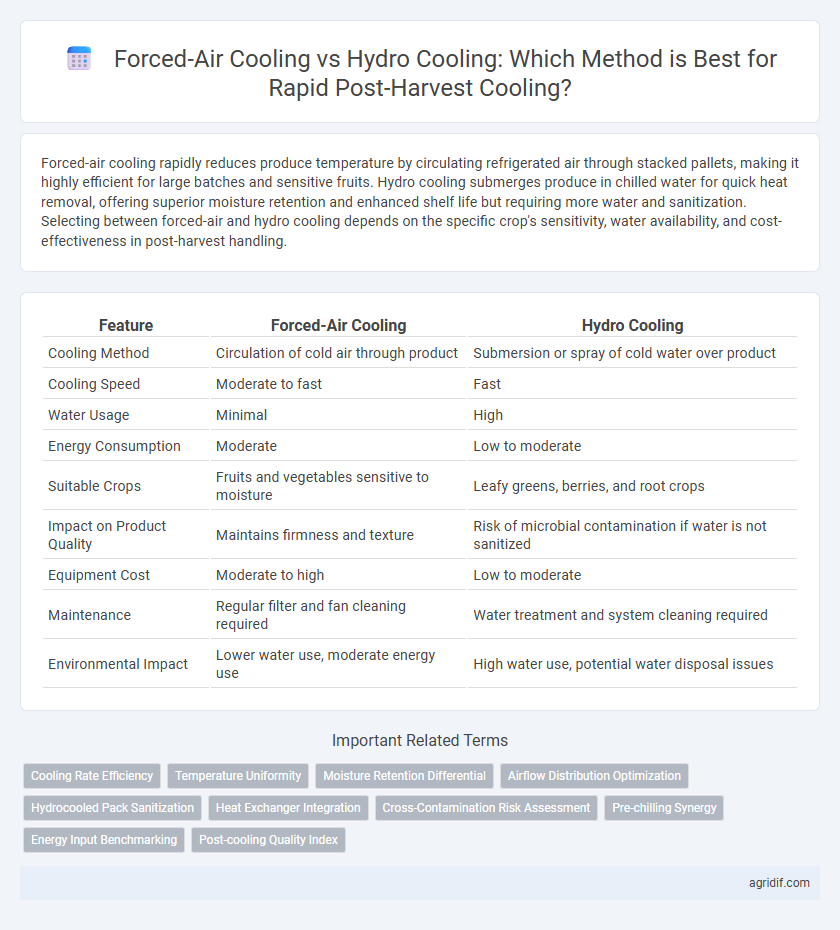

Forced-air cooling rapidly reduces produce temperature by circulating refrigerated air through stacked pallets, making it highly efficient for large batches and sensitive fruits. Hydro cooling submerges produce in chilled water for quick heat removal, offering superior moisture retention and enhanced shelf life but requiring more water and sanitization. Selecting between forced-air and hydro cooling depends on the specific crop's sensitivity, water availability, and cost-effectiveness in post-harvest handling.

Table of Comparison

| Feature | Forced-Air Cooling | Hydro Cooling |

|---|---|---|

| Cooling Method | Circulation of cold air through product | Submersion or spray of cold water over product |

| Cooling Speed | Moderate to fast | Fast |

| Water Usage | Minimal | High |

| Energy Consumption | Moderate | Low to moderate |

| Suitable Crops | Fruits and vegetables sensitive to moisture | Leafy greens, berries, and root crops |

| Impact on Product Quality | Maintains firmness and texture | Risk of microbial contamination if water is not sanitized |

| Equipment Cost | Moderate to high | Low to moderate |

| Maintenance | Regular filter and fan cleaning required | Water treatment and system cleaning required |

| Environmental Impact | Lower water use, moderate energy use | High water use, potential water disposal issues |

Introduction to Rapid Cooling in Post-Harvest Technology

Rapid cooling in post-harvest technology is essential to slow metabolic processes and reduce microbial growth, thereby extending the shelf life of fresh produce. Forced-air cooling uses high-velocity air to quickly lower product temperature, ensuring uniform cooling and suitability for packaged fruits and vegetables. Hydro cooling involves submerging produce in chilled water, offering rapid heat removal ideal for leafy greens but requiring careful management to prevent cross-contamination and waterlogging.

