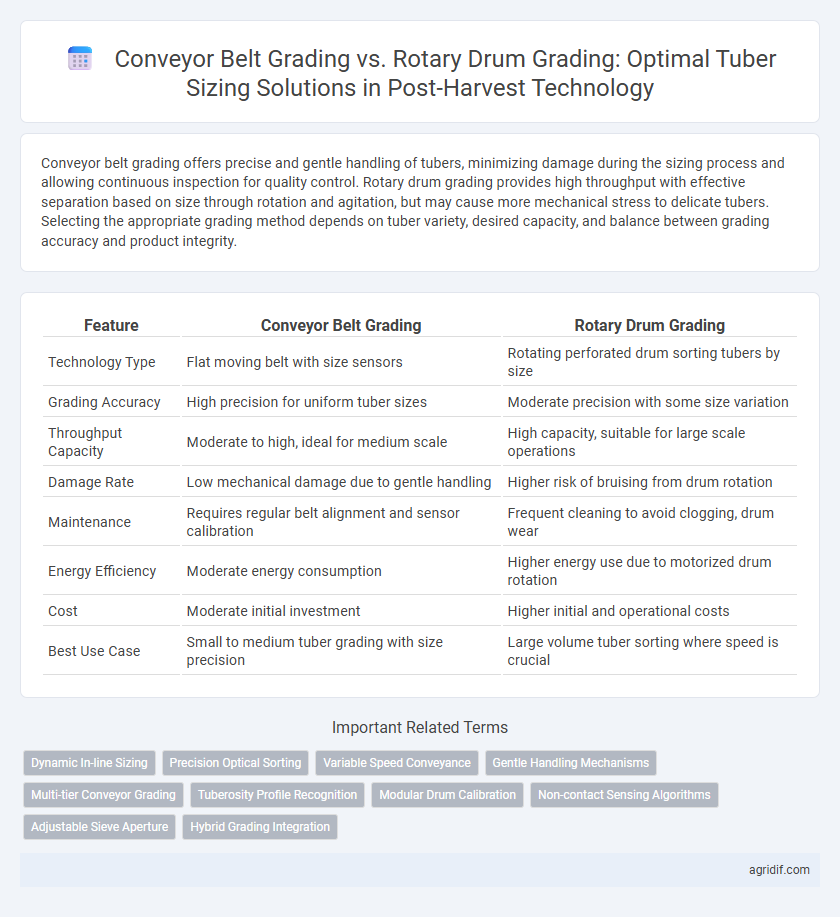

Conveyor belt grading offers precise and gentle handling of tubers, minimizing damage during the sizing process and allowing continuous inspection for quality control. Rotary drum grading provides high throughput with effective separation based on size through rotation and agitation, but may cause more mechanical stress to delicate tubers. Selecting the appropriate grading method depends on tuber variety, desired capacity, and balance between grading accuracy and product integrity.

Table of Comparison

| Feature | Conveyor Belt Grading | Rotary Drum Grading |

|---|---|---|

| Technology Type | Flat moving belt with size sensors | Rotating perforated drum sorting tubers by size |

| Grading Accuracy | High precision for uniform tuber sizes | Moderate precision with some size variation |

| Throughput Capacity | Moderate to high, ideal for medium scale | High capacity, suitable for large scale operations |

| Damage Rate | Low mechanical damage due to gentle handling | Higher risk of bruising from drum rotation |

| Maintenance | Requires regular belt alignment and sensor calibration | Frequent cleaning to avoid clogging, drum wear |

| Energy Efficiency | Moderate energy consumption | Higher energy use due to motorized drum rotation |

| Cost | Moderate initial investment | Higher initial and operational costs |

| Best Use Case | Small to medium tuber grading with size precision | Large volume tuber sorting where speed is crucial |

Introduction to Tuber Sizing in Post-Harvest Processing

Tuber sizing plays a critical role in post-harvest processing by ensuring uniformity and quality for market standards. Conveyor belt grading offers continuous, gentle handling suitable for delicate tubers, enhancing throughput and reducing mechanical damage. Rotary drum grading provides efficient separation by size and shape, but may cause higher impact stress, affecting sensitive tuber varieties.

