Blanching effectively preserves the color of processed potatoes by deactivating enzymes responsible for browning, ensuring a bright and appealing appearance. Sulfiting enhances color retention by preventing enzymatic and non-enzymatic browning, but its use may raise regulatory and health concerns due to sulfite residues. Combining both methods can optimize color stability while balancing safety and quality in post-harvest potato processing.

Table of Comparison

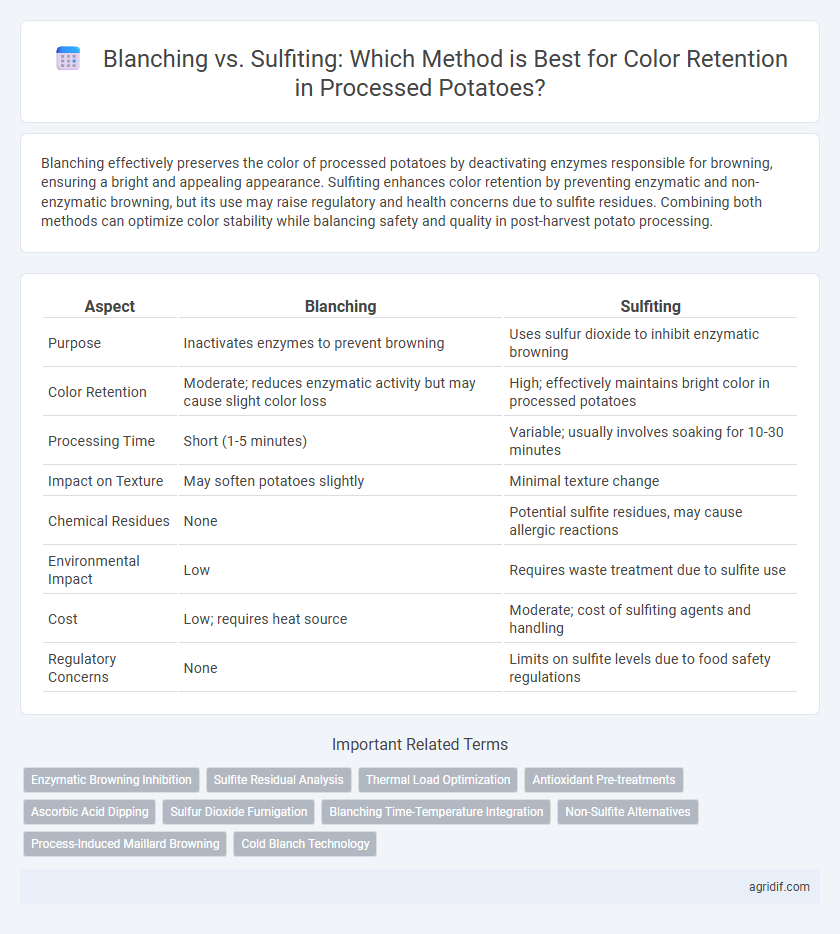

| Aspect | Blanching | Sulfiting |

|---|---|---|

| Purpose | Inactivates enzymes to prevent browning | Uses sulfur dioxide to inhibit enzymatic browning |

| Color Retention | Moderate; reduces enzymatic activity but may cause slight color loss | High; effectively maintains bright color in processed potatoes |

| Processing Time | Short (1-5 minutes) | Variable; usually involves soaking for 10-30 minutes |

| Impact on Texture | May soften potatoes slightly | Minimal texture change |

| Chemical Residues | None | Potential sulfite residues, may cause allergic reactions |

| Environmental Impact | Low | Requires waste treatment due to sulfite use |

| Cost | Low; requires heat source | Moderate; cost of sulfiting agents and handling |

| Regulatory Concerns | None | Limits on sulfite levels due to food safety regulations |

Understanding Color Retention in Processed Potatoes

Blanching effectively inactivates enzymes responsible for browning, preserving the natural color of processed potatoes by halting oxidative reactions. Sulfiting, through the addition of sulfur compounds, inhibits enzymatic and non-enzymatic browning but carries regulatory restrictions due to allergenic potential in some consumers. Optimizing blanching parameters like temperature and time ensures maximum color retention while minimizing nutrient loss, making it a preferred method in post-harvest potato processing.

