Mechanical dehulling enhances grain processing efficiency by significantly reducing labor and time compared to manual dehulling. It provides consistent hull removal and minimizes grain breakage, leading to higher product quality and yield. This technology supports large-scale operations, improving overall post-harvest handling and market readiness.

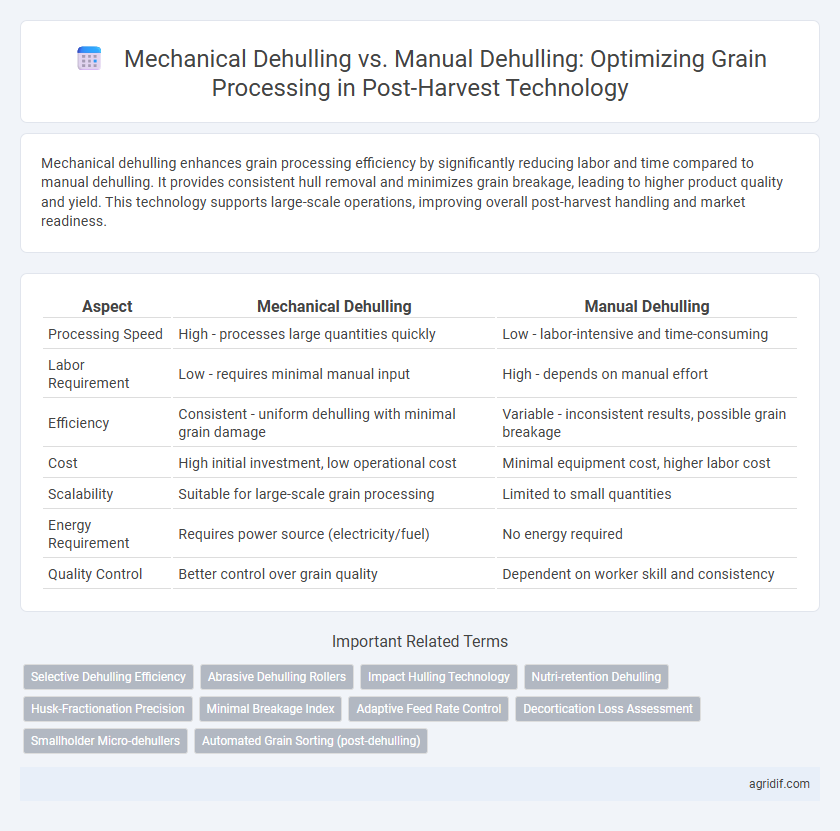

Table of Comparison

| Aspect | Mechanical Dehulling | Manual Dehulling |

|---|---|---|

| Processing Speed | High - processes large quantities quickly | Low - labor-intensive and time-consuming |

| Labor Requirement | Low - requires minimal manual input | High - depends on manual effort |

| Efficiency | Consistent - uniform dehulling with minimal grain damage | Variable - inconsistent results, possible grain breakage |

| Cost | High initial investment, low operational cost | Minimal equipment cost, higher labor cost |

| Scalability | Suitable for large-scale grain processing | Limited to small quantities |

| Energy Requirement | Requires power source (electricity/fuel) | No energy required |

| Quality Control | Better control over grain quality | Dependent on worker skill and consistency |

Introduction to Dehulling in Grain Processing

Mechanical dehulling offers higher efficiency and consistency compared to manual dehulling in grain processing, significantly reducing labor intensity and processing time. Mechanical systems enhance grain quality by minimizing kernel damage and ensuring uniform removal of husks across various cereal crops like millet, barley, and rice. Optimal dehulling technology selection directly impacts post-harvest losses and overall grain market value by improving milling yield and consumer acceptance.

Overview of Mechanical Dehulling Methods

Mechanical dehulling methods for grain processing utilize advanced equipment such as abrasive, impact, and centrifugal dehullers to efficiently remove husks and outer layers from grains like rice, barley, and sorghum. These machines enhance processing speed, improve grain quality by minimizing kernel damage, and ensure consistent dehulling outcomes compared to manual methods. High-capacity mechanical dehullers integrate automated features that optimize throughput and reduce labor intensity, making them essential in modern post-harvest technology.

Manual Dehulling Techniques: Traditional Approaches

Manual dehulling techniques in grain processing rely on traditional tools such as wooden mortars and pestles, stone rollers, or simple hand-operated threshers that enable the removal of husks without specialized machinery. These approaches preserve grain integrity by minimizing damage and are cost-effective for small-scale farmers or regions with limited access to modern equipment. Though labor-intensive and time-consuming, manual dehulling remains crucial for ensuring grain quality and supporting subsistence agriculture in diverse climatic and socioeconomic conditions.

Efficiency Comparison: Mechanical vs Manual Dehulling

Mechanical dehulling significantly enhances efficiency in grain processing by reducing labor time and increasing throughput compared to manual dehulling. Automated machines ensure consistent removal of husks with minimal grain damage, optimizing yield and quality. Manual dehulling, while cost-effective for small-scale operations, is labor-intensive and slower, limiting productivity and scalability.

Impact on Grain Quality and Yield

Mechanical dehulling significantly enhances grain processing efficiency by providing uniform hull removal, which preserves the integrity of the grain and reduces contamination compared to manual dehulling. Manual dehulling often results in inconsistent hull removal and higher kernel breakage, negatively impacting overall grain yield and quality. Optimizing mechanical dehulling parameters improves grain purity and minimizes losses, leading to superior post-harvest grain quality.

