Cold chain logistics ensures the preservation of vegetable freshness by maintaining a consistent low temperature throughout transport, significantly reducing spoilage and extending shelf life. In contrast, ambient storage exposes vegetables to unregulated temperatures, accelerating enzymatic activity and microbial growth, which leads to faster degradation. Choosing cold chain logistics over ambient storage is critical for minimizing post-harvest losses and maintaining quality during vegetable transport.

Table of Comparison

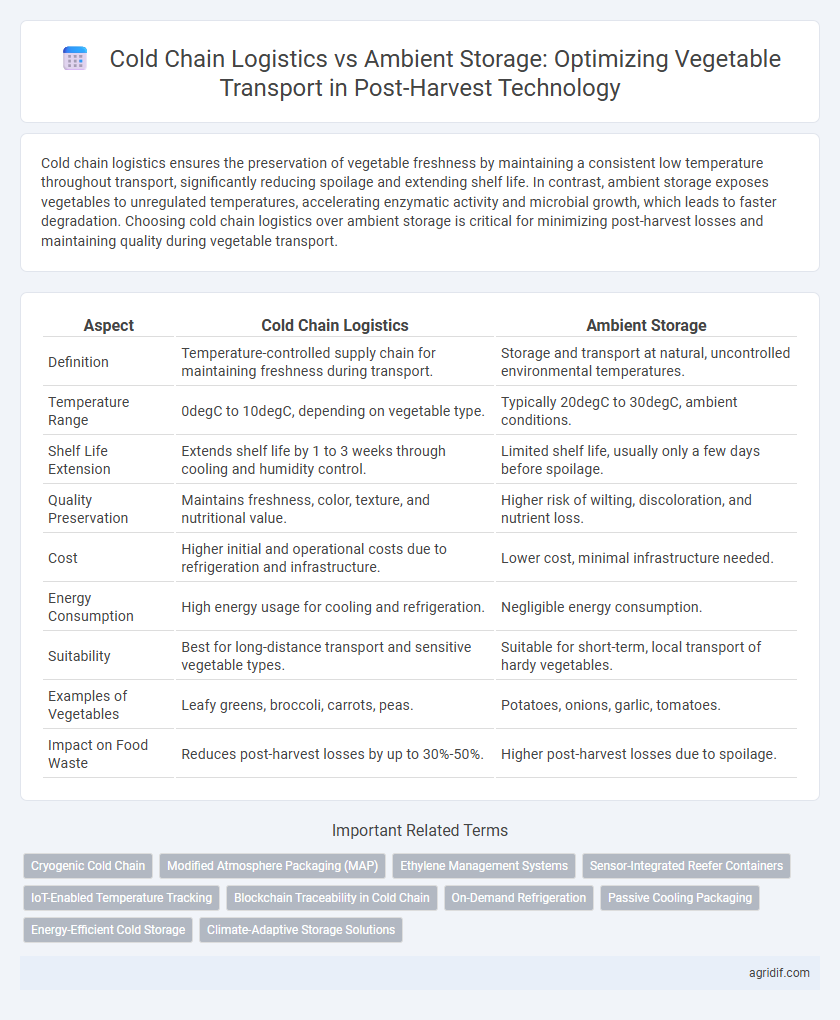

| Aspect | Cold Chain Logistics | Ambient Storage |

|---|---|---|

| Definition | Temperature-controlled supply chain for maintaining freshness during transport. | Storage and transport at natural, uncontrolled environmental temperatures. |

| Temperature Range | 0degC to 10degC, depending on vegetable type. | Typically 20degC to 30degC, ambient conditions. |

| Shelf Life Extension | Extends shelf life by 1 to 3 weeks through cooling and humidity control. | Limited shelf life, usually only a few days before spoilage. |

| Quality Preservation | Maintains freshness, color, texture, and nutritional value. | Higher risk of wilting, discoloration, and nutrient loss. |

| Cost | Higher initial and operational costs due to refrigeration and infrastructure. | Lower cost, minimal infrastructure needed. |

| Energy Consumption | High energy usage for cooling and refrigeration. | Negligible energy consumption. |

| Suitability | Best for long-distance transport and sensitive vegetable types. | Suitable for short-term, local transport of hardy vegetables. |

| Examples of Vegetables | Leafy greens, broccoli, carrots, peas. | Potatoes, onions, garlic, tomatoes. |

| Impact on Food Waste | Reduces post-harvest losses by up to 30%-50%. | Higher post-harvest losses due to spoilage. |

Overview of Cold Chain Logistics in Vegetable Transport

Cold chain logistics in vegetable transport maintains optimal low temperatures from harvest to consumer, significantly reducing spoilage and extending shelf life. It involves refrigerated vehicles, temperature-controlled storage, and real-time monitoring systems to ensure consistent cooling throughout the supply chain. This technology is crucial for preserving nutrient quality and minimizing post-harvest losses in highly perishable vegetables.

