Modified Atmosphere Pallet Covers provide superior field heat retention by creating a controlled environment that reduces oxygen and moisture exchange, effectively slowing down respiration and decay in post-harvest produce. Bin Tarping offers a basic layer of insulation but lacks the advanced gas permeability control that Modified Atmosphere Pallet Covers achieve, resulting in less effective temperature stabilization. Employing Modified Atmosphere Pallet Covers enhances freshness and extends shelf life by optimizing thermal and atmospheric conditions immediately after harvest.

Table of Comparison

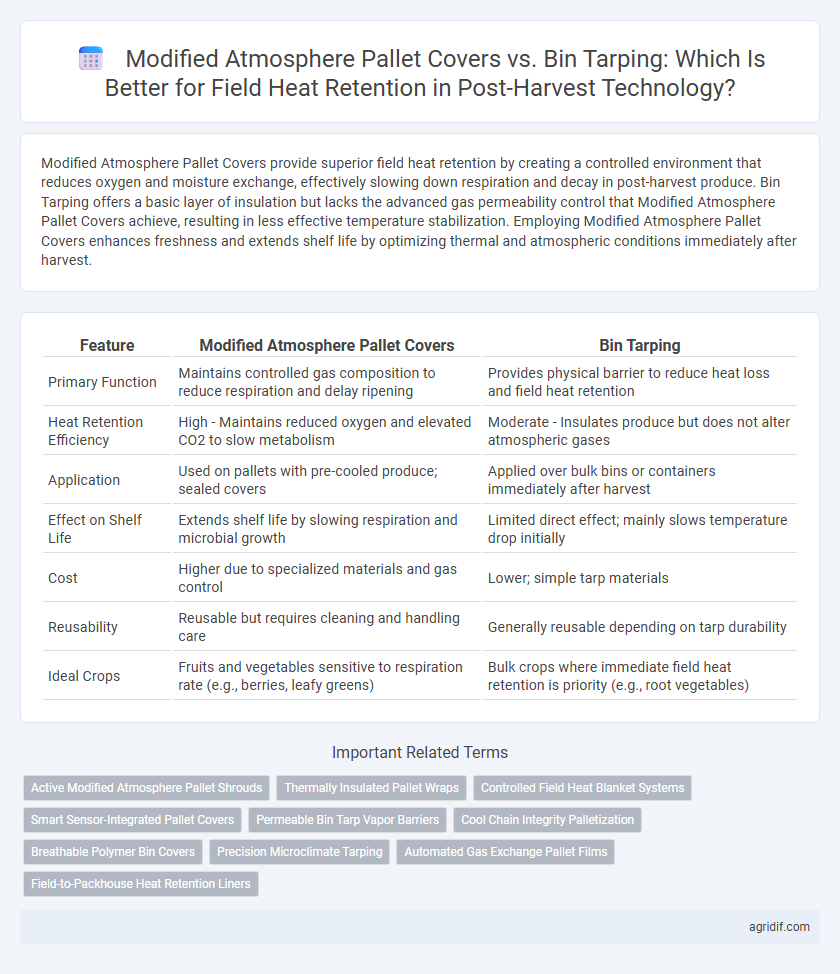

| Feature | Modified Atmosphere Pallet Covers | Bin Tarping |

|---|---|---|

| Primary Function | Maintains controlled gas composition to reduce respiration and delay ripening | Provides physical barrier to reduce heat loss and field heat retention |

| Heat Retention Efficiency | High - Maintains reduced oxygen and elevated CO2 to slow metabolism | Moderate - Insulates produce but does not alter atmospheric gases |

| Application | Used on pallets with pre-cooled produce; sealed covers | Applied over bulk bins or containers immediately after harvest |

| Effect on Shelf Life | Extends shelf life by slowing respiration and microbial growth | Limited direct effect; mainly slows temperature drop initially |

| Cost | Higher due to specialized materials and gas control | Lower; simple tarp materials |

| Reusability | Reusable but requires cleaning and handling care | Generally reusable depending on tarp durability |

| Ideal Crops | Fruits and vegetables sensitive to respiration rate (e.g., berries, leafy greens) | Bulk crops where immediate field heat retention is priority (e.g., root vegetables) |

Introduction to Field Heat Retention in Post-harvest Handling

Field heat retention is a critical factor in post-harvest handling, directly influencing the quality and shelf life of fresh produce. Modified atmosphere pallet covers create a controlled environment by reducing oxygen and carbon dioxide exchange, thereby slowing metabolic rates and maintaining freshness. In contrast, bin tarping primarily acts as a physical barrier to heat loss, offering less precise control over atmospheric composition but effective protection against external temperature fluctuations.