Labor and Cost Analysis: Mechanization vs Manual Labor

Mechanical dehulling significantly reduces labor intensity and increases throughput compared to manual dehulling, lowering overall labor costs in large-scale grain processing. While initial investment in mechanized equipment can be high, operational efficiency and consistency translate into long-term cost savings. Manual dehulling, although less capital-intensive, incurs higher labor costs and limits processing capacity, making it less viable for commercial-scale operations.

Scalability for Smallholder and Large-Scale Operations

Mechanical dehulling offers significant scalability advantages for large-scale grain processing by enhancing efficiency and reducing labor costs compared to manual dehulling. Smallholder farmers benefit from manual dehulling's low upfront investment and simplicity, but face limitations in processing volume and consistency. Integrating semi-mechanized solutions can bridge the gap, providing scalable options adaptable to both smallholder and commercial operations.

Maintenance and Operational Requirements

Mechanical dehulling systems require regular maintenance of components such as bearings, blades, and motors to ensure optimal performance, often involving lubrication, alignment checks, and replacement of worn parts. Manual dehulling demands minimal maintenance but is labor-intensive and slower, relying primarily on human effort without mechanical wear concerns. Operational requirements for mechanical dehullers include electricity or fuel, operator training, and safety protocols, whereas manual dehulling depends on skilled labor and ergonomic considerations to prevent fatigue.

Environmental and Sustainability Considerations

Mechanical dehulling reduces labor intensity and increases processing efficiency, significantly lowering post-harvest grain losses and resource use compared to manual methods. It optimizes energy consumption through mechanization, though initial machinery production has environmental impacts that can be mitigated by long-term operational gains. Manual dehulling, while low-tech and requiring minimal external inputs, often leads to higher grain wastage and slower processing, thus exerting greater cumulative strain on natural resources and limiting sustainability in large-scale applications.

Future Trends in Dehulling Technology

Future trends in dehulling technology emphasize the integration of advanced mechanical dehulling systems with precision sensors and automation to enhance efficiency and grain quality. Innovations such as AI-driven machinery and energy-efficient designs are poised to surpass manual dehulling methods by reducing labor costs and minimizing grain damage. Continued research in material science and machine learning will further optimize throughput and adapt processes for diverse grain types in large-scale post-harvest operations.

Related Important Terms

Selective Dehulling Efficiency

Mechanical dehulling offers higher selective dehulling efficiency by precisely removing hulls without damaging the grain, leading to improved grain quality and reduced breakage compared to manual dehulling. Manual dehulling, while more labor-intensive, often results in inconsistent hull removal and higher grain loss due to less control over pressure and friction applied during the process.

Abrasive Dehulling Rollers

Abrasive dehulling rollers in mechanical dehulling significantly enhance grain processing efficiency by providing consistent removal of hulls while minimizing grain damage compared to manual methods. This technology accelerates throughput, reduces labor intensity, and improves grain quality, making it a preferred choice in modern post-harvest technology.

Impact Hulling Technology

Mechanical dehulling using impact hulling technology significantly enhances grain processing efficiency by increasing throughput and reducing labor intensity compared to manual dehulling. Impact hullers employ centrifugal force to gently remove husks while preserving grain integrity, resulting in higher yield quality and consistency critical for post-harvest grain value addition.

Nutri-retention Dehulling

Mechanical dehulling in grain processing enhances nutri-retention by efficiently removing husks while preserving essential nutrients like proteins, vitamins, and minerals compared to manual dehulling, which often results in nutrient loss due to inconsistent husk removal and grain damage. Advanced mechanical dehullers utilize controlled abrasion and optimized pressure to maintain the structural integrity and nutritional profile of grains, promoting higher quality and more nutritious end products.

Husk-Fractionation Precision

Mechanical dehulling offers superior husk-fractionation precision by utilizing calibrated equipment that efficiently separates the husk from grains with minimal damage, enhancing grain quality and yield. Manual dehulling, relying on human labor, results in inconsistent husk removal and higher grain breakage, reducing overall processing efficiency and product uniformity.

Minimal Breakage Index

Mechanical dehulling significantly reduces the Minimal Breakage Index compared to manual dehulling, enhancing grain integrity and quality during processing. This technology ensures higher throughput with consistent kernel preservation, minimizing losses and improving overall efficiency in post-harvest grain handling.

Adaptive Feed Rate Control

Mechanical dehulling with adaptive feed rate control enhances grain processing efficiency by optimizing throughput and reducing breakage compared to manual dehulling methods that lack precise feed regulation. Implementing real-time sensors in mechanical systems adjusts feed rates based on grain moisture content and kernel hardness, leading to higher yield and consistent product quality.

Decortication Loss Assessment

Mechanical dehulling significantly reduces decortication loss by providing uniform grain removal and minimizing kernel breakage compared to manual dehulling, which often results in inconsistent grain removal and higher loss rates. Quantitative studies indicate mechanical methods can lower decortication loss by up to 15%, enhancing overall grain recovery and processing efficiency in post-harvest technology.

Smallholder Micro-dehullers

Smallholder micro-dehullers provide a more efficient and consistent mechanical dehulling process compared to manual dehulling, significantly reducing labor time and grain breakage rates while improving overall throughput for small-scale grain processors. Mechanical dehulling enhances grain quality by ensuring uniform removal of hulls, which preserves nutritional value and increases marketability, making it a preferred choice for smallholder farmers seeking to optimize post-harvest grain processing.

Automated Grain Sorting (post-dehulling)

Mechanical dehulling enhances efficiency by producing uniformly processed grains suitable for automated grain sorting systems, which improve accuracy and speed in post-dehulling quality assessment. Manual dehulling often results in inconsistent grain surfaces, reducing the effectiveness of automated sorting technologies in detecting impurities and defects.

Mechanical Dehulling vs Manual Dehulling for grain processing Infographic

agridif.com

agridif.com