Principles of Ambient Storage for Fresh Produce

Ambient storage for fresh produce relies on maintaining controlled temperature, humidity, and ventilation to slow down respiration and reduce moisture loss. This method preserves sensory quality by preventing condensation and microbial growth without the complexity and cost of refrigeration. Its effectiveness depends on factors like produce type, ambient climate, and duration of storage, making it suitable for short-term transport in moderate environments.

Comparative Analysis: Shelf-life of Vegetables

Cold chain logistics significantly extends the shelf-life of vegetables by maintaining optimal temperatures between 0degC to 5degC, minimizing enzymatic activity and microbial growth. In contrast, ambient storage at room temperature accelerates senescence and spoilage, typically reducing shelf-life by 30-50% depending on the vegetable type. Studies indicate that cold chain transport can preserve freshness for up to 2-3 weeks, whereas ambient conditions often limit shelf-life to less than one week.

Temperature Management and Quality Preservation

Cold chain logistics maintains vegetables at consistently low temperatures, effectively slowing metabolic processes and microbial growth to preserve freshness and nutritional quality during transport. Ambient storage exposes vegetables to fluctuating temperatures, increasing the risk of spoilage, moisture loss, and reduced shelf life due to accelerated enzymatic activity. Temperature management through cold chain systems ensures optimal quality preservation, reducing post-harvest losses and maintaining market value.

Cost Implications: Cold Chain vs Ambient Storage

Cold chain logistics for vegetable transport involves refrigerated storage and vehicles, significantly increasing operational costs compared to ambient storage, which relies on natural temperature conditions. Higher energy consumption, specialized equipment, and maintenance requirements contribute to the elevated expenses in cold chain systems, while ambient storage reduces costs but risks higher spoilage rates. Choosing cold chain logistics can result in cost savings by reducing post-harvest losses and extending shelf life, potentially offsetting the increased initial investment.

Impact on Nutritional Value and Food Safety

Cold chain logistics for vegetable transport maintains optimal low temperatures, significantly preserving nutritional value by reducing enzymatic degradation and microbial growth compared to ambient storage. Ambient storage, exposed to fluctuating temperatures and humidity, accelerates nutrient loss and increases the risk of foodborne pathogens, compromising food safety. Implementing cold chain systems ensures extended shelf life, higher vitamin retention, and reduced spoilage, thereby enhancing overall food quality and safety during post-harvest handling.

Infrastructure Requirements for Both Systems

Cold chain logistics for vegetable transport requires advanced refrigeration facilities, insulated containers, and continuous temperature monitoring systems to maintain optimal freshness and reduce spoilage. Ambient storage relies on well-ventilated warehouses, moisture control, and pest management but lacks temperature control infrastructure, making it less effective for perishable produce. Investments in energy-efficient cooling technology and real-time tracking frameworks are critical for optimizing cold chain infrastructure over ambient storage methods.

Environmental Concerns and Energy Consumption

Cold chain logistics for vegetable transport significantly reduces spoilage by maintaining temperatures between 0-10degC but involves high energy consumption from refrigeration units, contributing to increased greenhouse gas emissions. Ambient storage, despite lower energy use, leads to faster deterioration and higher post-harvest losses, indirectly causing greater environmental impact through discarded produce. Implementing energy-efficient refrigeration systems and optimizing transport routes can mitigate the environmental footprint of cold chain logistics in post-harvest vegetable distribution.

Best Practices for Reducing Post-harvest Losses

Cold chain logistics significantly reduces post-harvest losses by maintaining optimal low temperatures and humidity levels, slowing down respiration rates and microbial growth in vegetables during transport. Ambient storage, while cost-effective, increases the risk of spoilage and nutrient degradation due to temperature fluctuations and inadequate humidity control. Implementing cold chain systems combined with proper packaging and timely handling ensures maximum freshness and shelf-life extension for perishable vegetables.

