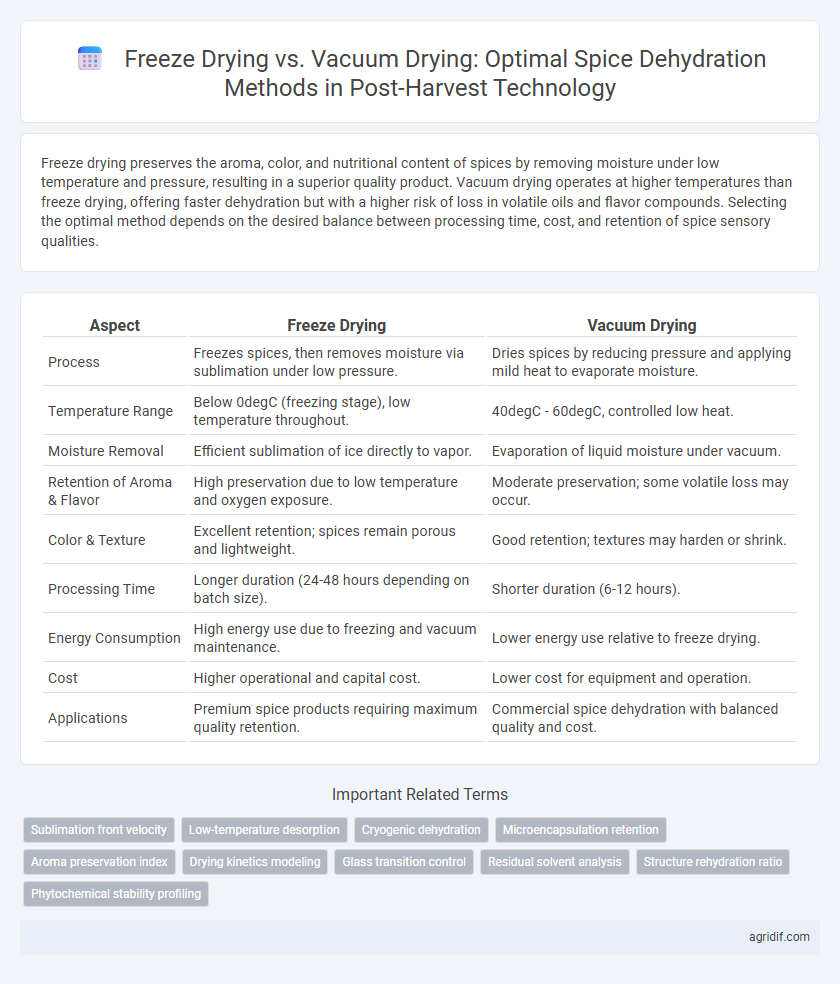

Freeze drying preserves the aroma, color, and nutritional content of spices by removing moisture under low temperature and pressure, resulting in a superior quality product. Vacuum drying operates at higher temperatures than freeze drying, offering faster dehydration but with a higher risk of loss in volatile oils and flavor compounds. Selecting the optimal method depends on the desired balance between processing time, cost, and retention of spice sensory qualities.

Table of Comparison

| Aspect | Freeze Drying | Vacuum Drying |

|---|---|---|

| Process | Freezes spices, then removes moisture via sublimation under low pressure. | Dries spices by reducing pressure and applying mild heat to evaporate moisture. |

| Temperature Range | Below 0degC (freezing stage), low temperature throughout. | 40degC - 60degC, controlled low heat. |

| Moisture Removal | Efficient sublimation of ice directly to vapor. | Evaporation of liquid moisture under vacuum. |

| Retention of Aroma & Flavor | High preservation due to low temperature and oxygen exposure. | Moderate preservation; some volatile loss may occur. |

| Color & Texture | Excellent retention; spices remain porous and lightweight. | Good retention; textures may harden or shrink. |

| Processing Time | Longer duration (24-48 hours depending on batch size). | Shorter duration (6-12 hours). |

| Energy Consumption | High energy use due to freezing and vacuum maintenance. | Lower energy use relative to freeze drying. |

| Cost | Higher operational and capital cost. | Lower cost for equipment and operation. |

| Applications | Premium spice products requiring maximum quality retention. | Commercial spice dehydration with balanced quality and cost. |

Introduction to Spice Dehydration Methods

Freeze drying and vacuum drying represent advanced techniques in spice dehydration, essential for preserving flavor, aroma, and bioactive compounds. Freeze drying involves sublimation of ice under low temperature and pressure, minimizing thermal degradation, whereas vacuum drying reduces boiling points to enable moisture removal at lower temperatures, preserving heat-sensitive compounds. Selecting the appropriate method depends on the desired quality attributes, cost considerations, and specific spice characteristics.

