Cryogenic freezing employs ultra-low temperatures using liquid nitrogen or carbon dioxide, resulting in rapid freezing that preserves the texture, flavor, and nutritional quality of seafood by preventing ice crystal formation. Blast freezing circulates extremely cold air at high velocity around seafood, efficiently removing heat and minimizing cellular damage but often at a slower rate than cryogenic methods. Both techniques enhance shelf-life and maintain freshness, with cryogenic freezing offering superior quality retention ideal for high-value seafood products.

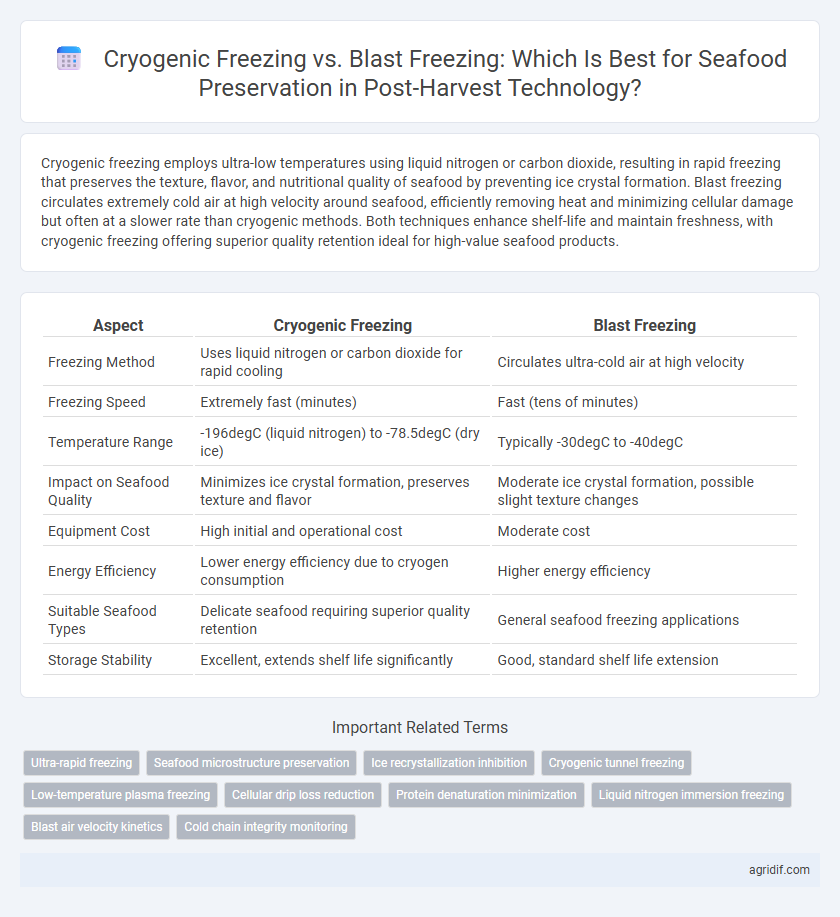

Table of Comparison

| Aspect | Cryogenic Freezing | Blast Freezing |

|---|---|---|

| Freezing Method | Uses liquid nitrogen or carbon dioxide for rapid cooling | Circulates ultra-cold air at high velocity |

| Freezing Speed | Extremely fast (minutes) | Fast (tens of minutes) |

| Temperature Range | -196degC (liquid nitrogen) to -78.5degC (dry ice) | Typically -30degC to -40degC |

| Impact on Seafood Quality | Minimizes ice crystal formation, preserves texture and flavor | Moderate ice crystal formation, possible slight texture changes |

| Equipment Cost | High initial and operational cost | Moderate cost |

| Energy Efficiency | Lower energy efficiency due to cryogen consumption | Higher energy efficiency |

| Suitable Seafood Types | Delicate seafood requiring superior quality retention | General seafood freezing applications |

| Storage Stability | Excellent, extends shelf life significantly | Good, standard shelf life extension |

Introduction to Seafood Preservation Methods

Cryogenic freezing employs liquid nitrogen or carbon dioxide to rapidly lower seafood temperatures, minimizing ice crystal formation and preserving cellular integrity better than slower freezing methods. Blast freezing uses extremely cold air circulated at high velocity to freeze seafood quickly, ensuring reduced microbial activity and extended shelf life. Both methods enhance post-harvest seafood quality by slowing enzymatic spoilage, with cryogenic freezing offering superior texture retention and blast freezing providing efficient large-scale processing.

