Gamma irradiation and ozone fumigation are effective post-harvest technologies for microbial decontamination, each offering unique advantages in preserving food quality and safety. Gamma irradiation penetrates deeply into produce, eliminating pathogens and extending shelf life without leaving residues, while ozone fumigation provides a chemical-free alternative that rapidly oxidizes microbial contaminants on surfaces. Choosing between these methods depends on factors such as the type of produce, desired microbial control level, and regulatory considerations.

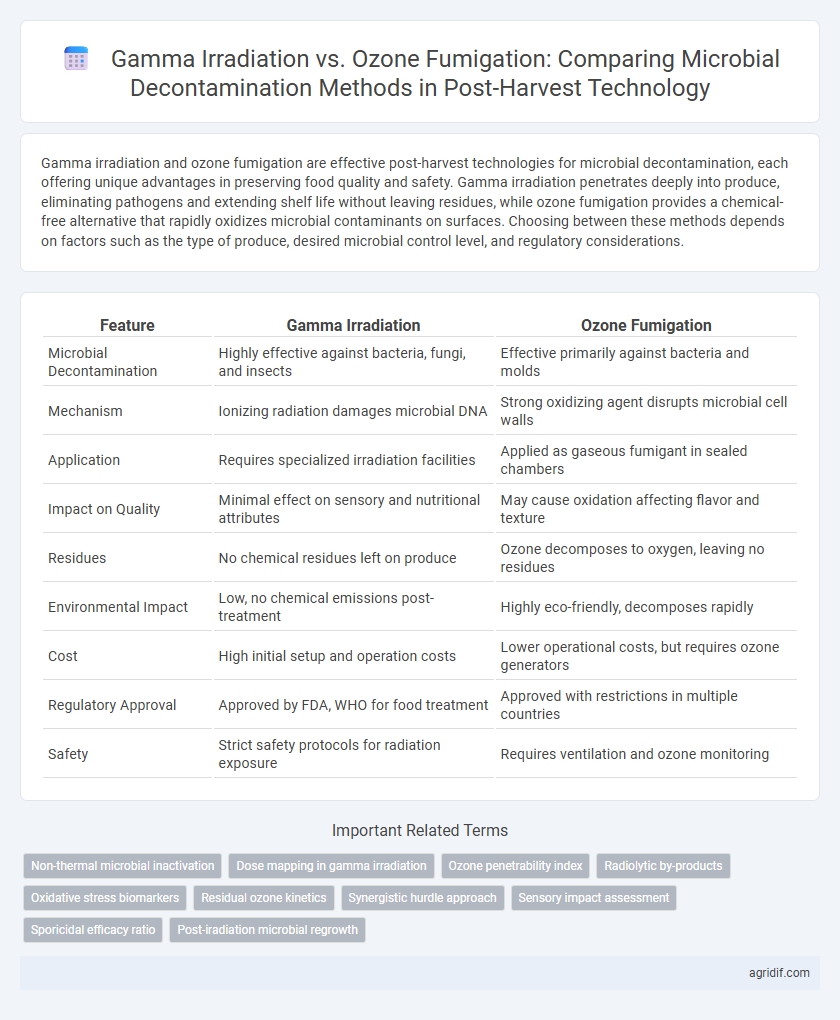

Table of Comparison

| Feature | Gamma Irradiation | Ozone Fumigation |

|---|---|---|

| Microbial Decontamination | Highly effective against bacteria, fungi, and insects | Effective primarily against bacteria and molds |

| Mechanism | Ionizing radiation damages microbial DNA | Strong oxidizing agent disrupts microbial cell walls |

| Application | Requires specialized irradiation facilities | Applied as gaseous fumigant in sealed chambers |

| Impact on Quality | Minimal effect on sensory and nutritional attributes | May cause oxidation affecting flavor and texture |

| Residues | No chemical residues left on produce | Ozone decomposes to oxygen, leaving no residues |

| Environmental Impact | Low, no chemical emissions post-treatment | Highly eco-friendly, decomposes rapidly |

| Cost | High initial setup and operation costs | Lower operational costs, but requires ozone generators |

| Regulatory Approval | Approved by FDA, WHO for food treatment | Approved with restrictions in multiple countries |

| Safety | Strict safety protocols for radiation exposure | Requires ventilation and ozone monitoring |

Introduction to Post-Harvest Microbial Contamination

Post-harvest microbial contamination significantly reduces the shelf life and quality of fruits and vegetables, posing challenges to food safety and marketability. Gamma irradiation effectively disrupts microbial DNA, leading to the inactivation of bacteria, fungi, and pathogens, while ozone fumigation oxidizes microbial cell components to achieve decontamination without chemical residues. Understanding these technologies is crucial for optimizing post-harvest treatments and minimizing microbial spoilage in agriculture supply chains.