Overview of Freeze Drying in Post-Harvest Spice Processing

Freeze drying in post-harvest spice processing involves sublimating ice directly from frozen spices under low pressure, preserving aromatic compounds and bioactive properties more effectively than conventional methods. This technique maintains cellular structure and color by removing moisture without exposing spices to high temperatures, resulting in superior flavor retention and longer shelf life. Freeze drying is particularly suited for high-value spices requiring minimal alteration, despite higher operational costs compared to vacuum drying.

Principles of Vacuum Drying for Spices

Vacuum drying for spices operates by lowering the pressure around the product, which reduces the boiling point of water and allows moisture to evaporate at lower temperatures, preserving volatile oils and flavor compounds. This method minimizes thermal degradation and oxidation, making it ideal for heat-sensitive spices such as basil and coriander. The controlled environment of vacuum drying enhances product quality by maintaining the original color, aroma, and nutritional content compared to conventional drying techniques.

Moisture Removal Efficiency: Freeze Drying vs Vacuum Drying

Freeze drying offers superior moisture removal efficiency for spice dehydration by sublimating ice directly from frozen spices, preserving volatile compounds and maintaining product quality. Vacuum drying removes moisture at lower pressures and temperatures but is generally less effective at eliminating bound water, potentially compromising aroma and flavor retention. The choice between freeze drying and vacuum drying depends on balancing moisture removal efficiency with energy consumption and desired spice quality.

Impact on Flavor and Aroma Retention

Freeze drying preserves the volatile compounds in spices more effectively than vacuum drying, resulting in superior flavor and aroma retention. By rapidly sublimating ice under low temperature, freeze drying minimizes thermal degradation and oxidation of essential oils. Vacuum drying, although efficient in moisture removal, can cause partial loss of delicate aromatic compounds due to prolonged exposure to heat and reduced pressure.

Color and Nutrient Preservation Comparison

Freeze drying preserves the vibrant color and nutrient content of spices more effectively than vacuum drying due to its low-temperature sublimation process that minimizes thermal degradation. Vacuum drying, while efficient in moisture removal, often leads to slight color darkening and nutrient loss because of higher drying temperatures. Studies indicate freeze-dried spices retain up to 90% of their original antioxidants and pigments, compared to 70-80% retention in vacuum-dried samples.

Processing Time and Energy Consumption Analysis

Freeze drying significantly reduces moisture content in spices with minimal thermal degradation but requires longer processing times, often extending to 24-48 hours. Vacuum drying offers faster dehydration, typically completed within 6-12 hours, by lowering boiling points and enabling efficient moisture removal. Energy consumption in freeze drying is higher due to sublimation under low temperatures and vacuum conditions, whereas vacuum drying consumes less energy by operating at higher temperatures and reduced pressure.

Cost Implications for Large-Scale Spice Producers

Freeze drying incurs higher initial investment and operational costs compared to vacuum drying, primarily due to the need for specialized equipment and prolonged processing times. Vacuum drying offers a more cost-effective solution for large-scale spice producers by reducing energy consumption and accelerating dehydration while maintaining quality. Economies of scale in vacuum drying further decrease per-unit costs, making it preferable for extensive spice production operations focused on cost efficiency.

Sustainability and Environmental Considerations

Freeze drying preserves spice quality with minimal nutrient loss and uses less water than traditional methods, but it consumes higher energy due to low-temperature conditions. Vacuum drying offers faster dehydration and lower energy consumption by reducing boiling points under vacuum, making it more sustainable for large-scale spice processing. Both methods reduce microbial contamination and preserve aroma, but vacuum drying typically has a smaller carbon footprint and better aligns with eco-friendly spice production goals.

