Pulsed Electric Field (PEF) technology offers a non-thermal alternative to traditional thermal pasteurization for juice sterilization, preserving nutrient content and sensory qualities more effectively. By applying short bursts of high voltage, PEF disrupts microbial cell membranes without significant heat generation, leading to better retention of vitamins, flavors, and antioxidants. This method enhances juice safety and shelf life while maintaining freshness, making it an innovative approach in post-harvest technology.

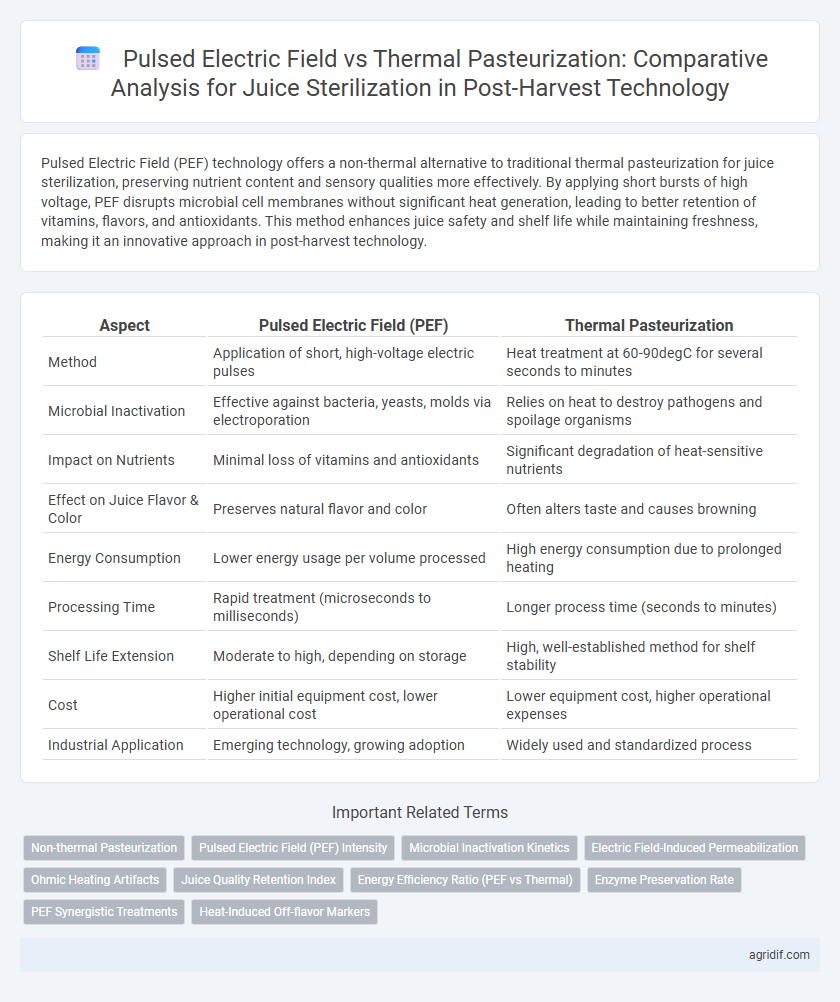

Table of Comparison

| Aspect | Pulsed Electric Field (PEF) | Thermal Pasteurization |

|---|---|---|

| Method | Application of short, high-voltage electric pulses | Heat treatment at 60-90degC for several seconds to minutes |

| Microbial Inactivation | Effective against bacteria, yeasts, molds via electroporation | Relies on heat to destroy pathogens and spoilage organisms |

| Impact on Nutrients | Minimal loss of vitamins and antioxidants | Significant degradation of heat-sensitive nutrients |

| Effect on Juice Flavor & Color | Preserves natural flavor and color | Often alters taste and causes browning |

| Energy Consumption | Lower energy usage per volume processed | High energy consumption due to prolonged heating |

| Processing Time | Rapid treatment (microseconds to milliseconds) | Longer process time (seconds to minutes) |

| Shelf Life Extension | Moderate to high, depending on storage | High, well-established method for shelf stability |

| Cost | Higher initial equipment cost, lower operational cost | Lower equipment cost, higher operational expenses |

| Industrial Application | Emerging technology, growing adoption | Widely used and standardized process |

Introduction to Juice Sterilization Methods

Pulsed Electric Field (PEF) and Thermal Pasteurization represent two primary juice sterilization methods aimed at ensuring microbial safety and extending shelf life. PEF utilizes short bursts of high voltage to inactivate microorganisms without significant heat generation, preserving juice quality and nutrients. Thermal pasteurization applies controlled heat to eliminate pathogens, which can impact flavor and nutrient content due to thermal degradation.