Overview of Cryogenic Freezing Technology

Cryogenic freezing technology for seafood preservation utilizes ultra-low temperatures achieved by liquid nitrogen or carbon dioxide to rapidly freeze products, minimizing ice crystal formation and maintaining cellular structure. This method ensures superior texture, flavor, and nutritional retention compared to slower freezing processes. Cryogenic freezing also offers advantages in flexibility and scalability for seafood processors, enabling efficient handling of varying batch sizes with minimal dehydration and oxidation.

Understanding Blast Freezing: Principles and Process

Blast freezing for seafood preservation involves rapidly lowering the temperature by circulating cold air at speeds up to 3,000 feet per minute, which minimizes ice crystal formation and preserves cellular structure. This technique typically operates at temperatures between -30degC to -40degC, allowing faster freezing times compared to conventional methods and reducing drip loss during thawing. By maintaining optimal airflow and temperature control, blast freezing ensures high-quality texture and flavor retention in seafood products.

Comparative Freezing Rates: Cryogenic vs Blast Freezing

Cryogenic freezing employs liquid nitrogen or carbon dioxide to achieve ultra-rapid freezing rates, often reaching -196degC, which minimizes ice crystal formation and preserves seafood texture and quality better than blast freezing. Blast freezing uses high-velocity cold air at temperatures typically between -40degC and -50degC, resulting in slower freezing rates that can cause larger ice crystals and potential cellular damage. The superior freezing speed of cryogenic methods significantly reduces enzymatic activity and microbial growth, extending seafood shelf life more effectively compared to traditional blast freezing techniques.

Effects on Seafood Quality and Texture

Cryogenic freezing uses liquid nitrogen or carbon dioxide to rapidly drop seafood temperature, minimizing ice crystal formation and preserving cellular structure, which results in superior texture and moisture retention. Blast freezing circulates cold air at high speeds to freeze seafood quickly, but slower freezing rates compared to cryogenic methods often cause larger ice crystals, potentially leading to protein degradation and texture changes. Both techniques reduce microbial activity, but cryogenic freezing consistently yields higher product quality by maintaining optimal freshness and firmness in fish and shellfish.

Impact on Nutritional Value and Shelf Life

Cryogenic freezing utilizes liquid nitrogen or carbon dioxide to rapidly freeze seafood at ultra-low temperatures, minimizing ice crystal formation and preserving cellular integrity, which maintains higher nutritional value and extends shelf life significantly compared to traditional methods. Blast freezing involves circulating very cold air at high velocity to freeze seafood quickly but at slower rates than cryogenic methods, leading to larger ice crystals that can damage tissues, potentially reducing nutrition retention and shelf stability. Studies demonstrate cryogenic freezing better preserves key nutrients such as omega-3 fatty acids and antioxidants while prolonging freshness up to several weeks more than blast freezing in typical seafood products.

Energy Efficiency and Operational Costs

Cryogenic freezing in seafood preservation offers superior energy efficiency by rapidly reducing temperature through liquid nitrogen or carbon dioxide, minimizing ice crystal formation and maintaining product integrity. Blast freezing uses cold air blasts at temperatures around -30degC to -40degC, resulting in higher energy consumption due to longer freezing cycles and greater operational costs. While cryogenic systems have higher initial capital investment, their reduced energy demands and minimal maintenance contribute to lower long-term operational expenses compared to blast freezing.

Equipment Requirements and Scalability

Cryogenic freezing of seafood requires specialized equipment such as liquid nitrogen or liquid carbon dioxide systems, which can rapidly achieve ultra-low temperatures but involve higher initial investment and operational costs. Blast freezing uses powerful refrigeration units that circulate cold air to freeze seafood quickly, offering more scalable solutions suitable for large volumes and continuous processing lines. While cryogenic freezing excels in small-batch, high-value seafood preservation, blast freezing provides greater flexibility and cost-effectiveness for large-scale commercial operations.

Environmental Considerations and Sustainability

Cryogenic freezing utilizes liquid nitrogen or carbon dioxide, providing rapid freezing that minimizes cellular damage in seafood but can result in higher greenhouse gas emissions due to energy-intensive cryogen production. Blast freezing employs cold air circulation, generally consuming more electricity but allowing easier integration with renewable energy sources, offering a potentially lower carbon footprint. Sustainable seafood preservation depends on optimizing energy efficiency and source renewable inputs while balancing freezing speed and product quality.

