Blanching uses high-temperature steam or hot water briefly to inactivate enzymes, preserving color, texture, and nutritional quality in fruits and vegetables. Pasteurization applies moderate heat for a longer time, targeting both enzyme inactivation and microbial reduction while maintaining product safety and shelf life. Choosing between blanching and pasteurization depends on the desired balance between enzyme control, microbial safety, and minimal impact on sensory attributes in post-harvest processing.

Table of Comparison

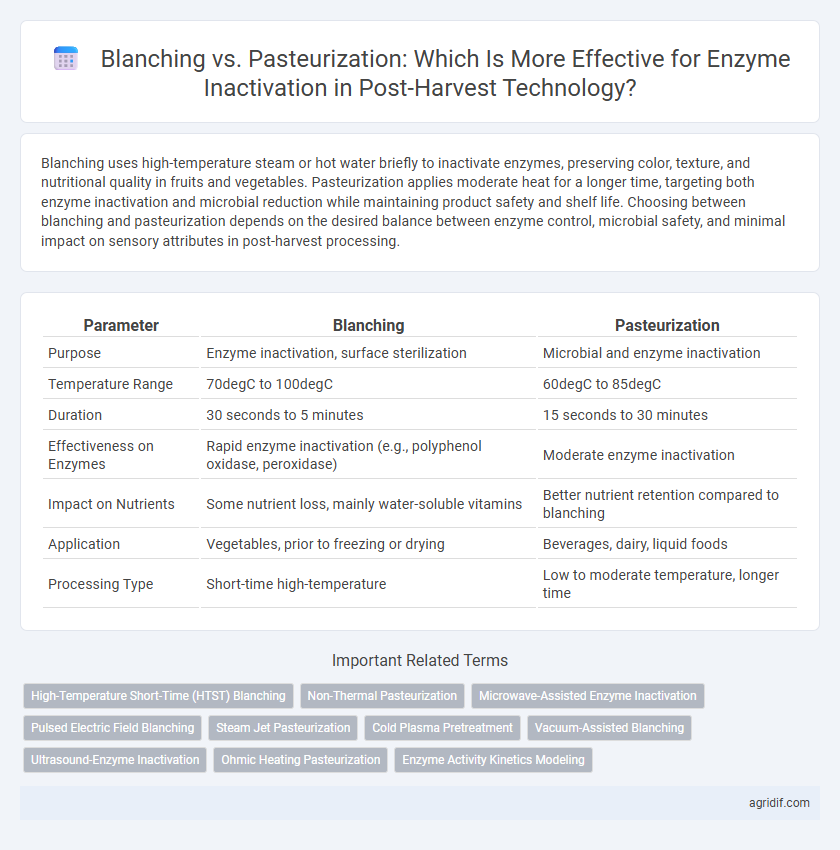

| Parameter | Blanching | Pasteurization |

|---|---|---|

| Purpose | Enzyme inactivation, surface sterilization | Microbial and enzyme inactivation |

| Temperature Range | 70degC to 100degC | 60degC to 85degC |

| Duration | 30 seconds to 5 minutes | 15 seconds to 30 minutes |

| Effectiveness on Enzymes | Rapid enzyme inactivation (e.g., polyphenol oxidase, peroxidase) | Moderate enzyme inactivation |

| Impact on Nutrients | Some nutrient loss, mainly water-soluble vitamins | Better nutrient retention compared to blanching |

| Application | Vegetables, prior to freezing or drying | Beverages, dairy, liquid foods |

| Processing Type | Short-time high-temperature | Low to moderate temperature, longer time |

Introduction to Enzyme Inactivation in Post-Harvest Technology

Enzyme inactivation is a critical process in post-harvest technology aimed at preserving the quality and extending the shelf life of fruits and vegetables by preventing enzymatic browning and texture degradation. Blanching, involving short-time exposure to hot water or steam, effectively denatures enzymes like polyphenol oxidase and peroxidase, while pasteurization uses controlled heat treatments to reduce microbial load and enzyme activity simultaneously. Understanding the differences in effectiveness, energy consumption, and impact on nutritional value helps optimize post-harvest processing strategies.