Overview of Gamma Irradiation Technology

Gamma irradiation technology employs high-energy photons from sources like Cobalt-60 to penetrate microbial cells in harvested produce, effectively disrupting DNA and inhibiting replication. This method offers deep and uniform microbial decontamination without raising the temperature, preserving the quality and shelf-life of fruits and vegetables. Its ability to reduce pathogenic bacteria, molds, and insect pests makes it a preferred non-thermal post-harvest treatment in global food safety protocols.

What is Ozone Fumigation?

Ozone fumigation is a post-harvest microbial decontamination technique that utilizes ozone gas (O3) to eliminate bacteria, fungi, and insects on agricultural produce. Its strong oxidative properties disrupt cell membranes and DNA of pathogens, ensuring effective sterilization without leaving harmful residues. This eco-friendly method is gaining preference over gamma irradiation due to its rapid action, ease of application, and minimal impact on fruit quality and nutritional value.

Mechanisms of Microbial Inactivation: Gamma Irradiation vs Ozone Fumigation

Gamma irradiation inactivates microbes by inducing DNA damage through ionizing radiation that creates free radicals, leading to lethal mutations and cellular death. Ozone fumigation disrupts microbial cell membranes and oxidizes intracellular components, causing structural damage and enzyme inactivation. The effectiveness of gamma irradiation depends on the radiation dose and microbial resistance, while ozone efficacy is influenced by concentration, exposure time, and humidity levels during treatment.

Efficacy of Gamma Irradiation on Different Crops

Gamma irradiation demonstrates high efficacy in microbial decontamination across various crops, including fruits like mangoes, tomatoes, and strawberries, significantly reducing pathogens such as bacteria, molds, and yeasts. This method penetrates deeply into produce without leaving chemical residues, preserving freshness and extending shelf life while effectively targeting pests and spoilage microorganisms. Studies confirm gamma irradiation doses between 0.5 to 3 kGy optimize microbial control while maintaining crop quality, making it a reliable alternative to ozone fumigation in post-harvest treatment.

Efficacy of Ozone Fumigation in Microbial Control

Ozone fumigation demonstrates high efficacy in microbial control by rapidly oxidizing cell components of bacteria, fungi, and viruses, leading to their inactivation on post-harvest produce. Its strong oxidative potential disrupts microbial cell membranes and genetic materials, ensuring significant reduction of pathogens such as Escherichia coli, Salmonella spp., and Aspergillus flavus. Moreover, ozone decomposes into oxygen without leaving harmful residues, making it an environmentally friendly alternative to chemical disinfectants in post-harvest technology.

Safety and Regulatory Considerations for Both Treatments

Gamma irradiation and ozone fumigation are widely used for microbial decontamination in post-harvest technology, each subject to stringent safety standards and regulatory frameworks. Regulatory bodies such as the FDA and WHO have approved gamma irradiation at specific doses, emphasizing controlled exposure to prevent harmful residues, while ozone fumigation is regulated for its rapid oxidative effects and must comply with occupational safety limits to avoid respiratory hazards. Both treatments require proper implementation of safety protocols, including monitoring of dosage and exposure times, to ensure consumer protection and meet international import-export regulations.

Impact on Food Quality and Nutritional Value

Gamma irradiation effectively reduces microbial load on post-harvest produce while preserving key nutrients such as vitamins A, C, and E, though high doses may cause minor textural changes. Ozone fumigation offers rapid microbial decontamination without chemical residues and minimally affects food sensory attributes, but prolonged exposure can degrade sensitive antioxidants and reduce shelf life. Both methods enhance food safety, yet gamma irradiation maintains nutritional quality better under controlled dosages, whereas ozone fumigation excels in preserving surface freshness and overall appearance.

Economic and Environmental Implications

Gamma irradiation offers effective microbial decontamination with high penetration but involves significant initial investment and strict regulatory controls, impacting its economic feasibility. Ozone fumigation provides a cost-effective, environmentally friendly alternative by decomposing into oxygen without chemical residues, reducing environmental hazards and operational costs. Both methods support post-harvest technology by enhancing food safety; however, ozone's lower energy consumption and minimal waste generation present advantages in sustainable agricultural practices.

