Aluminum silos offer lightweight construction, corrosion resistance, and ease of installation, making them ideal for quick deployment and minimal maintenance in grain storage. Concrete silos provide superior durability, thermal insulation, and protection from pests and environmental factors, ensuring long-term grain quality preservation. Choosing between aluminum and concrete silos depends on storage duration, budget constraints, and local climatic conditions to optimize post-harvest grain management.

Table of Comparison

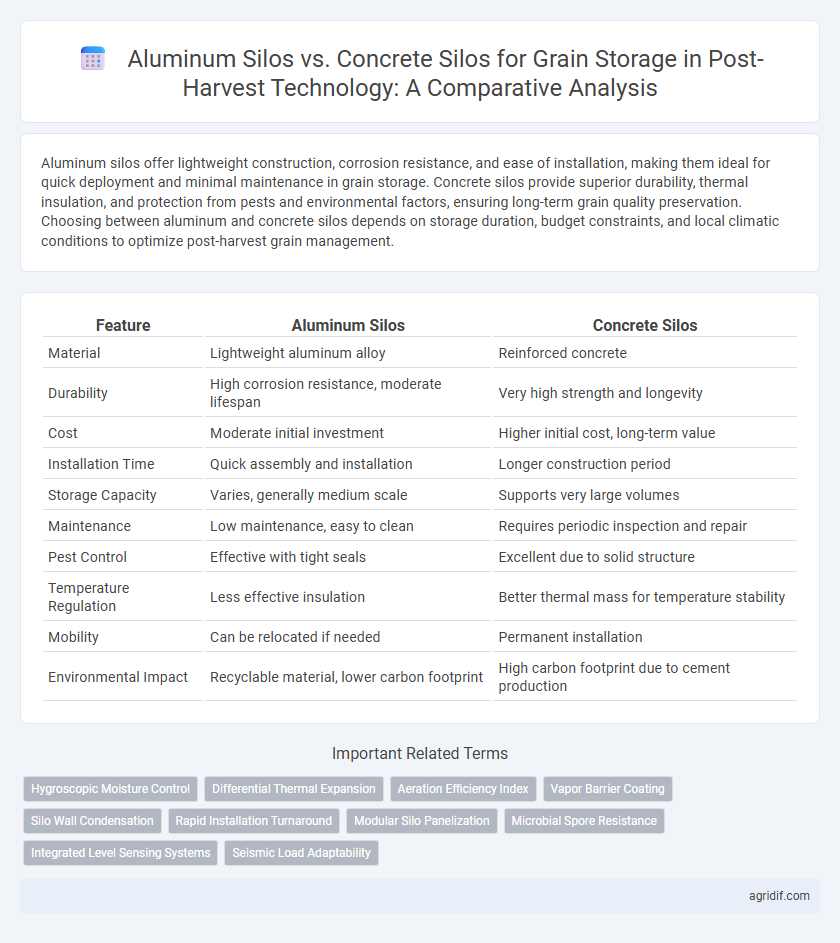

| Feature | Aluminum Silos | Concrete Silos |

|---|---|---|

| Material | Lightweight aluminum alloy | Reinforced concrete |

| Durability | High corrosion resistance, moderate lifespan | Very high strength and longevity |

| Cost | Moderate initial investment | Higher initial cost, long-term value |

| Installation Time | Quick assembly and installation | Longer construction period |

| Storage Capacity | Varies, generally medium scale | Supports very large volumes |

| Maintenance | Low maintenance, easy to clean | Requires periodic inspection and repair |

| Pest Control | Effective with tight seals | Excellent due to solid structure |

| Temperature Regulation | Less effective insulation | Better thermal mass for temperature stability |

| Mobility | Can be relocated if needed | Permanent installation |

| Environmental Impact | Recyclable material, lower carbon footprint | High carbon footprint due to cement production |

Introduction to Grain Storage Silos

Grain storage silos are essential for preserving crop quality and preventing post-harvest losses by providing controlled environments that protect against pests, moisture, and temperature fluctuations. Aluminum silos offer lightweight, corrosion-resistant structures with rapid deployment and lower maintenance, ideal for moderate storage needs. Concrete silos deliver robust durability, superior structural strength, and excellent thermal insulation, making them suitable for large-scale, long-term grain storage operations.

Importance of Proper Grain Storage in Post-Harvest Technology

Proper grain storage is vital in post-harvest technology to prevent losses caused by pests, moisture, and temperature fluctuations. Aluminum silos offer superior corrosion resistance and ease of maintenance, ensuring grain quality over time, while concrete silos provide excellent thermal insulation and durability for long-term storage. Selecting the appropriate silo type directly impacts the preservation of grain integrity, reducing post-harvest losses and enhancing food security.

Aluminum Silos: Features and Benefits

Aluminum silos offer lightweight yet durable construction, enabling easy installation and resistance to corrosion compared to concrete silos. Their smooth surface minimizes grain damage and reduces moisture retention, which significantly improves grain preservation during storage. Enhanced ventilation systems in aluminum silos prevent fungal growth and insect infestation, ensuring better post-harvest grain quality.

Concrete Silos: Construction and Advantages

Concrete silos for grain storage offer robust construction with reinforced concrete walls that provide excellent durability and resistance to environmental factors such as moisture, pests, and temperature fluctuations. Their thermal mass helps maintain stable internal temperatures, reducing the risk of grain spoilage and preserving quality during long-term storage. The structural integrity of concrete silos supports large storage capacities and requires minimal maintenance compared to aluminum silos, making them ideal for extensive agricultural operations.