Overview of Conveyor Belt Grading Technology

Conveyor belt grading technology in post-harvest tuber sizing uses continuous belts equipped with adjustable slots or sensors to separate tubers based on size, enhancing sorting accuracy and throughput. This system supports high-capacity processing with minimal damage to tubers, promoting efficient grading for potatoes, yams, and other root crops. Integration with automated sensors and digital controls further optimizes size classification, reducing labor costs and improving post-harvest quality management.

Rotary Drum Grading: Principles and Mechanisms

Rotary drum grading for tuber sizing operates on the principles of differential rotation and calibrated apertures that allow tubers to pass through size-specific openings, effectively separating them based on diameter. The mechanism consists of a cylindrical drum equipped with progressively larger holes, where smaller tubers fall through earlier openings while larger tubers continue along the drum, ensuring precise size classification. This method enhances sorting efficiency by reducing physical damage to tubers and maintaining high throughput during post-harvest processing.

Efficiency Comparison: Conveyor Belts vs Rotary Drums

Conveyor belt grading offers higher throughput and precise tuber size sorting through continuous movement and adjustable slot sizes, leading to reduced damage and operational downtime. Rotary drum grading provides effective separation by tumbling tubers but tends to have lower processing speeds and increased risk of bruising due to mechanical impact. Efficiency metrics favor conveyor belts for large-scale post-harvest operations, ensuring consistent grading quality and better scalability in tuber sizing applications.

Accuracy and Consistency in Tuber Sizing

Conveyor belt grading offers high accuracy in tuber sizing by providing a continuous and controlled flow that minimizes damage and ensures precise measurement of each tuber's dimensions. Rotary drum grading delivers consistent sizing by rotating tubers through calibrated apertures, effectively separating them based on diameter, but may have limitations in handling varying tuber shapes. For maximum accuracy and consistency, conveyor belt grading systems are preferred in advanced post-harvest technology due to their ability to integrate real-time sensors and automated sorting mechanisms.

Impact on Tubers: Damage and Quality Concerns

Conveyor belt grading minimizes tuber damage by providing gentle handling and consistent spacing, reducing bruising and cuts common in rotary drum grading. Rotary drum grading often causes higher impact and abrasion due to tumbling action, leading to increased skin damage and potential quality degradation. Choosing conveyor belt systems enhances the preservation of tuber integrity, crucial for maintaining market value and shelf life in post-harvest processing.

Throughput and Scalability in Grading Operations

Conveyor belt grading offers higher throughput and better scalability in tuber sizing operations by enabling continuous, automated sorting with adjustable speed controls, suitable for large-scale processing facilities. Rotary drum grading provides effective sizing but often limits throughput due to batch processing constraints and mechanical sorting capacity, making it less adaptable for rapid scale-up. For high-volume grading, conveyor belt systems optimize operational efficiency and accommodate increasing input loads more effectively than rotary drum graders.

Maintenance and Operational Costs

Conveyor belt grading for tuber sizing typically involves lower maintenance costs due to fewer moving parts and simpler construction, reducing downtime and repair frequency. Rotary drum grading systems, while effective for large volumes, often incur higher operational expenses because of complex mechanisms requiring regular servicing and replacement of wear components. Choosing conveyor belt grading can optimize long-term operational efficiency and minimize maintenance expenditure in post-harvest tuber processing.

Suitability for Different Tuber Types and Sizes

Conveyor belt grading provides precise sorting for diverse tuber types, accommodating irregular shapes with adjustable sensor technology, making it ideal for sensitive tubers like sweet potatoes. Rotary drum grading excels in high-capacity processing of uniform-sized tubers, such as potatoes and yams, using mechanical actions that efficiently separate by size but may cause damage to fragile varieties. Selecting the optimal grading system depends on tuber hardness, size variability, and processing speed requirements to ensure minimal damage and maximum grading accuracy.

