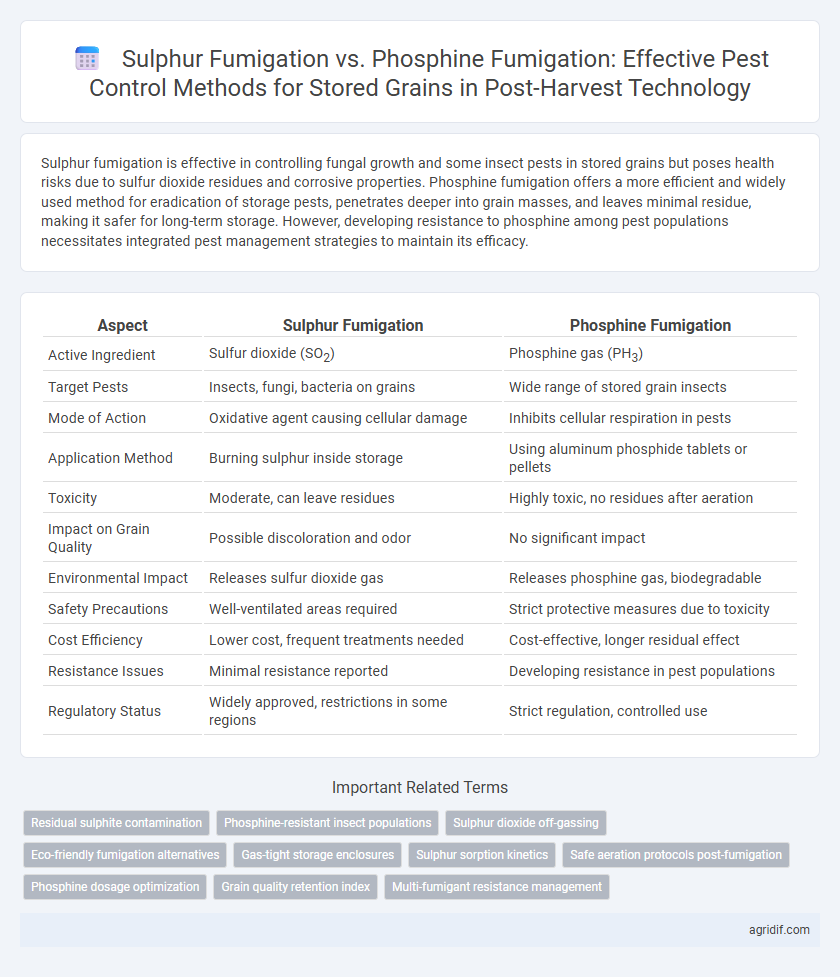

Sulphur fumigation is effective in controlling fungal growth and some insect pests in stored grains but poses health risks due to sulfur dioxide residues and corrosive properties. Phosphine fumigation offers a more efficient and widely used method for eradication of storage pests, penetrates deeper into grain masses, and leaves minimal residue, making it safer for long-term storage. However, developing resistance to phosphine among pest populations necessitates integrated pest management strategies to maintain its efficacy.

Table of Comparison

| Aspect | Sulphur Fumigation | Phosphine Fumigation |

|---|---|---|

| Active Ingredient | Sulfur dioxide (SO2) | Phosphine gas (PH3) |

| Target Pests | Insects, fungi, bacteria on grains | Wide range of stored grain insects |

| Mode of Action | Oxidative agent causing cellular damage | Inhibits cellular respiration in pests |

| Application Method | Burning sulphur inside storage | Using aluminum phosphide tablets or pellets |

| Toxicity | Moderate, can leave residues | Highly toxic, no residues after aeration |

| Impact on Grain Quality | Possible discoloration and odor | No significant impact |

| Environmental Impact | Releases sulfur dioxide gas | Releases phosphine gas, biodegradable |

| Safety Precautions | Well-ventilated areas required | Strict protective measures due to toxicity |

| Cost Efficiency | Lower cost, frequent treatments needed | Cost-effective, longer residual effect |

| Resistance Issues | Minimal resistance reported | Developing resistance in pest populations |

| Regulatory Status | Widely approved, restrictions in some regions | Strict regulation, controlled use |

Introduction to Fumigation Methods in Post-Harvest Grain Protection

Sulphur fumigation and phosphine fumigation are two widely used methods for controlling pests in stored grains, each offering distinct chemical properties and efficacy levels. Sulphur dioxide released during sulphur fumigation acts as a respiratory toxin targeting insects but can affect grain quality and leave residues, whereas phosphine gas generated from metal phosphides provides deeper penetration and higher toxicity against a broad spectrum of storage pests. Effective post-harvest grain protection relies on selecting the appropriate fumigant based on pest resistance, grain type, safety regulations, and storage conditions to minimize losses and maintain grain integrity.

