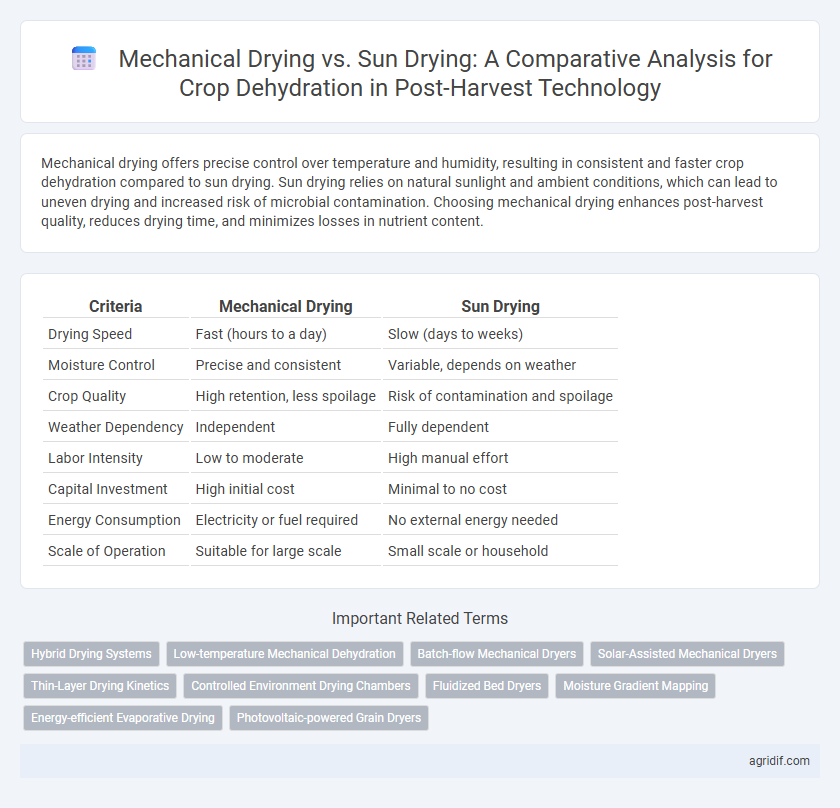

Mechanical drying offers precise control over temperature and humidity, resulting in consistent and faster crop dehydration compared to sun drying. Sun drying relies on natural sunlight and ambient conditions, which can lead to uneven drying and increased risk of microbial contamination. Choosing mechanical drying enhances post-harvest quality, reduces drying time, and minimizes losses in nutrient content.

Table of Comparison

| Criteria | Mechanical Drying | Sun Drying |

|---|---|---|

| Drying Speed | Fast (hours to a day) | Slow (days to weeks) |

| Moisture Control | Precise and consistent | Variable, depends on weather |

| Crop Quality | High retention, less spoilage | Risk of contamination and spoilage |

| Weather Dependency | Independent | Fully dependent |

| Labor Intensity | Low to moderate | High manual effort |

| Capital Investment | High initial cost | Minimal to no cost |

| Energy Consumption | Electricity or fuel required | No external energy needed |

| Scale of Operation | Suitable for large scale | Small scale or household |

Introduction to Post-Harvest Drying Methods

Post-harvest drying is crucial for reducing moisture content in crops, preventing microbial growth, and ensuring long-term storage stability. Mechanical drying uses controlled temperature, airflow, and humidity to accelerate dehydration, offering uniformity and reduced drying time compared to traditional sun drying. Sun drying relies on natural solar energy and ambient conditions but is vulnerable to weather variability and contamination risks, impacting product quality and shelf life.

Principles of Mechanical Drying in Agriculture

Mechanical drying in agriculture utilizes controlled heat and airflow to remove moisture from crops, enhancing preservation and reducing post-harvest losses. This process relies on principles such as heat transfer, mass transfer, and psychrometrics to optimize drying efficiency while maintaining crop quality. Precise regulation of temperature, humidity, and air velocity ensures uniform dehydration and minimizes microbial growth during storage.