Future Trends in Vegetable Transport and Storage

Emerging trends in post-harvest technology emphasize the integration of smart cold chain logistics with IoT-enabled sensors to monitor temperature and humidity in real-time, ensuring optimal freshness during vegetable transport. Advances in phase change materials and solar-powered refrigeration systems are improving energy efficiency and sustainability in cold chain solutions. Meanwhile, innovations in modified atmosphere packaging and ethylene scavengers are enhancing ambient storage viability by extending shelf life and maintaining vegetable quality without reliance on continuous refrigeration.

Related Important Terms

Cryogenic Cold Chain

Cryogenic cold chain logistics employs ultra-low temperatures using liquid nitrogen or carbon dioxide to preserve vegetable freshness, minimizing enzymatic activity and microbial growth during transport. This method significantly outperforms ambient storage by extending shelf life and maintaining nutritional quality, reducing post-harvest losses in the vegetable supply chain.

Modified Atmosphere Packaging (MAP)

Modified Atmosphere Packaging (MAP) significantly enhances vegetable freshness during transport by altering gas compositions to slow respiration and microbial growth, offering a cost-effective alternative to Cold Chain Logistics. While cold chain systems maintain low temperatures to preserve quality, MAP optimizes atmospheric conditions within packaging, reducing dependence on refrigeration and extending shelf life in ambient storage environments.

Ethylene Management Systems

Cold chain logistics significantly reduce ethylene accumulation by maintaining low temperatures, thereby slowing ethylene production and enzymatic activity, which preserves vegetable freshness and shelf life during transport. In contrast, ambient storage lacks temperature control, leading to rapid ethylene buildup that accelerates ripening and spoilage unless advanced ethylene management systems such as ethylene scrubbers or absorbers are employed.

Sensor-Integrated Reefer Containers

Sensor-integrated reefer containers in cold chain logistics enhance vegetable transport by maintaining precise temperature and humidity control, significantly reducing post-harvest losses compared to ambient storage. Real-time monitoring through IoT sensors ensures optimal freshness and extends shelf life by detecting and responding to environmental fluctuations during transit.

IoT-Enabled Temperature Tracking

IoT-enabled temperature tracking in cold chain logistics ensures precise monitoring and maintenance of optimal conditions, significantly reducing spoilage and extending the shelf life of transported vegetables. Ambient storage lacks real-time data feedback, increasing the risk of temperature fluctuations that compromise vegetable quality and safety during transit.

Blockchain Traceability in Cold Chain

Cold Chain Logistics employs temperature-controlled environments to maintain vegetable freshness and reduce spoilage during transport, enhancing quality through seamless blockchain traceability that records every stage from farm to market. Blockchain integration in cold chain systems ensures transparent, tamper-proof data on temperature, humidity, and handling conditions, outperforming ambient storage by providing real-time insights and accountability for post-harvest quality preservation.

On-Demand Refrigeration

On-demand refrigeration in cold chain logistics offers precise temperature control critical for maintaining vegetable freshness and extending shelf life during transport, unlike ambient storage which exposes produce to fluctuating temperatures leading to rapid quality degradation. Leveraging real-time cooling only when necessary reduces energy consumption and operational costs while ensuring optimal post-harvest quality preservation in supply chains.

Passive Cooling Packaging

Passive cooling packaging in cold chain logistics significantly reduces temperature fluctuations during vegetable transport, preserving freshness and extending shelf life compared to ambient storage methods. Utilizing materials with high thermal insulation and phase change properties, passive cooling systems maintain optimal conditions without active refrigeration, lowering energy costs and minimizing spoilage.

Energy-Efficient Cold Storage

Energy-efficient cold storage in cold chain logistics significantly reduces post-harvest losses by maintaining optimal temperature and humidity levels, extending vegetable freshness and shelf life compared to ambient storage. Implementing advanced insulation materials and renewable energy sources in cold storage facilities enhances energy efficiency, lowering operational costs and minimizing carbon footprints during vegetable transport.

Climate-Adaptive Storage Solutions

Cold chain logistics employs refrigerated transportation and storage to maintain optimal low temperatures, minimizing enzymatic degradation and microbial growth in vegetables, thus extending shelf life and preserving nutritional quality. In contrast, ambient storage relies on climate-adaptive technologies such as modified atmosphere packaging and evaporative cooling, which optimize local environmental conditions to reduce respiration rates and moisture loss in vegetables without continuous refrigeration.

Cold Chain Logistics vs Ambient Storage for Vegetable Transport Infographic

agridif.com

agridif.com