Dry cleaning for root crops uses mechanical methods like brushing or air blowing to remove soil and debris without moisture, reducing spoilage and microbial growth during storage. Wet cleaning involves washing and rinsing root crops with water, which effectively removes dirt and residues but increases moisture content, potentially accelerating decay if not properly dried afterward. Choosing between dry and wet cleaning depends on the crop type, intended storage period, and available post-harvest facilities, balancing cleanliness and shelf life.

Table of Comparison

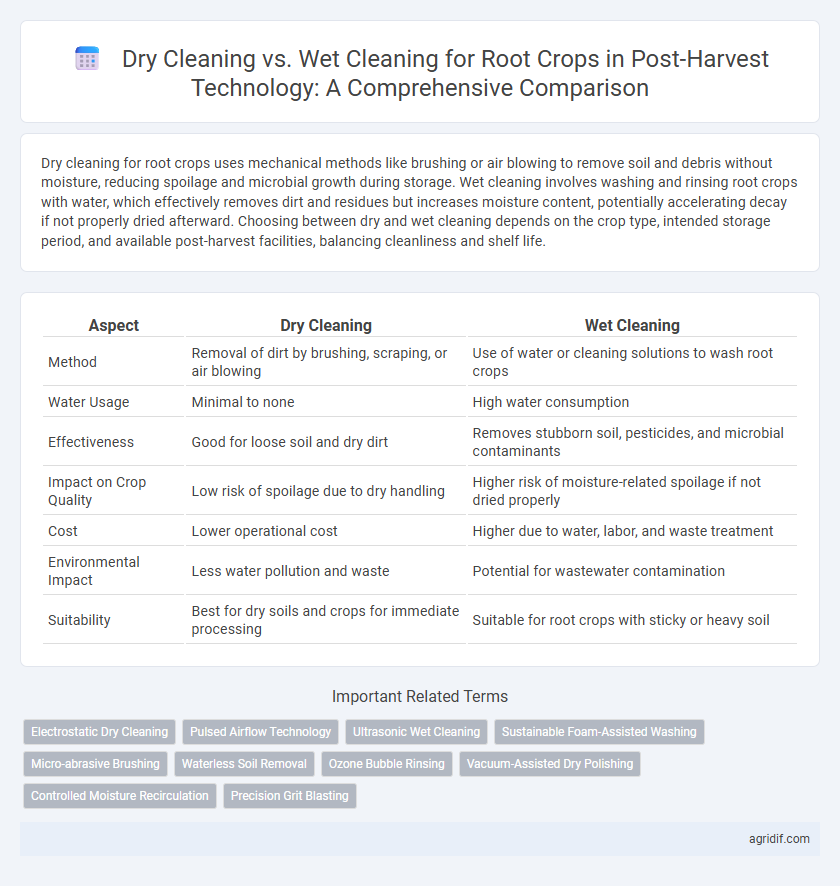

| Aspect | Dry Cleaning | Wet Cleaning |

|---|---|---|

| Method | Removal of dirt by brushing, scraping, or air blowing | Use of water or cleaning solutions to wash root crops |

| Water Usage | Minimal to none | High water consumption |

| Effectiveness | Good for loose soil and dry dirt | Removes stubborn soil, pesticides, and microbial contaminants |

| Impact on Crop Quality | Low risk of spoilage due to dry handling | Higher risk of moisture-related spoilage if not dried properly |

| Cost | Lower operational cost | Higher due to water, labor, and waste treatment |

| Environmental Impact | Less water pollution and waste | Potential for wastewater contamination |

| Suitability | Best for dry soils and crops for immediate processing | Suitable for root crops with sticky or heavy soil |

Introduction to Post-Harvest Cleaning Methods for Root Crops

Post-harvest cleaning methods for root crops critically influence quality preservation and shelf life, with dry cleaning and wet cleaning as predominant approaches. Dry cleaning involves mechanical removal of soil and debris through brushing or scraping, minimizing moisture exposure to reduce spoilage risks. Wet cleaning employs water or chemical solutions to loosen adherent soil, enhancing cleanliness but requiring effective drying to prevent microbial growth and maintain post-harvest integrity.