Understanding Blanching: Methods and Mechanisms

Blanching in post-harvest technology involves briefly exposing fruits or vegetables to hot water or steam to inactivate enzymes such as polyphenol oxidase and peroxidase, which cause quality deterioration. The primary methods include hot water blanching, steam blanching, and microwave blanching, each utilizing heat transfer to disrupt enzyme activity and microbial load. This thermal treatment denatures enzyme proteins and halts metabolic reactions, preserving color, texture, and nutritional value prior to further processing or storage.

Pasteurization: Principles and Techniques

Pasteurization in post-harvest technology employs precise heating to inactivate enzymes that degrade produce quality, maintaining nutritional value and texture. Techniques include batch and continuous flow methods with carefully controlled temperatures typically ranging from 60degC to 85degC for specific durations to optimize enzyme inactivation without compromising sensory attributes. Advanced methods such as high-pressure pasteurization and pulsed electric fields enhance enzyme control while reducing thermal damage in fresh-cut fruits and vegetables.

Comparative Analysis: Blanching vs Pasteurization

Blanching and pasteurization are critical post-harvest techniques for enzyme inactivation, with blanching using brief exposure to boiling water or steam, effectively halting enzymatic action in fruits and vegetables faster and with minimal nutrient loss. Pasteurization employs controlled heat treatment, typically at lower temperatures but longer durations, ensuring microbial reduction while partially inactivating enzymes, making it suitable for liquid products like juices. Comparative analysis highlights blanching's efficiency in preserving texture and color versus pasteurization's advantage in microbial safety and shelf-life extension.

Effectiveness of Blanching for Enzyme Inactivation

Blanching effectively inactivates enzymes such as polyphenol oxidase and peroxidase, which are responsible for quality deterioration in fruits and vegetables post-harvest. The process uses controlled heat treatment typically at 70-100degC for short durations, causing thermal denaturation of enzymes and preserving color, texture, and nutritional value. This method is widely preferred in post-harvest technology due to its efficiency, simplicity, and cost-effectiveness in maintaining product quality before further processing or storage.

Efficacy of Pasteurization on Enzyme Activity

Pasteurization effectively inactivates enzymes such as polyphenol oxidase and peroxidase by applying controlled heat treatments, typically between 60-85degC, for a specific time to preserve product quality and extend shelf life. Compared to blanching, pasteurization causes less thermal damage to texture and nutrients while sufficiently reducing enzyme activity to prevent spoilage and browning. Enzyme inactivation during pasteurization depends on temperature-time combinations optimized for each commodity to ensure minimal residual enzyme activity and maximize product stability.

Impact on Nutritional and Sensory Quality

Blanching rapidly inactivates enzymes in fruits and vegetables, preserving color and texture but can lead to nutrient loss, especially water-soluble vitamins like vitamin C. Pasteurization effectively kills microbial contaminants while retaining more nutrient content compared to blanching, though it may slightly alter flavor and aroma profiles due to heat exposure. Optimizing temperature and time parameters in both methods is crucial to balance enzyme inactivation and maintain maximum nutritional and sensory quality in post-harvest products.

Energy Consumption and Operational Efficiency

Blanching consumes less energy and requires shorter processing times compared to pasteurization, making it more energy-efficient for enzyme inactivation in post-harvest technology. However, pasteurization offers greater operational efficiency by providing uniform heat distribution and better retention of nutritional quality in sensitive produce. Choosing between blanching and pasteurization depends on balancing energy consumption with processing speed and product quality requirements.

Practical Applications in Post-Harvest Processing

Blanching effectively inactivates enzymes like peroxidase and polyphenol oxidase by applying brief high-temperature steam or hot water, preserving color and texture in vegetables before freezing or drying. Pasteurization uses milder heat treatments to reduce microbial load and enzymatic activity in liquid products such as fruit juices and milk, maintaining nutritional quality with minimal sensory changes. Selecting blanching or pasteurization depends on the product's physical state and desired shelf life, optimizing post-harvest quality and extending marketability.

