Mechanical drying offers precise control over temperature and airflow, resulting in faster and more uniform grain moisture reduction compared to sun drying. Sun drying depends heavily on weather conditions, making it less reliable and often slower, which can increase the risk of mold and spoilage. The advanced technology in mechanical drying improves grain quality by minimizing exposure to contaminants and reducing post-harvest losses.

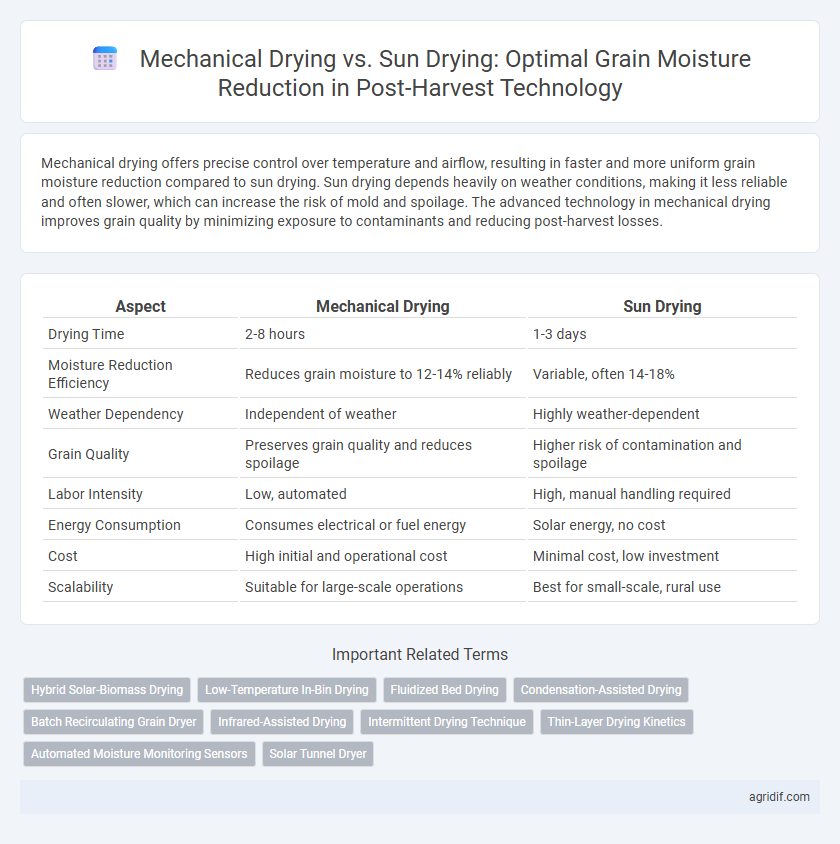

Table of Comparison

| Aspect | Mechanical Drying | Sun Drying |

|---|---|---|

| Drying Time | 2-8 hours | 1-3 days |

| Moisture Reduction Efficiency | Reduces grain moisture to 12-14% reliably | Variable, often 14-18% |

| Weather Dependency | Independent of weather | Highly weather-dependent |

| Grain Quality | Preserves grain quality and reduces spoilage | Higher risk of contamination and spoilage |

| Labor Intensity | Low, automated | High, manual handling required |

| Energy Consumption | Consumes electrical or fuel energy | Solar energy, no cost |

| Cost | High initial and operational cost | Minimal cost, low investment |

| Scalability | Suitable for large-scale operations | Best for small-scale, rural use |

Introduction to Grain Moisture Reduction Methods

Mechanical drying uses controlled heat and airflow to reduce grain moisture rapidly and uniformly, minimizing spoilage and improving storage stability. Sun drying relies on natural solar energy and ambient conditions, which can be inconsistent and slower but requires minimal equipment and energy input. Effective grain moisture reduction is critical for maintaining grain quality and preventing microbial growth during post-harvest storage.

Principles of Mechanical Drying in Agriculture

Mechanical drying in agriculture utilizes controlled heat and airflow to reduce grain moisture efficiently, ensuring uniform drying and minimizing spoilage risks. This technology relies on principles such as heat transfer, mass transfer, and thermodynamics to remove moisture from grain kernels while maintaining quality. Compared to sun drying, mechanical drying offers faster processing times, consistent moisture content, and reduced dependence on weather conditions, enhancing post-harvest grain preservation.

Understanding Sun Drying for Post-harvest Grains

Sun drying remains a widely used post-harvest method for reducing grain moisture due to its low cost and simplicity. It relies on natural sunlight and ambient airflow to evaporate moisture, which helps prevent fungal growth and spoilage in grains like maize, rice, and wheat. Factors such as weather conditions, drying surface hygiene, and drying duration significantly influence the efficiency and safety of sun-dried grains.

Comparative Efficiency: Mechanical vs Sun Drying

Mechanical drying reduces grain moisture content more rapidly and consistently than sun drying, achieving target levels within hours compared to days. This method minimizes exposure to contaminants and pests, enhancing grain quality and storage longevity. Sun drying, while cost-effective and energy-efficient, is more susceptible to weather disruptions and uneven drying, increasing the risk of spoilage and loss.

Impact on Grain Quality and Shelf Life

Mechanical drying significantly improves grain moisture reduction consistency, preserving grain quality by minimizing microbial growth and enzymatic activity compared to sun drying, which is susceptible to environmental fluctuations and contamination. Controlled temperature and airflow in mechanical dryers enhance the shelf life of grains by reducing moisture content uniformly without overheating, thus preventing nutrient degradation and physical damage. Sun drying, while cost-effective, often results in uneven drying and increased risk of insect infestation, leading to reduced grain quality and shorter storage periods.