Principles of Pulsed Electric Field (PEF) Technology

Pulsed Electric Field (PEF) technology sterilizes juice by applying short bursts of high-voltage electric pulses that permeabilize microbial cell membranes, causing irreversible electroporation and cell inactivation. Unlike thermal pasteurization, PEF maintains juice quality by minimizing heat exposure, thus preserving flavor, nutrients, and color. The process uses electric field strengths typically between 15 to 50 kV/cm with microsecond pulse durations to ensure microbial inactivation while retaining sensory and nutritional attributes.

Overview of Thermal Pasteurization in Juice Processing

Thermal pasteurization in juice processing involves heating the juice to specific temperatures, typically between 71degC and 95degC, for a defined time to inactivate pathogens and spoilage microorganisms. This method ensures microbial safety and extends shelf life but can cause nutrient degradation and sensory changes such as flavor and color loss. Despite these limitations, thermal pasteurization remains the most widely used and established technology for juice sterilization globally.

Microbial Inactivation: PEF vs Thermal Pasteurization

Pulsed Electric Field (PEF) technology in juice sterilization achieves microbial inactivation by applying short bursts of high voltage, disrupting microbial cell membranes without significantly raising the temperature, preserving juice quality. Thermal pasteurization relies on heat to inactivate microbes, effectively reducing pathogens but often degrading nutritional and sensory attributes. Comparative studies indicate PEF offers effective microbial reduction with minimal impact on juice flavor and nutrients, making it a promising alternative for cold pasteurization.

Nutritional Quality Retention in Sterilized Juices

Pulsed Electric Field (PEF) technology preserves nutritional quality in juice sterilization more effectively than thermal pasteurization by minimizing heat-induced degradation of vitamins, antioxidants, and flavor compounds. Studies show PEF-treated juices retain higher levels of vitamin C and phenolic content compared to thermally pasteurized counterparts, which often experience nutrient loss due to prolonged heat exposure. This non-thermal method ensures enhanced bioactive compound stability, contributing to improved sensory attributes and health benefits in sterilized juices.

Effects on Juice Flavor and Sensory Attributes

Pulsed Electric Field (PEF) technology preserves juice flavor and sensory attributes better than thermal pasteurization by minimizing heat-induced changes and maintaining volatile compounds. Studies show PEF-treated juices retain higher levels of fresh-like taste, color, and aroma profiles due to reduced thermal degradation. Consumer panels consistently prefer PEF juices for their closer resemblance to fresh juice compared to thermally pasteurized counterparts.

Energy Efficiency and Operational Costs Comparison

Pulsed Electric Field (PEF) technology for juice sterilization offers significant energy efficiency advantages over traditional thermal pasteurization, reducing energy consumption by up to 40%. The lower thermal input in PEF processes minimizes heat damage, preserving juice quality while decreasing operational costs related to energy use and maintenance. Although initial equipment investment for PEF is higher, long-term savings arise from reduced energy bills and shorter processing times, making it economically favorable for high-volume juice production.

Impact on Juice Shelf Life and Safety

Pulsed Electric Field (PEF) technology enhances juice shelf life by inactivating spoilage microorganisms while preserving sensory and nutritional qualities better than traditional thermal pasteurization. PEF treatment maintains higher vitamin retention and fresh-like flavor, extending shelf life without compromising safety, as it effectively reduces pathogenic bacteria. Thermal pasteurization, though reliable for microbial safety, often leads to nutrient degradation and flavor alteration, resulting in shorter shelf stability compared to PEF-processed juices.

Industrial Scalability of PEF and Thermal Pasteurization

Pulsed Electric Field (PEF) technology offers precise microbial inactivation with minimal heat, preserving juice quality while enabling continuous processing suitable for large-scale operations. Thermal pasteurization, a well-established method, provides robust sterilization with proven industrial scalability through standardized equipment and processes. Although thermal pasteurization dominates in terms of widespread adoption, PEF systems are increasingly optimized for industrial throughput, energy efficiency, and integration into existing production lines for commercial juice sterilization.

Future Trends in Juice Sterilization Technologies

Pulsed Electric Field (PEF) technology is emerging as a promising alternative to traditional thermal pasteurization for juice sterilization, offering enhanced preservation of flavor, nutrients, and color while ensuring microbial safety. Advances in high-voltage pulse generators and process control are driving increased energy efficiency and scalability of PEF systems for industrial applications. Integration of PEF with other non-thermal techniques, such as high-pressure processing and UV light, represents a future trend aimed at maximizing juice quality and extending shelf life without compromising safety.