Fundamentals of Modified Atmosphere Pallet Covers

Modified atmosphere pallet covers function by creating a controlled environment that reduces oxygen levels and increases carbon dioxide concentration, slowing respiration and moisture loss in harvested produce. These covers use gas-impermeable films and integrated gas flush systems to maintain optimal atmospheric conditions around pallets, effectively minimizing field heat retention compared to traditional bin tarping. The fundamental advantage lies in their ability to extend produce shelf life by maintaining lower temperatures and reducing metabolic activity immediately after harvest.

Understanding Bin Tarping Techniques

Bin tarping techniques effectively reduce post-harvest field heat by creating a barrier that minimizes heat exchange, preserving crop quality and extending shelf life. Utilizing breathable, UV-resistant materials in bin tarping ensures optimal moisture control and prevents condensation, which is critical for fruit and vegetable storage. Compared to modified atmosphere pallet covers, bin tarping offers a customizable solution tailored to different harvest volumes and varying field conditions.

Comparative Effectiveness: Heat Retention Capabilities

Modified atmosphere pallet covers provide superior heat retention capabilities by minimizing oxygen exposure and reducing respiration rates, which slows the cooling process more effectively than bin tarping. Bin tarp systems primarily act as physical barriers to heat loss but lack the gas composition control that enhances thermal insulation in modified atmosphere covers. As a result, pallet covers maintain higher produce temperatures longer, preserving quality and extending shelf life more efficiently in post-harvest settings.

Impact on Crop Quality and Shelf Life

Modified atmosphere pallet covers significantly enhance crop quality and extend shelf life by reducing oxygen levels and increasing carbon dioxide concentration, which slows respiration and inhibits microbial growth. In contrast, bin tarping primarily reduces physical heat exchange without altering the atmospheric composition, resulting in less effective control of respiration rates and limited impact on preserving freshness. Studies demonstrate that crops stored with modified atmosphere covers maintain firmness, color, and nutritional value longer compared to those using traditional bin tarp methods.

Ease of Application and Labor Considerations

Modified atmosphere pallet covers offer a simpler and faster application process compared to bin tarping, significantly reducing labor requirements during post-harvest handling. Pallet covers are designed for easy placement and removal, minimizing worker fatigue and time spent on field heat retention, whereas bin tarping involves more complex securing methods demanding additional manpower. This streamlined application improves operational efficiency and lowers labor costs in maintaining optimal storage temperatures.

Cost Analysis: Modified Atmosphere Covers vs Bin Tarping

Modified atmosphere pallet covers offer superior field heat retention with reduced cooling costs compared to traditional bin tarping, due to enhanced gas permeability and controlled humidity. The initial investment in modified atmosphere covers is higher, but long-term savings arise from decreased spoilage and extended shelf life of produce. Bin tarping shows lower upfront costs but may lead to increased cooling expenses and potential quality degradation, impacting overall cost efficiency.

Environmental Implications and Material Sustainability

Modified atmosphere pallet covers enhance field heat retention by creating a controlled microenvironment that reduces respiration rates and moisture loss, leading to improved produce shelf life with minimal energy input. These covers are typically made from recyclable polyethylene or biodegradable films, offering a more sustainable option compared to traditional bin tarping materials, which often use heavier-duty, non-breathable plastics that contribute to greater environmental waste. The choice of pallet covers significantly impacts resource efficiency and waste management in post-harvest handling, promoting reduced carbon footprint and aligned with sustainable agricultural practices.

Case Studies: Real-world Performance in Various Crops

Case studies comparing Modified Atmosphere Pallet Covers and Bin Tarping reveal that Modified Atmosphere Pallet Covers consistently maintain lower temperatures, reducing respiration rates and delaying spoilage in crops like berries, tomatoes, and leafy greens. Data from tomato and blueberry shipments indicate temperature reductions of up to 5degC with pallet covers compared to traditional bin tarp methods, enhancing shelf life by 20-30%. Field trials highlight the superior efficacy of Modified Atmosphere Pallet Covers in preserving product quality during transport and storage, especially under fluctuating ambient temperatures.