Importance of Cleaning Root Crops After Harvest

Effective cleaning of root crops after harvest is crucial for reducing microbial contamination and extending shelf life, with dry cleaning removing loose soil and debris mechanically, minimizing moisture-related decay. Wet cleaning utilizes water to thoroughly wash away soil and residues but increases the risk of pathogen proliferation and requires proper drying to prevent spoilage. Choosing the appropriate cleaning method depends on the crop type, post-harvest handling conditions, and storage requirements to maintain quality and safety.

Overview of Dry Cleaning Techniques for Root Crops

Dry cleaning techniques for root crops involve the removal of soil and debris through mechanical means such as brushing, scrubbing, or air blowing, which minimizes moisture exposure and reduces the risk of microbial growth. Methods like rotary brushes, vibrating screens, and air jets effectively clean tubers like potatoes, carrots, and cassava while preserving their structural integrity and extending shelf life. This approach is energy-efficient, reduces water usage, and lowers post-harvest losses compared to wet cleaning methods.

Wet Cleaning Methods: Processes and Applications

Wet cleaning methods for root crops involve using water or cleaning solutions to remove soil, debris, and contaminants, ensuring higher hygiene standards and minimal damage to the produce. Techniques such as hydro-washing, spray washing, and agitation washing facilitate effective removal of dirt while preserving the crop's texture and nutritional quality. These methods are especially applied to root vegetables like carrots, potatoes, and beets in commercial post-harvest operations to enhance shelf life and marketability.

Equipment Used in Dry vs Wet Cleaning of Root Crops

Dry cleaning of root crops utilizes equipment such as rotary brushes, air blowers, and vibrating sieves to remove soil and debris without water, preserving crop integrity and reducing moisture-related spoilage. Wet cleaning employs water sprays, hydro-cyclones, and flotation tanks to wash away dirt and contaminants, enhancing cleanliness but increasing post-cleaning drying requirements and potential microbial risks. Equipment choice impacts crop quality, shelf life, and suitability for storage or processing in post-harvest handling of root crops.

Impact on Crop Quality: Dry Cleaning vs Wet Cleaning

Dry cleaning preserves the structural integrity and nutrient content of root crops by minimizing moisture exposure, reducing the risk of microbial growth and physical damage. Wet cleaning effectively removes soil and contaminants but can lead to increased susceptibility to spoilage and nutrient leaching due to prolonged water contact. Optimal post-harvest handling balances cleaning efficacy with preservation of texture, flavor, and shelf life in root crops.

Efficiency and Throughput: Comparing Both Cleaning Methods

Dry cleaning of root crops utilizes air pressure and mechanical agitation, enabling higher throughput with minimal water usage and faster processing times. Wet cleaning employs water jets and agitation, which can effectively remove dense soil but often requires longer drying periods, reducing overall efficiency. Balancing throughput demands, dry cleaning is preferred for large-scale operations aiming for energy efficiency, while wet cleaning suits smaller batches requiring thorough soil removal.

Water and Energy Consumption in Post-Harvest Cleaning

Dry cleaning of root crops significantly reduces water consumption compared to wet cleaning, utilizing mechanical brushing or air jets to remove soil without water use. Wet cleaning demands substantial water volumes for soaking, washing, and rinsing, increasing both water usage and subsequent energy costs for water heating and wastewater treatment. Selecting dry cleaning methods enhances sustainability by lowering water and energy footprints during post-harvest processing of root crops.

Cost Implications: Dry Cleaning vs Wet Cleaning for Farmers

Dry cleaning root crops typically incurs lower operational costs due to reduced water usage and minimized wastewater treatment requirements, making it economically favorable for small-scale farmers. Wet cleaning demands significant investment in water supply, drainage infrastructure, and energy for drying, increasing overall expenses. Farmers must balance initial capital outlay and ongoing costs against crop quality and shelf-life benefits when choosing between dry and wet cleaning methods.