Future Trends in Tuber Grading Technologies

Future trends in tuber grading technologies emphasize enhanced accuracy and efficiency through the integration of AI-powered vision systems with conveyor belt grading, enabling precise size and quality assessment in real-time. Rotary drum grading, traditionally effective for bulk sorting, is evolving with sensor fusion to improve dynamic size classification and reduce damage rates during handling. Advances in automation and machine learning algorithms are driving the development of hybrid grading solutions that combine the continuous flow benefits of conveyor belts with the gentle, size-specific sorting capabilities of rotary drums to optimize post-harvest tuber processing.

Related Important Terms

Dynamic In-line Sizing

Dynamic in-line sizing for tubers utilizes conveyor belt grading systems to provide continuous, accurate size sorting through real-time measurement sensors integrated along the belt, enhancing throughput and minimizing handling damage. Rotary drum grading, while effective for bulk sorting, offers less precision and slower processing speeds compared to conveyor belt systems optimized for dynamic, real-time tuber size differentiation.

Precision Optical Sorting

Conveyor belt grading combined with precision optical sorting offers higher accuracy and real-time tuber size classification compared to rotary drum grading, minimizing damage and improving throughput efficiency. Advanced optical sensors detect subtle variations in shape, size, and defects, enabling consistent grading that enhances post-harvest quality control for tubers.

Variable Speed Conveyance

Variable speed conveyor belts offer precise control over the grading process in tuber sizing, enabling adjustable flow rates that minimize damage and optimize sorting accuracy. In contrast, rotary drum grading provides uniform tumbling action but lacks the flexible speed modulation, which may lead to increased tuber bruising and less adaptable throughput during post-harvest handling.

Gentle Handling Mechanisms

Conveyor belt grading systems employ gentle handling mechanisms by minimizing tuber contact and reducing impact, preserving tuber integrity during sizing operations. In contrast, rotary drum grading subjects tubers to continuous tumbling, which increases the risk of bruising and damage, making conveyor belts preferable for delicate tuber grading.

Multi-tier Conveyor Grading

Multi-tier conveyor grading systems offer precise tuber sizing by using multiple sorting levels that reduce damage and improve throughput compared to rotary drum graders, which can cause bruising due to tumbling. Conveyor belts ensure gentle handling and higher accuracy in size classification, enhancing overall post-harvest quality and efficiency in tuber processing.

Tuberosity Profile Recognition

Conveyor belt grading employs advanced sensors and machine vision systems to analyze tuberosity profiles, enabling precise tuber size classification based on surface irregularities and shape. Rotary drum grading relies on rotation and physical sorting mechanisms, which often lack the detailed recognition of tuber surface characteristics, resulting in less accurate tuberosity profile differentiation.

Modular Drum Calibration

Modular drum calibration in rotary drum grading offers precise tuber sizing by enabling adjustable compartment sizes, which enhances sorting accuracy compared to fixed-size conveyor belt grading systems. This adaptability improves grading efficiency and reduces damage rates in post-harvest tuber processing.

Non-contact Sensing Algorithms

Conveyor belt grading systems employ advanced non-contact sensing algorithms such as hyperspectral imaging and machine vision to accurately size and sort tubers based on surface and structural characteristics without physical contact, minimizing damage and enhancing throughput. Rotary drum grading, while effective for bulk sorting, relies primarily on mechanical size separation and lacks the precision and real-time data analysis capabilities provided by non-contact optical sensors integrated in conveyor belt systems.

Adjustable Sieve Aperture

Adjustable sieve apertures in conveyor belt grading systems offer precise control over tuber sizing, enabling efficient separation based on size variations and reducing damage during handling. Rotary drum grading, while effective for continuous sorting, generally lacks the fine-tuned aperture adjustability, limiting its adaptability to different tuber sizes and potentially increasing product loss or injury.

Hybrid Grading Integration

Hybrid grading integration combining conveyor belt grading and rotary drum grading enhances tuber sizing accuracy by leveraging the continuous flow and gentle handling of conveyor systems with the high-throughput, rotational sorting efficiency of drum graders. This integrated approach optimizes size uniformity and minimizes damage, improving post-harvest quality and grading precision for tubers such as potatoes and yams.

Conveyor belt grading vs rotary drum grading for tuber sizing Infographic

agridif.com

agridif.com