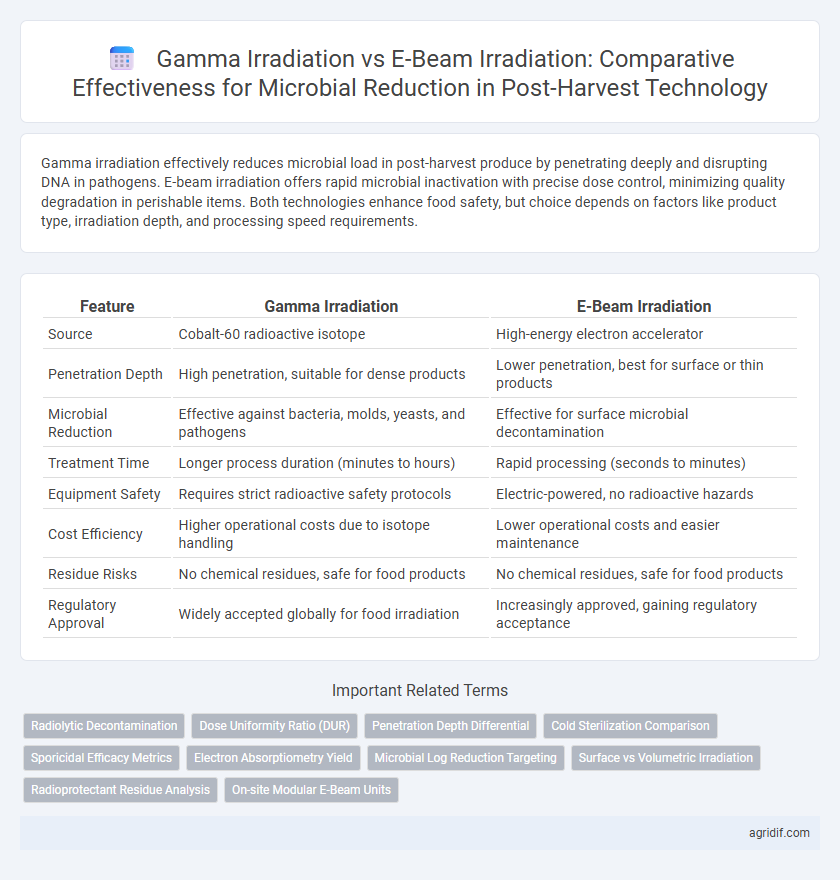

Gamma irradiation effectively reduces microbial load in post-harvest produce by penetrating deeply and disrupting DNA in pathogens. E-beam irradiation offers rapid microbial inactivation with precise dose control, minimizing quality degradation in perishable items. Both technologies enhance food safety, but choice depends on factors like product type, irradiation depth, and processing speed requirements.

Table of Comparison

| Feature | Gamma Irradiation | E-Beam Irradiation |

|---|---|---|

| Source | Cobalt-60 radioactive isotope | High-energy electron accelerator |

| Penetration Depth | High penetration, suitable for dense products | Lower penetration, best for surface or thin products |

| Microbial Reduction | Effective against bacteria, molds, yeasts, and pathogens | Effective for surface microbial decontamination |

| Treatment Time | Longer process duration (minutes to hours) | Rapid processing (seconds to minutes) |

| Equipment Safety | Requires strict radioactive safety protocols | Electric-powered, no radioactive hazards |

| Cost Efficiency | Higher operational costs due to isotope handling | Lower operational costs and easier maintenance |

| Residue Risks | No chemical residues, safe for food products | No chemical residues, safe for food products |

| Regulatory Approval | Widely accepted globally for food irradiation | Increasingly approved, gaining regulatory acceptance |

Introduction to Post-Harvest Microbial Reduction

Post-harvest microbial reduction techniques are essential for enhancing food safety and extending shelf life by minimizing pathogen load on fresh produce. Gamma irradiation utilizes high-energy photons from sources like cobalt-60 to penetrate products deeply, effectively disrupting microbial DNA and inactivating bacteria, molds, and yeasts. E-beam irradiation, employing high-energy electrons, offers a non-radioactive alternative with precise dose control and rapid processing times, but with lower penetration depth compared to gamma rays, making both methods valuable depending on specific product requirements.

