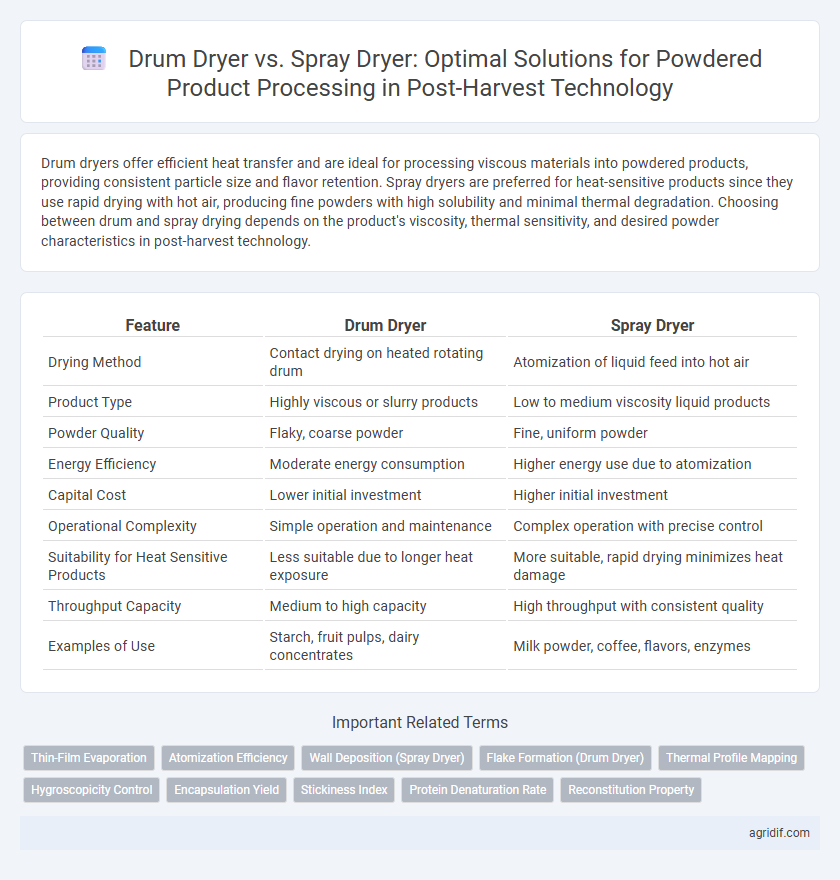

Drum dryers offer efficient heat transfer and are ideal for processing viscous materials into powdered products, providing consistent particle size and flavor retention. Spray dryers are preferred for heat-sensitive products since they use rapid drying with hot air, producing fine powders with high solubility and minimal thermal degradation. Choosing between drum and spray drying depends on the product's viscosity, thermal sensitivity, and desired powder characteristics in post-harvest technology.

Table of Comparison

| Feature | Drum Dryer | Spray Dryer |

|---|---|---|

| Drying Method | Contact drying on heated rotating drum | Atomization of liquid feed into hot air |

| Product Type | Highly viscous or slurry products | Low to medium viscosity liquid products |

| Powder Quality | Flaky, coarse powder | Fine, uniform powder |

| Energy Efficiency | Moderate energy consumption | Higher energy use due to atomization |

| Capital Cost | Lower initial investment | Higher initial investment |

| Operational Complexity | Simple operation and maintenance | Complex operation with precise control |

| Suitability for Heat Sensitive Products | Less suitable due to longer heat exposure | More suitable, rapid drying minimizes heat damage |

| Throughput Capacity | Medium to high capacity | High throughput with consistent quality |

| Examples of Use | Starch, fruit pulps, dairy concentrates | Milk powder, coffee, flavors, enzymes |

Introduction to Post-Harvest Drying Technologies

Drum dryers and spray dryers are essential post-harvest drying technologies used to convert liquid or semi-liquid agricultural products into powdered forms, enhancing shelf life and ease of storage. Drum drying involves spreading the product on a heated rotating drum, providing efficient drying for viscous materials but with potential nutrient loss due to higher temperatures. Spray drying atomizes the liquid into fine droplets exposed to hot air, enabling rapid drying with better retention of flavor and nutrients, making it ideal for heat-sensitive products.