Overview of Sulphur Fumigation: Mechanism and Applications

Sulphur fumigation controls pests in stored grains by releasing sulfur dioxide gas, which disrupts the respiratory system of insects and inhibits microbial growth. This method is effective against fungi and insect larvae, preserving grain quality and preventing spoilage. Sulphur fumigation is commonly applied in enclosed storage units and is valued for its antimicrobial properties alongside pest control benefits.

Phosphine Fumigation: Principles and Usage in Stored Grains

Phosphine fumigation relies on aluminum or magnesium phosphide tablets that release phosphine gas (PH3) upon contact with moisture, effectively penetrating stored grains to eradicate pests such as weevils, beetles, and moths. This method ensures uniform gas distribution, preserving grain quality by avoiding residue accumulation common with sulphur fumigation. Proper dosage and exposure time, typically 2-7 days at 25-30degC, are critical to achieving optimal pest mortality and maintaining grain safety for consumption and storage.

Comparative Effectiveness Against Key Grain Pests

Sulphur fumigation primarily targets fungal pathogens and some insect pests but is less effective against key stored grain insects like weevils and grain borers compared to phosphine fumigation. Phosphine exhibits broad-spectrum efficacy against major pests such as Sitophilus oryzae, Tribolium castaneum, and Rhyzopertha dominica, making it the preferred choice for comprehensive pest control in stored grains. Moreover, phosphine's penetration ability and longer-lasting toxic residues ensure sustained protection, outperforming sulphur fumigation in maintaining grain quality and reducing post-harvest losses.

Safety Considerations: Human Health and Environmental Impacts

Sulphur fumigation releases sulfur dioxide, which can cause respiratory irritation and has greater toxicity risks to workers and nearby communities compared to phosphine fumigation. Phosphine fumigation, while also hazardous due to its flammability and toxic nature, generally poses lower residual toxicity, making it preferable for reducing long-term environmental contamination in stored grain facilities. Proper ventilation, protective equipment, and adherence to regulatory exposure limits are critical for both methods to minimize human health risks and environmental damage.

Residue Levels and Food Safety in Treated Grains

Phosphine fumigation produces minimal residue in stored grains, making it a safer option for food safety compared to sulphur fumigation, which can leave harmful sulphur residues affecting grain quality and consumer health. Sulphur residues pose risks of toxicity and off-flavors, while phosphine dissipates quickly without compromising residue limits set by food safety authorities. Optimizing pest control with phosphine helps ensure compliance with international food safety standards and reduces contamination risks in stored grains.

Resistance Development in Pests: Sulphur vs Phosphine

Phosphine fumigation is widely used for controlling pests in stored grains but has led to significant resistance development in pest populations, reducing its long-term effectiveness. Sulphur fumigation, while less commonly applied, shows a lower incidence of resistance in pests due to its different chemical mode of action and less frequent use. Monitoring resistance levels and rotating fumigants, including integrating sulphur fumigation, can help mitigate resistance buildup in stored grain pest management.

Economic Costs and Operational Efficiency

Sulphur fumigation incurs higher economic costs due to the need for frequent applications and its corrosive effects on storage infrastructure, while phosphine fumigation is more cost-effective with longer residual activity reducing treatment frequency. Operational efficiency of phosphine fumigation is superior as it allows uniform penetration in grain masses and requires lower labor inputs compared to sulphur fumigation, which demands careful handling to mitigate health risks. Phosphine's compatibility with automated monitoring systems enhances control precision, further reducing operational expenses in large-scale grain storage facilities.

Regulatory Compliance and Legal Aspects

Sulphur fumigation for stored grains often faces strict regulatory scrutiny due to its potential residue toxicity, limiting permissible exposure levels under food safety standards such as the Codex Alimentarius and FDA regulations. Phosphine fumigation complies with international phytosanitary measures, including ISPM 15 and EPA guidelines, given its recognized efficacy and lower residue risks when applied within prescribed dosages. Grain storage operators must adhere to local and global legal frameworks governing fumigant use to avoid penalties and ensure market access.

