Ethylene scrubbing effectively removes ethylene gas from storage environments, slowing fruit ripening and extending shelf life by inhibiting the hormone responsible for maturation. Ozone fumigation, on the other hand, oxidizes ethylene molecules and also provides antimicrobial benefits that reduce spoilage. While both methods control ripening, ethylene scrubbing offers targeted removal with minimal oxidation effects, whereas ozone fumigation delivers a broader sanitizing action alongside ethylene degradation.

Table of Comparison

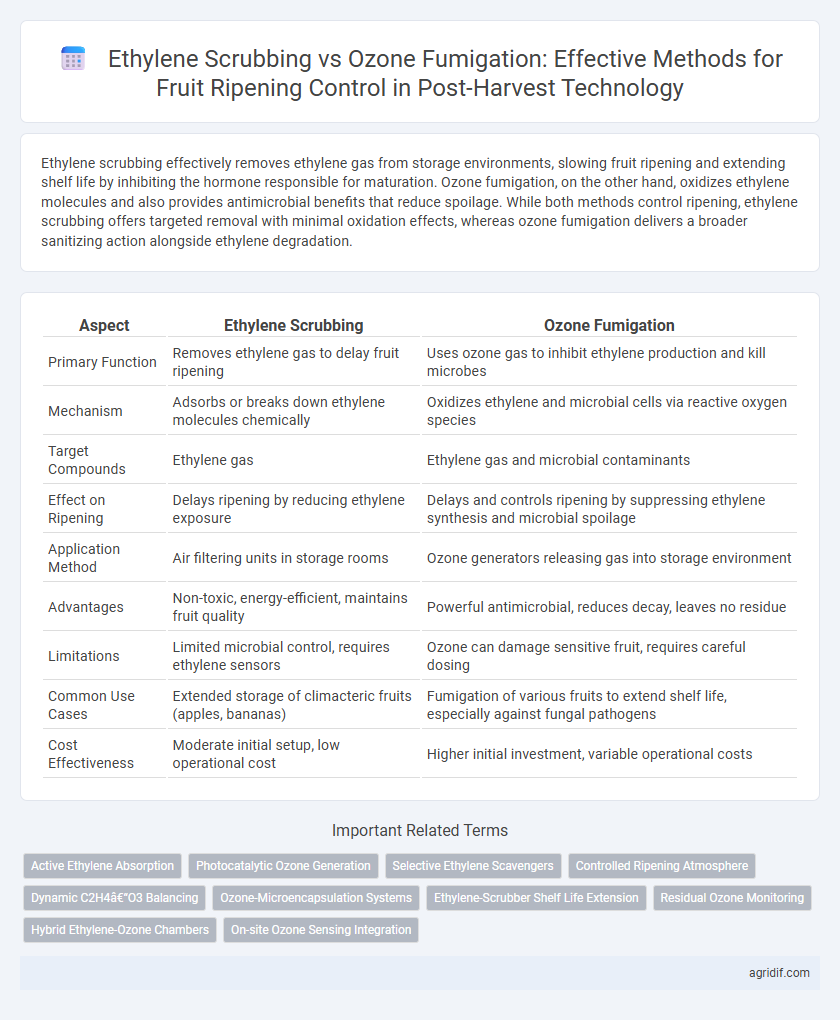

| Aspect | Ethylene Scrubbing | Ozone Fumigation |

|---|---|---|

| Primary Function | Removes ethylene gas to delay fruit ripening | Uses ozone gas to inhibit ethylene production and kill microbes |

| Mechanism | Adsorbs or breaks down ethylene molecules chemically | Oxidizes ethylene and microbial cells via reactive oxygen species |

| Target Compounds | Ethylene gas | Ethylene gas and microbial contaminants |

| Effect on Ripening | Delays ripening by reducing ethylene exposure | Delays and controls ripening by suppressing ethylene synthesis and microbial spoilage |

| Application Method | Air filtering units in storage rooms | Ozone generators releasing gas into storage environment |

| Advantages | Non-toxic, energy-efficient, maintains fruit quality | Powerful antimicrobial, reduces decay, leaves no residue |

| Limitations | Limited microbial control, requires ethylene sensors | Ozone can damage sensitive fruit, requires careful dosing |

| Common Use Cases | Extended storage of climacteric fruits (apples, bananas) | Fumigation of various fruits to extend shelf life, especially against fungal pathogens |

| Cost Effectiveness | Moderate initial setup, low operational cost | Higher initial investment, variable operational costs |

Introduction to Post-Harvest Fruit Ripening Technologies

Ethylene scrubbing and ozone fumigation represent critical advancements in post-harvest fruit ripening technologies, targeting the regulation of ethylene gas to extend shelf life and maintain fruit quality. Ethylene scrubbing involves the removal of ethylene from storage environments, thereby slowing down ripening processes, while ozone fumigation uses ozone gas to degrade ethylene and inhibit microbial growth, offering both ripening control and sanitation benefits. These technologies optimize post-harvest management by reducing spoilage, enhancing fruit firmness, and preserving sensory attributes during storage and transport.

