Perforated trays provide superior aeration for potato storage by allowing consistent airflow around each tuber, reducing moisture accumulation and minimizing the risk of rot. Mesh bags offer good ventilation but may cause uneven airflow and pressure points that can damage potatoes during handling. Optimizing aeration through perforated trays enhances shelf life and maintains quality by preventing spoilage and sprouting.

Table of Comparison

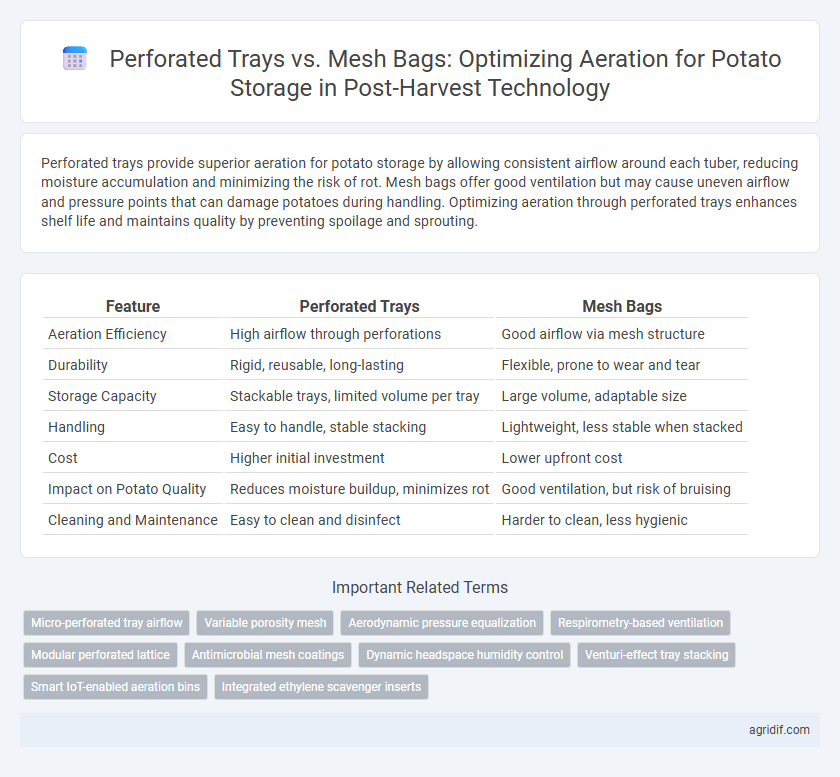

| Feature | Perforated Trays | Mesh Bags |

|---|---|---|

| Aeration Efficiency | High airflow through perforations | Good airflow via mesh structure |

| Durability | Rigid, reusable, long-lasting | Flexible, prone to wear and tear |

| Storage Capacity | Stackable trays, limited volume per tray | Large volume, adaptable size |

| Handling | Easy to handle, stable stacking | Lightweight, less stable when stacked |

| Cost | Higher initial investment | Lower upfront cost |

| Impact on Potato Quality | Reduces moisture buildup, minimizes rot | Good ventilation, but risk of bruising |

| Cleaning and Maintenance | Easy to clean and disinfect | Harder to clean, less hygienic |

Introduction to Aeration in Potato Storage

Proper aeration in potato storage is critical to maintain tuber quality and reduce spoilage by controlling temperature and humidity levels. Perforated trays provide structured airflow channels, enhancing ventilation around each potato and preventing moisture accumulation. Mesh bags offer flexibility and increased surface area for air exchange but may lead to uneven aeration compared to the consistent airflow facilitated by perforated trays.

Importance of Proper Post-Harvest Ventilation

Proper post-harvest ventilation is critical for maintaining the quality and extending the shelf life of stored potatoes by preventing moisture buildup and reducing the risk of microbial decay. Perforated trays offer structured airflow and support, enhancing aeration while minimizing physical damage to potatoes during storage. Mesh bags provide good ventilation due to their porous design but may offer less protection against mechanical injury and uneven airflow compared to perforated trays.

Perforated Trays: Design Features and Benefits

Perforated trays for potato storage feature strategically placed holes that ensure uniform airflow, reducing moisture buildup and minimizing rot during post-harvest handling. Their rigid structure supports better stacking and prevents tuber bruising compared to flexible mesh bags, enhancing overall storage efficiency. Optimized ventilation in perforated trays helps maintain tuber quality by controlling temperature and humidity, crucial factors in prolonging shelf-life.

Mesh Bags: Structure and Storage Advantages

Mesh bags, constructed from durable woven synthetic fibers, provide superior aeration due to their open, breathable design which allows consistent airflow around potatoes, reducing moisture buildup and minimizing spoilage. Their flexible structure conforms to irregular shapes, optimizing storage space and enabling easier handling during transportation and stacking in storage facilities. This combination of enhanced ventilation and adaptability makes mesh bags an effective solution for extending the shelf life and preserving the quality of stored potatoes.

Comparative Analysis: Airflow Efficiency

Perforated trays provide superior airflow efficiency in potato storage by allowing uniform air distribution through multiple precisely sized holes, reducing moisture buildup and minimizing spoilage. Mesh bags offer moderate aeration but often result in uneven airflow due to variable mesh size and overlap, potentially causing localized humidity and increased decay risk. Optimizing airflow through perforated trays enhances temperature control and extends potato shelf life more effectively than mesh bags.