Future Prospects and Trends in Microbial Decontamination Methods

Gamma irradiation and ozone fumigation represent advanced microbial decontamination technologies in post-harvest technology, with gamma irradiation offering deep penetration and effective microbial inactivation without chemical residues. Future prospects emphasize integrating gamma irradiation with ozone fumigation to enhance synergistic effects on microbial control while minimizing adverse impacts on produce quality. Trends focus on optimizing dosages, developing low-dose gamma irradiation protocols combined with controlled ozone exposure, and advancing regulatory frameworks to facilitate commercial adoption and consumer acceptance.

Related Important Terms

Non-thermal microbial inactivation

Gamma irradiation and ozone fumigation offer effective non-thermal microbial inactivation methods for post-harvest technology by targeting microbial DNA and cell membranes without compromising produce quality. Gamma irradiation excels in deep penetration and uniform microbial reduction, while ozone fumigation provides strong oxidative disinfection with minimal chemical residues, making both valuable for prolonging shelf life and ensuring food safety.

Dose mapping in gamma irradiation

Dose mapping in gamma irradiation involves precise measurement and distribution analysis to ensure effective microbial decontamination while preserving post-harvest quality, using dosimeters to identify the minimum lethal dose and avoid overexposure. Compared to ozone fumigation, gamma irradiation provides uniform penetration and controlled dosing critical for eliminating pathogens in various agricultural commodities.

Ozone penetrability index

Ozone fumigation demonstrates a higher penetrability index compared to gamma irradiation, enabling more effective microbial decontamination within dense or porous agricultural produce by penetrating cellular structures and eliminating pathogens. This superior penetrability allows ozone to inactivate a broader spectrum of microorganisms on both surface and subsurface levels, enhancing post-harvest shelf life and safety.

Radiolytic by-products

Gamma irradiation effectively reduces microbial load in post-harvest products but generates radiolytic by-products such as free radicals and reactive oxygen species that may affect food safety and quality. Ozone fumigation offers microbial decontamination without producing harmful radiolytic compounds, presenting a safer alternative for preserving produce integrity.

Oxidative stress biomarkers

Gamma irradiation effectively reduces microbial load on post-harvest produce by inducing oxidative stress, leading to elevated levels of biomarkers such as malondialdehyde (MDA) and catalase activity, which indicate lipid peroxidation and antioxidant response. In contrast, ozone fumigation generates reactive oxygen species that enhance oxidative damage markers like superoxide dismutase (SOD) and glutathione peroxidase (GPx), providing a distinct oxidative stress profile while achieving microbial decontamination.

Residual ozone kinetics

Gamma irradiation effectively reduces microbial load without leaving harmful residues, whereas ozone fumigation relies on residual ozone kinetics for its antimicrobial action, with ozone decomposing rapidly into oxygen within hours. Monitoring residual ozone concentration is crucial to ensure microbial decontamination efficacy while minimizing phytotoxic effects and maintaining post-harvest quality.

Synergistic hurdle approach

Gamma irradiation and ozone fumigation, when combined in a synergistic hurdle approach, significantly enhance microbial decontamination efficiency in post-harvest technology by targeting diverse microbial populations through complementary mechanisms. This integrated method reduces microbial resistance, extends shelf life, and maintains the quality of fresh produce by leveraging the deep penetration of gamma rays alongside the strong oxidative capacity of ozone.

Sensory impact assessment

Gamma irradiation effectively eliminates microbial contaminants in post-harvest produce with minimal alteration to taste, texture, and aroma, preserving consumer acceptability. Ozone fumigation offers rapid surface decontamination but may cause subtle changes in sensory attributes such as slight bitterness or off-odors, requiring careful dosage control to maintain quality.

Sporicidal efficacy ratio

Gamma irradiation demonstrates a higher sporicidal efficacy ratio compared to ozone fumigation, effectively reducing bacterial and fungal spores on post-harvest produce. Studies indicate that gamma irradiation achieves up to a 5-log reduction in spore count, whereas ozone fumigation typically results in a 2-3 log reduction under similar conditions.

Post-iradiation microbial regrowth

Gamma irradiation effectively reduces microbial load in post-harvest produce but may allow microbial regrowth due to sub-lethal damage to pathogens. Ozone fumigation offers strong oxidative microbial decontamination with minimal residual effects, reducing the risk of post-treatment microbial proliferation compared to gamma irradiation.

Gamma Irradiation vs Ozone Fumigation for microbial decontamination Infographic

agridif.com

agridif.com