Overview of Traditional Sun Drying Techniques

Traditional sun drying techniques for crop dehydration involve spreading harvested crops on open ground, mats, or raised platforms to leverage natural solar radiation and ambient airflow for moisture removal. This method is cost-effective and widely used in rural settings but is heavily dependent on weather conditions, requiring prolonged drying periods that may increase the risk of contamination and nutrient loss. Despite its simplicity, sun drying often results in inconsistent moisture reduction, affecting the shelf life and quality of the dried produce.

Efficiency Comparison: Mechanical vs Sun Drying

Mechanical drying offers higher efficiency compared to sun drying by significantly reducing moisture content in crops within hours rather than days, thereby minimizing microbial growth and spoilage. Controlled temperature and airflow in mechanical dryers ensure uniform dehydration and maintain crop quality, whereas sun drying depends heavily on weather conditions and exposes crops to contamination risks. Energy consumption and initial investment in mechanical drying are higher, but the consistent output and reduced post-harvest losses make it more cost-effective for large-scale agricultural operations.

Impact on Crop Quality and Nutrient Retention

Mechanical drying ensures consistent moisture reduction and better control of temperature, which helps preserve the integrity of crop nutrients such as vitamins and antioxidants. Sun drying exposes crops to variable environmental conditions, increasing the risk of contamination and nutrient degradation from prolonged UV exposure. Studies show mechanical drying reduces microbial spoilage and nutrient loss by up to 30% compared to traditional sun drying methods.

Cost Analysis: Investment and Operating Expenses

Mechanical drying involves higher initial investment due to the cost of equipment, energy infrastructure, and maintenance, while sun drying requires minimal capital expenditure as it relies on natural sunlight. Operating expenses for mechanical drying include energy costs, labor for machine operation, and periodic maintenance, often making it more expensive over time compared to sun drying, which has negligible running costs but higher risk of crop loss or contamination. Cost analysis must weigh the faster dehydration rates and quality control of mechanical drying against the low expense and simplicity of sun drying, particularly in regions with sufficient solar exposure.

Environmental Considerations and Sustainability

Mechanical drying offers precise control over temperature and humidity, reducing the risk of crop spoilage while consuming significant energy, often derived from fossil fuels. Sun drying relies on renewable solar energy, minimizing carbon emissions, but is vulnerable to weather conditions and requires larger land areas. Sustainable post-harvest dehydration balances energy efficiency, greenhouse gas emissions, and crop quality to optimize environmental impact.

Risks and Challenges in Each Drying Method

Mechanical drying poses risks such as high energy consumption, potential overheating leading to nutrient loss, and initial equipment costs, while sun drying faces challenges including exposure to contaminants, unpredictable weather conditions, and slower dehydration rates that can promote microbial growth. Maintaining optimal temperature and humidity levels is critical in mechanical drying to prevent quality degradation, whereas sun drying relies heavily on favorable climate, making it less reliable during rainy or humid seasons. Both methods require careful management to minimize post-harvest losses and preserve crop quality during dehydration.

Adaptability for Different Crop Types

Mechanical drying offers precise control over temperature and humidity, making it adaptable for a wide range of crops including grains, fruits, and vegetables, ensuring uniform moisture reduction and minimizing quality degradation. Sun drying, while cost-effective and traditional, is highly dependent on weather conditions and crop type, often resulting in uneven drying and increased risk of contamination for sensitive crops like leafy greens and high-moisture fruits. Advanced mechanical dryers can be customized with adjustable parameters to optimize drying protocols for specific crop characteristics, enhancing post-harvest preservation and shelf life.

Future Trends in Agricultural Drying Technologies

Mechanical drying systems increasingly integrate solar-assisted technologies and IoT sensors to optimize energy efficiency and moisture control during crop dehydration. Advancements in low-temperature drying and AI-driven process management enhance product quality while reducing nutrient loss compared to traditional sun drying methods. Future trends emphasize sustainable, precision drying solutions that adapt to varying crop types and climatic conditions for improved post-harvest preservation.