Impact on Potato Quality and Shelf Life

Perforated trays provide superior aeration compared to mesh bags, reducing moisture buildup and minimizing the risk of rot and sprouting during potato storage. Enhanced airflow in perforated trays helps maintain optimal temperature and humidity, preserving potato firmness, texture, and nutritional quality. Consequently, potatoes stored in perforated trays exhibit extended shelf life and reduced spoilage rates, making them a preferred choice for post-harvest storage management.

Cost and Durability Considerations

Perforated trays offer enhanced durability due to their rigid plastic or metal construction, which supports repeated use over multiple storage cycles, making them a cost-effective solution for long-term potato storage. Mesh bags, while generally cheaper upfront, may incur higher replacement costs due to wear and tear from handling and ventilation exposure. Cost analysis favors perforated trays for large-scale operations seeking sustainable investment, whereas mesh bags remain suitable for small-scale or short-term storage needs given their lower initial cost but limited lifespan.

Suitability for Small-Scale vs Large-Scale Storage

Perforated trays offer superior aeration and are ideal for small-scale potato storage due to their ease of handling and uniform ventilation, which minimizes spoilage. Mesh bags provide scalability and cost-effectiveness, making them suitable for large-scale storage where bulk handling and space optimization are critical. Choosing between these depends on storage capacity, handling logistics, and the need for airflow to maintain potato quality post-harvest.

Handling, Maintenance, and Reusability

Perforated trays offer superior handling ease due to their rigid structure, enabling stackability and minimizing bruising during potato storage. Maintenance of these trays involves simple cleaning protocols without significant wear, enhancing their durability and long-term reuse. In contrast, mesh bags provide flexible but less protective aeration; they require frequent inspection for tears and generally have limited reusability due to material degradation and handling stress.

Recommendations for Optimal Aeration Practices

Perforated trays offer superior aeration by facilitating uniform airflow around potatoes, reducing moisture buildup and minimizing spoilage during storage. Mesh bags provide moderate ventilation but often limit air circulation in densely packed conditions, potentially increasing the risk of anaerobic zones. For optimal aeration, use perforated trays in combination with controlled temperature and humidity to maintain tuber quality and extend shelf life effectively.

Related Important Terms

Micro-perforated tray airflow

Micro-perforated trays enhance potato storage aeration by providing controlled airflow that reduces moisture accumulation and inhibits microbial growth, ensuring prolonged tuber freshness. Compared to mesh bags, these trays optimize gas exchange while minimizing physical damage, ultimately improving post-harvest quality and shelf life.

Variable porosity mesh

Variable porosity mesh in mesh bags enhances aeration by allowing tailored airflow rates that prevent moisture accumulation and reduce sprout growth during potato storage. Perforated trays provide uniform ventilation but lack the adaptive airflow control offered by mesh bags, which better maintain optimal storage humidity and temperature conditions.

Aerodynamic pressure equalization

Perforated trays facilitate superior aerodynamic pressure equalization in potato storage by allowing consistent airflow around tubers, reducing moisture accumulation and minimizing spoilage. In contrast, mesh bags provide limited air exchange due to their flexible structure, often causing uneven aeration and increased risk of localized condensation and decay.

Respirometry-based ventilation

Perforated trays enhance respirometry-based ventilation in potato storage by providing uniform airflow and controlled gas exchange, reducing respiratory heat and moisture accumulation compared to mesh bags. Mesh bags offer less consistent aeration, leading to localized anaerobic conditions that increase spoilage and reduce shelf life.

Modular perforated lattice

Modular perforated lattice trays provide enhanced aeration for potato storage by allowing uniform airflow and reducing moisture buildup, which minimizes spoilage compared to mesh bags. This design improves ventilation efficiency, ensuring optimal temperature and humidity control critical for extending potato shelf life in post-harvest storage.

Antimicrobial mesh coatings

Perforated trays provide structured airflow but lack antimicrobial properties, whereas mesh bags with antimicrobial coatings enhance aeration by reducing microbial growth on stored potatoes, extending shelf life and maintaining quality. Studies show antimicrobial mesh coatings inhibit bacterial and fungal proliferation, crucial for minimizing post-harvest losses in potato storage.

Dynamic headspace humidity control

Perforated trays enable superior dynamic headspace humidity control by allowing consistent air circulation around stored potatoes, reducing moisture accumulation and minimizing spoilage. Mesh bags facilitate aeration but often create uneven humidity distribution, increasing the risk of condensation and subsequent tuber decay.

Venturi-effect tray stacking

Perforated trays enhance potato storage aeration by leveraging the Venturi effect through strategic tray stacking, promoting consistent airflow and reducing moisture accumulation. Compared to mesh bags, these trays facilitate superior ventilation dynamics, minimizing spoilage and extending tuber shelf life in post-harvest handling.

Smart IoT-enabled aeration bins

Smart IoT-enabled aeration bins equipped with perforated trays provide uniform oxygen distribution and precise humidity control, significantly reducing spoilage and sprouting in stored potatoes compared to traditional mesh bags. These advanced systems monitor real-time atmospheric conditions, optimizing ventilation cycles to enhance potato quality and extend shelf life in post-harvest storage.

Integrated ethylene scavenger inserts

Perforated trays equipped with integrated ethylene scavenger inserts enhance aeration and significantly reduce ethylene accumulation, prolonging potato shelf life compared to mesh bags. The improved gas exchange in perforated trays minimizes spoilage and maintains tuber quality by effectively controlling post-harvest ethylene levels.

Perforated Trays vs Mesh Bags for aeration in potato storage Infographic

agridif.com

agridif.com