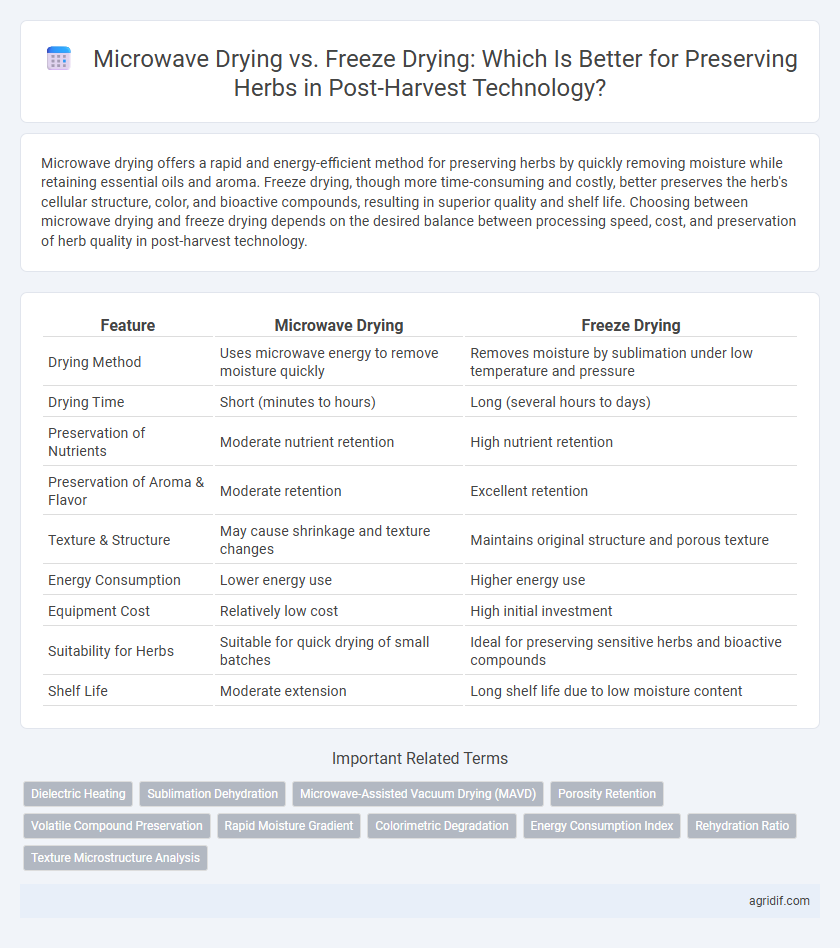

Microwave drying offers a rapid and energy-efficient method for preserving herbs by quickly removing moisture while retaining essential oils and aroma. Freeze drying, though more time-consuming and costly, better preserves the herb's cellular structure, color, and bioactive compounds, resulting in superior quality and shelf life. Choosing between microwave drying and freeze drying depends on the desired balance between processing speed, cost, and preservation of herb quality in post-harvest technology.

Table of Comparison

| Feature | Microwave Drying | Freeze Drying |

|---|---|---|

| Drying Method | Uses microwave energy to remove moisture quickly | Removes moisture by sublimation under low temperature and pressure |

| Drying Time | Short (minutes to hours) | Long (several hours to days) |

| Preservation of Nutrients | Moderate nutrient retention | High nutrient retention |

| Preservation of Aroma & Flavor | Moderate retention | Excellent retention |

| Texture & Structure | May cause shrinkage and texture changes | Maintains original structure and porous texture |

| Energy Consumption | Lower energy use | Higher energy use |

| Equipment Cost | Relatively low cost | High initial investment |

| Suitability for Herbs | Suitable for quick drying of small batches | Ideal for preserving sensitive herbs and bioactive compounds |

| Shelf Life | Moderate extension | Long shelf life due to low moisture content |

Introduction to Post-Harvest Herb Preservation

Microwave drying and freeze drying represent advanced post-harvest technologies crucial for preserving the quality, flavor, and bioactive compounds of herbs. Microwave drying offers rapid moisture removal with minimal nutrient degradation, while freeze drying maintains structural integrity and aroma through sublimation under low temperatures. These methods optimize shelf life and potency, addressing key challenges in post-harvest herb preservation and enhancing product value in the herbal supply chain.