The Science Behind Blanching: Methods and Benefits

Blanching involves briefly exposing potatoes to hot water or steam to inactivate enzymes responsible for browning and color degradation during storage and processing. This thermal treatment preserves the natural color by halting polyphenol oxidase activity and improving texture and shelf-life in processed potato products. Studies show that optimizing blanching time and temperature, typically at 70-90degC for 2-5 minutes, yields superior color retention compared to sulfiting, which relies on chemical inhibition of enzymatic reactions.

Sulfiting Explained: Mechanisms and Applications

Sulfiting preserves the color of processed potatoes by inhibiting enzymatic browning through the reduction of polyphenol oxidase activity and the maintenance of phenolic compounds in their reduced forms. Its application involves treating potato slices with sulfur dioxide or sodium metabisulfite, which acts as a potent antioxidant and antimicrobial agent, extending shelf life and maintaining quality. This method is preferred over blanching for color retention due to its effectiveness in preventing discoloration without significant texture loss or nutrient degradation.

Comparing Blanching and Sulfiting Techniques

Blanching in processed potatoes involves briefly boiling or steaming to inactivate enzymes, effectively preserving color by preventing enzymatic browning and softening tissue for better texture. Sulfiting employs sulfur dioxide-based compounds that act as antioxidants and antimicrobial agents, significantly enhancing color retention while extending shelf life by inhibiting enzymatic and non-enzymatic browning. Compared to blanching, sulfiting offers superior preservation of the natural potato color but requires careful regulation due to potential allergenic effects and regulatory limits on residual sulfite levels.

Impact on Nutritional Quality: Blanching vs Sulfiting

Blanching in post-harvest processing of potatoes effectively inactivates enzymes, preserving color while slightly reducing water-soluble vitamins such as vitamin C. Sulfiting maintains vibrant color by preventing enzymatic browning but may introduce sulfite residues that can affect nutritional content and cause sensitivity in some consumers. Comparing both, blanching offers a safer method for maintaining nutritional quality, whereas sulfiting ensures superior color retention at the cost of potential nutritional and allergenic concerns.

Effects on Flavor and Texture During Processing

Blanching preserves the natural flavor and texture of potatoes by inactivating enzymes that cause browning while maintaining firmness through brief heat application. Sulfiting effectively enhances color retention by preventing enzymatic browning but may impart a slight sulfurous taste, potentially altering the potato's flavor profile. Texture after sulfiting can become softer due to chemical interactions, whereas blanching typically results in a more desirable, consistent potato texture during processing.

Health and Safety Considerations in Sulfite Use

Sulfiting is effective for color retention in processed potatoes by preventing enzymatic browning but poses health risks for sulfite-sensitive individuals, potentially triggering asthma and allergic reactions. Strict regulations limit sulfite concentrations in food products to ensure consumer safety, requiring clear labeling of sulfite-containing items. Alternatives like blanching reduce microbial load and enzyme activity without chemical residues, offering a safer option for maintaining potato quality.

Regulatory Standards for Color Preservation Methods

Blanching and sulfiting are common post-harvest treatments for color retention in processed potatoes, with respective regulatory standards ensuring consumer safety and product quality. Regulatory agencies such as the FDA and EFSA impose strict limits on sulfite residues due to potential allergenic effects, often favoring blanching as a chemically safer alternative for color preservation. Compliance with these standards is essential for market approval, making blanching a preferred method where sulfite regulation is stringent or consumer demand for clean labeling is high.

Sustainable Practices in Post-Harvest Potato Processing

Blanching effectively preserves the color of processed potatoes by inactivating enzymes responsible for browning while minimizing nutrient loss, making it a sustainable choice due to its low chemical inputs. Sulfiting, although highly efficient in maintaining color by preventing enzymatic browning through sulfur dioxide application, raises environmental concerns and potential health risks from residual chemicals. Sustainable post-harvest potato processing favors blanching techniques integrated with low-energy technologies to balance color retention and environmental impact without compromising food safety.

