Wax coating enhances fruit shelf life by creating a moisture barrier that reduces water loss and delays ripening, but often relies on synthetic materials that may raise consumer health concerns. Edible biofilm coatings, composed of natural polymers such as proteins and polysaccharides, offer an eco-friendly alternative that can improve gas exchange while providing antimicrobial properties. These biofilms are increasingly preferred for sustainable post-harvest technology due to their biodegradability and compatibility with organic fruit preservation practices.

Table of Comparison

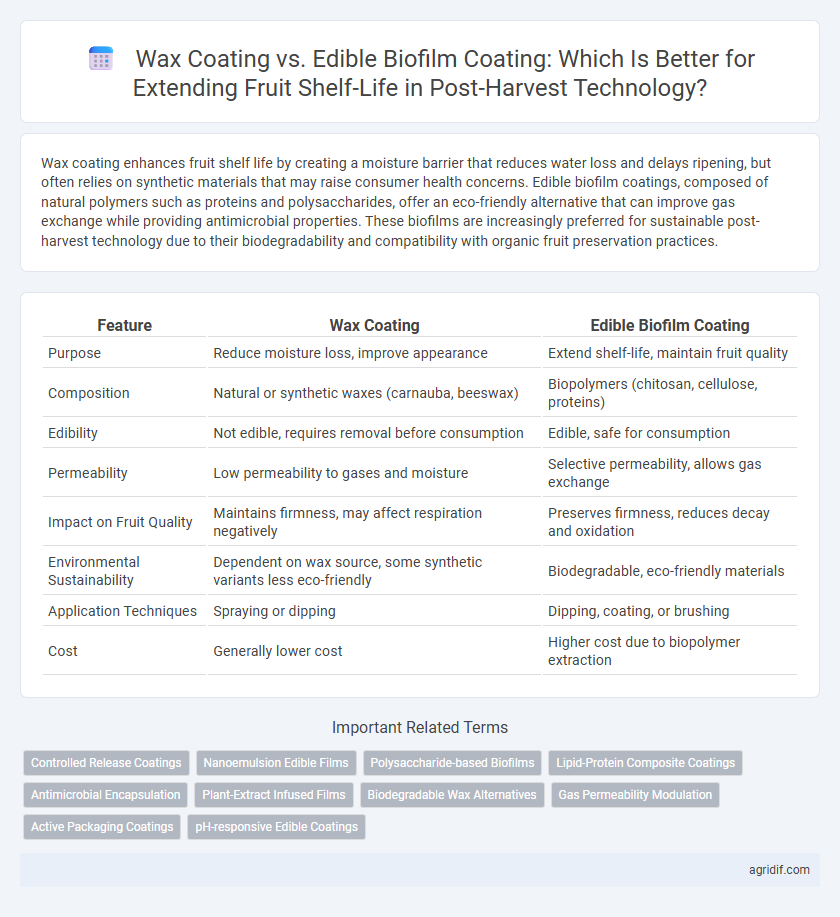

| Feature | Wax Coating | Edible Biofilm Coating |

|---|---|---|

| Purpose | Reduce moisture loss, improve appearance | Extend shelf-life, maintain fruit quality |

| Composition | Natural or synthetic waxes (carnauba, beeswax) | Biopolymers (chitosan, cellulose, proteins) |

| Edibility | Not edible, requires removal before consumption | Edible, safe for consumption |

| Permeability | Low permeability to gases and moisture | Selective permeability, allows gas exchange |

| Impact on Fruit Quality | Maintains firmness, may affect respiration negatively | Preserves firmness, reduces decay and oxidation |

| Environmental Sustainability | Dependent on wax source, some synthetic variants less eco-friendly | Biodegradable, eco-friendly materials |

| Application Techniques | Spraying or dipping | Dipping, coating, or brushing |

| Cost | Generally lower cost | Higher cost due to biopolymer extraction |

Introduction to Post-Harvest Fruit Preservation

Wax coating is widely used in post-harvest fruit preservation for its effectiveness in reducing moisture loss and delaying ripening by creating a semi-permeable barrier on the fruit surface. Edible biofilm coatings, derived from natural polymers like proteins, lipids, and polysaccharides, offer a biodegradable alternative that not only extends shelf-life but also enhances fruit quality by providing antimicrobial properties. Both methods play crucial roles in maintaining fruit firmness, reducing decay, and improving storage life, with biofilm coatings gaining importance due to consumer demand for eco-friendly and safe preservation solutions.