Ethylene’s Role in Fruit Ripening: A Scientific Overview

Ethylene functions as a critical plant hormone that regulates fruit ripening by triggering enzymatic reactions responsible for softening, color change, and aroma development. Ethylene scrubbing techniques remove or reduce ethylene concentrations in storage environments, thereby slowing down the ripening process and extending shelf life. In contrast, ozone fumigation oxidizes ethylene molecules and microbial contaminants, offering a dual approach to controlling ripening and enhancing post-harvest fruit quality.

Ethylene Scrubbing: Mechanism and Technology

Ethylene scrubbing technology employs catalysts or adsorbents such as potassium permanganate or activated carbon to remove ethylene gas from storage atmospheres, effectively slowing down fruit ripening and extending shelf life. This method targets ethylene molecules by oxidizing or adsorbing them, thereby inhibiting ethylene-induced enzymatic processes that accelerate ripening in climacteric fruits. Advanced ethylene scrubbers integrate continuous monitoring systems and controlled airflow to optimize gas removal efficiency, ensuring uniform quality preservation during post-harvest storage and transportation.

Ozone Fumigation: Principles and Application Methods

Ozone fumigation in post-harvest technology utilizes ozone's strong oxidizing properties to control fruit ripening by degrading ethylene, a natural plant hormone responsible for ripening. This method involves generating ozone gas on-site and exposing harvested fruits to controlled ozone concentrations in sealed chambers, effectively delaying ripening and reducing spoilage by inhibiting microbial growth. Ozone fumigation offers an eco-friendly alternative to chemical treatments, enhancing shelf life and maintaining fruit quality during storage and transportation.

Efficacy of Ethylene Scrubbing in Delaying Ripening

Ethylene scrubbing effectively removes ethylene gas from storage atmospheres, significantly slowing down the ripening process of climacteric fruits such as bananas, tomatoes, and avocados. This technology maintains fruit firmness, reduces respiration rates, and extends shelf life by controlling ethylene concentrations to levels below 0.1 ppm. Compared to ozone fumigation, ethylene scrubbing offers more precise management of ripening without causing oxidative damage to delicate fruit tissues.

Impact of Ozone Fumigation on Fruit Quality and Shelf Life

Ozone fumigation effectively reduces ethylene levels, delaying fruit ripening and extending shelf life by slowing enzymatic activity and microbial growth. It maintains fruit firmness, color, and nutritional quality by minimizing oxidative damage and controlling decay-causing pathogens. Studies show treated fruits exhibit prolonged freshness and reduced spoilage compared to ethylene scrubbing alone, enhancing post-harvest storage outcomes.

Comparative Analysis: Ethylene Scrubbing vs Ozone Fumigation

Ethylene scrubbing effectively removes ethylene gas to delay fruit ripening and extend shelf life by maintaining low ethylene concentrations in storage environments. Ozone fumigation not only degrades ethylene but also acts as a powerful antimicrobial agent, reducing pathogen-induced spoilage during post-harvest storage. Comparative analysis reveals that while ethylene scrubbing primarily targets ripening regulation, ozone fumigation offers dual benefits of ripening control and microbial reduction, though its oxidative properties require careful dosage management to prevent fruit damage.

Safety Considerations and Regulatory Guidelines

Ethylene scrubbing offers a safer alternative to ozone fumigation by effectively reducing ethylene levels without generating harmful oxidative byproducts, making it preferable for maintaining fruit quality and worker safety. Regulatory guidelines from agencies like the EPA emphasize strict ozone concentration limits to minimize respiratory hazards, while ethylene scrubbing systems typically operate within less stringent safety thresholds. Compliance with these regulations ensures both methods maintain safe post-harvest environments, but ethylene scrubbing presents fewer risks associated with oxidative damage and chemical exposure.

Cost-Benefit Analysis for Commercial Implementation

Ethylene scrubbing technology offers precise control over fruit ripening by reducing ethylene concentration, often resulting in lower operational costs and energy consumption compared to ozone fumigation systems. Ozone fumigation, while effective in microbial control and ethylene degradation, requires higher capital investment and maintenance expenses due to equipment complexity and safety measures. Commercial implementation favors ethylene scrubbing when prioritizing cost-efficiency and long-term sustainability in ripening facilities.

