Static cooling relies on natural air circulation and tends to be slower, often leading to uneven temperature distribution in leafy greens, which can reduce shelf life. Forced-air cooling accelerates the cooling process by actively circulating chilled air around the produce, improving temperature uniformity and preserving freshness longer. Optimizing post-harvest handling with forced-air cooling enhances quality and reduces spoilage for leafy greens.

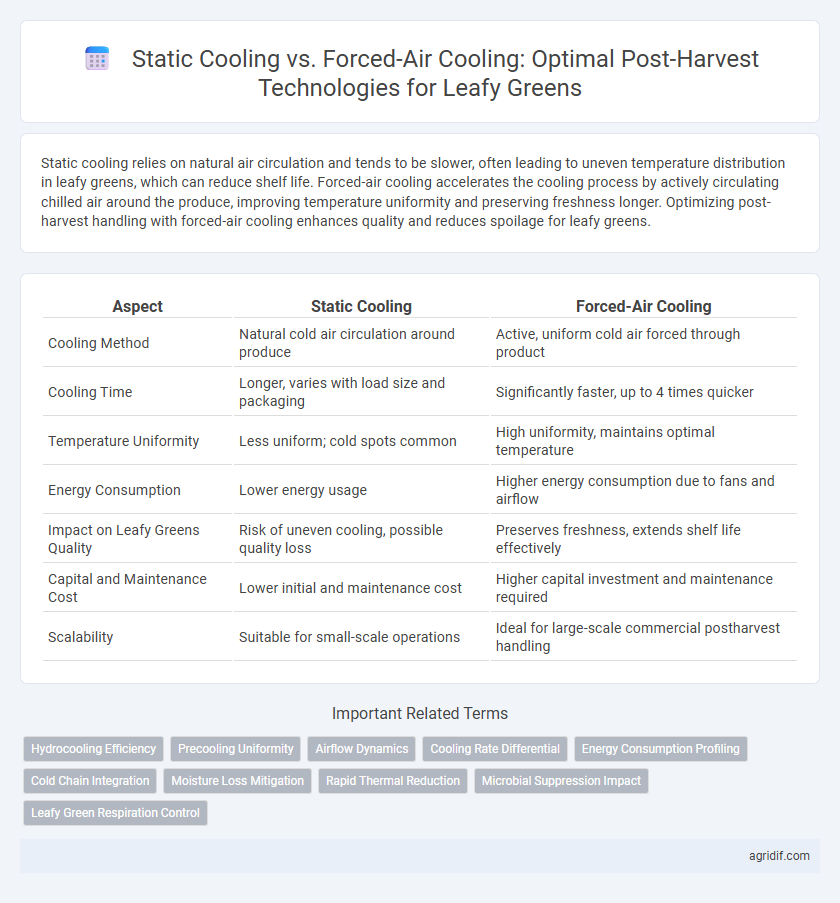

Table of Comparison

| Aspect | Static Cooling | Forced-Air Cooling |

|---|---|---|

| Cooling Method | Natural cold air circulation around produce | Active, uniform cold air forced through product |

| Cooling Time | Longer, varies with load size and packaging | Significantly faster, up to 4 times quicker |

| Temperature Uniformity | Less uniform; cold spots common | High uniformity, maintains optimal temperature |

| Energy Consumption | Lower energy usage | Higher energy consumption due to fans and airflow |

| Impact on Leafy Greens Quality | Risk of uneven cooling, possible quality loss | Preserves freshness, extends shelf life effectively |

| Capital and Maintenance Cost | Lower initial and maintenance cost | Higher capital investment and maintenance required |

| Scalability | Suitable for small-scale operations | Ideal for large-scale commercial postharvest handling |

Introduction to Post-Harvest Cooling Methods for Leafy Greens

Static cooling relies on natural air circulation to lower the temperature of leafy greens after harvest, which often results in slower cooling rates and less uniform temperature reduction. Forced-air cooling uses fans to actively circulate chilled air through the product, significantly accelerating the cooling process and enhancing product quality by minimizing respiration and spoilage. Studies indicate forced-air cooling reduces cooling time by up to 80% compared to static methods, making it more effective for maintaining freshness and extending shelf life of leafy greens.