Overview of Wax Coating in Fruit Shelf-Life Extension

Wax coating serves as a traditional method in post-harvest technology to extend fruit shelf-life by creating a protective barrier that reduces moisture loss and gas exchange. This coating improves appearance and delays ripening by minimizing respiration rates and preventing microbial contamination. Common wax materials include carnauba, shellac, and beeswax, chosen for their hydrophobic properties and compatibility with various fruit surfaces.

Edible Biofilm Coating: Definition and Types

Edible biofilm coatings are thin, consumable layers applied to fruits, enhancing shelf-life by reducing moisture loss and microbial spoilage. These coatings are primarily composed of natural polymers such as polysaccharides, proteins, and lipids, with common types including alginate, chitosan, and starch-based films. Their biodegradable and non-toxic nature makes them an environmentally friendly alternative to traditional wax coatings in post-harvest fruit protection.

Comparative Effect on Shelf-Life: Wax vs. Edible Biofilm

Wax coating and edible biofilm coatings both enhance fruit shelf-life by reducing moisture loss and slowing respiration, but edible biofilms offer superior biodegradability and reduced chemical residue. Wax coatings provide a durable barrier that extends shelf-life by up to 2-3 weeks depending on fruit type, while edible biofilms, enriched with natural antimicrobials and antioxidants, can further inhibit microbial spoilage and preserve nutritional quality. Comparative studies indicate that fruits treated with edible biofilm coatings retain firmness and sensory attributes longer than wax-coated counterparts, making biofilms a promising sustainable alternative in post-harvest technology.

Impact on Fruit Quality and Sensory Attributes

Wax coating enhances fruit shelf-life by creating a moisture barrier that reduces dehydration and decay, but it may cause a waxy texture and off-flavors affecting sensory appeal. Edible biofilm coatings, composed of natural polymers like chitosan or alginate, improve gas exchange and retain fruit firmness, flavor, and aroma more effectively, preserving sensory attributes. Studies show biofilm coatings maintain better visual quality and consumer acceptance compared to conventional wax coatings in fruits such as apples and tomatoes.

Safety and Regulatory Considerations

Wax coatings, commonly used to extend fruit shelf-life, are subject to strict food safety regulations ensuring the use of food-grade, non-toxic substances approved by agencies like the FDA and EFSA. Edible biofilm coatings, derived from natural polymers such as chitosan, starch, or proteins, offer a safer alternative with biodegradable properties and reduced chemical residues, aligning with organic and clean-label standards. Regulatory concerns for biofilms emphasize allergenicity and source transparency, requiring comprehensive safety assessments and compliance with regional food additive laws for market approval.

Environmental Sustainability of Coating Materials

Wax coating for fruit preservation offers effective barrier properties but often relies on petroleum-based ingredients, raising concerns about environmental sustainability and biodegradability. Edible biofilm coatings derived from natural polymers such as chitosan, starch, and proteins provide eco-friendly alternatives that are biodegradable and reduce reliance on synthetic chemicals. Utilizing bio-based coatings supports sustainable agriculture by minimizing plastic waste and enhancing post-harvest shelf-life through renewable, non-toxic materials.

Consumer Perceptions and Market Acceptance

Wax coating provides a glossy finish and extends fruit shelf-life by reducing moisture loss, but consumer concerns about chemical residues limit its market acceptance. Edible biofilm coatings, made from natural polymers like chitosan and alginate, offer a biodegradable and non-toxic alternative that aligns with growing demand for sustainable and health-conscious products. Consumer preference increasingly favors biofilm coatings due to perceived safety and environmental benefits, driving market trends toward cleaner-label post-harvest technologies.

Case Studies: Real-World Applications and Results

Wax coating and edible biofilm coatings have been extensively studied for fruit shelf-life extension, showing distinct advantages in different case studies. For instance, wax coatings on apples demonstrated up to a 30% reduction in weight loss over 30 days, while starch-based edible biofilms on strawberries extended freshness by maintaining moisture and reducing microbial growth. Comparative results from mango trials revealed edible biofilms provided superior gas exchange regulation, enhancing firmness retention and delaying ripening more effectively than traditional wax coatings.