Understanding Microwave Drying Technology

Microwave drying technology uses electromagnetic waves to generate heat within herb tissues, enabling rapid moisture evaporation while preserving essential oils and active compounds. This method offers significant advantages in reducing drying time and energy consumption compared to traditional techniques, making it ideal for maintaining the quality and aroma of herbs. Understanding microwave drying's impact on cell structure and nutrient retention is crucial for optimizing post-harvest herb preservation and ensuring superior product quality.

Overview of Freeze Drying Methods

Freeze drying, also known as lyophilization, removes moisture from herbs by freezing them and then reducing pressure to allow sublimation. This method preserves the cellular structure, flavor, color, and nutritional content of herbs more effectively than microwave drying. Freeze drying extends shelf life significantly while maintaining superior quality and potency for post-harvest herb preservation.

Efficiency and Speed: Comparing Drying Times

Microwave drying significantly reduces drying times for herbs, often completing the process within minutes compared to freeze drying, which can take several hours to days. This efficiency in drying speed helps maintain the herb's aromatic and medicinal properties by minimizing thermal degradation. Faster microwave drying enhances throughput in post-harvest processing, making it ideal for large-scale herb preservation operations.

Impact on Herb Flavor and Aroma Retention

Microwave drying rapidly removes moisture from herbs, preserving their natural oils and resulting in a strong, concentrated flavor and aroma. Freeze drying retains the herb's volatile compounds by sublimating ice under low temperatures, maintaining a more authentic and fresh profile. Both techniques offer superior preservation of herb flavor and aroma compared to traditional drying methods, with freeze drying typically delivering the closest match to the fresh herb's sensory qualities.

Color and Texture Preservation in Dried Herbs

Microwave drying preserves the vibrant green color and natural texture of herbs by rapidly removing moisture without prolonged heat exposure, minimizing enzymatic browning and cell wall damage. Freeze drying excels in maintaining the original cellular structure and bright hues of herbs through sublimation, resulting in superior texture retention and color stability. Both methods outperform traditional drying techniques, though freeze drying offers the highest fidelity in preserving the sensory qualities of dried herbs.

Nutrient Retention: Microwave vs Freeze Drying

Microwave drying preserves more vitamins, especially vitamin C and carotenoids, by reducing exposure time to heat compared to traditional methods. Freeze drying excels at retaining volatile oils and fragile phytochemicals due to its low-temperature dehydration process, maintaining herb flavor and nutritional profile. Comparing nutrient retention, freeze drying generally offers superior preservation of bioactive compounds, while microwave drying provides a faster alternative with moderate nutrient loss.

Energy Consumption and Cost Analysis

Microwave drying significantly reduces energy consumption compared to freeze drying, utilizing rapid electromagnetic waves to dehydrate herbs efficiently within minutes versus hours or days. Cost analysis reveals microwave drying has lower operational and equipment expenses due to shorter processing times and less specialized machinery, while freeze drying incurs higher energy costs for freezing and vacuum maintenance. Despite higher initial investments, freeze drying maintains superior herb quality and shelf life, but microwave drying offers an energy-efficient and cost-effective solution for large-scale herb preservation.

Scalability for Commercial Herb Processing

Microwave drying offers faster throughput and reduced energy consumption, making it highly scalable for large-scale commercial herb processing. Freeze drying preserves delicate flavors and nutrients more effectively but requires higher capital investment and longer processing times, limiting its scalability. Commercial operations often prefer microwave drying for cost efficiency and expedited production, while freeze drying suits premium herb products demanding superior quality.