Principles of Gamma Irradiation

Gamma irradiation employs high-energy photons emitted from isotopes such as Cobalt-60 to penetrate food products, disrupting the DNA of microorganisms and effectively reducing microbial load. This process provides deep penetration and uniform treatment, making it suitable for bulkier or densely packed produce. The ionizing radiation alters cellular structures and metabolic pathways of bacteria, molds, and pests without significantly raising temperature, preserving post-harvest quality.

Fundamentals of E-Beam Irradiation

E-beam irradiation employs high-energy electrons to disrupt microbial DNA, effectively reducing pathogens on post-harvest products without raising product temperature. This technology offers precise dosage control and rapid treatment times, enhancing shelf life and food safety. Unlike gamma irradiation, e-beam does not involve radioactive sources, reducing regulatory and waste disposal concerns.

Mechanisms of Microbial Inactivation

Gamma irradiation utilizes high-energy photons to penetrate microbial cells, inducing DNA strand breaks and oxidative damage that compromise cellular function and replication. E-beam irradiation employs high-energy electrons that directly interact with microbial DNA and cellular components, causing ionization and free radical formation leading to rapid microbial inactivation. Both methods disrupt microbial integrity through DNA damage and reactive oxygen species, but gamma irradiation offers deeper penetration while e-beam irradiation provides precise, surface-level treatment with minimal residue.

Comparative Efficacy: Gamma vs. E-Beam

Gamma irradiation and E-beam irradiation are both effective post-harvest technologies for microbial reduction, with gamma rays offering deeper penetration suitable for bulkier produce and E-beam providing faster treatment times with precise dosing. Comparative studies indicate gamma irradiation achieves higher microbial log reductions in dense commodities due to its high penetration power, while E-beam excels in surface decontamination and preserving commodity quality. Optimization of dose levels is critical for both methods to maximize microbial inactivation while minimizing quality degradation in fruits, vegetables, and spices.

Impact on Food Quality and Nutritional Value

Gamma irradiation and e-beam irradiation are effective post-harvest technologies for microbial reduction with distinct impacts on food quality and nutritional value. Gamma irradiation penetrates deeply, ensuring uniform microbial inactivation but may cause slight changes in texture and minimal loss of sensitive nutrients like vitamins C and E. E-beam irradiation offers rapid treatment with minimal heat generation, better preserving sensory attributes and essential nutrients, although its penetration depth is limited compared to gamma rays, potentially affecting efficacy in thicker food products.

Safety Considerations and Regulatory Framework

Gamma irradiation utilizes cobalt-60 sources emitting high-energy photons, while e-beam irradiation employs accelerated electrons for microbial reduction in post-harvest technology. Both methods are recognized as safe by international regulatory bodies such as the FDA and WHO, yet gamma irradiation poses challenges related to radioactive material handling and disposal, whereas e-beam systems require substantial electrical infrastructure but avoid radioactive waste. Compliance with Codex Alimentarius standards and adherence to dose limits, typically between 1-10 kGy for microbial control, ensure product safety and consumer acceptance across global markets.

Operational Costs and Scalability

Gamma irradiation offers deep penetration and effective microbial reduction but involves higher operational costs due to the use of radioactive isotopes and extensive safety measures, limiting scalability. E-beam irradiation provides rapid processing with lower operational expenses and easier scalability for post-harvest applications, benefiting from on-demand usage without radioactive sources. Cost-efficiency and scalability in microbial reduction favor e-beam technology for large-scale, continuous post-harvest treatment operations.

Environmental and Logistical Factors

Gamma irradiation offers deep penetration and effective microbial reduction for post-harvest products but requires radioactive sources, posing disposal challenges and strict regulatory controls. E-beam irradiation provides a faster, on-demand process with no radioactive materials, reducing environmental risks and improving onsite integration, though it has limited penetration depth compared to gamma rays. Logistically, e-beam systems allow easier installation and shutdown flexibility, while gamma facilities typically demand more extensive infrastructure and safety protocols.

Future Trends in Post-Harvest Irradiation Technologies

Gamma irradiation and E-beam irradiation are emerging as critical technologies for microbial reduction in post-harvest treatments, with E-beam offering faster processing times and minimal residual radioactivity. Future trends indicate a shift towards integrated irradiation systems that combine E-beam with advanced sensing technologies to ensure real-time quality control and optimize microbial inactivation. Innovations in portable irradiation units and energy-efficient E-beam sources are expected to enhance adoption in decentralized agricultural supply chains, improving food safety and extending shelf life.