Overview of Drum Dryers in Powder Production

Drum dryers utilize a rotating heated drum to rapidly dry liquid or slurry into powder, offering efficient moisture reduction for heat-sensitive materials. They provide uniform drying surfaces, resulting in consistent particle size and enhanced powder flowability. This method is suitable for large-scale production of powders with high solid content and viscous feedstocks.

Principles of Spray Dryers for Agricultural Products

Spray dryers convert liquid agricultural products into powders by atomizing the feed into a heated air chamber, enabling rapid moisture evaporation and preserving product quality. This process involves the formation of fine droplets that maximize surface area for efficient drying, suitable for heat-sensitive materials like fruit juices or dairy-based powders. Compared to drum dryers, spray drying maintains better flavor retention and nutrient stability due to its shorter drying time and controlled thermal exposure.

Key Differences Between Drum and Spray Drying

Drum dryers use a rotating heated drum to dry viscous or pasty materials into flakes or powders, offering cost-effective operation for heat-sensitive and low-viscosity products. Spray dryers atomize liquid feed into fine droplets within a hot air chamber, producing fine, uniform powders with rapid drying times suitable for heat-sensitive powders like milk or coffee. Key differences include drying mechanism, particle size control, energy efficiency, and suitability for product viscosity, where drum drying handles thicker materials better, while spray drying excels in producing fine powder consistency.

Energy Efficiency: Drum Dryer vs Spray Dryer

Drum dryers consume less energy than spray dryers due to their lower air volume requirements and direct contact drying method, making them more efficient for high-moisture slurries. Spray dryers require higher energy input to atomize liquids and maintain hot air flow, resulting in greater operational costs for powder production. Energy efficiency in drum dryers often translates to reduced fuel consumption and lower greenhouse gas emissions compared to spray dryers.

Product Quality and Nutrient Retention Comparisons

Drum dryers provide better retention of heat-sensitive nutrients such as vitamins in powdered products due to their gentle drying process compared to spray dryers, which utilize high-temperature air leading to greater nutrient degradation. Spray drying offers superior control over particle size and produces uniform, fine powders but can compromise product quality by causing increased oxidation and loss of volatile compounds. Selecting drum drying over spray drying enhances product quality and nutrient preservation, particularly for powders derived from heat-sensitive ingredients like milk, fruit juices, and plant extracts.

Suitability for Various Agricultural Raw Materials

Drum dryers excel in processing high-viscosity agricultural raw materials such as fruit pulps, purees, and starch slurries, offering efficient moisture removal and forming uniform flakes that can be ground into powder. Spray dryers are more suitable for heat-sensitive liquids like milk, plant extracts, and sugar solutions, providing rapid drying through atomization into fine droplets and resulting in a consistent, fine powder. Selection depends on the raw material's viscosity, thermal sensitivity, and desired powder characteristics, with drum dryers favored for thicker substances and spray dryers optimal for delicate liquid products.

Operational Costs and Maintenance Considerations

Drum dryers typically have lower initial investment and energy consumption compared to spray dryers, making them cost-effective for processing viscous or concentrated products into powders. Spray dryers, while having higher operational costs due to energy-intensive atomization and drying processes, offer superior product quality and flexibility for heat-sensitive materials. Maintenance for drum dryers involves routine cleaning of drums and rollers to prevent product buildup, whereas spray dryers require regular inspection and upkeep of nozzles, cyclone separators, and air handling systems to ensure consistent performance and prevent clogging.

Environmental Impact of Drum and Spray Dryers

Drum dryers consume less energy compared to spray dryers due to their lower operating temperatures, resulting in reduced greenhouse gas emissions during powdered product processing. Spray dryers, while offering finer particle control, require higher thermal input, which increases their carbon footprint and operational energy consumption. Wastewater generation is minimal in both systems, but spray dryers tend to produce more airborne particulates, necessitating advanced filtration to mitigate environmental pollution.