Principles of Forced-Air Cooling

Forced-air cooling uses high-velocity fans to force cool air through stacks of produce, rapidly removing field heat and reducing produce temperature uniformly. This method relies on controlled airflow patterns and temperature differentials to maintain optimal cooling rates and extend shelf life. Its energy-efficient design minimizes moisture loss and prevents surface condensation, ensuring produce quality during storage and transport.

Principles of Hydro Cooling

Hydro cooling rapidly reduces the temperature of harvested produce by immersing or spraying it with chilled water, effectively removing field heat through direct contact and conductive heat transfer. This method enhances cooling efficiency by maintaining consistent temperature and humidity levels, reducing respiration rates, and minimizing weight loss and decay. Compared to forced-air cooling, hydro cooling is especially effective for heat-sensitive and high-density fruits and vegetables requiring rapid temperature reduction.

Comparative Cooling Efficiency

Forced-air cooling achieves rapid temperature reduction by circulating chilled air over produce, providing uniform cooling and minimizing moisture loss, which is essential for maintaining fruit and vegetable quality. Hydro cooling, involving immersion in cold water or spraying, offers faster initial cooling rates but may increase risks of cross-contamination and higher water usage. Comparative studies indicate forced-air cooling is more energy-efficient and suitable for delicate commodities, whereas hydro cooling delivers superior rapid cooling for bulk produce with higher heat load.

Impact on Produce Quality and Shelf Life

Forced-air cooling rapidly removes field heat by circulating cold air around produce, effectively reducing respiration rates and delaying ripening, which enhances shelf life and maintains firmness and color. Hydro cooling cools produce through direct contact with cold water, offering faster cooling for dense products but increasing risks of microbial contamination and moisture-related quality degradation. Selecting between these methods depends on produce type, desired shelf life, and sensitivity to water exposure to optimize post-harvest quality preservation.

Energy Consumption and Operational Costs

Forced-air cooling consumes significantly less energy compared to hydro cooling due to the use of fans to circulate cold air, making it more cost-effective for large-scale operations. Hydro cooling requires substantial water usage and energy to pump and maintain cold water temperatures, resulting in higher operational costs and increased resource demand. Selecting forced-air cooling can optimize energy efficiency and reduce overall expenses in post-harvest cooling processes.

Suitability for Different Crop Types

Forced-air cooling is highly effective for leafy greens, berries, and herbs due to its ability to uniformly and rapidly remove field heat by circulating cold air through porous packaging or bulk bins. Hydro cooling suits fruits like strawberries, cherries, and broccoli that tolerate moisture exposure, leveraging cold water immersion to quickly reduce product temperature while maintaining surface hydration. Selecting the appropriate method depends on crop sensitivity to moisture and structure, optimizing shelf life and quality in post-harvest handling.

Equipment Maintenance and Sanitation

Forced-air cooling systems require regular inspection and cleaning of fans, ducts, and filters to maintain airflow efficiency and prevent microbial contamination. Hydro cooling equipment demands frequent water quality monitoring, tank sanitation, and disinfection to minimize pathogen risks and biofilm formation. Proper maintenance protocols and sanitation practices are critical to ensure both systems effectively reduce produce temperature while preserving safety and quality.

Environmental Considerations

Forced-air cooling utilizes refrigerated air circulated through packed produce to rapidly reduce field heat, consuming substantial electricity with potential carbon emissions depending on energy sources. Hydro cooling involves immersion or misting with chilled water, raising concerns about water consumption, potential contamination, and wastewater management affecting local ecosystems. Selection between these methods depends on balancing energy efficiency and water resource sustainability to minimize environmental impact in post-harvest cooling operations.