Related Important Terms

Radiolytic Decontamination

Gamma irradiation uses high-energy gamma rays from Cobalt-60 sources to achieve deep microbial reduction through radiolytic decontamination, effectively breaking down DNA and cellular structures of pathogens in food products. E-beam irradiation employs high-energy electron beams for rapid surface and near-surface microbial inactivation, offering precise dose control and minimal heat generation, making it suitable for sensitive produce.

Dose Uniformity Ratio (DUR)

Gamma irradiation exhibits a higher Dose Uniformity Ratio (DUR) compared to E-beam irradiation, resulting in more consistent microbial reduction across treated produce. The improved DUR in gamma irradiation ensures effective pathogen control while minimizing quality degradation in post-harvest applications.

Penetration Depth Differential

Gamma irradiation offers significantly deeper penetration depths than E-beam irradiation, enabling more effective microbial reduction in bulkier agricultural products. E-beam irradiation, with its limited penetration, is more suitable for surface decontamination and thin-layer applications in post-harvest technology.

Cold Sterilization Comparison

Gamma irradiation and E-beam irradiation both serve as effective cold sterilization techniques in post-harvest technology, with gamma rays offering deeper penetration suitable for bulkier products, while E-beam provides faster processing times with minimal heat generation. Studies indicate gamma irradiation achieves higher microbial reduction rates in dense commodities, whereas E-beam excels in surface decontamination and maintaining produce quality.

Sporicidal Efficacy Metrics

Gamma irradiation and E-beam irradiation both serve as effective post-harvest microbial reduction methods, with gamma rays demonstrating higher penetration depth but slower dose delivery compared to the rapid, surface-targeted action of E-beam. Studies measuring sporicidal efficacy show gamma irradiation achieves log reductions of Bacillus spores up to 6-log at doses around 10 kGy, while E-beam requires slightly higher doses, typically 12-15 kGy, to reach comparable spore inactivation levels.

Electron Absorptiometry Yield

Gamma irradiation and E-beam irradiation are both effective for microbial reduction in post-harvest technology, but E-beam offers higher electron absorptiometry yield, enabling more precise dose control and reduced treatment time. This results in enhanced microbial inactivation efficiency while preserving the quality of fresh produce and minimizing radiation exposure.

Microbial Log Reduction Targeting

Gamma irradiation achieves microbial log reductions typically ranging from 3 to 6 logs, effectively targeting a wide spectrum of pathogens in post-harvest produce, while e-beam irradiation offers comparable log reductions with advantages in dose uniformity and reduced treatment time. Both technologies aim for microbial log reduction targets critical for food safety, but e-beam's precise energy control allows for tailored doses optimizing microbial inactivation with minimal quality degradation.

Surface vs Volumetric Irradiation

Gamma irradiation provides deep volumetric microbial reduction by penetrating and treating the entire volume of agricultural produce, ensuring uniform microbial inactivation throughout. In contrast, e-beam irradiation primarily offers surface-level microbial reduction due to its limited penetration depth, making it more suitable for thin or surface-contaminated products.

Radioprotectant Residue Analysis

Gamma irradiation and E-beam irradiation are effective post-harvest technologies for microbial reduction, with gamma rays exhibiting deeper penetration and uniform dose distribution while E-beam offers faster processing and minimal heat generation. Radioprotectant residue analysis reveals that gamma irradiation may cause slight chemical alterations requiring careful residue monitoring, whereas E-beam irradiation results in lower radiolytic byproducts, making it preferable for sensitive produce in maintaining food safety and quality.

On-site Modular E-Beam Units

On-site modular E-beam units enable precise microbial reduction in post-harvest technology by delivering high-energy electron beams that rapidly penetrate produce surfaces without residual radiation, contrasting with gamma irradiation which relies on radioactive isotopes and requires extensive shielding and regulatory oversight. E-beam irradiation offers advantages in scalability, operational safety, and immediate dose control, making it an efficient solution for reducing microbial load while maintaining produce quality.

Gamma Irradiation vs E-Beam Irradiation for Microbial Reduction Infographic

agridif.com

agridif.com