Understanding Static Cooling: Principles and Applications

Static cooling relies on natural convection whereby cooler air surrounds the leafy greens, gradually reducing field heat without mechanical assistance. This method is energy-efficient and simple to implement, making it suitable for small-scale operations or environments with limited infrastructure. Understanding the principles of static cooling helps optimize storage conditions, prevent moisture loss, and maintain the freshness and shelf life of leafy greens post-harvest.

Forced-Air Cooling: How It Works and Its Relevance

Forced-air cooling rapidly removes field heat from leafy greens by circulating chilled air through perforated pallets, achieving uniform temperature reduction crucial for maintaining freshness and extending shelf life. This method enhances cooling efficiency compared to static cooling by significantly reducing cooling time and minimizing moisture loss, which is essential for preserving texture and nutritional quality. Implementing forced-air cooling in post-harvest technology is vital for optimizing cold chain management and reducing post-harvest spoilage of leafy greens.

Temperature Reduction Efficiency: Static vs. Forced-Air Cooling

Forced-air cooling significantly accelerates temperature reduction in leafy greens by uniformly circulating chilled air around the product, achieving optimal cooling within 1-2 hours. Static cooling relies on natural convection, resulting in slower temperature decline, often taking over 4 hours to reach the ideal storage temperature. Efficient temperature reduction in forced-air cooling helps preserve leaf turgidity and extends shelf life by minimizing enzymatic activity and microbial growth.

Impact on Leafy Greens Quality and Shelf Life

Static cooling relies on natural convection, leading to slower temperature reduction and uneven cooling of leafy greens, which can accelerate enzymatic activity and microbial growth, reducing shelf life and quality. Forced-air cooling rapidly removes field heat by circulating cold air uniformly around the produce, preserving texture, color, and nutritional content while significantly extending shelf life. Studies indicate that forced-air cooling can maintain optimal quality of leafy greens up to 50% longer compared to static cooling methods.

Energy Consumption and Operational Costs Comparison

Static cooling consumes significantly less energy than forced-air cooling due to the absence of continuous fan operation, making it more cost-effective for small-scale leafy greens storage. Forced-air cooling, while faster in reducing field heat, incurs higher operational costs from increased electricity usage and equipment maintenance. Choosing between these methods depends on balancing energy efficiency with cooling speed requirements specific to leafy green post-harvest handling.

Equipment Requirements for Each Cooling Method

Static cooling for leafy greens requires minimal equipment, typically involving insulated rooms or storage containers that rely on natural air circulation to lower temperatures gradually. Forced-air cooling demands more specialized equipment, such as high-capacity fans, duct systems, and temperature-controlled chambers to rapidly remove field heat by circulating cold air uniformly around the produce. The choice between these methods depends on investments in cooling infrastructure and desired cooling speed to maintain optimal freshness and shelf life.

Suitability for Different Types of Leafy Greens

Static cooling is more suitable for delicate leafy greens like spinach and lettuce that require gentle handling to prevent bruising. Forced-air cooling efficiently removes field heat from denser or more robust greens such as kale and Swiss chard, ensuring uniform temperature reduction. Selecting the appropriate cooling method improves shelf life and maintains the quality of specific leafy green varieties.

Common Challenges and Solutions in Both Cooling Methods

Static cooling and forced-air cooling both face challenges such as uneven temperature distribution and moisture loss in leafy greens, leading to quality degradation. Solutions include optimizing airflow patterns in forced-air systems and enhancing insulation in static cooling to minimize temperature fluctuations. Effective humidity control and rapid cooling rates are critical in both methods to preserve freshness and extend shelf life.

