Chemical ripening of bananas accelerates the maturation process by using ethylene gas or calcium carbide, resulting in uniform ripening and reduced post-harvest losses. Natural ripening relies on the fruit's own ethylene production, offering safer and more organic quality but often requires longer time and careful environmental control. Choosing between chemical and natural methods impacts shelf life, fruit quality, and consumer safety in post-harvest banana management.

Table of Comparison

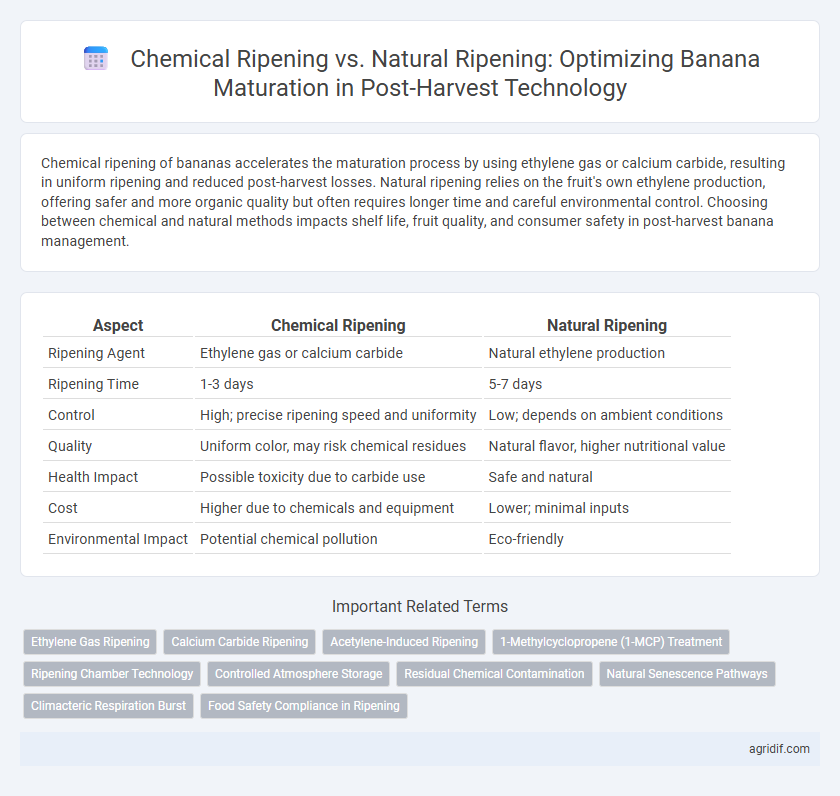

| Aspect | Chemical Ripening | Natural Ripening |

|---|---|---|

| Ripening Agent | Ethylene gas or calcium carbide | Natural ethylene production |

| Ripening Time | 1-3 days | 5-7 days |

| Control | High; precise ripening speed and uniformity | Low; depends on ambient conditions |

| Quality | Uniform color, may risk chemical residues | Natural flavor, higher nutritional value |

| Health Impact | Possible toxicity due to carbide use | Safe and natural |

| Cost | Higher due to chemicals and equipment | Lower; minimal inputs |

| Environmental Impact | Potential chemical pollution | Eco-friendly |

Introduction to Banana Ripening Methods

Banana ripening methods include chemical ripening and natural ripening, each influencing maturation speed and quality. Chemical ripening typically uses ethylene gas to accelerate the process, ensuring uniform ripening and reducing post-harvest losses. Natural ripening relies on ambient conditions and endogenous ethylene production, often resulting in slower, less controlled maturation but preserving traditional flavor and texture profiles.

Overview of Natural Ripening Process

Natural ripening of bananas involves enzymatic breakdown of starches into sugars, leading to softening and color change driven by ethylene production within the fruit. This process allows for gradual development of flavor, aroma, and nutritional quality without chemical intervention. Natural ripening ensures a balanced metabolic transformation, resulting in optimal taste and consumer acceptance.

Chemical Ripening Techniques Used in Agriculture

Chemical ripening techniques for bananas commonly utilize ethylene gas, calcium carbide, and ethephon to accelerate the maturation process, optimizing harvest schedules and market readiness. Ethylene gas, a natural plant hormone, is preferred for its effectiveness and minimal residue risk, while calcium carbide, though cost-effective, raises health concerns due to its toxic byproducts. Ethephon serves as a controlled ethylene-releasing agent, enabling uniform ripening and improved shelf life, supporting large-scale agricultural operations with enhanced post-harvest quality control.

Key Differences Between Chemical and Natural Ripening

Chemical ripening of bananas utilizes ethylene gas or calcium carbide to accelerate maturation, resulting in uniform color change and reduced ripening time. Natural ripening depends on the fruit's own ethylene production and ambient conditions, leading to gradual flavor development and nutrient retention. Key differences include the control over ripening speed, impact on taste and texture, and potential health risks associated with chemical agents.

Impact on Nutritional Value and Taste

Chemical ripening of bananas using ethylene gas accelerates the maturation process but can result in a slight reduction of essential nutrients such as vitamin C and antioxidants compared to natural ripening. Naturally ripened bananas develop a richer, sweeter taste profile due to the gradual enzymatic breakdown of starches into sugars, enhancing flavor complexity. Studies indicate that natural ripening preserves higher levels of phytonutrients, improving both nutritional value and sensory quality.

Health and Safety Concerns

Chemical ripening of bananas, commonly using ethylene gas or calcium carbide, accelerates the maturation process but poses significant health risks due to potential residues and toxic byproducts. Natural ripening relies on ambient environmental factors, ensuring safer fruit consumption by avoiding harmful chemicals, thereby reducing risks like respiratory issues and neurological damage. Emphasizing natural ripening aligns with safer post-harvest practices and promotes consumer health safety in banana production.