Related Important Terms

Non-thermal Pasteurization

Pulsed Electric Field (PEF) technology offers a non-thermal pasteurization method that preserves juice quality by inactivating microorganisms without significant heat exposure, maintaining vitamins, flavors, and nutritional profiles better than traditional thermal pasteurization. This energy-efficient process enhances shelf life while avoiding thermal degradation, making it a superior choice for heat-sensitive juice products.

Pulsed Electric Field (PEF) Intensity

Pulsed Electric Field (PEF) intensity, measured in kilovolts per centimeter (kV/cm), directly influences the inactivation of microorganisms in juice sterilization by creating pores in cell membranes through electroporation. Higher PEF intensities, typically ranging from 20 to 40 kV/cm, achieve efficient microbial reduction while preserving juice quality better than traditional thermal pasteurization, which relies on high temperatures that can degrade nutrients and alter flavor profiles.

Microbial Inactivation Kinetics

Pulsed Electric Field (PEF) technology achieves rapid microbial inactivation kinetics by applying short bursts of high voltage electric pulses, effectively disrupting microbial cell membranes without significantly raising juice temperature. In contrast, Thermal Pasteurization relies on prolonged heat treatment to denature microbial proteins, resulting in slower inactivation rates and potential loss of juice quality due to thermal degradation.

Electric Field-Induced Permeabilization

Pulsed Electric Field (PEF) technology utilizes electric field-induced permeabilization to disrupt microbial cell membranes, achieving juice sterilization while preserving nutritional and sensory qualities better than traditional thermal pasteurization. This non-thermal method applies short bursts of high voltage, causing electroporation that enhances microbial inactivation without the heat-associated degradation of vitamins and flavors commonly seen in thermal processes.

Ohmic Heating Artifacts

Pulsed Electric Field (PEF) technology offers non-thermal sterilization of juices, minimizing quality degradation compared to traditional thermal pasteurization methods that often induce off-flavors and nutrient loss. Ohmic heating artifacts, characterized by uneven temperature distribution and localized overheating, commonly affect thermal pasteurization, whereas PEF maintains microbial safety while preserving sensory and nutritional attributes without such artifacts.

Juice Quality Retention Index

Pulsed Electric Field (PEF) technology significantly enhances the Juice Quality Retention Index by preserving key nutrients, flavors, and color more effectively than Thermal Pasteurization, which often results in nutrient degradation and altered taste profiles. Studies indicate that PEF-treated juices maintain higher levels of vitamin C and antioxidants, with minimal thermal damage, thereby supporting superior sensory and nutritional quality.

Energy Efficiency Ratio (PEF vs Thermal)

Pulsed Electric Field (PEF) technology demonstrates a significantly higher Energy Efficiency Ratio compared to traditional Thermal Pasteurization in juice sterilization, reducing energy consumption by up to 40%. The non-thermal process of PEF preserves nutritional quality and flavor while achieving effective microbial inactivation with lower power input.

Enzyme Preservation Rate

Pulsed Electric Field (PEF) technology significantly enhances enzyme preservation rates in juice sterilization by minimizing thermal damage compared to traditional thermal pasteurization, which often leads to substantial enzyme degradation due to high temperatures. Studies demonstrate that PEF-treated juices retain over 80% of native enzyme activity such as polyphenol oxidase and peroxidase, ensuring better nutritional and sensory quality.

PEF Synergistic Treatments

Pulsed Electric Field (PEF) technology enhances juice sterilization by preserving sensory and nutritional qualities while effectively inactivating microorganisms, outperforming traditional thermal pasteurization in maintaining juice freshness. Synergistic treatments combining PEF with mild thermal or antimicrobial agents accelerate microbial inactivation and extend shelf life, optimizing energy efficiency and product quality in post-harvest juice processing.

Heat-Induced Off-flavor Markers

Pulsed Electric Field (PEF) technology preserves juice quality by minimizing heat-induced off-flavor markers such as furfural and hydroxymethylfurfural, which are commonly elevated during Thermal Pasteurization due to Maillard reactions and caramelization. This non-thermal method enhances microbial inactivation while maintaining sensory attributes, making it a preferable alternative to conventional heat treatment for juice sterilization.

Pulsed Electric Field vs Thermal Pasteurization for juice sterilization Infographic

agridif.com

agridif.com