations to slow apple ripening, while dynamic controlled atmosphere adjusts oxygen and carbon dioxide levels in real-time for optimal conditions. Ethylene scrubber systems integrated into dynamic controlled atmosphere storage effectively reduce ethylene gas, prolonging apple shelf life and maintaining fruit firmness and flavor quality.

Individual Fruit Monitoring (IFM)

Controlled Atmosphere (CA) storage regulates oxygen, carbon dioxide, and humidity levels to prolong apple shelf life, while Dynamic Controlled Atmosphere (DCA) adjusts these parameters in real-time based on Individual Fruit Monitoring (IFM) data, enhancing precision in ripeness and quality management. IFM enables sensors to track respiration rates and ethylene production of each apple, allowing DCA systems to optimize storage conditions dynamically for improved fruit preservation and reduced spoilage.

Hypobaric Storage

Hypobaric storage, a form of controlled atmosphere storage, reduces oxygen levels by lowering ambient pressure, significantly slowing apple respiration and extending shelf life compared to static controlled atmosphere methods. Dynamic controlled atmosphere adjusts gas compositions in real-time based on fruit physiological responses, but hypobaric systems offer enhanced control over ethylene suppression and decay reduction, optimizing apple quality during long-term storage.

Smart Gas Exchange Regulation

Controlled atmosphere (CA) storage for apples maintains a fixed composition of oxygen, carbon dioxide, and humidity, slowing metabolism and delaying ripening, while dynamic controlled atmosphere (DCA) storage uses continuous monitoring and smart gas exchange regulation to adjust gas levels in real-time based on the fruit's respiratory response. This advanced regulation in DCA minimizes oxidative stress and maintains optimal apple firmness and flavor by precisely controlling oxygen below the anaerobic compensation point, significantly extending storage life compared to traditional CA methods.

Non-Destructive Quality Assessment

Controlled atmosphere storage maintains fixed oxygen and carbon dioxide levels to slow apple respiration and preserve firmness, while dynamic controlled atmosphere continuously adjusts gas concentrations based on apple metabolic rates, enhancing storage efficiency. Non-destructive quality assessment techniques like near-infrared spectroscopy and computer vision play a crucial role in monitoring apple firmness, sugar content, and browning without compromising fruit integrity during both storage methods.

Microclimate Cluster Analysis

Controlled atmosphere storage for apples relies on maintaining fixed levels of oxygen and carbon dioxide to slow respiration, whereas dynamic controlled atmosphere adjusts gas concentrations in response to real-time fruit physiological responses, optimizing storage conditions; Microclimate Cluster Analysis enables precise monitoring and classification of different microenvironments within storage units to tailor gas adjustments effectively. This analytical method enhances the efficacy of dynamic controlled atmosphere technology by identifying variations in apple clusters' respiration rates and environmental factors, leading to improved fruit quality preservation and reduced storage losses.

Controlled atmosphere storage vs dynamic controlled atmosphere for apple storage Infographic

agridif.com

agridif.com