Future Trends and Innovations in Grain Fumigation

Future trends in grain fumigation emphasize the development of safer and more effective alternatives to traditional sulphur and phosphine fumigation, addressing resistance issues and environmental concerns. Innovations include the integration of controlled atmosphere techniques, nanotechnology-based fumigants, and precision application systems to enhance pest control efficacy while minimizing chemical residues. Research on biodegradable fumigants and real-time monitoring technologies aims to optimize fumigation processes and promote sustainable post-harvest grain management.

Related Important Terms

Residual sulphite contamination

Sulphur fumigation in stored grains often results in residual sulphite contamination, which poses health risks and may affect grain quality by altering taste and nutritional content. Phosphine fumigation, in contrast, leaves no harmful residues, making it a safer alternative for controlling pests in post-harvest grain storage.

Phosphine-resistant insect populations

Phosphine fumigation is widely used for stored grain pest control, but the emergence of phosphine-resistant insect populations, such as resistant strains of Tribolium castaneum and Rhyzopertha dominica, has compromised its effectiveness. Sulphur fumigation offers an alternative with a different mode of action, reducing the risk of resistance development and providing effective control against phosphine-resistant pests in post-harvest management.

Sulphur dioxide off-gassing

Sulphur fumigation in post-harvest grain storage releases sulphur dioxide, leading to off-gassing that can cause corrosion, respiratory irritation, and residual grain quality deterioration. Phosphine fumigation offers a more effective pest control alternative with minimal off-gassing, preserving grain stability and safety during storage.

Eco-friendly fumigation alternatives

Sulphur fumigation, while effective against pests in stored grains, releases sulfur dioxide which poses environmental and health hazards, contrasting with phosphine fumigation that utilizes aluminum or magnesium phosphide producing phosphine gas, a more eco-friendly alternative due to its lower residue and minimal impact on grain quality. Phosphine fumigation is widely preferred in sustainable post-harvest technology for its efficient pest control and reduced ecological footprint compared to traditional sulphur fumigation methods.

Gas-tight storage enclosures

Sulphur fumigation creates sulfur dioxide gas effective against pests but requires careful gas-tight storage enclosures to prevent leakage and ensure safety. Phosphine fumigation relies on phosphine gas, which penetrates stored grains efficiently in airtight enclosures, offering superior insect control with lower residue risks in post-harvest grain management.

Sulphur sorption kinetics

Sulphur fumigation for pest control in stored grains involves the sorption of sulphur dioxide onto grain surfaces, which occurs at a slower rate compared to phosphine fumigation, impacting its efficacy and residual toxicity. Understanding sulphur sorption kinetics is crucial for optimizing dosage and exposure time to ensure effective pest eradication while minimizing grain quality degradation.

Safe aeration protocols post-fumigation

Safe aeration protocols following sulphur fumigation require extended ventilation periods of 3-7 days to dissipate sulfur dioxide residues, minimizing health risks and preventing grain quality degradation. In contrast, phosphine fumigation demands rapid aeration typically within 24-48 hours due to phosphine's faster dissipation, ensuring effective pest control while maintaining grain safety and reducing toxic residue buildup.

Phosphine dosage optimization

Phosphine fumigation in stored grains requires precise dosage optimization, typically ranging from 1 to 3 mg/L for durations of 3 to 7 days, to ensure effective pest eradication while minimizing residue and resistance risks. Unlike sulphur fumigation, phosphine penetrates deeply and provides broad-spectrum control with lower toxicity, making dosage calibration critical for maintaining grain quality and safety standards.

Grain quality retention index

Sulphur fumigation effectively controls pests but may lead to higher grain quality degradation due to increased moisture and residue accumulation, lowering the Grain Quality Retention Index (GQRI). Phosphine fumigation preserves grain quality by minimizing moisture uptake and chemical residues, resulting in a higher GQRI and better maintenance of nutritional and physical properties during storage.

Multi-fumigant resistance management

Sulphur fumigation and phosphine fumigation serve as critical methods for pest control in stored grains, with phosphine widely preferred due to its effectiveness and lower residue concerns, while sulphur fumigation offers rapid knockdown but poses risks of grain quality degradation. Employing a multi-fumigant resistance management strategy, alternating between sulphur and phosphine fumigants can mitigate resistance development in pest populations, ensuring long-term efficacy in post-harvest grain protection.

Sulphur fumigation vs Phosphine fumigation for pest control in stored grains Infographic

agridif.com

agridif.com