Future Trends in Fruit Ripening Control Technologies

Emerging trends in fruit ripening control emphasize integrating ethylene scrubbing systems with ozone fumigation to enhance shelf life and reduce microbial growth. Advanced sensors coupled with AI-driven automation enable precise modulation of ethylene levels and ozone concentration, optimizing ripening rates while minimizing quality degradation. Research is increasingly focused on eco-friendly, energy-efficient technologies that support sustainability and reduce chemical residues in post-harvest fruit management.

Related Important Terms

Active Ethylene Absorption

Active ethylene absorption through ethylene scrubbing effectively reduces ethylene concentration in storage environments, slowing fruit ripening and extending shelf life by preventing premature senescence. Compared to ozone fumigation, which oxidizes ethylene and may cause oxidative stress on fruit tissues, ethylene scrubbers provide a controlled, non-destructive method for maintaining optimal post-harvest fruit quality.

Photocatalytic Ozone Generation

Photocatalytic ozone generation offers a highly efficient method for ozone fumigation in fruit ripening control, producing ozone through light-activated catalysts that ensure consistent and controlled ethylene degradation. This technology outperforms traditional ethylene scrubbing by providing enhanced antimicrobial effects and reducing residue risks, ultimately extending shelf life and maintaining fruit quality during post-harvest storage.

Selective Ethylene Scavengers

Selective ethylene scavengers utilize adsorption materials like potassium permanganate or activated carbon to target and remove ethylene gas, effectively slowing fruit ripening and extending shelf life during post-harvest storage. Compared to ozone fumigation, which relies on strong oxidizing properties and can cause fruit surface damage if not carefully controlled, ethylene scrubbing offers a safer and more controlled approach to managing ripening by specifically reducing ethylene concentration without adverse effects on fruit quality.

Controlled Ripening Atmosphere

Ethylene scrubbing efficiently removes ethylene gas from storage environments, delaying fruit ripening by maintaining optimal controlled ripening atmospheres and extending shelf life in post-harvest technology. Ozone fumigation offers antimicrobial benefits and degrades ethylene but requires precise concentration control to prevent oxidative damage to fruit tissues during controlled atmosphere storage.

Dynamic C2H4–O3 Balancing

Dynamic C2H4-O3 balancing in post-harvest technology leverages ethylene scrubbing to remove excess ethylene, thereby delaying fruit ripening, while ozone fumigation oxidizes ethylene molecules, controlling ripening and inhibiting microbial growth. Optimizing the interaction between ethylene absorption and ozone application enhances fruit quality preservation by maintaining controlled ripening rates and reducing post-harvest losses.

Ozone-Microencapsulation Systems

Ozone-microencapsulation systems enhance fruit ripening control by providing a sustained release of ozone, minimizing ethylene accumulation and delaying over-ripening more effectively than traditional ethylene scrubbing methods. This technology improves post-harvest quality by reducing microbial spoilage and oxidative damage, extending shelf life while maintaining fruit firmness and nutritional value.

Ethylene-Scrubber Shelf Life Extension

Ethylene scrubbing effectively extends shelf life by removing ethylene gas, which slows down fruit ripening and reduces spoilage rates. Compared to ozone fumigation, ethylene scrubbers offer more stable and continuous control, minimizing oxidative damage and preserving fruit quality during storage and transport.

Residual Ozone Monitoring

Residual ozone monitoring is critical in ozone fumigation for fruit ripening control, as excessive ozone residues can cause oxidative damage to fruit quality and pose health risks. Ethylene scrubbing, in contrast, does not leave harmful residues, making it a safer alternative for maintaining fruit integrity and ensuring consumer safety during post-harvest treatment.

Hybrid Ethylene-Ozone Chambers

Hybrid ethylene-ozone chambers combine ethylene scrubbing and ozone fumigation to optimize fruit ripening control by precisely regulating ethylene levels and reducing microbial load. This integrated approach enhances shelf-life, maintains fruit firmness, and minimizes decay compared to using either ethylene scrubbing or ozone fumigation alone.

On-site Ozone Sensing Integration

On-site ozone sensing integration enhances the precision of ozone fumigation for fruit ripening control by providing real-time monitoring and regulation of ozone levels, minimizing oxidative damage to produce. Compared to ethylene scrubbing, this technology ensures optimal ozone concentration to accelerate ripening while maintaining fruit quality and extending shelf life in post-harvest processes.

Ethylene Scrubbing vs Ozone Fumigation for fruit ripening control Infographic

agridif.com

agridif.com