Choosing the Right Freezing Method for Seafood Processing

Cryogenic freezing utilizes liquid nitrogen or carbon dioxide, achieving ultra-rapid freezing that preserves seafood's cellular structure and quality by minimizing ice crystal formation. Blast freezing circulates extremely cold air at high velocity, offering efficient freezing suitable for large seafood volumes with slightly slower freezing rates than cryogenic methods. Selecting the right freezing method depends on factors like processing capacity, cost efficiency, seafood type, and desired quality retention to optimize freshness and shelf life in seafood processing.

Related Important Terms

Ultra-rapid freezing

Ultra-rapid freezing in cryogenic freezing utilizes liquid nitrogen or carbon dioxide to achieve temperatures as low as -196degC, drastically reducing ice crystal formation and preserving seafood texture and flavor more effectively than blast freezing, which typically operates around -30degC to -40degC. The intense cooling rate in cryogenic freezing minimizes cellular damage and enzymatic activity, extending shelf life and maintaining product quality superior to conventional blast freezing methods.

Seafood microstructure preservation

Cryogenic freezing employs ultra-low temperatures using liquid nitrogen or carbon dioxide, rapidly freezing seafood and preserving its microstructure by minimizing ice crystal formation and cellular damage. Blast freezing, while faster than traditional methods, often results in larger ice crystals that can disrupt seafood tissue integrity, leading to moisture loss and texture degradation during thawing.

Ice recrystallization inhibition

Cryogenic freezing, utilizing liquid nitrogen at extremely low temperatures, offers superior ice recrystallization inhibition in seafood preservation by rapidly solidifying water molecules and preventing large ice crystal formation that damages tissue. Blast freezing, while effective for quick freezing, typically results in slower temperature reduction, allowing ice crystals to grow larger and compromise seafood texture and quality.

Cryogenic tunnel freezing

Cryogenic tunnel freezing employs liquid nitrogen or carbon dioxide to rapidly lower the temperature of seafood, minimizing ice crystal formation and preserving cellular integrity better than conventional blast freezing. This ultra-fast freezing technology enhances shelf life and maintains texture, flavor, and nutritional value, making it optimal for high-quality seafood preservation.

Low-temperature plasma freezing

Low-temperature plasma freezing enhances seafood preservation by combining cryogenic freezing's rapid temperature drop with the uniform cooling effect of blast freezing, reducing ice crystal formation and preserving texture and nutritional quality. This emerging technology utilizes ionized gas to achieve supercooling at low temperatures, improving microbial inhibition and extending shelf life compared to traditional freezing methods.

Cellular drip loss reduction

Cryogenic freezing uses ultra-low temperatures with liquid nitrogen or carbon dioxide, rapidly solidifying seafood to minimize ice crystal formation and reduce cellular drip loss compared to blast freezing, which employs high-velocity cold air but freezes at a slower rate. The faster freezing rate in cryogenic methods preserves cell integrity better, resulting in improved texture, moisture retention, and overall seafood quality during storage and thawing.

Protein denaturation minimization

Cryogenic freezing uses liquid nitrogen to achieve ultra-rapid freezing, significantly reducing ice crystal size and minimizing protein denaturation in seafood. Blast freezing, while faster than traditional methods, forms larger ice crystals that can cause more cellular damage and protein loss, affecting texture and nutritional quality.

Liquid nitrogen immersion freezing

Liquid nitrogen immersion freezing offers ultra-rapid freezing rates that preserve seafood quality by minimizing ice crystal formation and cellular damage, outperforming traditional blast freezing methods. This cryogenic freezing technique enhances texture, flavor, and shelf life, making it ideal for maintaining the freshness of delicate seafood products.

Blast air velocity kinetics

Blast freezing leverages high air velocity, often exceeding 3 m/s, to rapidly remove heat from seafood surfaces, significantly reducing ice crystal size and preserving cellular integrity more effectively than slower methods. This enhanced air velocity accelerates the freezing rate, minimizing drip loss and maintaining texture and flavor quality crucial for post-harvest seafood preservation.

Cold chain integrity monitoring

Cryogenic freezing employs ultra-low temperatures using liquid nitrogen or carbon dioxide, ensuring rapid freeze rates that minimize ice crystal formation and preserve seafood texture and flavor; blast freezing uses high-velocity cold air to quickly drop temperatures but generally operates at higher temperatures than cryogenic methods. Cold chain integrity monitoring for cryogenic freezing demands real-time temperature tracking with highly sensitive sensors to detect fluctuations below -150degC, while blast freezing requires robust airflow and temperature sensors to maintain consistent freezing temperatures typically between -30degC and -40degC, ensuring optimal preservation of seafood quality.

Cryogenic freezing vs Blast freezing for seafood preservation Infographic

agridif.com

agridif.com