Economic Considerations: Costs and Returns

Mechanical drying incurs higher initial investment and operational costs compared to sun drying but offers faster moisture reduction and lower post-harvest losses, enhancing overall profitability. Sun drying requires minimal capital but often results in inconsistent moisture levels and greater susceptibility to contamination, which can reduce grain quality and market value. Evaluating cost-benefit trade-offs, mechanical drying can yield higher returns in large-scale operations due to improved efficiency and grain quality preservation.

Time Requirements and Scalability

Mechanical drying significantly reduces grain moisture levels within hours, compared to several days required for sun drying, allowing faster processing and minimizing spoilage risks. It offers scalable solutions suited for large-scale operations with controlled environment dryers capable of handling tons of grain simultaneously. Sun drying is limited by weather conditions and labor intensity, making it less viable for high-volume commercial grain storage.

Environmental Implications of Drying Methods

Mechanical drying of grains often consumes significant amounts of energy, leading to higher greenhouse gas emissions compared to traditional sun drying techniques. Sun drying relies on natural solar energy, reducing carbon footprint but can be less efficient and more dependent on weather conditions. Sustainable post-harvest practices increasingly advocate for solar-assisted mechanical dryers to balance environmental impact with drying efficiency.

Suitability for Smallholder vs Commercial Farms

Mechanical drying offers precise control over grain moisture reduction, making it highly suitable for commercial farms that require consistent drying efficiency and large-scale processing. Sun drying, while cost-effective and accessible, is better suited for smallholder farms due to its low capital requirement and reliance on ambient weather conditions. Smallholder farms benefit from sun drying's simplicity despite longer drying times and potential quality variability compared to mechanical drying systems.

Future Trends in Grain Drying Technologies

Mechanical drying offers precise control over temperature and humidity, significantly reducing grain moisture content more efficiently than traditional sun drying methods. Future trends in grain drying technologies emphasize energy-efficient systems, integration of IoT sensors for real-time moisture monitoring, and the use of solar-powered mechanical dryers to combine sustainability with speed. Advances in hybrid drying techniques aim to optimize drying time while preserving grain quality and minimizing environmental impact.

Related Important Terms

Hybrid Solar-Biomass Drying

Hybrid solar-biomass drying systems significantly improve grain moisture reduction by combining solar energy with biomass heat, achieving faster drying rates and reducing post-harvest losses compared to traditional sun drying. Mechanical drying through this hybrid method offers controlled temperature and humidity settings, ensuring uniform drying and preserving grain quality while minimizing energy consumption and environmental impact.

Low-Temperature In-Bin Drying

Low-temperature in-bin drying offers precise control of grain moisture reduction by maintaining consistent airflow and temperature, minimizing kernel damage compared to sun drying. This method enhances grain quality and storage stability while reducing dependence on weather conditions and contamination risks inherent in traditional sun drying.

Fluidized Bed Drying

Fluidized bed drying offers superior grain moisture reduction compared to traditional sun drying by providing uniform heat distribution and rapid drying rates, which minimize spoilage and preserve grain quality. This mechanical drying method enhances post-harvest efficiency, reduces dependency on weather conditions, and maintains optimal moisture levels crucial for long-term storage and market value.

Condensation-Assisted Drying

Condensation-assisted drying in mechanical drying systems enhances grain moisture reduction by using controlled temperature and humidity to prevent surface hardening and maintain grain quality, outperforming traditional sun drying methods vulnerable to uneven drying and contamination. This technology accelerates drying rates and reduces post-harvest losses by minimizing moisture gradients and preserving grain viability during storage.

Batch Recirculating Grain Dryer

Batch recirculating grain dryers offer precise control over temperature and airflow, resulting in uniform moisture reduction and minimized grain damage compared to traditional sun drying. This mechanical drying method significantly shortens drying time, reduces post-harvest losses, and ensures consistent grain quality for long-term storage.

Infrared-Assisted Drying

Infrared-assisted drying significantly accelerates grain moisture reduction compared to traditional sun drying by utilizing infrared radiation to penetrate grains, ensuring uniform heat distribution and minimizing nutrient loss. This advanced mechanical drying method enhances drying efficiency, reduces dependency on weather conditions, and improves overall grain quality during post-harvest processing.

Intermittent Drying Technique

Intermittent drying technique in mechanical drying effectively reduces grain moisture by alternating drying and tempering periods, minimizing thermal damage and improving grain quality compared to continuous sun drying. This method optimizes moisture removal rates and energy use, ensuring better preservation of nutritional content and reducing post-harvest losses in grains.

Thin-Layer Drying Kinetics

Mechanical drying offers controlled temperature and airflow, enabling consistent thin-layer drying kinetics that enhance grain moisture reduction efficiency compared to the variable conditions of sun drying. Thin-layer drying models applied to mechanical drying provide precise moisture loss predictions, optimizing drying time and minimizing grain quality degradation.

Automated Moisture Monitoring Sensors

Automated moisture monitoring sensors enable precise control during mechanical drying of grains, optimizing drying time and energy consumption compared to traditional sun drying methods. These sensors provide real-time moisture data, reducing the risk of over-drying or mold growth and improving overall grain quality and storage stability.

Solar Tunnel Dryer

Solar Tunnel Dryers offer a controlled environment that significantly reduces grain moisture more efficiently than traditional sun drying, minimizing contamination and spoilage risks. Their energy-efficient design harnesses solar radiation to maintain optimal drying temperatures, improving grain quality and reducing drying time by up to 50% compared to open sun drying.

Mechanical Drying vs Sun Drying for grain moisture reduction Infographic

agridif.com

agridif.com