Choosing the Right Drying Method for Optimized Herb Quality

Microwave drying accelerates moisture removal in herbs by using electromagnetic waves, preserving essential oils and flavor more efficiently than traditional methods, but may cause uneven drying and nutrient loss if not carefully controlled. Freeze drying removes moisture through sublimation at low temperatures, maintaining the herb's structural integrity, color, and bioactive compounds with minimal degradation, making it ideal for premium quality preservation despite higher operational costs. Selecting between microwave and freeze drying depends on the desired balance between processing time, cost, and the level of retention in aroma, texture, and nutrient content for targeted herb applications.

Related Important Terms

Dielectric Heating

Microwave drying utilizes dielectric heating, rapidly agitating polar molecules within herbs to achieve uniform moisture removal while preserving essential oils and active compounds. Freeze drying, although effective in retaining sensory and nutritional qualities by sublimating ice under low pressure, is more energy-intensive and slower compared to the efficient, volumetric heating mechanism of microwave drying.

Sublimation Dehydration

Microwave drying uses rapid dielectric heating to remove moisture efficiently, whereas freeze drying, based on sublimation dehydration, preserves herbs by transforming frozen water directly from solid ice to vapor, maintaining cell structure and volatile compounds. Sublimation dehydration in freeze drying ensures minimal thermal degradation, enhancing the shelf life and quality of herbs compared to microwave drying methods.

Microwave-Assisted Vacuum Drying (MAVD)

Microwave-Assisted Vacuum Drying (MAVD) significantly reduces drying time and energy consumption compared to traditional freeze drying while maintaining higher retention of essential oils and bioactive compounds in herbs. MAVD offers superior product quality with enhanced color, aroma, and nutritional values due to reduced oxidation and thermal degradation during the drying process.

Porosity Retention

Microwave drying preserves herb porosity more effectively than freeze drying by rapidly removing moisture without causing extensive cellular collapse, maintaining the structural integrity crucial for aroma and flavor retention. Freeze drying, while excellent for nutrient preservation, often results in lower porosity due to ice crystal formation disrupting the cell matrix.

Volatile Compound Preservation

Microwave drying preserves volatile compounds in herbs more efficiently by rapidly removing moisture without significant heat degradation, maintaining aroma and flavor profiles. Freeze drying excels in retaining delicate volatile oils through sublimation at low temperatures, ensuring minimal loss of essential oils and superior preservation of herbal quality.

Rapid Moisture Gradient

Microwave drying creates a rapid moisture gradient by quickly heating water molecules inside herb tissues, resulting in faster drying times and reduced nutrient loss compared to freeze drying, which uses sublimation under low temperatures but requires prolonged processing. Rapid moisture removal in microwave drying minimizes enzymatic and microbial activity, preserving aroma and bioactive compounds more efficiently than the slow, energy-intensive freeze drying method typically used for delicate herbs.

Colorimetric Degradation

Microwave drying causes significant colorimetric degradation in herbs due to rapid heat exposure, leading to browning and pigment loss, while freeze drying preserves color integrity more effectively by sublimating moisture under low temperatures. Studies show freeze drying maintains chlorophyll and carotenoid content better, crucial for retaining the vibrant green and aromatic qualities in dried herbs.

Energy Consumption Index

Microwave drying consumes significantly less energy than freeze drying, with an Energy Consumption Index (ECI) often reduced by up to 60%, making it a more sustainable option for preserving herbs. Freeze drying, while offering superior preservation of aroma and nutrients, typically has a higher ECI due to its prolonged low-temperature sublimation process and extensive vacuum requirements.

Rehydration Ratio

Microwave drying of herbs generally yields a higher rehydration ratio compared to freeze drying, indicating better water absorption and texture restoration after drying. Freeze drying preserves cellular structure more effectively but often results in a lower rehydration ratio, affecting the herb's ability to regain its original moisture content.

Texture Microstructure Analysis

Microwave drying induces rapid moisture removal in herbs, leading to partial cellular disruption visible under microstructure analysis, which can result in slightly altered texture but retains structural integrity better than conventional drying. Freeze drying preserves the cellular microstructure of herbs almost intact by sublimating moisture under low temperatures, maintaining original texture and color, making it superior for quality retention in post-harvest herb preservation.

Microwave Drying vs Freeze Drying for preserving herbs Infographic

agridif.com

agridif.com