Future Trends in Post-Harvest Cooling Technologies

Emerging post-harvest cooling technologies are shifting towards integrating forced-air and hydro-cooling methods with smart sensors and IoT-based monitoring systems to enhance cooling speed and energy efficiency. Advances in nanotechnology and phase change materials (PCMs) are being explored to maintain optimal produce temperatures, reducing spoilage and extending shelf life significantly. Research emphasizes sustainable, low-energy cooling innovations, including solar-powered forced-air units and evaporative hydro-cooling systems tailored for perishable fruit and vegetable supply chains.

Related Important Terms

Cooling Rate Efficiency

Forced-air cooling achieves a cooling rate efficiency of up to 90% by rapidly removing field heat through high-velocity air circulation, making it ideal for bulky fruits and vegetables with irregular shapes. Hydro cooling offers faster and more uniform cooling rates for small, smooth-skinned produce by immersing products in cold water, achieving cooling times up to 50% shorter than forced-air methods.

Temperature Uniformity

Forced-air cooling ensures more consistent temperature uniformity by circulating chilled air evenly around produce, reducing hotspots and moisture loss compared to hydro cooling. Hydro cooling rapidly lowers surface temperature but often results in uneven cooling due to variable water contact and potential thermal gradients within bulk commodities.

Moisture Retention Differential

Forced-air cooling rapidly reduces produce temperature by circulating chilled air, yet it often causes more moisture loss due to prolonged exposure to dry air. Hydro cooling submerges produce in cold water, significantly enhancing moisture retention and reducing wilting compared to forced-air methods.

Airflow Distribution Optimization

Forced-air cooling optimizes rapid cooling by ensuring uniform airflow distribution through adjustable vents and fan speeds, effectively reducing produce temperature within hours while minimizing moisture loss. In contrast, hydro cooling relies on water immersion but often faces challenges in achieving even cooling distribution, leading to variable temperature gradients and potential surface damage.

Hydrocooled Pack Sanitization

Hydro Cooling offers superior pack sanitization by submerging produce in cold, sanitized water that reduces microbial load and minimizes cross-contamination risks compared to Forced-Air Cooling. This method ensures rapid temperature reduction while maintaining post-harvest quality through effective pathogen removal on produce surfaces and packaging materials.

Heat Exchanger Integration

Forced-air cooling achieves rapid temperature reduction by circulating cold air through products, integrating heat exchangers that optimize airflow and thermal exchange efficiency, enhancing moisture removal and extending shelf life. Hydro cooling employs chilled water for direct heat transfer, with heat exchanger systems designed to maintain water temperature and quality, ensuring uniform cooling and reducing post-harvest respiration rates.

Cross-Contamination Risk Assessment

Forced-air cooling minimizes cross-contamination risk by circulating filtered and temperature-controlled air, reducing direct contact with waterborne pathogens common in hydro cooling systems. Hydro cooling poses a higher risk due to shared water usage that can harbor bacteria and viruses, necessitating rigorous water quality monitoring and sanitation protocols.

Pre-chilling Synergy

Forced-air cooling utilizes high-velocity fans to circulate cold air rapidly around produce, effectively removing field heat, while hydro cooling submerges products in chilled water to achieve uniform temperature reduction; combining these methods in a pre-chilling synergy enhances cooling rates by optimizing thermal exchange and minimizing moisture loss. This integrated approach accelerates the reduction of core temperature, improves produce quality, and extends shelf life by leveraging the strengths of air circulation and conductive heat transfer.

Energy Input Benchmarking

Forced-air cooling typically requires less energy input than hydro cooling due to its system design optimizing airflow through produce piles, reducing the need for excessive refrigeration load. Hydro cooling consumes higher energy levels primarily from pumping and water chilling processes, making it less efficient for energy benchmarking in large-scale rapid cooling applications.

Post-cooling Quality Index

Forced-air cooling significantly enhances the Post-cooling Quality Index by reducing field heat rapidly and uniformly, minimizing moisture loss and microbial growth compared to hydro cooling. Hydro cooling, while effective in surface cooling, often results in higher water consumption and potential pathogen spread, impacting overall post-harvest produce quality.

Forced-Air Cooling vs Hydro Cooling for Rapid Cooling Infographic

agridif.com

agridif.com