Selecting the Right Method: Key Factors and Recommendations

Blanching effectively inactivates enzymes through rapid heating, preserving color and texture, making it ideal for vegetables requiring minimal nutrient loss. Pasteurization offers precise temperature control, suitable for liquid products like fruit juices, ensuring microbial safety while maintaining flavor integrity. Selection depends on product type, desired shelf life, and nutrient retention goals to optimize post-harvest quality.

Related Important Terms

High-Temperature Short-Time (HTST) Blanching

High-Temperature Short-Time (HTST) blanching effectively inactivates enzymes such as polyphenol oxidase and peroxidase by rapidly heating produce to 70-100degC for 15-60 seconds, preserving texture and nutrients better than traditional pasteurization methods. This technique minimizes thermal damage while ensuring microbial safety, making HTST blanching a preferred method in post-harvest technology for extending shelf life and maintaining quality of fruits and vegetables.

Non-Thermal Pasteurization

Non-thermal pasteurization techniques such as high-pressure processing (HPP) and pulsed electric fields (PEF) effectively inactivate enzymes without the nutrient degradation and texture loss associated with traditional blanching. These methods preserve the sensory and nutritional quality of produce while ensuring microbial safety and extending shelf life in post-harvest technology.

Microwave-Assisted Enzyme Inactivation

Microwave-assisted enzyme inactivation leverages rapid, volumetric heating to effectively denature enzymes such as polyphenol oxidase and peroxidase in post-harvest treatments, offering superior retention of nutritional and sensory qualities compared to traditional blanching and pasteurization. Its precise control of temperature and exposure time reduces thermal damage while ensuring microbial safety and extended shelf life in fruits and vegetables.

Pulsed Electric Field Blanching

Pulsed Electric Field (PEF) blanching offers a non-thermal alternative to conventional pasteurization by using short bursts of high voltage to inactivate enzymes, preserving nutritional and sensory qualities in post-harvest produce. Unlike traditional blanching or pasteurization, PEF minimizes heat damage while effectively controlling enzymatic activity, extending shelf life and maintaining product integrity.

Steam Jet Pasteurization

Steam jet pasteurization offers superior enzyme inactivation compared to blanching by applying rapid high-temperature steam that preserves nutritional quality and texture while effectively deactivating enzymes. This method reduces processing time and minimizes nutrient loss, making it ideal for sensitive fruits and vegetables in post-harvest technology.

Cold Plasma Pretreatment

Cold plasma pretreatment enhances enzyme inactivation by generating reactive species that disrupt enzyme structures more effectively than traditional blanching or pasteurization methods. This non-thermal technology preserves nutritional quality and extends shelf life by minimizing heat-induced damage during the post-harvest processing of fruits and vegetables.

Vacuum-Assisted Blanching

Vacuum-assisted blanching enhances enzyme inactivation by reducing blanching time and temperature, thereby preserving nutritional quality and minimizing thermal degradation compared to conventional pasteurization. This method efficiently disrupts cellular structures under reduced pressure, accelerating heat transfer and improving the retention of color and flavor in post-harvest fruits and vegetables.

Ultrasound-Enzyme Inactivation

Ultrasound-enzyme inactivation leverages high-frequency sound waves to disrupt enzyme structures more effectively than traditional blanching or pasteurization methods, enhancing the preservation of nutritional and sensory qualities in agricultural products. This non-thermal technique minimizes thermal degradation while achieving rapid enzyme inactivation, making it a promising post-harvest technology for improving shelf life and product quality.

Ohmic Heating Pasteurization

Ohmic heating pasteurization uses electrical currents to rapidly heat food, ensuring effective enzyme inactivation while preserving quality and nutrients better than traditional blanching methods, which rely on hot water or steam. This technology offers precise temperature control and uniform heating, minimizing thermal damage and extending the shelf life of post-harvest products.

Enzyme Activity Kinetics Modeling

Blanching rapidly inactivates enzymes like polyphenol oxidase and peroxidase through thermal denaturation, with enzyme activity kinetics modeled using first-order reaction rates to describe residual activity over time and temperature. Pasteurization, operating at lower temperatures for longer durations, achieves partial enzyme inactivation where kinetics often follow non-linear models reflecting complex thermal resistance and recovery phases in enzyme activity.

Blanching vs Pasteurization for Enzyme Inactivation Infographic

agridif.com

agridif.com