Choosing the Best Drying Method for Spice Quality

Freeze drying preserves spice quality by maintaining essential oils and color through sublimation, resulting in superior aroma and flavor retention compared to vacuum drying. Vacuum drying offers faster dehydration but may cause slight loss of volatile compounds and color degradation due to higher temperature exposure. Selecting freeze drying ensures optimal spice quality for premium culinary applications, while vacuum drying suits bulk processing where speed is prioritized.

Related Important Terms

Sublimation front velocity

Freeze drying achieves higher sublimation front velocity compared to vacuum drying, resulting in faster moisture removal while preserving volatile compounds and flavor profiles in spices. The enhanced sublimation rate in freeze drying minimizes thermal degradation, maintaining the quality and texture of dehydrated spices more effectively than vacuum drying.

Low-temperature desorption

Freeze drying in spice dehydration preserves volatile oils and aroma compounds by sublimating ice under low temperature and pressure, ensuring minimal thermal degradation. Vacuum drying uses reduced pressure to lower the boiling point, enabling moisture removal through low-temperature desorption while slightly compromising some heat-sensitive components compared to freeze drying.

Cryogenic dehydration

Cryogenic dehydration using freeze drying preserves the volatile oils and flavor compounds of spices more effectively than vacuum drying by rapidly freezing and sublimating moisture at ultra-low temperatures, ensuring minimal thermal degradation. Vacuum drying operates at higher temperatures under reduced pressure, which can cause partial loss of aromatic profiles and nutrient degradation in spices.

Microencapsulation retention

Freeze drying preserves the highest levels of bioactive compounds and volatile oils in spices by removing moisture under low temperatures and pressure, which optimally retains microencapsulation integrity and flavor profile. Vacuum drying, while faster and less energy-intensive, often results in greater loss of microencapsulated aroma compounds due to elevated temperatures that accelerate degradation and reduce overall spice quality.

Aroma preservation index

Freeze drying maintains a higher aroma preservation index compared to vacuum drying by sublimating ice directly from the frozen state, thus minimizing thermal degradation of volatile compounds in spices. Vacuum drying, while effective at moisture removal under reduced pressure, causes greater loss of essential oils and aromatic constituents due to longer exposure to elevated temperatures.

Drying kinetics modeling

Freeze drying preserves spices by sublimating ice directly from frozen material, ensuring minimal shrinkage and nutrient loss, while vacuum drying uses reduced pressure to lower boiling points, accelerating moisture removal with moderate heat exposure. Drying kinetics models for freeze drying emphasize mass transfer and phase change dynamics, whereas vacuum drying kinetics focus on coupled heat and mass transfer under low-pressure conditions, influencing drying time and quality retention.

Glass transition control

Freeze drying preserves the glass transition temperature of spices by sublimating moisture at low temperatures, maintaining cellular structure and volatile compounds essential for flavor and aroma. Vacuum drying reduces drying temperature and oxygen exposure, controlling glass transition and minimizing thermal degradation, but may cause slight shrinkage compared to freeze drying.

Residual solvent analysis

Freeze drying preserves spice integrity by sublimating ice under low pressure, resulting in minimal residual solvents and superior retention of volatile oils compared to vacuum drying, which often leaves higher levels of residual solvents due to prolonged heat exposure. Residual solvent analysis reveals that freeze drying significantly reduces solvent traces, ensuring safer, higher-quality dehydrated spices with enhanced flavor and aroma profiles.

Structure rehydration ratio

Freeze drying preserves the cellular structure of spices, resulting in a higher rehydration ratio compared to vacuum drying, which may cause more cell collapse and reduce water absorption capacity. This structural integrity retained by freeze drying enhances aroma retention and texture restoration upon rehydration, making it superior for high-quality spice dehydration.

Phytochemical stability profiling

Freeze drying preserves phytochemical stability in spices more effectively than vacuum drying by maintaining low temperatures and minimizing oxidative degradation, resulting in higher retention of antioxidants and volatile compounds. Vacuum drying, while faster and energy-efficient, can cause partial loss of heat-sensitive phytochemicals due to higher operational temperatures and prolonged exposure to oxygen.

Freeze Drying vs Vacuum Drying for spice dehydration Infographic

agridif.com

agridif.com