Recommendations for Choosing the Right Cooling Technique

Static cooling offers a low-cost solution but is less efficient for leafy greens with dense packaging or large volume, leading to slower temperature reduction and potential quality loss. Forced-air cooling is recommended for optimal temperature uniformity and faster cooling rates, preserving texture and extending shelf life in commercial operations. Choosing the right technique depends on factors like facility scale, product volume, and required cooling speed to maintain post-harvest freshness.

Related Important Terms

Hydrocooling Efficiency

Hydrocooling efficiency surpasses both static and forced-air cooling for leafy greens by rapidly removing field heat through direct water contact, significantly reducing cooling time and maintaining product quality. While static cooling relies on natural air circulation and forced-air cooling uses fans to accelerate heat removal, hydrocooling ensures uniform temperature reduction, minimizing moisture loss and extending shelf life.

Precooling Uniformity

Forced-air cooling provides superior precooling uniformity for leafy greens by distributing cold air evenly around the product, reducing temperature gradients and minimizing spoilage risk. Static cooling relies on natural convection, often resulting in uneven cooling and longer precooling times, which can compromise the quality and shelf life of leafy greens.

Airflow Dynamics

Static cooling relies on natural airflow and temperature gradients, resulting in slower heat removal and uneven cooling of leafy greens, which can lead to quality degradation. Forced-air cooling utilizes fans to actively circulate cold air evenly throughout the storage area, enhancing airflow dynamics, reducing cooling time, and improving the retention of freshness and nutritional quality in leafy greens.

Cooling Rate Differential

Static cooling of leafy greens typically results in slower cooling rates, often taking several hours to reduce field heat, whereas forced-air cooling significantly accelerates the process by rapidly circulating chilled air through the product, achieving cooling within one to two hours. Faster cooling rates in forced-air systems help minimize respiration and moisture loss, thus preserving quality and extending shelf life more effectively than static cooling methods.

Energy Consumption Profiling

Static cooling for leafy greens involves natural air circulation and typically consumes less energy but results in slower cooling rates, leading to potential quality degradation. Forced-air cooling significantly reduces cooling time by actively circulating chilled air, increasing energy consumption but improving freshness retention and shelf life.

Cold Chain Integration

Static cooling relies on natural air convection to reduce the temperature of leafy greens, leading to slower cooling rates and increased risk of microbial growth, whereas forced-air cooling uses fans to circulate cold air efficiently, ensuring rapid temperature reduction and maintaining cold chain integrity. Integrating forced-air cooling within the cold chain enhances freshness, extends shelf life, and minimizes post-harvest losses by controlling respiration rates and delaying senescence in leafy greens.

Moisture Loss Mitigation

Forced-air cooling effectively reduces moisture loss in leafy greens by rapidly removing field heat and maintaining uniform temperature, compared to static cooling which often results in uneven cooling and higher water loss. The enhanced airflow in forced-air systems preserves leaf turgidity and prolongs shelf life by minimizing dehydration and wilting.

Rapid Thermal Reduction

Static cooling for leafy greens relies on natural convection to remove field heat, resulting in slower temperature reduction that may compromise freshness. Forced-air cooling utilizes high-velocity fans to rapidly circulate cold air around produce, achieving rapid thermal reduction that extends shelf life and maintains post-harvest quality.

Microbial Suppression Impact

Forced-air cooling significantly enhances microbial suppression in leafy greens by rapidly reducing temperature and humidity, thereby inhibiting bacterial growth compared to static cooling. The improved airflow in forced-air systems prevents condensation buildup, reducing the risk of microbial contamination and extending post-harvest shelf life.

Leafy Green Respiration Control

Static cooling slows leafy green respiration by reducing field heat through natural air circulation, but forced-air cooling rapidly lowers temperature and humidity levels by actively circulating cold air, significantly extending shelf life and preserving quality. Forced-air cooling enhances gas exchange and moisture removal, crucial for maintaining optimal respiration rates and preventing spoilage in leafy greens post-harvest.

Static cooling vs forced-air cooling for leafy greens Infographic

agridif.com

agridif.com