Related Important Terms

Hybrid Drying Systems

Hybrid drying systems combine mechanical drying and sun drying to optimize crop dehydration by balancing energy efficiency and drying speed, significantly reducing post-harvest losses. These systems enhance moisture removal uniformity and improve product quality by utilizing controlled temperature and humidity conditions alongside natural solar energy.

Low-temperature Mechanical Dehydration

Low-temperature mechanical dehydration preserves nutrient quality and reduces microbial contamination more effectively than sun drying by maintaining controlled temperatures typically below 60degC during crop drying. This method enhances dehydration uniformity and shortens processing time, ensuring higher market value and extended shelf-life of agricultural produce compared to traditional sun drying methods.

Batch-flow Mechanical Dryers

Batch-flow mechanical dryers enhance crop dehydration by providing controlled temperature and airflow, ensuring uniform drying and minimizing microbial growth compared to sun drying. These dryers reduce drying time significantly, maintain nutritional quality, and decrease post-harvest losses by preventing contamination and weather-related risks common in sun drying.

Solar-Assisted Mechanical Dryers

Solar-assisted mechanical dryers enhance crop dehydration efficiency by combining renewable solar energy with controlled mechanical airflow, significantly reducing moisture content faster than traditional sun drying. This hybrid technology improves drying uniformity, minimizes crop spoilage, and extends shelf life while lowering energy consumption and environmental impact compared to conventional mechanical drying methods.

Thin-Layer Drying Kinetics

Mechanical drying in thin-layer drying kinetics provides controlled temperature and airflow, resulting in faster moisture removal and improved uniformity compared to sun drying, which is subject to environmental variability and slower dehydration rates. Precise control of drying parameters in mechanical systems enhances product quality by minimizing microbial growth and enzymatic activity during crop dehydration.

Controlled Environment Drying Chambers

Mechanical drying using controlled environment drying chambers offers precise temperature and humidity regulation, significantly reducing drying time and minimizing microbial contamination compared to traditional sun drying. This technology enhances crop quality retention, uniform moisture removal, and reduces crop losses caused by unpredictable weather and pest exposure inherent in sun drying methods.

Fluidized Bed Dryers

Fluidized bed dryers provide controlled temperature and airflow, enhancing uniformity and efficiency in crop dehydration compared to traditional sun drying methods, which depend heavily on weather conditions and can lead to inconsistent moisture removal. This mechanical drying technology reduces drying time and minimizes nutrient loss, preserving crop quality while preventing microbial spoilage and post-harvest losses.

Moisture Gradient Mapping

Mechanical drying offers precise control over temperature and airflow, enabling uniform moisture gradient mapping throughout the crop, which significantly reduces spoilage risks compared to the uneven moisture levels typical in sun drying. Sun drying exposes crops to variable environmental conditions, leading to inconsistent dehydration rates and moisture gradients that can promote microbial growth and reduce overall product quality.

Energy-efficient Evaporative Drying

Mechanical drying using energy-efficient evaporative drying methods significantly reduces moisture content in crops faster than traditional sun drying, optimizing dehydration while conserving energy. This technology enhances crop quality and shelf life by maintaining optimal temperature and humidity conditions, minimizing microbial growth and nutrient loss.

Photovoltaic-powered Grain Dryers

Photovoltaic-powered grain dryers harness solar energy to provide a sustainable, efficient alternative to traditional sun drying, reducing post-harvest losses and preserving crop quality by maintaining controlled temperature and humidity levels. These mechanical drying systems enhance dehydration speed and uniformity, offering improved moisture removal while minimizing contamination and dependency on inconsistent weather conditions.

Mechanical Drying vs Sun Drying for Crop Dehydration Infographic

agridif.com

agridif.com