Future Trends: Innovations in Color Retention Technologies

Emerging trends in post-harvest technology emphasize advanced enzymatic blanching techniques combined with natural sulfiting alternatives to enhance color retention in processed potatoes. Innovations include the integration of non-thermal plasma treatment and edible coatings infused with antioxidants, minimizing enzymatic browning and preserving visual appeal. These cutting-edge approaches aim to reduce chemical residues while maintaining potato quality and consumer acceptance.

Related Important Terms

Enzymatic Browning Inhibition

Blanching effectively inactivates polyphenol oxidase enzymes, preventing enzymatic browning and thus maintaining the natural color of processed potatoes. Sulfiting works by chemically inhibiting enzymatic browning through sulfite compounds, offering superior color retention but raising concerns about residual sulfite levels and regulatory limits.

Sulfite Residual Analysis

Sulfiting in processed potatoes effectively enhances color retention by inhibiting enzymatic browning through the use of sulfur dioxide compounds, which require precise sulfite residual analysis to ensure food safety and regulatory compliance. Accurate quantification of sulfite residues using methods such as ion chromatography or titration is essential to monitor limits set by food safety authorities and prevent potential health risks associated with excessive sulfur dioxide exposure.

Thermal Load Optimization

Blanching applies controlled thermal treatment to inactivate enzymes responsible for browning in processed potatoes, optimizing thermal load to preserve color while minimizing texture degradation. Sulfiting introduces chemical antioxidants to retain color but requires careful management of residual sulfite levels and may not offer the same thermal control advantages as blanching.

Antioxidant Pre-treatments

Blanching enhances color retention in processed potatoes by inactivating enzymes responsible for oxidation, while sulfiting acts as a potent antioxidant by preventing enzymatic browning through sulfur dioxide application. Combining blanching with sulfiting significantly improves the preservation of natural potato color during storage and processing, optimizing product quality and consumer appeal.

Ascorbic Acid Dipping

Blanching reduces enzymatic browning in processed potatoes by inactivating polyphenol oxidase, while sulfiting inhibits browning through sulfur dioxide's antioxidant properties; however, ascorbic acid dipping serves as an effective alternative that preserves color by reducing oxidation without chemical residues. Incorporating ascorbic acid dipping in post-harvest treatment enhances color retention and shelf life, making it a preferred method for maintaining the visual quality of processed potatoes.

Sulfur Dioxide Fumigation

Sulfur dioxide fumigation in sulfiting effectively preserves the natural color of processed potatoes by inhibiting enzymatic browning and microbial growth, outperforming blanching which primarily inactivates enzymes through heat but may cause texture changes. The use of SO2 not only enhances color retention but also extends shelf life, making it the preferred post-harvest treatment for maintaining potato quality in frozen and dehydrated products.

Blanching Time-Temperature Integration

Blanching time-temperature integration plays a critical role in color retention of processed potatoes by inactivating enzymatic browning agents like polyphenol oxidase, with optimal conditions typically around 85-95degC for 3-5 minutes ensuring minimal nutrient loss and vibrant color preservation. Compared to sulfiting, which relies on chemical inhibition of enzymatic activity, precise thermal control in blanching offers an environmentally safer and residue-free method for maintaining potato color during post-harvest processing.

Non-Sulfite Alternatives

Blanching effectively inactivates enzymes responsible for browning in processed potatoes, preserving natural color without chemical residues. Non-sulfite alternatives like steam blanching and controlled atmosphere storage offer sustainable solutions for color retention while avoiding sulfite-related health concerns.

Process-Induced Maillard Browning

Blanching reduces enzymatic browning by inactivating polyphenol oxidase, thus preserving the natural color of processed potatoes, while sulfiting acts as a chemical antioxidant inhibiting Maillard browning by reacting with carbonyl compounds. Sulfiting demonstrates superior effectiveness in minimizing process-induced Maillard browning, maintaining color stability in high-temperature processed potato products.

Cold Blanch Technology

Cold blanch technology offers superior color retention in processed potatoes by inactivating enzymes responsible for browning without the heat-induced texture loss seen in traditional blanching. Compared to sulfiting, it avoids chemical residues and potential allergenic effects while maintaining the natural appearance and extended shelf life of potato products.

Blanching vs Sulfiting for color retention in processed potatoes Infographic

agridif.com

agridif.com