Cost Comparison: Aluminum vs Concrete Silos

Aluminum silos generally incur higher initial costs due to material and fabrication expenses but offer reduced installation time and lower maintenance costs compared to concrete silos. Concrete silos have a lower upfront cost and provide durable, long-lasting storage but require more extensive construction efforts and periodic repairs, increasing lifetime expenses. Considering factors such as lifecycle cost, maintenance frequency, and regional labor expenses is essential for an accurate cost comparison between aluminum and concrete silos in grain storage.

Durability and Lifespan of Silo Materials

Aluminum silos offer superior corrosion resistance, making them highly durable in humid and wet post-harvest environments, which significantly extends their lifespan compared to concrete silos. Concrete silos, while robust against mechanical damage and pests, are prone to cracking and moisture penetration over time, potentially compromising grain quality and requiring more frequent maintenance. The choice between aluminum and concrete silos directly impacts longevity and cost-effectiveness in grain storage, with aluminum silos generally providing enhanced durability for prolonged storage cycles.

Grain Quality Preservation in Aluminum and Concrete Silos

Aluminum silos offer superior grain quality preservation due to their resistance to corrosion and airtight sealing, which minimizes moisture ingress and pest infestation. Concrete silos provide robust structural stability and thermal mass that helps in maintaining stable internal temperatures, reducing grain spoilage risks. Both silo types must ensure proper ventilation and moisture control to optimize grain longevity and prevent quality degradation.

Maintenance Requirements: Aluminum vs Concrete

Aluminum silos require minimal maintenance due to their resistance to corrosion and ease of cleaning, significantly reducing downtime and repair costs in grain storage operations. Concrete silos, while robust, often need regular inspections for cracks and sealing to prevent moisture ingress, which can compromise grain quality and structural integrity. Choosing aluminum silos minimizes long-term maintenance efforts and ensures better preservation of stored grains.

Environmental Impact and Sustainability Considerations

Aluminum silos offer a lower carbon footprint due to their recyclability and lightweight structure, reducing transportation emissions compared to concrete silos. Concrete silos demand significant energy during production and emit high levels of CO2, impacting their overall environmental sustainability. Long-term durability and resistance to weathering make aluminum silos a more sustainable option for grain storage with less environmental degradation.

Best Practices for Choosing the Right Silo for Your Farm

Choosing the right silo for grain storage depends on factors like storage capacity, durability, and environmental conditions. Aluminum silos offer excellent corrosion resistance and ease of installation, making them suitable for smaller to medium-scale farms in humid areas. Concrete silos provide superior thermal insulation and long-term durability, ideal for large-scale farms requiring permanent storage solutions with minimal maintenance.

Related Important Terms

Hygroscopic Moisture Control

Aluminum silos provide superior hygroscopic moisture control due to their non-porous surfaces and ability to maintain consistent internal temperatures, minimizing moisture absorption by stored grain. Concrete silos, while durable, can absorb and transfer moisture through micropores, increasing the risk of grain spoilage from fluctuating humidity levels.

Differential Thermal Expansion

Aluminum silos exhibit higher thermal conductivity and significant differential thermal expansion compared to concrete silos, causing potential structural stress and deformation during temperature fluctuations in grain storage. Concrete silos maintain dimensional stability due to low thermal expansion coefficients, enhancing long-term durability and reducing the risk of grain spoilage caused by temperature-induced cracks.

Aeration Efficiency Index

Aluminum silos demonstrate a higher Aeration Efficiency Index compared to concrete silos, enabling more uniform airflow and better temperature control within the grain mass. This enhanced aeration reduces spoilage risks and maintains grain quality by promoting optimal moisture removal during post-harvest storage.

Vapor Barrier Coating

Aluminum silos with vapor barrier coatings offer superior moisture resistance compared to concrete silos, significantly reducing grain spoilage and mold growth. This enhanced protection maintains grain quality by preventing water vapor infiltration and condensation inside the storage environment.

Silo Wall Condensation

Aluminum silos exhibit higher thermal conductivity than concrete silos, resulting in increased wall condensation during humid conditions and posing potential risks for grain moisture accumulation and spoilage. Concrete silos offer better thermal insulation, reducing condensation on silo walls and maintaining grain quality by minimizing moisture-related deterioration.

Rapid Installation Turnaround

Aluminum silos offer rapid installation turnaround due to their prefabricated lightweight panels and modular design, enabling quick assembly compared to the labor-intensive and curing requirements of concrete silos. This speed reduces downtime and allows for faster initiation of post-harvest grain storage, optimizing operational efficiency and maintaining grain quality.

Modular Silo Panelization

Aluminum silos offer enhanced modular panelization, allowing for rapid assembly, scalability, and ease of maintenance compared to traditional concrete silos. Modular aluminum panels improve post-harvest grain storage efficiency by providing superior corrosion resistance, airtight sealing, and better temperature regulation, which are critical for preserving grain quality.

Microbial Spore Resistance

Aluminum silos offer superior resistance to microbial spore proliferation due to their non-porous, smooth surfaces that inhibit moisture retention and fungal growth, unlike concrete silos which can absorb moisture and harbor microbes within their porous structure. This enhanced microbial spore resistance in aluminum silos ensures better grain preservation by reducing the risk of spoilage and contamination during long-term storage.

Integrated Level Sensing Systems

Aluminum silos, equipped with integrated level sensing systems, offer superior corrosion resistance and real-time grain level monitoring, enhancing storage efficiency and minimizing spoilage compared to concrete silos. Concrete silos often lack advanced sensor integration, leading to less precise inventory management and increased maintenance costs over time.

Seismic Load Adaptability

Aluminum silos offer superior seismic load adaptability due to their lightweight structure and flexibility, minimizing damage during earthquakes and preserving grain integrity. In contrast, concrete silos, while more rigid and heavy, are prone to cracking under seismic stress, increasing the risk of structural failure and grain contamination.

Aluminum Silos vs Concrete Silos for grain storage Infographic

agridif.com

agridif.com