Sustainability Considerations in Root Crop Cleaning Methods

Dry cleaning of root crops minimizes water usage and reduces effluent generation, aligning with sustainable agricultural practices by conserving natural resources. Wet cleaning, while effective in removing soil and debris, often leads to high water consumption and wastewater treatment challenges, raising environmental concerns. Selecting dry cleaning methods supports sustainability goals by lowering operational water footprints and preventing soil nutrient runoff.

Related Important Terms

Electrostatic Dry Cleaning

Electrostatic dry cleaning of root crops effectively removes soil and debris without water, reducing microbial contamination and extending shelf life compared to wet cleaning methods. This technology leverages electrostatic forces to dislodge particles, preserving crop texture and minimizing nutrient loss typically associated with moisture exposure.

Pulsed Airflow Technology

Pulsed Airflow Technology enhances dry cleaning for root crops by efficiently removing soil and debris without moisture, preserving crop quality and reducing post-harvest spoilage. Compared to wet cleaning, this method minimizes water usage and prevents microbial contamination, optimizing storage life and maintaining nutritional value.

Ultrasonic Wet Cleaning

Ultrasonic wet cleaning for root crops uses high-frequency sound waves to dislodge soil, microorganisms, and pesticide residues more effectively than traditional dry cleaning, enhancing produce hygiene and shelf life. This method reduces mechanical damage to delicate roots while improving water penetration into crevices, ensuring thorough cleaning with minimal resource consumption.

Sustainable Foam-Assisted Washing

Sustainable foam-assisted washing for root crops uses biodegradable surfactants to create foam that efficiently removes soil and debris with minimal water consumption, contrasting traditional dry cleaning methods that rely on mechanical abrasion and dry soil removal. This wet cleaning approach enhances product quality by reducing physical damage and microbial contamination while promoting environmental sustainability through lower water usage and improved wastewater management.

Micro-abrasive Brushing

Micro-abrasive brushing in dry cleaning effectively removes soil and debris from root crops by gently scrubbing the surface without moisture, preserving texture and reducing microbial contamination. Compared to wet cleaning, this method minimizes water use and limits the risk of promoting spoilage or disease during post-harvest handling.

Waterless Soil Removal

Dry cleaning methods for root crops effectively remove soil without water, preserving crop quality and reducing moisture-related spoilage risks. This waterless soil removal technique enhances shelf life, minimizes microbial contamination, and conserves critical water resources in post-harvest handling.

Ozone Bubble Rinsing

Ozone bubble rinsing in wet cleaning effectively reduces microbial load and pesticide residues on root crops, enhancing shelf-life and quality compared to traditional dry cleaning methods that mainly remove surface dirt without sanitization. This advanced wet cleaning technique utilizes ozone's strong oxidation properties combined with microbubbles to penetrate crevices, ensuring thorough decontamination while preserving the structural integrity of root crops.

Vacuum-Assisted Dry Polishing

Vacuum-assisted dry polishing offers enhanced removal of soil and impurities from root crops compared to traditional wet cleaning, minimizing moisture-induced spoilage and extending shelf life. This dry cleaning method preserves the structural integrity of root crops while achieving efficient dirt removal through controlled vacuum pressure and abrasive polishing media.

Controlled Moisture Recirculation

Controlled Moisture Recirculation enhances wet cleaning of root crops by maintaining optimal moisture levels, reducing tissue damage and microbial growth compared to dry cleaning methods. This approach improves post-harvest quality by preserving texture and extending shelf life through precise moisture management.

Precision Grit Blasting

Precision Grit Blasting in dry cleaning effectively removes soil and debris from root crops without damaging their delicate surfaces, preserving quality and extending shelf life. This method outperforms wet cleaning by minimizing moisture exposure, which reduces microbial growth and post-harvest spoilage in root vegetables.

Dry Cleaning vs Wet Cleaning for root crops Infographic

agridif.com

agridif.com