Recommendations for Optimal Field Heat Retention Practices

Modified Atmosphere Pallet Covers (MAPC) provide superior field heat retention compared to traditional Bin Tarping by creating a controlled microenvironment that reduces respiration rates and moisture loss in harvested produce. For optimal field heat retention, it is recommended to use MAPC immediately after harvest, ensuring tight seals and minimal air exchange to maintain cooler temperatures and extend freshness. Bin Tarping can be used as a secondary method during transport but should be combined with rapid cooling techniques to prevent metabolic heat buildup and quality degradation.

Related Important Terms

Active Modified Atmosphere Pallet Shrouds

Active Modified Atmosphere Pallet Shrouds outperform traditional bin tarping by precisely controlling oxygen and carbon dioxide levels to significantly reduce respiration rates and field heat in harvested produce. These shrouds create a dynamic environment that extends shelf life and maintains quality by actively adjusting gas compositions, unlike passive bin tarping which mainly provides insulation without gas modulation.

Thermally Insulated Pallet Wraps

Thermally insulated pallet wraps significantly outperform traditional bin tarping in retaining field heat, reducing temperature loss by up to 40%, which preserves fruit quality during post-harvest handling. Unlike bin tarps, these modified atmosphere pallet covers provide enhanced thermal insulation and moisture control, minimizing cold injury and maintaining optimal storage conditions.

Controlled Field Heat Blanket Systems

Controlled Field Heat Blanket Systems using Modified Atmosphere Pallet Covers significantly reduce respiratory rates and moisture loss in harvested produce compared to traditional Bin Tarping methods, optimizing temperature regulation during transport. These covers create a microenvironment with tailored gas composition, enhancing field heat retention and extending shelf life while minimizing post-harvest quality degradation.

Smart Sensor-Integrated Pallet Covers

Smart sensor-integrated modified atmosphere pallet covers significantly enhance field heat retention by continuously monitoring and adjusting microclimate conditions to optimize produce freshness and reduce spoilage. Unlike traditional bin tarping, these advanced covers provide real-time data on temperature and humidity, enabling proactive management and minimizing post-harvest losses.

Permeable Bin Tarp Vapor Barriers

Modified atmosphere pallet covers significantly reduce field heat loss by creating a controlled microenvironment, while permeable bin tarp vapor barriers allow selective moisture exchange, mitigating condensation and preserving produce quality. Compared to impermeable covers, permeable bin tarping balances vapor permeability and insulation, optimizing temperature retention and reducing decay during post-harvest storage.

Cool Chain Integrity Palletization

Modified Atmosphere Pallet Covers enhance cool chain integrity by reducing oxygen and moisture exchange, effectively retaining field heat and extending produce freshness compared to Bin Tarping, which offers less consistent temperature control. Cool chain palletization using Modified Atmosphere covers maintains optimal post-harvest quality and reduces spoilage rates during transportation and storage.

Breathable Polymer Bin Covers

Breathable polymer bin covers enhance field heat retention by allowing controlled gas exchange, reducing condensation and moisture buildup compared to traditional bin tarping. Modified atmosphere pallet covers complement this by creating a regulated environment that slows respiration rates and prolongs produce freshness during post-harvest storage and transport.

Precision Microclimate Tarping

Precision Microclimate Tarping using Modified Atmosphere Pallet Covers significantly enhances field heat retention by creating a controlled environment that reduces respiration rates and moisture loss in harvested produce. Compared to traditional Bin Tarping, this technology offers superior insulation and gas exchange regulation, leading to extended freshness and reduced post-harvest spoilage.

Automated Gas Exchange Pallet Films

Automated Gas Exchange Pallet Films in Modified Atmosphere Pallet Covers provide superior field heat retention compared to traditional Bin Tarping by dynamically regulating oxygen and carbon dioxide levels, reducing respiration rates and moisture loss in harvested produce. These advanced films enhance temperature control and extend shelf life, optimizing post-harvest quality during storage and transportation.

Field-to-Packhouse Heat Retention Liners

Field-to-packhouse heat retention liners, such as Modified Atmosphere Pallet Covers, provide enhanced thermal insulation by creating a controlled microenvironment that minimizes temperature fluctuations during transit, significantly reducing field heat loss compared to traditional bin tarping methods. The advanced permeability and sealing properties of these pallet covers optimize respiration rates and moisture retention, ensuring better produce quality and extended shelf life from field to packhouse.

Modified Atmosphere Pallet Covers vs Bin Tarping for field heat retention Infographic

agridif.com

agridif.com