Influence on Shelf Life and Market Quality

Chemical ripening of bananas, typically using ethylene gas or calcium carbide, accelerates the maturation process, reducing shelf life due to increased respiration and moisture loss. Natural ripening results in more uniform color development and better flavor, preserving firmness and extending market quality by slowing over-ripening. Shelf life is significantly longer in naturally ripened bananas, which maintain higher antioxidant levels and reduced spoilage compared to chemically ripened fruits.

Regulatory Guidelines and Compliance

Chemical ripening of bananas involves the use of ethylene gas or calcium carbide, both regulated substances under food safety authorities such as the FDA and EFSA, requiring strict adherence to concentration limits and exposure durations to prevent health risks. Natural ripening relies on controlled environmental conditions like temperature and humidity, aligning with organic standards and minimizing regulatory scrutiny related to chemical residues. Compliance with international guidelines mandates thorough documentation and monitoring to ensure consumer safety and market acceptance in both chemical and natural ripening processes.

Economic Implications for Farmers and Traders

Chemical ripening of bananas accelerates the maturation process, enabling faster market availability, which can increase turnover for farmers and traders but may incur higher costs for ripening agents and require careful handling to avoid quality loss. Natural ripening reduces expense on chemicals and aligns with organic market demands, potentially attracting premium prices but involves longer storage times, increasing risk of spoilage and reduced shelf life. Balancing faster sales cycles against cost efficiency and market preferences is critical for optimizing economic returns in banana post-harvest management.

Future Trends in Banana Ripening Technology

Emerging trends in banana ripening technology emphasize eco-friendly chemical alternatives and precision-controlled atmospheric conditions to enhance fruit quality and shelf life. Advances in ethylene gas manipulation and natural plant-based ripening agents aim to replace traditional calcium carbide usage, reducing health risks and environmental impact. Integration of smart sensors and IoT devices enables real-time monitoring and optimized ripening cycles, tailoring maturation processes for global supply chains and reducing post-harvest losses significantly.

Related Important Terms

Ethylene Gas Ripening

Ethylene gas ripening accelerates banana maturation by triggering enzymatic reactions that soften the fruit, enhance sugar conversion, and develop the characteristic yellow color within 24 to 48 hours, offering precise control over ripening stages compared to natural processes. This chemical method ensures uniform ripening, reduces post-harvest losses, and facilitates supply chain management by synchronizing market demand with fruit readiness.

Calcium Carbide Ripening

Calcium carbide ripening accelerates banana maturation by releasing acetylene gas, which mimics natural ethylene production but poses health risks due to impurities like arsenic and phosphorous hydrides. Natural ripening relies on endogenous ethylene production, ensuring safer fruit quality and extended shelf life without chemical residues affecting consumer safety.

Acetylene-Induced Ripening

Acetylene-induced ripening accelerates banana maturation by mimicking ethylene, enhancing enzymatic activities that break down starch into sugars, resulting in uniform color and texture compared to slower, variable natural ripening. Chemical ripening using acetylene enables precise control over shelf life and market timing, reducing post-harvest losses and improving commercial viability.

1-Methylcyclopropene (1-MCP) Treatment

1-Methylcyclopropene (1-MCP) treatment effectively delays banana maturation by inhibiting ethylene perception, thereby extending shelf life and reducing post-harvest losses compared to natural ripening. This chemical ripening method preserves firmness and color, offering improved control over ripening uniformity and timing in commercial banana post-harvest management.

Ripening Chamber Technology

Ripening chamber technology accelerates banana maturation through controlled temperature, humidity, and ethylene gas application, enabling uniform chemical ripening that reduces post-harvest losses and extends shelf life. Natural ripening relies on ambient conditions and endogenous ethylene, resulting in slower, less predictable ripening with higher susceptibility to spoilage and market variability.

Controlled Atmosphere Storage

Controlled atmosphere storage optimizes banana maturation by regulating oxygen, carbon dioxide, and humidity levels, enhancing natural ripening while delaying spoilage and preserving fruit quality compared to chemical ripening methods that rely on ethylene gas exposure. This technology ensures uniform ripening, extends shelf life, and reduces the risk of chemical residues, making it a preferred choice in commercial banana post-harvest management.

Residual Chemical Contamination

Chemical ripening of bananas often involves the use of calcium carbide or ethylene gas, which can leave residual chemical contaminants on the fruit, posing potential health risks to consumers. Natural ripening relies on controlled environmental factors such as temperature and humidity, ensuring safer maturation without chemical residues.

Natural Senescence Pathways

Natural ripening of bananas relies on ethylene production and activation of natural senescence pathways, leading to gradual starch-to-sugar conversion and optimal flavor development. Chemical ripening, often using ethylene-releasing agents like ethephon, accelerates this process but may bypass key enzymatic interactions, potentially affecting fruit texture and nutrient composition.

Climacteric Respiration Burst

Chemical ripening of bananas triggers a controlled climacteric respiration burst through ethylene application, accelerating starch-to-sugar conversion and uniform maturation. Natural ripening relies on the fruit's endogenous ethylene production, resulting in a slower and less predictable climacteric peak that can affect texture and flavor consistency.

Food Safety Compliance in Ripening

Chemical ripening of bananas involves agents like calcium carbide, which poses significant food safety risks due to toxic residues and strict regulatory restrictions, whereas natural ripening using ethylene gas or controlled atmospheric conditions ensures compliance with food safety standards by avoiding harmful chemicals. Adhering to natural ripening methods enhances banana quality and consumer safety, meeting global food safety regulations and minimizing health hazards associated with chemical residues.

Chemical Ripening vs Natural Ripening for banana maturation Infographic

agridif.com

agridif.com