Choosing the Right Drying Technology for Powder Processing

Drum dryers are ideal for heat-sensitive materials and produce powders with higher bulk density, while spray dryers excel in handling liquid feeds with better control over particle size and morphology. Selecting the right drying technology depends on factors such as feed viscosity, thermal sensitivity, and desired powder characteristics like solubility and flowability. Optimizing drying parameters ensures improved product quality, energy efficiency, and reduced processing time in post-harvest powdered product processing.

Related Important Terms

Thin-Film Evaporation

Drum dryers use thin-film evaporation by spreading liquid product into a heated rotating drum, enabling efficient moisture removal while preserving heat-sensitive nutrients, making them suitable for viscous materials; spray dryers atomize the product into fine droplets for rapid drying but rely on hot air instead of thin-film evaporation, which can degrade delicate compounds. Thin-film evaporation in drum dryers enhances uniform drying and reduces thermal damage, offering advantages for powdered product processing where quality retention is critical.

Atomization Efficiency

Drum dryers exhibit lower atomization efficiency compared to spray dryers, as spray drying utilizes fine nozzles or rotary atomizers to create uniform droplets, enhancing drying speed and product consistency. Spray drying's superior atomization enables better control over particle size distribution, moisture content, and overall powder quality in post-harvest technology.

Wall Deposition (Spray Dryer)

Spray dryers often face challenges with wall deposition due to the sticky nature of concentrated liquids, leading to product loss and potential contamination in powdered product processing. In contrast, drum dryers exhibit less wall build-up, offering more consistent drying performance for heat-sensitive materials.

Flake Formation (Drum Dryer)

Drum dryers excel in producing flake-like powdered products due to their continuous thin film drying on heated drums, which promotes uniform drying and maintains product integrity. This method enhances flake formation by allowing better control over moisture content and texture compared to spray dryers, which typically produce fine, granular powders.

Thermal Profile Mapping

Drum dryers provide a distinct thermal profile with higher temperature gradients concentrated at the drum surface, enabling efficient moisture removal but posing risks of overheating sensitive powdered products. Spray dryers offer a more uniform thermal profile through atomized droplets exposed to hot air, ensuring better control over product temperature and quality in powdered product processing.

Hygroscopicity Control

Drum dryers provide better control over hygroscopicity in powdered products by producing denser, less porous particles that absorb less moisture compared to the finer, more porous particles produced by spray dryers. The reduced surface area and slower drying process in drum drying enhance powder stability and prolong shelf life in high-humidity environments.

Encapsulation Yield

Drum dryers typically offer lower encapsulation yield compared to spray dryers due to uneven heat distribution and longer processing times leading to greater product degradation. Spray dryers optimize encapsulation yield by rapidly atomizing the feed into fine droplets, ensuring uniform drying and minimal thermal damage to sensitive bioactive compounds.

Stickiness Index

Drum dryers exhibit a higher Stickiness Index compared to spray dryers, resulting in increased product adhesion and reduced powder flowability during post-harvest processing. Spray drying effectively minimizes stickiness by rapidly evaporating moisture, producing free-flowing powdered products suitable for long-term storage.

Protein Denaturation Rate

Drum dryers exhibit a higher protein denaturation rate due to prolonged exposure to elevated temperatures during the drying process, compared to spray dryers that utilize rapid drying with hot air, preserving protein integrity more effectively. Spray drying is preferred for heat-sensitive protein powders as it minimizes thermal degradation, ensuring better functional properties and nutritional quality.

Reconstitution Property

Spray dryers produce powders with superior reconstitution properties due to their finer particle size and uniform morphology, enhancing solubility and dispersibility in liquids. Drum dryers often yield denser, less porous powders that rehydrate slower and less completely, impacting the quality of reconstituted products in post-harvest technology.

Drum Dryer vs Spray Dryer for Powdered Product Processing Infographic

agridif.com

agridif.com