Future Trends and Innovations in Fruit Coating Technologies

Wax coating remains a widely used method for extending fruit shelf life due to its cost-effectiveness and moisture barrier properties, but edible biofilm coatings are emerging with significant innovations driven by biopolymer blends, antimicrobial agents, and nanotechnology. Future trends emphasize enhancing the biodegradability, sensory acceptance, and functional attributes of edible films to reduce synthetic chemical use and improve fruit preservation. Innovations such as smart coatings with embedded sensors for real-time freshness monitoring and controlled-release systems for antioxidants represent the next generation of sustainable fruit coating technologies.

Related Important Terms

Controlled Release Coatings

Controlled release coatings in wax and edible biofilm applications enhance fruit shelf-life by regulating moisture loss and gas exchange, optimizing respiration rates and delaying senescence. Edible biofilm coatings, often derived from natural polymers like chitosan or alginate, provide biodegradable, non-toxic barriers with improved controlled release properties compared to traditional wax coatings, reducing environmental impact and maintaining fruit quality.

Nanoemulsion Edible Films

Nanoemulsion edible films provide a superior alternative to traditional wax coatings by enhancing fruit shelf-life through improved barrier properties against moisture and gases, while maintaining safety and biodegradability. These films incorporate nano-sized emulsions that allow for controlled release of antimicrobial and antioxidant agents, significantly reducing post-harvest spoilage and preserving fruit quality longer than conventional wax coatings.

Polysaccharide-based Biofilms

Polysaccharide-based biofilms offer a biodegradable, eco-friendly alternative to traditional wax coatings by forming a semi-permeable barrier that regulates gas exchange, thus enhancing fruit shelf-life while maintaining quality. These biofilms reduce moisture loss and oxidative damage, effectively delaying ripening and senescence compared to conventional wax coatings.

Lipid-Protein Composite Coatings

Lipid-protein composite coatings in post-harvest technology enhance fruit shelf-life by creating a semi-permeable barrier that reduces moisture loss and gas exchange, maintaining firmness and freshness. Compared to traditional wax coatings, these edible biofilms provide biodegradability and improved barrier properties without compromising fruit quality or safety.

Antimicrobial Encapsulation

Wax coatings provide a physical barrier that reduces moisture loss and gas exchange, but edible biofilm coatings with antimicrobial encapsulation actively inhibit microbial growth by releasing antimicrobial agents, significantly enhancing fruit shelf-life. Encapsulated antimicrobials in biofilms ensure controlled release, improving effectiveness against pathogens without compromising fruit quality or safety.

Plant-Extract Infused Films

Plant-extract infused edible biofilm coatings enhance fruit shelf-life by creating a natural barrier that reduces moisture loss and inhibits microbial growth, outperforming traditional wax coatings in biodegradability and consumer safety. These biofilms leverage antimicrobial and antioxidant properties from plant extracts, effectively preserving fruit quality while supporting sustainability in post-harvest technology.

Biodegradable Wax Alternatives

Wax coatings have traditionally been used to extend fruit shelf-life by reducing moisture loss and delaying ripening; however, edible biofilm coatings derived from biodegradable materials like chitosan and alginate offer environmentally friendly alternatives that enhance gas exchange and antimicrobial protection. These biofilm coatings improve fruit preservation while minimizing plastic waste, aligning with sustainable post-harvest technology trends.

Gas Permeability Modulation

Wax coating provides a hydrophobic barrier that reduces water loss but often limits gas exchange, potentially causing anaerobic respiration and off-flavors in fruits. Edible biofilm coatings composed of polysaccharides or proteins offer tailored gas permeability, enabling controlled oxygen and carbon dioxide diffusion that better preserves fruit quality and extends shelf life by modulating respiratory activity.

Active Packaging Coatings

Wax coating serves as a traditional method to reduce moisture loss and delay respiration in fruits, but edible biofilm coatings integrated with active packaging components provide enhanced antimicrobial and antioxidant properties, effectively extending shelf-life by inhibiting microbial growth and oxidative degradation. Active biofilm coatings, composed of biodegradable polymers infused with natural extracts or nanomaterials, offer controlled gas exchange and targeted release of preservatives, surpassing conventional wax coatings in maintaining fruit quality and freshness.

pH-responsive Edible Coatings

pH-responsive edible biofilm coatings enhance fruit shelf-life by adapting to environmental pH changes, providing targeted antimicrobial activity and reducing spoilage more effectively than traditional wax coatings. These smart coatings maintain fruit quality by controlling respiration and moisture loss while offering a biodegradable alternative to synthetic waxes.

Wax coating vs edible biofilm coating for fruit shelf-life extension Infographic

agridif.com

agridif.com